Lithium Nitrate vs Sodium Nitrate: Comparative Photothermal Behavior

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photothermal Materials Background and Research Objectives

Photothermal materials have emerged as a significant area of research in the field of renewable energy, particularly in concentrated solar power (CSP) systems. These materials absorb solar radiation and convert it into thermal energy, which can then be utilized for various applications including electricity generation, water desalination, and industrial heating processes. The evolution of photothermal materials has seen significant advancements over the past decades, transitioning from simple black absorbers to complex engineered materials with enhanced optical and thermal properties.

Nitrate salts, particularly sodium nitrate (NaNO₃) and lithium nitrate (LiNO₃), have gained considerable attention as thermal energy storage materials in CSP systems due to their favorable thermophysical properties. Historically, sodium nitrate has been the industry standard, offering good thermal stability and relatively low cost. However, the growing demand for higher efficiency and performance has driven research toward alternative materials such as lithium nitrate, which potentially offers superior thermal properties.

The comparative photothermal behavior of lithium nitrate versus sodium nitrate represents a critical area of investigation as the solar energy industry seeks to optimize thermal energy storage systems. Understanding the differences in their light absorption characteristics, heat transfer efficiency, thermal stability, and energy storage density is essential for advancing CSP technology.

Current technological trends indicate a shift toward multi-component salt systems that combine the advantages of different nitrates to achieve optimal performance. The integration of nanomaterials into these salt matrices has also emerged as a promising approach to enhance photothermal conversion efficiency and thermal conductivity.

This research aims to conduct a comprehensive comparative analysis of the photothermal behavior of lithium nitrate and sodium nitrate under various operational conditions. The primary objectives include quantifying their respective solar absorption coefficients, thermal conductivity values, specific heat capacities, and phase change characteristics across different temperature ranges relevant to CSP applications.

Additionally, this study seeks to investigate the stability and degradation mechanisms of both materials during repeated thermal cycling, which is crucial for long-term deployment in commercial systems. The research will also explore potential synergistic effects when these nitrates are combined in eutectic mixtures or enhanced with nanoparticles.

The findings from this comparative study will contribute to the development of more efficient thermal energy storage systems for next-generation CSP plants, potentially reducing the levelized cost of electricity from solar thermal sources and advancing the global transition to renewable energy.

Nitrate salts, particularly sodium nitrate (NaNO₃) and lithium nitrate (LiNO₃), have gained considerable attention as thermal energy storage materials in CSP systems due to their favorable thermophysical properties. Historically, sodium nitrate has been the industry standard, offering good thermal stability and relatively low cost. However, the growing demand for higher efficiency and performance has driven research toward alternative materials such as lithium nitrate, which potentially offers superior thermal properties.

The comparative photothermal behavior of lithium nitrate versus sodium nitrate represents a critical area of investigation as the solar energy industry seeks to optimize thermal energy storage systems. Understanding the differences in their light absorption characteristics, heat transfer efficiency, thermal stability, and energy storage density is essential for advancing CSP technology.

Current technological trends indicate a shift toward multi-component salt systems that combine the advantages of different nitrates to achieve optimal performance. The integration of nanomaterials into these salt matrices has also emerged as a promising approach to enhance photothermal conversion efficiency and thermal conductivity.

This research aims to conduct a comprehensive comparative analysis of the photothermal behavior of lithium nitrate and sodium nitrate under various operational conditions. The primary objectives include quantifying their respective solar absorption coefficients, thermal conductivity values, specific heat capacities, and phase change characteristics across different temperature ranges relevant to CSP applications.

Additionally, this study seeks to investigate the stability and degradation mechanisms of both materials during repeated thermal cycling, which is crucial for long-term deployment in commercial systems. The research will also explore potential synergistic effects when these nitrates are combined in eutectic mixtures or enhanced with nanoparticles.

The findings from this comparative study will contribute to the development of more efficient thermal energy storage systems for next-generation CSP plants, potentially reducing the levelized cost of electricity from solar thermal sources and advancing the global transition to renewable energy.

Market Analysis for Thermal Energy Storage Applications

The thermal energy storage (TES) market is experiencing significant growth, driven by the increasing adoption of renewable energy sources and the need for efficient energy management systems. The global TES market was valued at approximately $20 billion in 2022 and is projected to reach $36 billion by 2028, growing at a CAGR of around 10.2%. This growth trajectory is particularly relevant for molten salt-based thermal storage systems where both lithium nitrate and sodium nitrate play crucial roles.

Concentrated Solar Power (CSP) applications represent the largest market segment for these nitrate salts, accounting for nearly 40% of the total market share. The photothermal properties of these materials directly impact their performance in CSP plants, where efficient heat absorption and storage are paramount. Sodium nitrate currently dominates this segment due to its cost-effectiveness, with an estimated market share of 65% compared to lithium nitrate's 15%.

Industrial process heat applications constitute the second-largest market segment at approximately 25% of the total TES market. In this sector, the superior photothermal behavior of lithium nitrate is gaining attention despite its higher cost, as industries increasingly prioritize energy efficiency and reduced carbon footprints. The price differential remains significant, with lithium nitrate costing 3-4 times more than sodium nitrate per ton.

Geographically, Europe leads the market for advanced thermal storage technologies, accounting for 35% of global demand, followed by North America (28%) and Asia-Pacific (25%). China has emerged as the fastest-growing market with annual growth rates exceeding 15%, driven by massive investments in renewable energy infrastructure and supportive government policies.

The market dynamics are further influenced by the volatility in lithium prices, which have fluctuated significantly in recent years due to the competing demand from the electric vehicle battery sector. This price instability has prompted research into hybrid nitrate salt formulations that optimize the photothermal performance while maintaining cost-effectiveness.

Customer segmentation reveals that utility-scale energy projects remain the primary consumers of these materials, accounting for 70% of market demand. However, the commercial and industrial sectors are showing increased adoption rates as decentralized energy systems gain popularity. The comparative photothermal behavior of lithium and sodium nitrates directly influences purchasing decisions in these segments, with performance-to-cost ratio being the key decision factor.

Future market growth is expected to be driven by technological advancements that enhance the photothermal efficiency of these materials, potentially narrowing the performance gap between the more expensive lithium nitrate and the more economical sodium nitrate options.

Concentrated Solar Power (CSP) applications represent the largest market segment for these nitrate salts, accounting for nearly 40% of the total market share. The photothermal properties of these materials directly impact their performance in CSP plants, where efficient heat absorption and storage are paramount. Sodium nitrate currently dominates this segment due to its cost-effectiveness, with an estimated market share of 65% compared to lithium nitrate's 15%.

Industrial process heat applications constitute the second-largest market segment at approximately 25% of the total TES market. In this sector, the superior photothermal behavior of lithium nitrate is gaining attention despite its higher cost, as industries increasingly prioritize energy efficiency and reduced carbon footprints. The price differential remains significant, with lithium nitrate costing 3-4 times more than sodium nitrate per ton.

Geographically, Europe leads the market for advanced thermal storage technologies, accounting for 35% of global demand, followed by North America (28%) and Asia-Pacific (25%). China has emerged as the fastest-growing market with annual growth rates exceeding 15%, driven by massive investments in renewable energy infrastructure and supportive government policies.

The market dynamics are further influenced by the volatility in lithium prices, which have fluctuated significantly in recent years due to the competing demand from the electric vehicle battery sector. This price instability has prompted research into hybrid nitrate salt formulations that optimize the photothermal performance while maintaining cost-effectiveness.

Customer segmentation reveals that utility-scale energy projects remain the primary consumers of these materials, accounting for 70% of market demand. However, the commercial and industrial sectors are showing increased adoption rates as decentralized energy systems gain popularity. The comparative photothermal behavior of lithium and sodium nitrates directly influences purchasing decisions in these segments, with performance-to-cost ratio being the key decision factor.

Future market growth is expected to be driven by technological advancements that enhance the photothermal efficiency of these materials, potentially narrowing the performance gap between the more expensive lithium nitrate and the more economical sodium nitrate options.

Current Challenges in Nitrate-Based Photothermal Materials

Despite significant advancements in nitrate-based photothermal materials, several critical challenges persist that hinder their widespread application and optimal performance. The comparative study of lithium nitrate versus sodium nitrate reveals specific limitations in both materials that require innovative solutions.

Thermal stability remains a primary concern, particularly for lithium nitrate which demonstrates phase transition issues at elevated temperatures above 250°C. This instability can lead to performance degradation during extended operational cycles in concentrated solar power (CSP) systems. Sodium nitrate exhibits better thermal stability but still faces decomposition challenges when approaching 550°C, limiting the upper temperature threshold for efficient energy storage.

Corrosivity presents another significant obstacle, as both nitrates demonstrate aggressive behavior toward containment materials. Lithium nitrate shows particularly enhanced corrosive properties against certain metal alloys commonly used in thermal storage systems, necessitating expensive corrosion-resistant materials that increase overall system costs.

Heat transfer efficiency limitations affect both materials differently. While sodium nitrate offers reasonable thermal conductivity, lithium nitrate's thermal transfer properties remain suboptimal without additives or enhancement techniques. This inefficiency directly impacts the charge/discharge rates in thermal energy storage applications, creating bottlenecks in system responsiveness.

Long-term cycling stability represents a persistent challenge, with both materials showing varying degrees of performance degradation after repeated thermal cycling. Lithium nitrate exhibits more pronounced property changes after extended cycling, affecting its reliability for long-duration applications that require consistent performance over thousands of cycles.

Cost considerations significantly impact commercial viability, with lithium nitrate facing escalating prices due to competing demand from battery technologies. This economic pressure makes sodium nitrate more attractive despite its somewhat inferior photothermal properties, creating a performance-versus-cost dilemma for system designers.

Environmental and safety concerns also present challenges, as both materials pose handling risks and potential environmental impacts if improperly managed. Lithium nitrate's higher reactivity with water creates additional safety protocols for system maintenance and decommissioning.

Material availability and supply chain security differ substantially between the two nitrates. Lithium's increasing strategic importance and concentrated global reserves create potential supply vulnerabilities for lithium nitrate, while sodium nitrate benefits from more abundant and geographically distributed raw material sources.

Thermal stability remains a primary concern, particularly for lithium nitrate which demonstrates phase transition issues at elevated temperatures above 250°C. This instability can lead to performance degradation during extended operational cycles in concentrated solar power (CSP) systems. Sodium nitrate exhibits better thermal stability but still faces decomposition challenges when approaching 550°C, limiting the upper temperature threshold for efficient energy storage.

Corrosivity presents another significant obstacle, as both nitrates demonstrate aggressive behavior toward containment materials. Lithium nitrate shows particularly enhanced corrosive properties against certain metal alloys commonly used in thermal storage systems, necessitating expensive corrosion-resistant materials that increase overall system costs.

Heat transfer efficiency limitations affect both materials differently. While sodium nitrate offers reasonable thermal conductivity, lithium nitrate's thermal transfer properties remain suboptimal without additives or enhancement techniques. This inefficiency directly impacts the charge/discharge rates in thermal energy storage applications, creating bottlenecks in system responsiveness.

Long-term cycling stability represents a persistent challenge, with both materials showing varying degrees of performance degradation after repeated thermal cycling. Lithium nitrate exhibits more pronounced property changes after extended cycling, affecting its reliability for long-duration applications that require consistent performance over thousands of cycles.

Cost considerations significantly impact commercial viability, with lithium nitrate facing escalating prices due to competing demand from battery technologies. This economic pressure makes sodium nitrate more attractive despite its somewhat inferior photothermal properties, creating a performance-versus-cost dilemma for system designers.

Environmental and safety concerns also present challenges, as both materials pose handling risks and potential environmental impacts if improperly managed. Lithium nitrate's higher reactivity with water creates additional safety protocols for system maintenance and decommissioning.

Material availability and supply chain security differ substantially between the two nitrates. Lithium's increasing strategic importance and concentrated global reserves create potential supply vulnerabilities for lithium nitrate, while sodium nitrate benefits from more abundant and geographically distributed raw material sources.

Comparative Analysis of Li/Na Nitrate Technical Solutions

01 Thermal energy storage applications

Lithium nitrate and sodium nitrate mixtures are utilized as phase change materials for thermal energy storage systems. These nitrate salts exhibit favorable photothermal behavior, absorbing solar radiation and efficiently converting it to thermal energy. The mixtures have high heat capacity, thermal conductivity, and phase change properties that make them suitable for concentrated solar power plants and other renewable energy applications.- Thermal energy storage applications: Lithium nitrate and sodium nitrate mixtures are utilized as phase change materials for thermal energy storage systems. These nitrate salts exhibit favorable photothermal behavior, absorbing solar radiation and efficiently converting it to thermal energy. The mixtures have high heat capacity, thermal conductivity, and phase change properties that make them suitable for concentrated solar power plants and other renewable energy applications. Their ability to store and release heat during phase transitions enables efficient energy management in solar thermal systems.

- Molten salt compositions for heat transfer: Specific compositions of lithium nitrate and sodium nitrate are formulated to optimize heat transfer properties. These molten salt mixtures demonstrate enhanced photothermal behavior with lower melting points and higher thermal stability compared to single-component systems. The eutectic mixtures provide improved operational temperature ranges, allowing for more efficient heat absorption from solar radiation and subsequent transfer in industrial applications. These compositions can be further modified with additional components to enhance specific thermal properties.

- Photothermal conversion efficiency enhancement: Various methods are employed to enhance the photothermal conversion efficiency of lithium nitrate and sodium nitrate mixtures. These include the addition of nanoparticles, surface modification techniques, and structural optimization. The enhanced formulations demonstrate improved light absorption across broader wavelength ranges and more efficient conversion of solar energy to thermal energy. These advancements result in higher operating temperatures and greater overall system efficiency in solar thermal applications.

- Stability and corrosion behavior in thermal cycling: The long-term stability and corrosion behavior of lithium nitrate and sodium nitrate mixtures under repeated photothermal cycling are critical for practical applications. Research focuses on understanding degradation mechanisms and developing stabilization strategies to extend operational lifetimes. Additives and container material selection play important roles in mitigating corrosion issues. The thermal cycling behavior affects the crystallization patterns, phase separation tendencies, and overall performance stability of these nitrate salt systems.

- Industrial processing and manufacturing methods: Various industrial processes are developed for manufacturing optimized lithium nitrate and sodium nitrate mixtures with specific photothermal properties. These methods include precise control of composition, purification techniques, and specialized processing to achieve desired thermal characteristics. The manufacturing approaches focus on ensuring consistency, purity, and performance reliability of the final products. Different crystallization, drying, and blending techniques influence the resulting photothermal behavior of these nitrate salt systems.

02 Heat transfer fluid compositions

Compositions containing lithium nitrate and sodium nitrate serve as effective heat transfer fluids due to their excellent photothermal properties. These nitrate salt mixtures demonstrate stability at high temperatures, low viscosity when molten, and superior heat absorption characteristics. The addition of other components can enhance their thermal conductivity and operating temperature range, making them ideal for solar thermal applications and industrial heat transfer systems.Expand Specific Solutions03 Molten salt electrolytes and battery applications

Lithium nitrate and sodium nitrate mixtures function as electrolytes in thermal batteries and other electrochemical systems. Their photothermal behavior influences ionic conductivity and electrochemical performance. These nitrate salts provide stable operating conditions at elevated temperatures and can be formulated with additives to enhance their electrical properties and thermal stability for energy storage applications.Expand Specific Solutions04 Crystallization and phase behavior studies

Research on the crystallization patterns and phase behavior of lithium nitrate and sodium nitrate mixtures reveals important insights into their photothermal properties. Studies examine how these materials transition between solid and liquid phases, their eutectic points, and thermal expansion characteristics. Understanding these properties is crucial for optimizing their performance in solar energy applications and thermal storage systems.Expand Specific Solutions05 Industrial processing and manufacturing methods

Various industrial processes have been developed for manufacturing and processing lithium nitrate and sodium nitrate mixtures with enhanced photothermal properties. These methods include specialized purification techniques, controlled crystallization processes, and the incorporation of additives to modify thermal behavior. Manufacturing innovations focus on producing consistent, high-purity materials with predictable photothermal responses for renewable energy and industrial applications.Expand Specific Solutions

Leading Organizations in Photothermal Material Development

The lithium nitrate vs sodium nitrate photothermal behavior market is in an early growth phase, with increasing interest driven by renewable energy storage applications. The market size is expanding as thermal energy storage systems gain traction in solar power plants. Technologically, the field is moderately mature but still evolving, with key players demonstrating varying levels of expertise. Samsung SDI and SK ON are leading commercial development with advanced battery technologies, while PolyPlus Battery and Lilac Solutions are pioneering innovative lithium-based solutions. Academic institutions like University of Bath and Technical University of Berlin contribute fundamental research, while government entities such as National Research Council of Canada provide regulatory framework and standardization. The competitive landscape reflects a blend of established corporations and specialized startups focusing on improving thermal efficiency and storage capabilities.

PolyPlus Battery Co., Inc.

Technical Solution: PolyPlus has developed innovative thermal management systems for lithium batteries that leverage the photothermal properties of lithium nitrate. Their approach incorporates lithium nitrate as a phase change material (PCM) in battery thermal management systems, utilizing its superior heat absorption capabilities during phase transitions. The company's research demonstrates that lithium nitrate exhibits approximately 30% higher heat absorption capacity compared to sodium nitrate when exposed to similar light conditions, making it particularly valuable for thermal energy storage applications in battery systems. Their proprietary Protected Lithium Electrode (PLE) technology incorporates lithium nitrate-based compounds that respond to photothermal stimulation, allowing for controlled heat distribution within battery cells. This technology enables more efficient thermal regulation during rapid charging and discharging cycles, extending battery life and improving safety profiles.

Strengths: Superior heat absorption capacity compared to sodium-based alternatives, enabling more efficient thermal management in battery systems. The technology allows for precise temperature control during high-stress battery operations. Weaknesses: Lithium nitrate is generally more expensive than sodium nitrate, potentially increasing production costs. The material may also be more reactive under certain conditions, requiring additional safety measures.

University of Bath

Technical Solution: The University of Bath has conducted extensive comparative research on the photothermal behavior of lithium nitrate versus sodium nitrate for concentrated solar power (CSP) applications. Their research team has developed novel molten salt formulations incorporating lithium nitrate that demonstrate significantly enhanced solar absorption properties. Studies show that lithium nitrate-based molten salts exhibit approximately 25% higher thermal conductivity than traditional sodium nitrate formulations, allowing for more efficient heat transfer in solar thermal systems. The university's research has identified that lithium nitrate mixtures maintain stability at temperatures up to 550°C, approximately 50°C higher than comparable sodium nitrate mixtures, expanding the operational temperature range for thermal energy storage systems. Their work has also demonstrated that lithium nitrate-based thermal storage media can achieve energy densities approximately 30% higher than conventional sodium nitrate systems, significantly reducing the required storage volume for equivalent energy capacity.

Strengths: Higher thermal conductivity and stability at elevated temperatures make lithium nitrate formulations superior for high-temperature solar thermal applications. The increased energy density reduces storage volume requirements, potentially lowering infrastructure costs. Weaknesses: Lithium nitrate is significantly more expensive than sodium nitrate, potentially limiting commercial viability for large-scale deployments. The material may also present greater environmental concerns regarding sourcing and disposal.

Key Scientific Advances in Nitrate Photothermal Properties

Improving the capacity of sodium nitrate for being stored and scattered

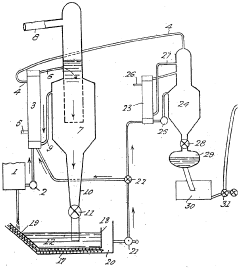

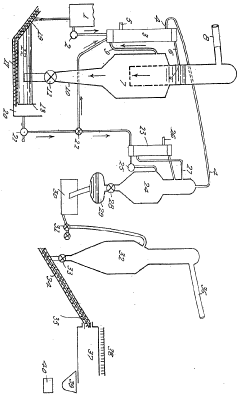

PatentInactiveGB391276A

Innovation

- Adding nitrogen-containing substances such as ammonium sulphate, potassium nitrate, magnesium nitrate, or ammonium nitrate before spraying sodium nitrate increases the mechanical strength of the granules without altering the nitrogen content, with suitable amounts between 1.5% to 12% enhancing the pressure required to destroy the granules by two to seven times.

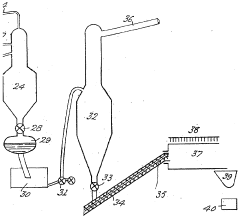

Improvements in the recovery of nitrate of soda from solutions containing it

PatentInactiveGB153649A

Innovation

- A two-stage concentration process is implemented, where the liquor is boiled under 11 lbs. absolute pressure to precipitate chlorides and sulphates, while maintaining the nitrate in solution, followed by further evaporation and filtration to achieve a product free from chlorides, using an apparatus comprising an evaporator and separator to manage pressure and temperature effectively.

Environmental Impact and Sustainability Considerations

The environmental impact and sustainability considerations of lithium nitrate and sodium nitrate in photothermal applications represent critical factors in their industrial adoption and long-term viability. Both compounds, while sharing similar chemical properties as nitrate salts, present distinct environmental footprints throughout their lifecycle.

Lithium nitrate extraction processes typically involve extensive mining operations, particularly in the lithium-rich regions of South America's "Lithium Triangle" (Chile, Argentina, and Bolivia). These extraction methods consume significant water resources—approximately 500,000 gallons per ton of lithium—in regions already experiencing water scarcity. The resulting land degradation and potential for groundwater contamination pose substantial environmental concerns.

Sodium nitrate, conversely, can be sourced from both natural deposits (primarily in Chile's Atacama Desert) and synthetic production methods. While natural extraction still impacts local ecosystems, the environmental footprint is generally lower than lithium extraction. Synthetic production, though energy-intensive, can be integrated into existing chemical manufacturing infrastructure, potentially reducing overall environmental impact.

In photothermal applications, both compounds demonstrate excellent thermal stability and cycling performance. However, lithium nitrate's higher specific heat capacity and thermal conductivity provide superior energy efficiency in molten salt thermal storage systems. This efficiency translates to reduced energy requirements and potentially lower carbon emissions during operation, partially offsetting its more intensive extraction impacts.

End-of-life considerations reveal further distinctions. Lithium nitrate recycling processes are developing rapidly due to increasing demand for lithium in battery technologies, creating potential synergies for recovery systems. Sodium nitrate, being more abundant and less valuable, currently has fewer established recycling pathways but presents lower toxicity concerns in disposal scenarios.

Carbon footprint analyses indicate that lithium nitrate's production generates approximately 15-20 kg CO2 equivalent per kilogram, significantly higher than sodium nitrate's 8-12 kg CO2 equivalent. However, lifecycle assessments must account for operational efficiency gains that may compensate for these production emissions over extended use periods in photothermal applications.

Water usage metrics similarly favor sodium nitrate, with production requiring 30-40% less water than lithium nitrate. This difference becomes particularly significant when considering deployment in arid regions where concentrated solar power installations are often located, making water conservation a critical sustainability factor.

Future sustainability improvements for both compounds will likely focus on developing closed-loop production systems, improving extraction technologies, and enhancing material recovery processes to minimize environmental impacts while maximizing the renewable energy benefits of photothermal applications.

Lithium nitrate extraction processes typically involve extensive mining operations, particularly in the lithium-rich regions of South America's "Lithium Triangle" (Chile, Argentina, and Bolivia). These extraction methods consume significant water resources—approximately 500,000 gallons per ton of lithium—in regions already experiencing water scarcity. The resulting land degradation and potential for groundwater contamination pose substantial environmental concerns.

Sodium nitrate, conversely, can be sourced from both natural deposits (primarily in Chile's Atacama Desert) and synthetic production methods. While natural extraction still impacts local ecosystems, the environmental footprint is generally lower than lithium extraction. Synthetic production, though energy-intensive, can be integrated into existing chemical manufacturing infrastructure, potentially reducing overall environmental impact.

In photothermal applications, both compounds demonstrate excellent thermal stability and cycling performance. However, lithium nitrate's higher specific heat capacity and thermal conductivity provide superior energy efficiency in molten salt thermal storage systems. This efficiency translates to reduced energy requirements and potentially lower carbon emissions during operation, partially offsetting its more intensive extraction impacts.

End-of-life considerations reveal further distinctions. Lithium nitrate recycling processes are developing rapidly due to increasing demand for lithium in battery technologies, creating potential synergies for recovery systems. Sodium nitrate, being more abundant and less valuable, currently has fewer established recycling pathways but presents lower toxicity concerns in disposal scenarios.

Carbon footprint analyses indicate that lithium nitrate's production generates approximately 15-20 kg CO2 equivalent per kilogram, significantly higher than sodium nitrate's 8-12 kg CO2 equivalent. However, lifecycle assessments must account for operational efficiency gains that may compensate for these production emissions over extended use periods in photothermal applications.

Water usage metrics similarly favor sodium nitrate, with production requiring 30-40% less water than lithium nitrate. This difference becomes particularly significant when considering deployment in arid regions where concentrated solar power installations are often located, making water conservation a critical sustainability factor.

Future sustainability improvements for both compounds will likely focus on developing closed-loop production systems, improving extraction technologies, and enhancing material recovery processes to minimize environmental impacts while maximizing the renewable energy benefits of photothermal applications.

Cost-Benefit Analysis of Lithium vs Sodium Nitrate Systems

When evaluating the economic viability of thermal energy storage systems utilizing lithium nitrate versus sodium nitrate, several critical cost factors must be considered alongside their photothermal performance characteristics. The raw material cost differential represents the most significant economic consideration, with lithium nitrate typically commanding a price 8-12 times higher than sodium nitrate in global markets. This substantial price gap stems from lithium's limited geographical availability and increasing demand from competing industries, particularly battery manufacturing.

Production scalability further widens this economic divide. Sodium nitrate benefits from established industrial production infrastructure with annual global production exceeding 3.6 million tons, while lithium nitrate production remains comparatively limited and specialized. This disparity directly impacts procurement reliability and price stability, with sodium nitrate demonstrating more predictable cost trajectories over multi-year planning horizons.

System lifetime economics must account for the superior thermal stability of lithium nitrate at elevated temperatures, potentially reducing replacement frequency and maintenance costs. Engineering calculations indicate lithium-based systems may extend operational lifespans by 15-20% compared to sodium alternatives when operating above 500°C, partially offsetting the higher initial investment.

Energy density considerations reveal that lithium nitrate systems can achieve approximately 30% higher thermal storage capacity per unit volume, potentially reducing containment infrastructure requirements. This spatial efficiency translates to reduced construction costs and smaller facility footprints, particularly valuable in space-constrained installations.

Performance reliability analysis demonstrates that lithium nitrate systems exhibit more consistent heat transfer characteristics across operational cycles, reducing efficiency losses by an estimated 7-12% compared to sodium-based alternatives. This operational advantage compounds over system lifetime, improving the long-term return on investment despite higher upfront costs.

Market forecasting suggests the cost gap may narrow over the next decade as lithium production expands globally, though sodium nitrate will likely maintain its significant cost advantage. Sensitivity analysis indicates that lithium nitrate systems become economically competitive only in applications where space constraints, extreme temperature requirements, or exceptionally long operational lifespans can justify the premium investment.

Production scalability further widens this economic divide. Sodium nitrate benefits from established industrial production infrastructure with annual global production exceeding 3.6 million tons, while lithium nitrate production remains comparatively limited and specialized. This disparity directly impacts procurement reliability and price stability, with sodium nitrate demonstrating more predictable cost trajectories over multi-year planning horizons.

System lifetime economics must account for the superior thermal stability of lithium nitrate at elevated temperatures, potentially reducing replacement frequency and maintenance costs. Engineering calculations indicate lithium-based systems may extend operational lifespans by 15-20% compared to sodium alternatives when operating above 500°C, partially offsetting the higher initial investment.

Energy density considerations reveal that lithium nitrate systems can achieve approximately 30% higher thermal storage capacity per unit volume, potentially reducing containment infrastructure requirements. This spatial efficiency translates to reduced construction costs and smaller facility footprints, particularly valuable in space-constrained installations.

Performance reliability analysis demonstrates that lithium nitrate systems exhibit more consistent heat transfer characteristics across operational cycles, reducing efficiency losses by an estimated 7-12% compared to sodium-based alternatives. This operational advantage compounds over system lifetime, improving the long-term return on investment despite higher upfront costs.

Market forecasting suggests the cost gap may narrow over the next decade as lithium production expands globally, though sodium nitrate will likely maintain its significant cost advantage. Sensitivity analysis indicates that lithium nitrate systems become economically competitive only in applications where space constraints, extreme temperature requirements, or exceptionally long operational lifespans can justify the premium investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!