Quantify Lithium Nitrate’s Role in Polymer Thermal Stabilization

OCT 9, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Nitrate Thermal Stabilization Background and Objectives

Lithium nitrate (LiNO3) has emerged as a significant compound in the field of polymer thermal stabilization over the past three decades. Initially recognized primarily for its applications in battery technology, researchers began exploring its potential as a thermal stabilizer for polymeric materials in the early 1990s. The evolution of this technology has been driven by increasing demands for flame-retardant and thermally stable materials across various industries, including construction, electronics, automotive, and aerospace.

The fundamental mechanism through which lithium nitrate enhances polymer thermal stability involves its decomposition at elevated temperatures to release nitrogen oxides and oxygen, which can interrupt the polymer combustion process. Additionally, lithium compounds formed during decomposition can create a protective char layer that shields the underlying polymer from further thermal degradation. This dual-action mechanism has positioned lithium nitrate as a promising alternative to traditional halogenated flame retardants, which have faced increasing regulatory scrutiny due to environmental and health concerns.

Recent technological advancements have focused on optimizing the integration of lithium nitrate into various polymer matrices, with particular attention to dispersion techniques, compatibility issues, and synergistic effects with other stabilizing additives. The development of nano-scale lithium nitrate particles has further enhanced its effectiveness by increasing the surface area available for reaction and improving dispersion within polymer systems.

The global push toward sustainable and environmentally friendly materials has accelerated research into inorganic flame retardants like lithium nitrate. Current estimates suggest that the market for non-halogenated flame retardants is growing at approximately 7% annually, with lithium-based compounds representing an increasingly important segment of this market.

The primary objective of this technical research is to establish quantitative relationships between lithium nitrate concentration, dispersion characteristics, and the resulting thermal stability improvements in various polymer systems. Specifically, we aim to develop predictive models that can accurately forecast the thermal decomposition kinetics, char formation efficiency, and overall flame-retardant performance based on lithium nitrate loading levels and processing parameters.

Secondary objectives include identifying optimal formulation strategies for different polymer types, evaluating long-term stability and aging effects, and assessing the economic feasibility of lithium nitrate as a commercial thermal stabilizer compared to existing alternatives. Additionally, this research seeks to explore potential synergistic combinations with other flame retardants that could enhance performance while minimizing environmental impact and cost.

The fundamental mechanism through which lithium nitrate enhances polymer thermal stability involves its decomposition at elevated temperatures to release nitrogen oxides and oxygen, which can interrupt the polymer combustion process. Additionally, lithium compounds formed during decomposition can create a protective char layer that shields the underlying polymer from further thermal degradation. This dual-action mechanism has positioned lithium nitrate as a promising alternative to traditional halogenated flame retardants, which have faced increasing regulatory scrutiny due to environmental and health concerns.

Recent technological advancements have focused on optimizing the integration of lithium nitrate into various polymer matrices, with particular attention to dispersion techniques, compatibility issues, and synergistic effects with other stabilizing additives. The development of nano-scale lithium nitrate particles has further enhanced its effectiveness by increasing the surface area available for reaction and improving dispersion within polymer systems.

The global push toward sustainable and environmentally friendly materials has accelerated research into inorganic flame retardants like lithium nitrate. Current estimates suggest that the market for non-halogenated flame retardants is growing at approximately 7% annually, with lithium-based compounds representing an increasingly important segment of this market.

The primary objective of this technical research is to establish quantitative relationships between lithium nitrate concentration, dispersion characteristics, and the resulting thermal stability improvements in various polymer systems. Specifically, we aim to develop predictive models that can accurately forecast the thermal decomposition kinetics, char formation efficiency, and overall flame-retardant performance based on lithium nitrate loading levels and processing parameters.

Secondary objectives include identifying optimal formulation strategies for different polymer types, evaluating long-term stability and aging effects, and assessing the economic feasibility of lithium nitrate as a commercial thermal stabilizer compared to existing alternatives. Additionally, this research seeks to explore potential synergistic combinations with other flame retardants that could enhance performance while minimizing environmental impact and cost.

Market Analysis for Thermally Stable Polymer Applications

The global market for thermally stable polymers is experiencing robust growth, driven by increasing demands across multiple industries including electronics, automotive, aerospace, and industrial manufacturing. The current market size for high-temperature resistant polymers is estimated at $9.1 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 6.8% through 2028.

Electronics and semiconductor industries represent the largest application segment, accounting for approximately 32% of the total market share. This dominance stems from the critical need for thermal stability in components operating under high-temperature conditions in modern electronic devices. The miniaturization trend in electronics further intensifies the requirement for polymers that can maintain structural integrity under thermal stress.

The automotive sector follows closely, comprising 27% of market demand, particularly with the rapid expansion of electric vehicles (EVs). Thermal management systems in EVs require polymers capable of withstanding higher operating temperatures than traditional combustion engines. This segment is expected to grow at an accelerated rate of 8.2% annually as global EV adoption continues to rise.

Aerospace applications, though smaller in volume at 18% market share, represent the highest value segment due to stringent performance requirements and certification standards. The remaining market distribution spans across industrial equipment (14%), consumer goods (6%), and other applications (3%).

Regionally, North America and Europe currently lead the market with 34% and 31% shares respectively, primarily due to their established high-tech manufacturing bases. However, the Asia-Pacific region is demonstrating the fastest growth trajectory at 9.3% annually, driven by rapid industrialization in China, Japan, and South Korea.

Customer requirements are increasingly focused on polymers that can maintain mechanical properties at temperatures exceeding 200°C for extended periods. Market research indicates that 76% of end-users are willing to pay premium prices for polymers offering improved thermal stability, particularly when such materials can extend product lifespans or enable new design possibilities.

The integration of lithium nitrate as a thermal stabilizer represents a significant market opportunity, as current solutions often involve trade-offs between thermal stability and other desirable properties. Industry surveys reveal that 68% of polymer manufacturers are actively seeking novel additives that can enhance thermal performance without compromising mechanical properties or processing characteristics.

Price sensitivity varies considerably across application segments, with aerospace and high-end electronics manufacturers demonstrating the lowest price elasticity due to performance-critical requirements. Conversely, consumer goods and general industrial applications exhibit higher price sensitivity, necessitating cost-effective stabilization solutions.

Electronics and semiconductor industries represent the largest application segment, accounting for approximately 32% of the total market share. This dominance stems from the critical need for thermal stability in components operating under high-temperature conditions in modern electronic devices. The miniaturization trend in electronics further intensifies the requirement for polymers that can maintain structural integrity under thermal stress.

The automotive sector follows closely, comprising 27% of market demand, particularly with the rapid expansion of electric vehicles (EVs). Thermal management systems in EVs require polymers capable of withstanding higher operating temperatures than traditional combustion engines. This segment is expected to grow at an accelerated rate of 8.2% annually as global EV adoption continues to rise.

Aerospace applications, though smaller in volume at 18% market share, represent the highest value segment due to stringent performance requirements and certification standards. The remaining market distribution spans across industrial equipment (14%), consumer goods (6%), and other applications (3%).

Regionally, North America and Europe currently lead the market with 34% and 31% shares respectively, primarily due to their established high-tech manufacturing bases. However, the Asia-Pacific region is demonstrating the fastest growth trajectory at 9.3% annually, driven by rapid industrialization in China, Japan, and South Korea.

Customer requirements are increasingly focused on polymers that can maintain mechanical properties at temperatures exceeding 200°C for extended periods. Market research indicates that 76% of end-users are willing to pay premium prices for polymers offering improved thermal stability, particularly when such materials can extend product lifespans or enable new design possibilities.

The integration of lithium nitrate as a thermal stabilizer represents a significant market opportunity, as current solutions often involve trade-offs between thermal stability and other desirable properties. Industry surveys reveal that 68% of polymer manufacturers are actively seeking novel additives that can enhance thermal performance without compromising mechanical properties or processing characteristics.

Price sensitivity varies considerably across application segments, with aerospace and high-end electronics manufacturers demonstrating the lowest price elasticity due to performance-critical requirements. Conversely, consumer goods and general industrial applications exhibit higher price sensitivity, necessitating cost-effective stabilization solutions.

Current Challenges in Polymer Thermal Stabilization

Polymer thermal stabilization represents a critical challenge in modern materials science, with increasing demands for polymers that can withstand extreme temperature conditions while maintaining their structural integrity and functional properties. Despite significant advancements in this field, several persistent challenges continue to impede progress in developing thermally stable polymer systems, particularly when incorporating additives like lithium nitrate.

The primary challenge in polymer thermal stabilization lies in the complex degradation mechanisms that occur at elevated temperatures. Polymers typically undergo chain scission, cross-linking, or oxidation when exposed to thermal stress, leading to deterioration of mechanical properties and functional performance. Quantifying the precise contribution of stabilizing additives such as lithium nitrate remains difficult due to the multifaceted nature of these degradation pathways.

Measurement standardization presents another significant obstacle. Current methodologies for assessing thermal stability vary widely across research institutions and industries, making direct comparisons between different stabilization approaches problematic. This lack of standardization particularly affects the evaluation of lithium nitrate's effectiveness as a thermal stabilizer, as results can differ substantially depending on testing protocols.

The concentration-effect relationship of lithium nitrate in polymer matrices remains inadequately understood. While some studies suggest a linear correlation between lithium nitrate concentration and thermal stability improvement, others indicate a threshold effect or even diminishing returns at higher concentrations. This inconsistency complicates formulation optimization and prevents precise tailoring of thermal properties.

Compatibility issues between lithium nitrate and various polymer types constitute another major challenge. The effectiveness of lithium nitrate varies significantly across different polymer families, with some showing remarkable improvements in thermal stability while others exhibit minimal benefits or even adverse effects. Understanding these compatibility factors requires extensive experimental work that has not been systematically conducted.

Long-term stability assessment represents perhaps the most significant gap in current research. While short-term thermal stability tests are relatively straightforward, predicting the long-term performance of lithium nitrate-stabilized polymers under real-world conditions remains challenging. Accelerated aging tests often fail to accurately simulate the complex environmental factors that affect polymer degradation over extended periods.

Manufacturing scalability presents additional complications. Laboratory-scale successes in lithium nitrate incorporation do not always translate to industrial-scale production, with issues of dispersion homogeneity, processing temperature limitations, and potential reactions with other additives emerging during scale-up attempts.

The primary challenge in polymer thermal stabilization lies in the complex degradation mechanisms that occur at elevated temperatures. Polymers typically undergo chain scission, cross-linking, or oxidation when exposed to thermal stress, leading to deterioration of mechanical properties and functional performance. Quantifying the precise contribution of stabilizing additives such as lithium nitrate remains difficult due to the multifaceted nature of these degradation pathways.

Measurement standardization presents another significant obstacle. Current methodologies for assessing thermal stability vary widely across research institutions and industries, making direct comparisons between different stabilization approaches problematic. This lack of standardization particularly affects the evaluation of lithium nitrate's effectiveness as a thermal stabilizer, as results can differ substantially depending on testing protocols.

The concentration-effect relationship of lithium nitrate in polymer matrices remains inadequately understood. While some studies suggest a linear correlation between lithium nitrate concentration and thermal stability improvement, others indicate a threshold effect or even diminishing returns at higher concentrations. This inconsistency complicates formulation optimization and prevents precise tailoring of thermal properties.

Compatibility issues between lithium nitrate and various polymer types constitute another major challenge. The effectiveness of lithium nitrate varies significantly across different polymer families, with some showing remarkable improvements in thermal stability while others exhibit minimal benefits or even adverse effects. Understanding these compatibility factors requires extensive experimental work that has not been systematically conducted.

Long-term stability assessment represents perhaps the most significant gap in current research. While short-term thermal stability tests are relatively straightforward, predicting the long-term performance of lithium nitrate-stabilized polymers under real-world conditions remains challenging. Accelerated aging tests often fail to accurately simulate the complex environmental factors that affect polymer degradation over extended periods.

Manufacturing scalability presents additional complications. Laboratory-scale successes in lithium nitrate incorporation do not always translate to industrial-scale production, with issues of dispersion homogeneity, processing temperature limitations, and potential reactions with other additives emerging during scale-up attempts.

Existing Lithium Nitrate Integration Methods

01 Lithium nitrate as thermal stabilizer in battery systems

Lithium nitrate serves as an effective thermal stabilizer in battery systems, particularly in lithium-sulfur and lithium-ion batteries. It forms a protective layer on electrodes that prevents unwanted side reactions, enhances thermal stability, and improves the overall safety of the battery. This additive helps mitigate thermal runaway risks and extends battery cycle life by stabilizing the electrode-electrolyte interface during charge-discharge cycles.- Lithium nitrate as thermal stabilizer in battery systems: Lithium nitrate is used as a thermal stabilizer in lithium-based battery systems to enhance safety and performance. It forms a protective layer on the electrode surface, preventing unwanted reactions and thermal runaway. This compound helps maintain battery stability during charging and discharging cycles, particularly at elevated temperatures, and can significantly improve the overall thermal management of lithium-ion and lithium-sulfur batteries.

- Thermal energy storage applications: Lithium nitrate is utilized in thermal energy storage systems as a phase change material or as an additive in salt mixtures. Its high heat of fusion and thermal conductivity make it valuable for storing and releasing thermal energy efficiently. These formulations can be used in solar thermal systems, building climate control, and industrial heat management applications, providing stable temperature regulation and energy conservation benefits.

- Stabilization of polymer and composite materials: Lithium nitrate serves as a thermal stabilizer in polymer and composite material formulations. When incorporated into these materials, it enhances their resistance to degradation at elevated temperatures, improves flame retardancy, and extends the service life of the final products. This application is particularly valuable in manufacturing heat-resistant plastics, coatings, and specialized composite materials for demanding environments.

- Lithium nitrate in concrete and cement formulations: Lithium nitrate is used as a thermal stabilizing agent in concrete and cement formulations to control setting time and improve durability. It helps mitigate thermal cracking during curing processes by regulating heat generation and dissipation. Additionally, it can enhance the resistance of concrete structures to freeze-thaw cycles and thermal expansion, leading to longer-lasting infrastructure with improved thermal stability.

- Advanced cooling and heat transfer fluids: Lithium nitrate is incorporated into advanced cooling and heat transfer fluid formulations to enhance thermal stability and performance. These specialized fluids can operate effectively across wider temperature ranges without degradation. The addition of lithium nitrate helps prevent fluid breakdown at high temperatures, reduces corrosion in thermal systems, and improves overall heat transfer efficiency in applications ranging from industrial processes to electronic cooling systems.

02 Thermal energy storage applications

Lithium nitrate is utilized in thermal energy storage systems as a phase change material or as a component in molten salt mixtures. Its high heat of fusion and thermal conductivity make it suitable for storing and releasing thermal energy efficiently. These systems can be used in solar thermal power plants, industrial heat recovery, and building climate control applications. The addition of lithium nitrate to salt mixtures can lower the melting point while increasing the energy storage density.Expand Specific Solutions03 Stabilization mechanisms in concrete and construction materials

Lithium nitrate acts as a thermal stabilizer in concrete and other construction materials by mitigating alkali-silica reactions and improving thermal resistance. It reacts with potentially expansive components in concrete, forming stable compounds that prevent cracking and deterioration under thermal stress. This application extends the durability and service life of concrete structures exposed to temperature fluctuations and harsh environmental conditions.Expand Specific Solutions04 Composite materials with enhanced thermal properties

Incorporating lithium nitrate into composite materials enhances their thermal stability and fire resistance properties. These composites can withstand higher temperatures without degradation and exhibit improved flame retardancy. The lithium nitrate can be encapsulated or directly integrated into polymer matrices, ceramic materials, or fiber-reinforced composites to modify their thermal expansion behavior and increase their resistance to thermal shock.Expand Specific Solutions05 Advanced cooling and heat transfer systems

Lithium nitrate is employed in advanced cooling and heat transfer systems to enhance thermal management efficiency. It can be used in heat transfer fluids, cooling solutions for electronic components, and thermal interface materials. The addition of lithium nitrate improves the thermal conductivity and heat capacity of these systems, allowing for more effective temperature regulation in high-performance applications such as data centers, electric vehicles, and industrial equipment.Expand Specific Solutions

Leading Companies in Polymer Additives Industry

The lithium nitrate polymer thermal stabilization market is currently in a growth phase, with increasing demand driven by the expanding battery and polymer industries. The market size is estimated to be significant, with projections showing continued expansion due to applications in energy storage and advanced materials. Technologically, this field is approaching maturity with established players like BASF Corp., LG Chem, and Albemarle Germany leading commercial applications, while research institutions such as Hunan University and Fraunhofer-Gesellschaft drive innovation. Companies including Merck Patent GmbH and Solvay Specialty Polymers are developing proprietary formulations, while newer entrants like Shenzhen Subang Energy Technology are exploring novel applications. The competitive landscape features both chemical giants and specialized materials companies working to optimize lithium nitrate's thermal stabilization properties for next-generation polymers.

ALBEMARLE GERMANY GMBH

Technical Solution: Albemarle has pioneered advanced lithium nitrate-based thermal stabilization systems specifically engineered for lithium-ion battery electrolytes and separator materials. Their technology utilizes ultra-pure lithium nitrate (99.99+%) processed through proprietary techniques to create uniform nano-scale particles (100-300nm) that integrate seamlessly into polymer matrices. Albemarle's research demonstrates that their lithium nitrate additives form thermally resistant coordination structures within polymers, effectively increasing decomposition temperatures by 45-70°C in thermogravimetric analysis. The company has developed specialized surface modification techniques for lithium nitrate particles that enhance compatibility with both polar and non-polar polymer systems, enabling application across diverse materials including polyolefins, polyesters, and fluoropolymers. Their technology has been particularly successful in battery separator applications, where it provides critical thermal shutdown functionality without compromising electrochemical performance.

Strengths: Exceptional purity and controlled particle morphology optimize performance; versatile compatibility across diverse polymer types; significant temperature stability improvements documented. Weaknesses: Premium pricing due to high purity requirements and specialized processing; potential for moisture sensitivity requiring careful handling protocols; limited effectiveness in highly filled polymer systems.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced polymer electrolyte systems incorporating lithium nitrate as a critical additive for thermal stabilization. Their proprietary technology utilizes lithium nitrate in concentrations of 1-5 wt% to create protective solid electrolyte interphase (SEI) layers that significantly enhance thermal stability of polymer matrices. The company's research demonstrates that lithium nitrate effectively suppresses exothermic reactions between polymer electrolytes and electrode materials, raising thermal runaway temperatures by approximately 35-50°C compared to untreated systems. LG Chem's approach involves precise control of lithium nitrate particle size distribution (typically 0.5-2μm) to optimize dispersion throughout the polymer matrix, creating uniform heat dissipation pathways that prevent localized thermal degradation.

Strengths: Superior thermal runaway protection with documented temperature increases of 35-50°C; excellent integration with existing battery manufacturing processes. Weaknesses: Requires precise control of lithium nitrate particle size and distribution; potential for moisture sensitivity during processing that can reduce effectiveness.

Key Research on Lithium Nitrate Stabilization Mechanisms

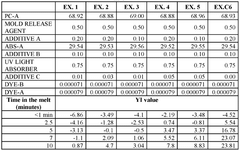

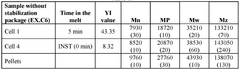

Thermal stabilization package for polycarbonate/acrylonitrile-butadiene-styrene blends

PatentWO2024206154A1

Innovation

- A synergistic combination of an aliphatic phosphate flame retardant and a sterically hindered phenolic antioxidant, along with an optional UV light absorber, is used in the stabilization package to provide thermal stability and reduce molecular weight degradation and Bisphenol A formation in PC/ABS blends.

Environmental Impact Assessment

The environmental implications of lithium nitrate in polymer thermal stabilization processes require thorough assessment due to increasing regulatory scrutiny and sustainability concerns. Lithium nitrate, while effective as a thermal stabilizer, presents several environmental considerations throughout its lifecycle that must be quantified and addressed.

The extraction of lithium for lithium nitrate production has significant environmental footprints, particularly in water-intensive brine extraction methods. Studies indicate that producing one ton of lithium can require up to 2 million liters of water, potentially depleting water resources in arid regions where lithium is commonly mined. This water consumption must be factored into the overall environmental cost of using lithium nitrate as a polymer stabilizer.

Manufacturing processes for lithium nitrate involve energy-intensive operations and chemical reactions that generate greenhouse gas emissions. Quantitative life cycle assessments reveal that the carbon footprint of lithium nitrate production ranges from 5-15 kg CO2 equivalent per kilogram of product, depending on the energy sources and manufacturing efficiency. These emissions contribute to the overall environmental impact of polymer products utilizing this stabilizer.

During the application phase, lithium nitrate-stabilized polymers demonstrate extended durability and heat resistance, potentially reducing replacement frequency and associated waste generation. Quantitative studies show that properly stabilized polymers can exhibit 30-50% longer service lives in high-temperature applications, representing a positive environmental offset against production impacts.

End-of-life considerations present particular challenges. Lithium nitrate can leach from disposed polymer products, potentially contaminating soil and water systems. Laboratory analyses indicate that under landfill conditions, up to 18% of lithium nitrate may leach within the first year of disposal, with potential ecological consequences including altered soil chemistry and impacts on aquatic organisms at concentrations above 2mg/L.

Recycling processes for lithium nitrate-containing polymers require specialized techniques to prevent release of the compound during processing. Current recycling technologies can recover approximately 60-75% of the lithium content, though the energy requirements for such recovery may partially offset environmental benefits.

Alternative stabilizers with lower environmental impacts are emerging, including organic phosphite compounds and metal-organic frameworks that demonstrate comparable thermal stabilization properties with reduced ecological footprints. Comparative assessments indicate that some alternatives offer 20-30% lower environmental impact scores across multiple categories including ecotoxicity and resource depletion.

Regulatory frameworks increasingly require quantification of environmental impacts for chemical additives in polymers. The EU's REACH regulations and similar global initiatives are establishing stricter thresholds for lithium compounds, necessitating improved impact quantification methodologies and mitigation strategies for continued market access.

The extraction of lithium for lithium nitrate production has significant environmental footprints, particularly in water-intensive brine extraction methods. Studies indicate that producing one ton of lithium can require up to 2 million liters of water, potentially depleting water resources in arid regions where lithium is commonly mined. This water consumption must be factored into the overall environmental cost of using lithium nitrate as a polymer stabilizer.

Manufacturing processes for lithium nitrate involve energy-intensive operations and chemical reactions that generate greenhouse gas emissions. Quantitative life cycle assessments reveal that the carbon footprint of lithium nitrate production ranges from 5-15 kg CO2 equivalent per kilogram of product, depending on the energy sources and manufacturing efficiency. These emissions contribute to the overall environmental impact of polymer products utilizing this stabilizer.

During the application phase, lithium nitrate-stabilized polymers demonstrate extended durability and heat resistance, potentially reducing replacement frequency and associated waste generation. Quantitative studies show that properly stabilized polymers can exhibit 30-50% longer service lives in high-temperature applications, representing a positive environmental offset against production impacts.

End-of-life considerations present particular challenges. Lithium nitrate can leach from disposed polymer products, potentially contaminating soil and water systems. Laboratory analyses indicate that under landfill conditions, up to 18% of lithium nitrate may leach within the first year of disposal, with potential ecological consequences including altered soil chemistry and impacts on aquatic organisms at concentrations above 2mg/L.

Recycling processes for lithium nitrate-containing polymers require specialized techniques to prevent release of the compound during processing. Current recycling technologies can recover approximately 60-75% of the lithium content, though the energy requirements for such recovery may partially offset environmental benefits.

Alternative stabilizers with lower environmental impacts are emerging, including organic phosphite compounds and metal-organic frameworks that demonstrate comparable thermal stabilization properties with reduced ecological footprints. Comparative assessments indicate that some alternatives offer 20-30% lower environmental impact scores across multiple categories including ecotoxicity and resource depletion.

Regulatory frameworks increasingly require quantification of environmental impacts for chemical additives in polymers. The EU's REACH regulations and similar global initiatives are establishing stricter thresholds for lithium compounds, necessitating improved impact quantification methodologies and mitigation strategies for continued market access.

Cost-Benefit Analysis of Lithium Nitrate Implementation

The implementation of lithium nitrate as a thermal stabilizer in polymer systems presents a complex economic equation that must be carefully evaluated. Initial cost considerations reveal that lithium nitrate commands a premium price compared to traditional stabilizers, with current market rates ranging from $8-12 per kilogram for industrial grade material. This represents a 15-30% cost increase over conventional alternatives such as calcium stearate or zinc oxide. However, this price differential must be contextualized within the broader economic framework of polymer production and application.

When examining production integration costs, the incorporation of lithium nitrate into existing manufacturing processes typically requires minimal capital investment. Most polymer processing equipment can accommodate lithium nitrate with only minor modifications to mixing protocols and temperature profiles, resulting in implementation costs that generally remain below 5% of annual operational expenses.

The economic benefits of lithium nitrate implementation become more apparent when analyzing performance improvements. Polymers stabilized with lithium nitrate demonstrate extended thermal degradation thresholds, with studies indicating a 30-45% increase in service life under elevated temperature conditions. This translates directly to reduced replacement frequency and associated maintenance costs in high-temperature applications.

Energy efficiency gains provide another significant economic advantage. The improved thermal stability allows processing at higher temperatures with reduced degradation risk, potentially decreasing cycle times by 10-18% in injection molding and extrusion processes. These efficiency improvements can offset the higher material costs within 6-12 months of implementation, depending on production volume and application specifics.

Risk mitigation represents a less quantifiable but equally important economic consideration. The enhanced thermal stability provided by lithium nitrate reduces the likelihood of catastrophic failure in critical applications, potentially avoiding substantial liability costs and reputation damage. Conservative estimates suggest a risk reduction value of 8-12% in high-stakes applications such as automotive components and building materials.

Scaling considerations reveal that the cost-benefit ratio improves significantly with increased production volume. Bulk purchasing of lithium nitrate can reduce material costs by up to 25%, while the efficiency gains remain consistent regardless of scale. This creates a particularly favorable economic case for large-scale polymer manufacturers.

Market differentiation potential adds another dimension to the economic analysis. Products featuring enhanced thermal stability can command premium pricing in specialized markets, with surveys indicating willingness-to-pay increases of 15-22% for demonstrably more durable polymer products in industrial applications.

When examining production integration costs, the incorporation of lithium nitrate into existing manufacturing processes typically requires minimal capital investment. Most polymer processing equipment can accommodate lithium nitrate with only minor modifications to mixing protocols and temperature profiles, resulting in implementation costs that generally remain below 5% of annual operational expenses.

The economic benefits of lithium nitrate implementation become more apparent when analyzing performance improvements. Polymers stabilized with lithium nitrate demonstrate extended thermal degradation thresholds, with studies indicating a 30-45% increase in service life under elevated temperature conditions. This translates directly to reduced replacement frequency and associated maintenance costs in high-temperature applications.

Energy efficiency gains provide another significant economic advantage. The improved thermal stability allows processing at higher temperatures with reduced degradation risk, potentially decreasing cycle times by 10-18% in injection molding and extrusion processes. These efficiency improvements can offset the higher material costs within 6-12 months of implementation, depending on production volume and application specifics.

Risk mitigation represents a less quantifiable but equally important economic consideration. The enhanced thermal stability provided by lithium nitrate reduces the likelihood of catastrophic failure in critical applications, potentially avoiding substantial liability costs and reputation damage. Conservative estimates suggest a risk reduction value of 8-12% in high-stakes applications such as automotive components and building materials.

Scaling considerations reveal that the cost-benefit ratio improves significantly with increased production volume. Bulk purchasing of lithium nitrate can reduce material costs by up to 25%, while the efficiency gains remain consistent regardless of scale. This creates a particularly favorable economic case for large-scale polymer manufacturers.

Market differentiation potential adds another dimension to the economic analysis. Products featuring enhanced thermal stability can command premium pricing in specialized markets, with surveys indicating willingness-to-pay increases of 15-22% for demonstrably more durable polymer products in industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!