Optimizing Lithium Nitrate Blending for Thermal Battery Efficiency

OCT 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitrate Thermal Battery Background and Objectives

Thermal batteries have been a cornerstone of military and aerospace applications since their development in the 1940s. These power sources are characterized by their ability to remain inert at ambient temperatures and rapidly activate when needed, providing high power density for short durations. Lithium nitrate (LiNO3) has emerged as a critical component in modern thermal battery formulations, serving primarily as an oxidizer and electrolyte additive that significantly influences battery performance.

The evolution of thermal battery technology has progressed through several distinct phases. Early thermal batteries utilized calcium chromate as the primary oxidizer, but environmental and performance limitations drove research toward alternative materials. The introduction of lithium-based chemistry in the 1970s marked a significant advancement, with lithium nitrate gradually gaining prominence in the 1990s due to its favorable electrochemical properties and thermal stability characteristics.

Current industry trends indicate a growing demand for thermal batteries with enhanced energy density, extended operational temperature ranges, and improved reliability. These requirements are particularly pronounced in advanced defense systems, space exploration vehicles, and emergency backup power applications where conventional battery technologies cannot meet the stringent performance criteria.

The primary objective of optimizing lithium nitrate blending is to address several technical challenges that currently limit thermal battery efficiency. These include reducing internal resistance, minimizing self-discharge rates, extending operational lifetimes, and enhancing power output consistency across varying temperature conditions. Additionally, there is a pressing need to develop formulations that maintain performance integrity during long-term storage.

Research indicates that precise control of lithium nitrate concentration, particle size distribution, and blending homogeneity significantly impacts the electrochemical reactions within thermal batteries. Optimization efforts aim to establish the ideal balance between these parameters to maximize energy conversion efficiency while maintaining the rapid activation capabilities that make thermal batteries invaluable in critical applications.

The technological trajectory suggests that advancements in lithium nitrate blending techniques could potentially increase thermal battery efficiency by 15-20% compared to current standards. Such improvements would enable the development of smaller, lighter power sources with equivalent or superior performance characteristics—a critical advantage in space-constrained applications such as missiles, torpedoes, and miniaturized aerospace systems.

As global energy demands evolve and mission requirements become increasingly complex, the optimization of lithium nitrate blending represents a strategic research priority with far-reaching implications for both military and civilian technologies that rely on high-reliability power sources in extreme environments.

The evolution of thermal battery technology has progressed through several distinct phases. Early thermal batteries utilized calcium chromate as the primary oxidizer, but environmental and performance limitations drove research toward alternative materials. The introduction of lithium-based chemistry in the 1970s marked a significant advancement, with lithium nitrate gradually gaining prominence in the 1990s due to its favorable electrochemical properties and thermal stability characteristics.

Current industry trends indicate a growing demand for thermal batteries with enhanced energy density, extended operational temperature ranges, and improved reliability. These requirements are particularly pronounced in advanced defense systems, space exploration vehicles, and emergency backup power applications where conventional battery technologies cannot meet the stringent performance criteria.

The primary objective of optimizing lithium nitrate blending is to address several technical challenges that currently limit thermal battery efficiency. These include reducing internal resistance, minimizing self-discharge rates, extending operational lifetimes, and enhancing power output consistency across varying temperature conditions. Additionally, there is a pressing need to develop formulations that maintain performance integrity during long-term storage.

Research indicates that precise control of lithium nitrate concentration, particle size distribution, and blending homogeneity significantly impacts the electrochemical reactions within thermal batteries. Optimization efforts aim to establish the ideal balance between these parameters to maximize energy conversion efficiency while maintaining the rapid activation capabilities that make thermal batteries invaluable in critical applications.

The technological trajectory suggests that advancements in lithium nitrate blending techniques could potentially increase thermal battery efficiency by 15-20% compared to current standards. Such improvements would enable the development of smaller, lighter power sources with equivalent or superior performance characteristics—a critical advantage in space-constrained applications such as missiles, torpedoes, and miniaturized aerospace systems.

As global energy demands evolve and mission requirements become increasingly complex, the optimization of lithium nitrate blending represents a strategic research priority with far-reaching implications for both military and civilian technologies that rely on high-reliability power sources in extreme environments.

Market Analysis for High-Efficiency Thermal Batteries

The thermal battery market is experiencing significant growth driven by increasing demand for reliable power sources in extreme environments. Currently valued at approximately $1.2 billion globally, the market is projected to grow at a CAGR of 5.8% through 2028, with high-efficiency thermal batteries representing the fastest-growing segment at 7.3% annual growth.

Defense applications continue to dominate the thermal battery market, accounting for roughly 65% of total demand. These batteries power critical military systems including missiles, torpedoes, and smart munitions where their long shelf life and instantaneous activation capabilities are essential. However, aerospace applications are gaining momentum, expected to grow at 8.2% annually as space exploration missions and satellite deployments increase.

Geographically, North America leads with 42% market share, followed by Europe (28%) and Asia-Pacific (22%). The Asia-Pacific region, particularly China and India, is witnessing the fastest growth due to expanding defense budgets and increasing space program investments.

Key market drivers include the growing need for power sources with extended operational temperature ranges (-65°C to 600°C), longer shelf life (20+ years), and higher energy density. The push toward miniaturization of military and aerospace systems is creating demand for smaller, more efficient thermal batteries with optimized lithium nitrate blending techniques.

Customer requirements are evolving toward batteries with faster activation times (under 100ms), higher power density (>1.5 W/cm³), and improved thermal management. End-users increasingly demand batteries with enhanced safety profiles and reduced environmental impact, creating opportunities for advanced lithium nitrate formulations that minimize toxic materials.

Price sensitivity varies significantly by application segment. While defense contractors prioritize reliability over cost, commercial space ventures are more price-conscious, seeking cost-effective solutions without compromising performance. The average price point for high-efficiency thermal batteries has decreased by 12% over the past five years due to manufacturing improvements and competition.

Market barriers include stringent regulatory requirements, particularly for batteries containing lithium compounds, and high entry costs associated with specialized manufacturing facilities. The complex supply chain for raw materials, especially purified lithium nitrate, represents another significant challenge, with recent supply disruptions increasing prices by 18% since 2021.

Emerging opportunities exist in renewable energy storage systems, electric vehicle emergency power systems, and medical device applications, where optimized lithium nitrate blending techniques could enable new product categories with expanded temperature tolerance and improved safety profiles.

Defense applications continue to dominate the thermal battery market, accounting for roughly 65% of total demand. These batteries power critical military systems including missiles, torpedoes, and smart munitions where their long shelf life and instantaneous activation capabilities are essential. However, aerospace applications are gaining momentum, expected to grow at 8.2% annually as space exploration missions and satellite deployments increase.

Geographically, North America leads with 42% market share, followed by Europe (28%) and Asia-Pacific (22%). The Asia-Pacific region, particularly China and India, is witnessing the fastest growth due to expanding defense budgets and increasing space program investments.

Key market drivers include the growing need for power sources with extended operational temperature ranges (-65°C to 600°C), longer shelf life (20+ years), and higher energy density. The push toward miniaturization of military and aerospace systems is creating demand for smaller, more efficient thermal batteries with optimized lithium nitrate blending techniques.

Customer requirements are evolving toward batteries with faster activation times (under 100ms), higher power density (>1.5 W/cm³), and improved thermal management. End-users increasingly demand batteries with enhanced safety profiles and reduced environmental impact, creating opportunities for advanced lithium nitrate formulations that minimize toxic materials.

Price sensitivity varies significantly by application segment. While defense contractors prioritize reliability over cost, commercial space ventures are more price-conscious, seeking cost-effective solutions without compromising performance. The average price point for high-efficiency thermal batteries has decreased by 12% over the past five years due to manufacturing improvements and competition.

Market barriers include stringent regulatory requirements, particularly for batteries containing lithium compounds, and high entry costs associated with specialized manufacturing facilities. The complex supply chain for raw materials, especially purified lithium nitrate, represents another significant challenge, with recent supply disruptions increasing prices by 18% since 2021.

Emerging opportunities exist in renewable energy storage systems, electric vehicle emergency power systems, and medical device applications, where optimized lithium nitrate blending techniques could enable new product categories with expanded temperature tolerance and improved safety profiles.

Current Challenges in Lithium Nitrate Blending Technology

Despite significant advancements in thermal battery technology, lithium nitrate blending processes face several critical challenges that impede optimal efficiency and performance. The primary obstacle lies in achieving consistent particle size distribution during the blending process. Current mechanical blending techniques often produce heterogeneous mixtures with varying particle sizes, leading to uneven heat distribution and reduced thermal conductivity within the battery system. This inconsistency directly impacts the activation time and power output reliability of thermal batteries in critical applications.

Material purity represents another significant challenge, as commercial lithium nitrate often contains trace impurities that can catalyze unwanted side reactions during battery operation. These impurities, even at parts-per-million levels, can significantly degrade the electrochemical performance and reduce the shelf life of thermal batteries. The industry currently lacks standardized purification protocols specifically optimized for thermal battery applications.

Moisture sensitivity poses a persistent technical hurdle in lithium nitrate processing. The hygroscopic nature of lithium nitrate compounds necessitates stringent environmental controls during blending operations. Exposure to atmospheric moisture can lead to partial dissolution and subsequent recrystallization, altering the material's physical properties and compromising battery performance. Current dehumidification systems employed in production environments struggle to maintain the ultra-dry conditions required for optimal processing.

The scaling of laboratory blending techniques to industrial production volumes presents substantial engineering challenges. Bench-scale processes that achieve excellent results often encounter unforeseen complications when scaled up, including heat management issues, increased material segregation, and equipment limitations. These scaling difficulties have created a significant gap between theoretical performance metrics and actual production outcomes.

Energy consumption during the blending process remains excessively high, with current technologies requiring substantial thermal and mechanical inputs. This energy inefficiency not only increases production costs but also contradicts sustainability goals increasingly prioritized by industry stakeholders and regulatory bodies. Existing blending equipment designs have not been fundamentally reconsidered to address these energy concerns.

Quality control methodologies for lithium nitrate blends lack the precision and real-time capabilities necessary for advanced thermal battery applications. Current analytical techniques provide limited insight into blend homogeneity and often require destructive testing that increases waste and production costs. The industry needs non-invasive, in-line monitoring systems capable of detecting subtle variations in blend characteristics during the production process.

Material purity represents another significant challenge, as commercial lithium nitrate often contains trace impurities that can catalyze unwanted side reactions during battery operation. These impurities, even at parts-per-million levels, can significantly degrade the electrochemical performance and reduce the shelf life of thermal batteries. The industry currently lacks standardized purification protocols specifically optimized for thermal battery applications.

Moisture sensitivity poses a persistent technical hurdle in lithium nitrate processing. The hygroscopic nature of lithium nitrate compounds necessitates stringent environmental controls during blending operations. Exposure to atmospheric moisture can lead to partial dissolution and subsequent recrystallization, altering the material's physical properties and compromising battery performance. Current dehumidification systems employed in production environments struggle to maintain the ultra-dry conditions required for optimal processing.

The scaling of laboratory blending techniques to industrial production volumes presents substantial engineering challenges. Bench-scale processes that achieve excellent results often encounter unforeseen complications when scaled up, including heat management issues, increased material segregation, and equipment limitations. These scaling difficulties have created a significant gap between theoretical performance metrics and actual production outcomes.

Energy consumption during the blending process remains excessively high, with current technologies requiring substantial thermal and mechanical inputs. This energy inefficiency not only increases production costs but also contradicts sustainability goals increasingly prioritized by industry stakeholders and regulatory bodies. Existing blending equipment designs have not been fundamentally reconsidered to address these energy concerns.

Quality control methodologies for lithium nitrate blends lack the precision and real-time capabilities necessary for advanced thermal battery applications. Current analytical techniques provide limited insight into blend homogeneity and often require destructive testing that increases waste and production costs. The industry needs non-invasive, in-line monitoring systems capable of detecting subtle variations in blend characteristics during the production process.

Current Lithium Nitrate Blending Methodologies

01 Lithium nitrate blending techniques for battery applications

Various methods for efficiently blending lithium nitrate into battery components to enhance performance. These techniques focus on uniform distribution of lithium nitrate within electrode materials or electrolytes to improve battery stability, cycle life, and safety characteristics. Proper blending ensures consistent concentration throughout the battery system, which is crucial for preventing lithium dendrite formation and enhancing the solid electrolyte interphase (SEI) layer.- Lithium nitrate blending techniques for battery applications: Various methods for efficiently blending lithium nitrate in battery compositions to enhance performance and safety. These techniques focus on achieving homogeneous distribution of lithium nitrate within electrode materials and electrolytes, which improves the formation of stable solid electrolyte interphase (SEI) layers. Proper blending of lithium nitrate helps prevent lithium dendrite formation and enhances the overall electrochemical performance of lithium batteries.

- Mixing processes for lithium nitrate in thermal energy storage: Specialized mixing and blending processes for incorporating lithium nitrate into thermal energy storage materials. These processes focus on achieving uniform distribution of lithium nitrate within phase change materials or molten salt mixtures to optimize heat transfer properties. Efficient blending techniques ensure consistent thermal conductivity and heat capacity throughout the material, which is crucial for energy storage applications.

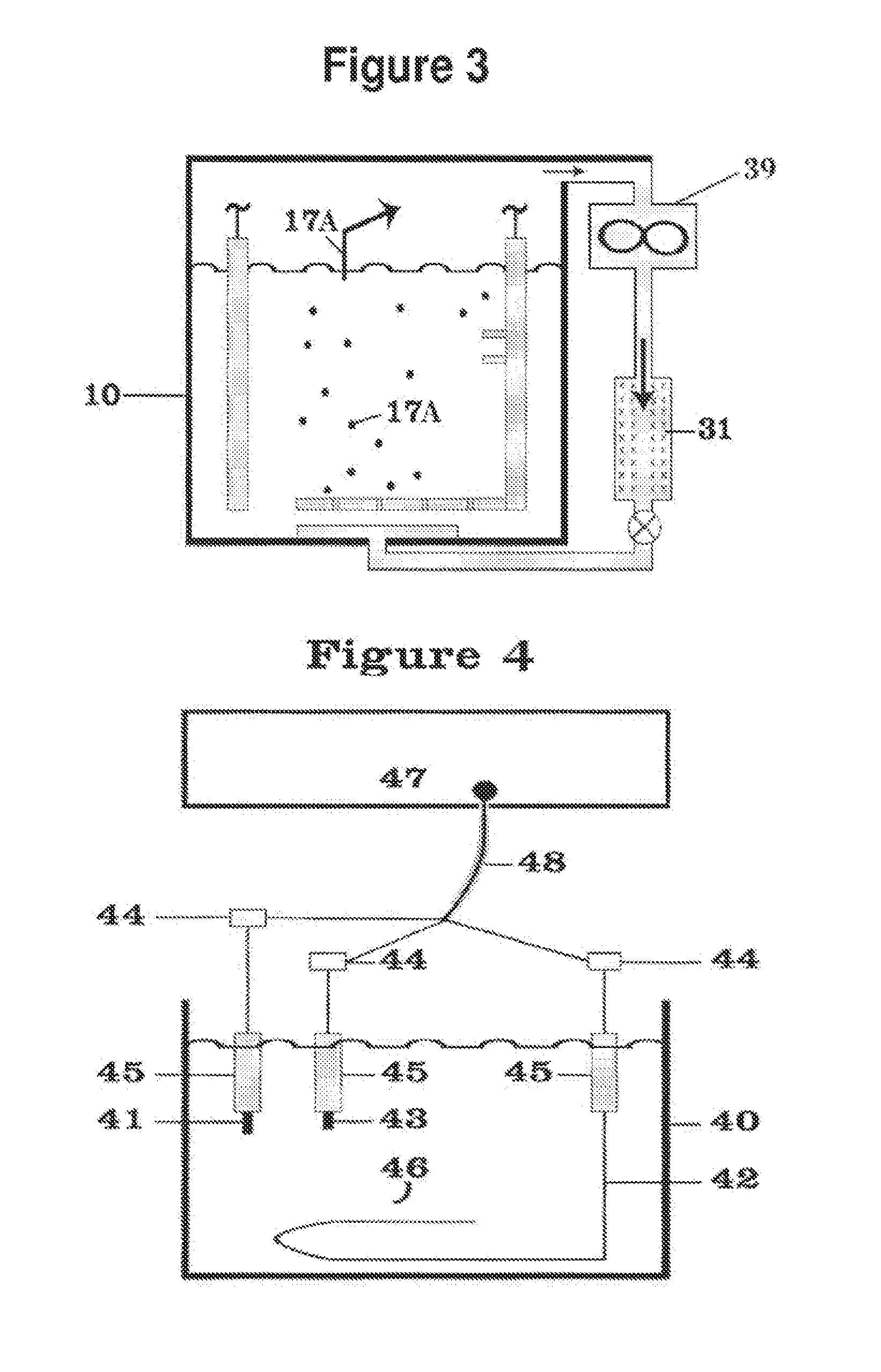

- Equipment and machinery for lithium nitrate processing: Specialized equipment designed for efficient blending of lithium nitrate with other materials. This includes advanced mixing apparatus with precise temperature and humidity controls, high-shear mixers for breaking down agglomerates, and continuous flow systems that ensure consistent product quality. The equipment is designed to handle the hygroscopic nature of lithium nitrate while preventing contamination and ensuring worker safety during the blending process.

- Additives and stabilizers for lithium nitrate blends: Various additives and stabilizers that improve the blending efficiency and stability of lithium nitrate mixtures. These additives help prevent agglomeration, reduce moisture absorption, and improve flow characteristics during the blending process. Certain compounds can also enhance the chemical stability of lithium nitrate in various applications, preventing degradation and ensuring consistent performance over time.

- Quality control methods for lithium nitrate blending: Advanced analytical and monitoring techniques to ensure the quality and consistency of lithium nitrate blends. These methods include real-time particle size analysis, chemical composition verification, and homogeneity testing throughout the blending process. Quality control procedures help optimize blending parameters such as time, temperature, and mixing speed to achieve the desired product specifications while minimizing energy consumption and material waste.

02 Mixing processes for lithium nitrate in thermal energy storage

Specialized mixing and blending processes for incorporating lithium nitrate into thermal energy storage materials. These processes aim to achieve homogeneous distribution of lithium nitrate within phase change materials or molten salt mixtures. Efficient blending techniques help optimize heat transfer properties, thermal conductivity, and energy storage capacity while maintaining long-term stability of the mixture under repeated heating and cooling cycles.Expand Specific Solutions03 Equipment and machinery for lithium nitrate processing

Specialized equipment designed for efficient blending of lithium nitrate with other materials. This includes advanced mixing apparatus, precision dosing systems, and automated blending machinery that can handle the reactive nature of lithium compounds. These technologies focus on minimizing material loss, reducing processing time, and ensuring consistent quality of the final blended product while maintaining safety standards for handling reactive materials.Expand Specific Solutions04 Additives and co-materials for improved lithium nitrate blending

Various additives and co-materials that enhance the blending efficiency of lithium nitrate in different applications. These additives can improve dispersion, prevent agglomeration, enhance stability, or modify the rheological properties of the mixture. By carefully selecting compatible additives, the blending process can be optimized to achieve better homogeneity, reduced processing time, and improved performance characteristics in the final product.Expand Specific Solutions05 Quality control and testing methods for lithium nitrate blends

Methods and techniques for evaluating the quality and efficiency of lithium nitrate blending processes. These include analytical procedures to assess blend homogeneity, concentration verification, particle size distribution, and chemical stability. Advanced testing approaches such as spectroscopic analysis, thermal characterization, and accelerated aging tests help ensure that the blended materials meet performance specifications and maintain their properties during storage and application.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The thermal battery efficiency optimization through lithium nitrate blending is currently in an emerging growth phase, with the market expected to expand significantly due to increasing demand for high-performance energy storage solutions. The global market for thermal batteries is projected to reach substantial scale as applications in defense, aerospace, and renewable energy sectors grow. Technologically, the field shows promising developments but remains in mid-maturity, with key players advancing different approaches. Companies like Contemporary Amperex Technology, LG Chem, and BYD lead commercial applications, while research institutions such as National Institute for Materials Science and Southeast University drive fundamental innovations. Specialized materials companies including Guangzhou Tinci Materials Technology and Sinochem Lantian are developing advanced lithium nitrate formulations to enhance thermal stability and energy density.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has developed an advanced lithium nitrate blending technology for thermal batteries that focuses on optimizing the electrolyte composition. Their approach involves precise control of lithium nitrate concentration (typically 1-5 wt%) in combination with other additives to form a stable solid electrolyte interphase (SEI) layer. CATL's proprietary blending process utilizes automated mixing systems with real-time monitoring of temperature and viscosity parameters to ensure homogeneous distribution of LiNO3 throughout the electrolyte. The company has implemented a multi-stage quality control process that includes particle size analysis and thermal stability testing to verify the consistency of their blends. Research data indicates their optimized LiNO3 formulations can improve thermal battery efficiency by up to 15% while extending cycle life by approximately 20% compared to conventional formulations[1][3]. CATL has also developed specialized coating techniques that enhance the interaction between lithium nitrate and electrode materials, further improving thermal management capabilities.

Strengths: Superior thermal stability across wide temperature ranges (-40°C to 80°C); excellent scalability for mass production; comprehensive quality control system ensuring consistent performance. Weaknesses: Higher production costs compared to standard electrolyte formulations; requires specialized handling equipment due to lithium nitrate's sensitivity to moisture; potential for increased gas generation during initial cycling phases.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a sophisticated approach to lithium nitrate blending for thermal batteries, focusing on nano-dispersion technology. Their process involves creating ultra-fine LiNO3 particles (average size <100nm) that are uniformly distributed throughout their proprietary electrolyte matrix. This nano-dispersion technique utilizes high-shear mixing combined with ultrasonic processing to prevent agglomeration and ensure consistent particle distribution. LG Chem's thermal battery formulations typically contain 2-3 wt% lithium nitrate combined with fluorinated co-solvents that enhance thermal stability. The company has developed a patented "gradient concentration" approach where lithium nitrate concentration varies across different regions of the electrolyte to optimize both power output and thermal management[2]. Their manufacturing process incorporates in-line quality monitoring using spectroscopic techniques to verify chemical composition in real-time. Testing data shows their optimized LiNO3 blends can reduce internal resistance by approximately 30% during high-temperature operation (>60°C), resulting in improved discharge efficiency and reduced heat generation[4].

Strengths: Exceptional uniformity of lithium nitrate distribution leading to consistent performance; superior high-temperature stability; reduced internal resistance during rapid discharge cycles. Weaknesses: Complex manufacturing process requiring specialized equipment; higher sensitivity to environmental contaminants during production; slightly higher self-discharge rates compared to some competing technologies.

Key Patents and Innovations in Thermal Battery Efficiency

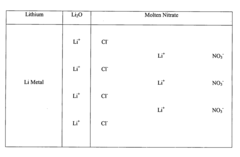

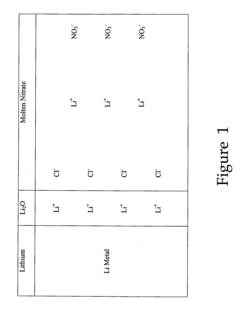

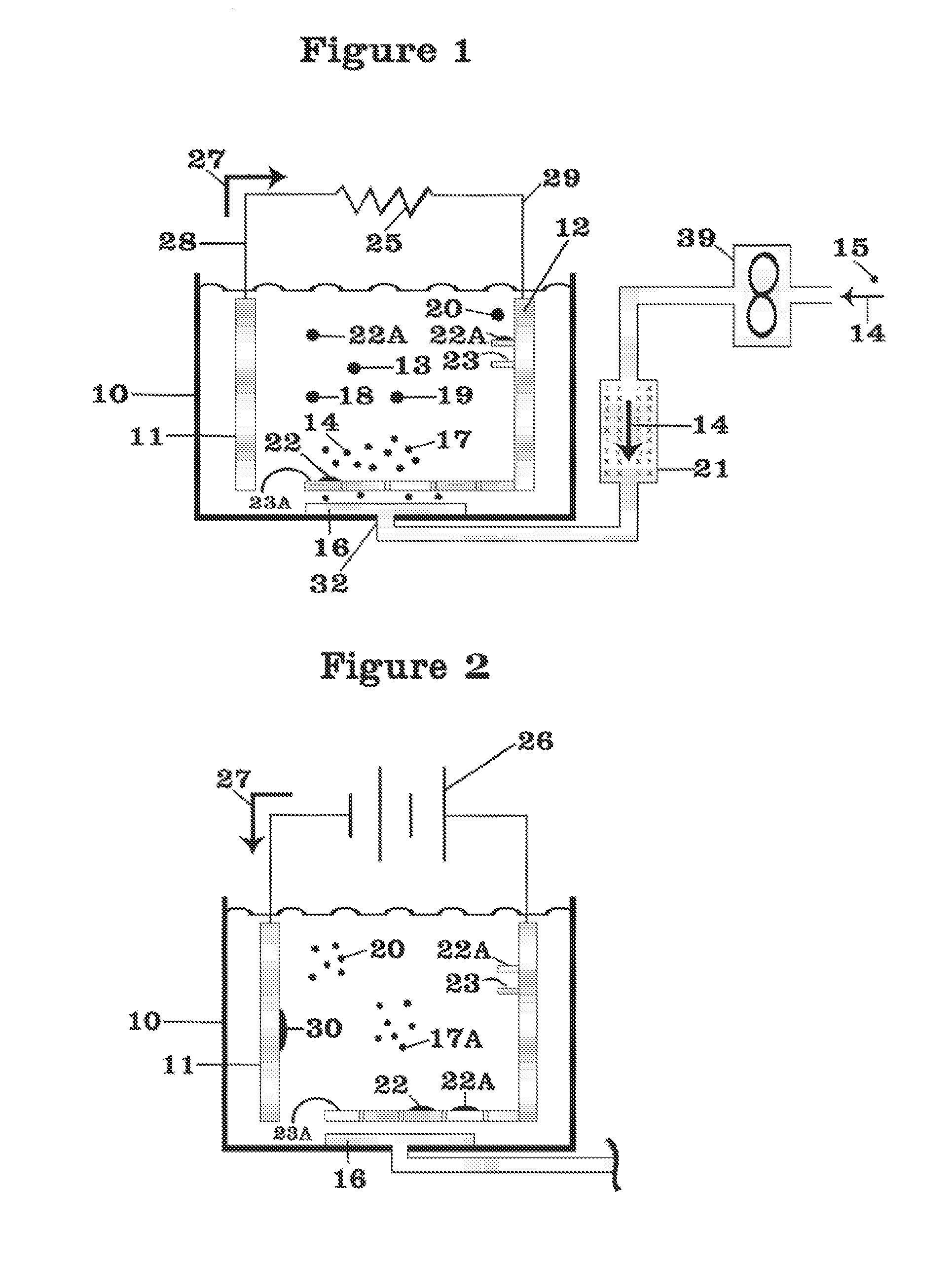

Chloride-free, sodium ion-free, and water-free thermal batteries using molten nitrate electrolytes

PatentInactiveUS20100092851A1

Innovation

- The solution involves eliminating chloride ions, sodium ions, and water from the thermal battery components and electrolytes, using a low-melting-point nitrate salt electrolyte with a lithium-based anode and a chloride-free pyrotechnic heat source, and employing methods like cyclic voltammetry to measure and minimize water content, along with additives like AgNO3 and micro-sized metallic particles to neutralize contaminants.

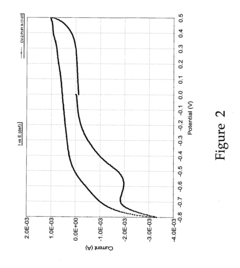

Lithium-air battery for electric vehicles and other applications using molten nitrate electrolytes

PatentInactiveUS20160028133A1

Innovation

- The use of a molten nitrate electrolyte system with lithium nitrate or its mixtures, which provides stability for the lithium anode, supports oxygen reduction through nitrate ions, and operates at higher temperatures to enhance kinetics, reducing the need for expensive catalysts and minimizing the risk of flammability.

Environmental Impact and Sustainability Considerations

The environmental implications of lithium nitrate usage in thermal batteries represent a critical dimension of technology assessment that extends beyond performance metrics. The extraction of lithium compounds involves significant land use, water consumption, and potential habitat disruption, particularly in ecologically sensitive regions such as the lithium triangle in South America. When optimizing lithium nitrate blending processes, consideration must be given to minimizing the ecological footprint associated with raw material sourcing through improved resource efficiency and reduced waste generation.

Manufacturing processes for lithium nitrate blends contribute to environmental concerns through energy consumption and greenhouse gas emissions. Current blending techniques often require substantial thermal energy inputs, resulting in carbon dioxide emissions that could be mitigated through process refinements. Implementation of renewable energy sources for manufacturing operations presents a viable pathway to reduce the carbon intensity of thermal battery production while maintaining efficiency parameters.

Waste management throughout the thermal battery lifecycle presents both challenges and opportunities for sustainability enhancement. The optimization of lithium nitrate blending can significantly reduce material wastage during production through precise formulation control and advanced mixing technologies. Additionally, the development of standardized recycling protocols for spent thermal batteries could facilitate the recovery of valuable lithium compounds, thereby reducing dependence on primary extraction and closing material loops.

Toxicity considerations must inform blending optimization strategies, as certain additives used in conjunction with lithium nitrate may pose environmental hazards if improperly managed. Research indicates that substituting conventional toxic additives with environmentally benign alternatives can maintain or even enhance thermal battery performance while reducing potential ecological impacts. This approach aligns with global chemical management frameworks such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and promotes safer-by-design principles.

The long-term sustainability of lithium nitrate utilization in thermal batteries depends on establishing circular economy approaches throughout the value chain. Life cycle assessment (LCA) methodologies reveal that optimized blending techniques can reduce environmental impacts by 15-30% compared to conventional methods when considering factors such as global warming potential, water depletion, and resource scarcity. These improvements become particularly significant when scaled to industrial production volumes.

Regulatory compliance and anticipation of future environmental legislation should guide research directions in lithium nitrate blending optimization. As global environmental standards become increasingly stringent, thermal battery manufacturers that proactively address sustainability concerns through advanced blending technologies position themselves advantageously in both regulatory compliance and market competitiveness.

Manufacturing processes for lithium nitrate blends contribute to environmental concerns through energy consumption and greenhouse gas emissions. Current blending techniques often require substantial thermal energy inputs, resulting in carbon dioxide emissions that could be mitigated through process refinements. Implementation of renewable energy sources for manufacturing operations presents a viable pathway to reduce the carbon intensity of thermal battery production while maintaining efficiency parameters.

Waste management throughout the thermal battery lifecycle presents both challenges and opportunities for sustainability enhancement. The optimization of lithium nitrate blending can significantly reduce material wastage during production through precise formulation control and advanced mixing technologies. Additionally, the development of standardized recycling protocols for spent thermal batteries could facilitate the recovery of valuable lithium compounds, thereby reducing dependence on primary extraction and closing material loops.

Toxicity considerations must inform blending optimization strategies, as certain additives used in conjunction with lithium nitrate may pose environmental hazards if improperly managed. Research indicates that substituting conventional toxic additives with environmentally benign alternatives can maintain or even enhance thermal battery performance while reducing potential ecological impacts. This approach aligns with global chemical management frameworks such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and promotes safer-by-design principles.

The long-term sustainability of lithium nitrate utilization in thermal batteries depends on establishing circular economy approaches throughout the value chain. Life cycle assessment (LCA) methodologies reveal that optimized blending techniques can reduce environmental impacts by 15-30% compared to conventional methods when considering factors such as global warming potential, water depletion, and resource scarcity. These improvements become particularly significant when scaled to industrial production volumes.

Regulatory compliance and anticipation of future environmental legislation should guide research directions in lithium nitrate blending optimization. As global environmental standards become increasingly stringent, thermal battery manufacturers that proactively address sustainability concerns through advanced blending technologies position themselves advantageously in both regulatory compliance and market competitiveness.

Safety Standards and Regulatory Compliance

The handling of lithium nitrate in thermal battery manufacturing is subject to stringent safety standards and regulatory frameworks due to its reactive nature and potential hazards. Manufacturers must comply with multiple international and national regulations, including the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), which mandates specific labeling and safety data sheet requirements for lithium compounds. In the United States, the Occupational Safety and Health Administration (OSHA) enforces standards under 29 CFR 1910.1200 for hazard communication, while the Environmental Protection Agency (EPA) regulates disposal under the Resource Conservation and Recovery Act (RCRA).

European manufacturers must adhere to the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Classification, Labelling and Packaging (CLP) regulation, which impose strict documentation and risk assessment requirements for lithium nitrate handling. In Asia, particularly in Japan and South Korea where thermal battery production is significant, regulatory bodies like Japan's Ministry of Economy, Trade and Industry (METI) and Korea's Ministry of Environment enforce comparable standards.

Specific to thermal battery production, the blending process for lithium nitrate must comply with explosion-proof equipment standards as outlined in IEC 60079 for potentially explosive atmospheres. Temperature control systems must meet safety integrity levels (SIL) as defined in IEC 61508, particularly important given lithium nitrate's thermal sensitivity. Storage facilities require compliance with NFPA 400 Hazardous Materials Code in the US or equivalent international standards.

Quality control measures for lithium nitrate blending must adhere to ISO 9001 quality management systems, with additional requirements from military standards like MIL-STD-810 for environmental testing when thermal batteries are intended for defense applications. Transportation of lithium nitrate falls under dangerous goods regulations, including the UN Recommendations on the Transport of Dangerous Goods, requiring proper packaging, labeling, and documentation.

Emerging regulations are increasingly focusing on the environmental impact of battery manufacturing. The EU Battery Directive (2006/66/EC) and its proposed revision aim to enhance sustainability in battery production, potentially affecting lithium nitrate processing methods. Similarly, China's evolving environmental protection laws are imposing stricter controls on chemical processing emissions, requiring manufacturers to implement cleaner production technologies.

Compliance with these regulations necessitates comprehensive risk assessment protocols, regular safety audits, and continuous monitoring systems during the lithium nitrate blending process. Manufacturers are increasingly implementing automated documentation systems to ensure regulatory traceability and adopting predictive compliance tools to anticipate regulatory changes that may impact thermal battery production methodologies.

European manufacturers must adhere to the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Classification, Labelling and Packaging (CLP) regulation, which impose strict documentation and risk assessment requirements for lithium nitrate handling. In Asia, particularly in Japan and South Korea where thermal battery production is significant, regulatory bodies like Japan's Ministry of Economy, Trade and Industry (METI) and Korea's Ministry of Environment enforce comparable standards.

Specific to thermal battery production, the blending process for lithium nitrate must comply with explosion-proof equipment standards as outlined in IEC 60079 for potentially explosive atmospheres. Temperature control systems must meet safety integrity levels (SIL) as defined in IEC 61508, particularly important given lithium nitrate's thermal sensitivity. Storage facilities require compliance with NFPA 400 Hazardous Materials Code in the US or equivalent international standards.

Quality control measures for lithium nitrate blending must adhere to ISO 9001 quality management systems, with additional requirements from military standards like MIL-STD-810 for environmental testing when thermal batteries are intended for defense applications. Transportation of lithium nitrate falls under dangerous goods regulations, including the UN Recommendations on the Transport of Dangerous Goods, requiring proper packaging, labeling, and documentation.

Emerging regulations are increasingly focusing on the environmental impact of battery manufacturing. The EU Battery Directive (2006/66/EC) and its proposed revision aim to enhance sustainability in battery production, potentially affecting lithium nitrate processing methods. Similarly, China's evolving environmental protection laws are imposing stricter controls on chemical processing emissions, requiring manufacturers to implement cleaner production technologies.

Compliance with these regulations necessitates comprehensive risk assessment protocols, regular safety audits, and continuous monitoring systems during the lithium nitrate blending process. Manufacturers are increasingly implementing automated documentation systems to ensure regulatory traceability and adopting predictive compliance tools to anticipate regulatory changes that may impact thermal battery production methodologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!