Benchmarking Direct Lithium Extraction: Energy Cost Metrics

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a transformative technology in the lithium production landscape over the past decade. Traditional lithium extraction methods, primarily evaporative brine processing and hard rock mining, have dominated the industry since commercial lithium production began in the 1950s. However, these conventional approaches face significant limitations including lengthy production timelines (12-18 months for evaporation ponds), substantial land and water requirements, and variable recovery rates typically below 50%.

The evolution of DLE technologies began in earnest during the early 2000s, with significant acceleration occurring after 2010 as global demand for lithium increased dramatically due to the electric vehicle revolution and expanding energy storage applications. This technological progression has been driven by the need to address the inefficiencies of traditional methods while meeting rapidly growing market demands for this critical battery material.

DLE encompasses a diverse range of selective extraction technologies including adsorption, ion exchange, solvent extraction, and membrane processes. These approaches aim to directly extract lithium from brine resources with greater efficiency, reduced environmental impact, and accelerated production timelines. The fundamental technical objective is to selectively separate lithium ions from complex brine solutions containing numerous competing ions such as sodium, magnesium, calcium, and potassium.

Energy consumption represents a critical metric for evaluating DLE technologies, as it directly impacts both operational costs and environmental sustainability. Current DLE processes typically require between 5-15 kWh per kilogram of lithium carbonate equivalent (LCE) produced, though significant variations exist between different technological approaches and brine compositions.

The primary technical objectives driving DLE development include achieving lithium recovery rates exceeding 80%, reducing processing times from months to days, minimizing freshwater consumption, decreasing land footprint requirements, and critically, optimizing energy efficiency across the extraction process. Energy optimization is particularly crucial as it represents both a significant operational cost driver and a determinant of the overall carbon footprint of lithium production.

Recent technological advancements have focused on developing more selective sorbents and membranes, improving regeneration processes, and integrating renewable energy sources to power DLE operations. The industry is increasingly moving toward establishing standardized benchmarking metrics for energy consumption to enable meaningful comparisons between different DLE technologies and conventional extraction methods.

As global lithium demand projections indicate a potential supply gap by 2030, the successful development and deployment of energy-efficient DLE technologies has become strategically important for meeting future battery material requirements while aligning with decarbonization objectives across the supply chain.

The evolution of DLE technologies began in earnest during the early 2000s, with significant acceleration occurring after 2010 as global demand for lithium increased dramatically due to the electric vehicle revolution and expanding energy storage applications. This technological progression has been driven by the need to address the inefficiencies of traditional methods while meeting rapidly growing market demands for this critical battery material.

DLE encompasses a diverse range of selective extraction technologies including adsorption, ion exchange, solvent extraction, and membrane processes. These approaches aim to directly extract lithium from brine resources with greater efficiency, reduced environmental impact, and accelerated production timelines. The fundamental technical objective is to selectively separate lithium ions from complex brine solutions containing numerous competing ions such as sodium, magnesium, calcium, and potassium.

Energy consumption represents a critical metric for evaluating DLE technologies, as it directly impacts both operational costs and environmental sustainability. Current DLE processes typically require between 5-15 kWh per kilogram of lithium carbonate equivalent (LCE) produced, though significant variations exist between different technological approaches and brine compositions.

The primary technical objectives driving DLE development include achieving lithium recovery rates exceeding 80%, reducing processing times from months to days, minimizing freshwater consumption, decreasing land footprint requirements, and critically, optimizing energy efficiency across the extraction process. Energy optimization is particularly crucial as it represents both a significant operational cost driver and a determinant of the overall carbon footprint of lithium production.

Recent technological advancements have focused on developing more selective sorbents and membranes, improving regeneration processes, and integrating renewable energy sources to power DLE operations. The industry is increasingly moving toward establishing standardized benchmarking metrics for energy consumption to enable meaningful comparisons between different DLE technologies and conventional extraction methods.

As global lithium demand projections indicate a potential supply gap by 2030, the successful development and deployment of energy-efficient DLE technologies has become strategically important for meeting future battery material requirements while aligning with decarbonization objectives across the supply chain.

Lithium Market Demand Analysis

The global lithium market is experiencing unprecedented growth driven primarily by the rapid expansion of electric vehicle (EV) production and energy storage systems. Current market valuations place the lithium industry at approximately $7.5 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 12-14% through 2030, potentially reaching $18-20 billion by decade's end. This remarkable trajectory is fundamentally reshaping mining operations and extraction technologies worldwide.

Demand forecasts suggest lithium consumption will increase from roughly 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 1.5 million metric tons by 2030. The automotive sector represents the dominant demand driver, accounting for 70-75% of lithium consumption, with consumer electronics (15%) and energy storage systems (10%) comprising most remaining market share. As battery manufacturers continue scaling production capacity, this sectoral distribution is expected to further skew toward automotive applications.

Regional analysis reveals China currently dominates lithium processing (controlling approximately 60% of global capacity), while Australia, Chile, and Argentina lead in raw material production. However, significant market shifts are underway as the United States, European Union, and Canada actively develop domestic supply chains to reduce dependency on foreign sources. This geopolitical dimension has elevated lithium to "critical mineral" status in many jurisdictions, spurring governmental initiatives to secure supplies.

The energy intensity of lithium extraction represents a critical market consideration, particularly as sustainability metrics increasingly influence purchasing decisions. Traditional extraction methods require 5-15 kWh/kg LCE for brine operations and 8-20 kWh/kg LCE for hard rock mining. Direct Lithium Extraction (DLE) technologies promise potential efficiency improvements, with leading processes targeting 3-7 kWh/kg LCE, representing a significant competitive advantage in both cost structure and environmental impact.

Price volatility remains a defining market characteristic, with lithium carbonate prices fluctuating between $8,000-$80,000 per metric ton over the past five years. This instability creates significant challenges for both producers and consumers, driving interest in technologies that can operate profitably across price cycles. Energy-efficient extraction methods that minimize operational costs become particularly valuable in this context.

End-user specifications are simultaneously becoming more stringent, with battery manufacturers requiring 99.5%+ purity levels and specific impurity profiles. This quality dimension creates premium market segments where advanced extraction technologies capable of producing battery-grade lithium command significant price premiums, often 30-40% above technical-grade material.

Demand forecasts suggest lithium consumption will increase from roughly 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 1.5 million metric tons by 2030. The automotive sector represents the dominant demand driver, accounting for 70-75% of lithium consumption, with consumer electronics (15%) and energy storage systems (10%) comprising most remaining market share. As battery manufacturers continue scaling production capacity, this sectoral distribution is expected to further skew toward automotive applications.

Regional analysis reveals China currently dominates lithium processing (controlling approximately 60% of global capacity), while Australia, Chile, and Argentina lead in raw material production. However, significant market shifts are underway as the United States, European Union, and Canada actively develop domestic supply chains to reduce dependency on foreign sources. This geopolitical dimension has elevated lithium to "critical mineral" status in many jurisdictions, spurring governmental initiatives to secure supplies.

The energy intensity of lithium extraction represents a critical market consideration, particularly as sustainability metrics increasingly influence purchasing decisions. Traditional extraction methods require 5-15 kWh/kg LCE for brine operations and 8-20 kWh/kg LCE for hard rock mining. Direct Lithium Extraction (DLE) technologies promise potential efficiency improvements, with leading processes targeting 3-7 kWh/kg LCE, representing a significant competitive advantage in both cost structure and environmental impact.

Price volatility remains a defining market characteristic, with lithium carbonate prices fluctuating between $8,000-$80,000 per metric ton over the past five years. This instability creates significant challenges for both producers and consumers, driving interest in technologies that can operate profitably across price cycles. Energy-efficient extraction methods that minimize operational costs become particularly valuable in this context.

End-user specifications are simultaneously becoming more stringent, with battery manufacturers requiring 99.5%+ purity levels and specific impurity profiles. This quality dimension creates premium market segments where advanced extraction technologies capable of producing battery-grade lithium command significant price premiums, often 30-40% above technical-grade material.

Global DLE Technology Status and Challenges

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives to traditional lithium extraction methods, with varying levels of development and implementation across the globe. Currently, the global DLE landscape is characterized by a mix of pilot projects, early commercial deployments, and ongoing research initiatives, with North America, South America, and parts of Europe leading in technology development.

The most advanced DLE technologies have demonstrated lithium recovery rates of 70-90% in controlled environments, significantly higher than the 30-50% typically achieved through conventional evaporation pond methods. However, field implementation at commercial scale remains limited, with fewer than ten fully operational commercial DLE facilities worldwide as of 2023.

A primary challenge facing DLE technologies is energy intensity, with current systems requiring between 5-15 kWh per kilogram of lithium carbonate equivalent (LCE) produced. This energy requirement varies significantly based on the specific technology employed, brine chemistry, and operational parameters. For comparison, traditional evaporation methods consume approximately 2-5 kWh/kg LCE but require substantially more time and physical space.

Water consumption presents another significant challenge, particularly in water-stressed regions where many lithium resources are located. Advanced DLE systems claim water usage reductions of up to 70% compared to evaporation ponds, but actual performance data from commercial operations remains limited and inconsistent across different technologies and geographies.

Selectivity and contaminant management continue to pose technical hurdles. Most DLE technologies struggle with achieving consistent lithium purity when processing brines with high concentrations of competing ions such as magnesium, calcium, and sodium. This necessitates additional downstream processing, increasing both energy requirements and operational costs.

Geographically, DLE technology development shows distinct regional patterns. North American companies lead in ion-exchange and adsorption-based technologies, while European research institutions have made significant advances in membrane and electrochemical processes. Chinese entities have focused primarily on scaling existing technologies rather than fundamental innovation.

The regulatory landscape for DLE varies substantially across regions, with some jurisdictions expediting permitting processes for DLE projects due to their reduced environmental footprint compared to evaporation ponds, while others maintain stringent requirements that slow implementation. This regulatory inconsistency creates additional challenges for global technology standardization and deployment.

Economic viability remains a critical concern, with current DLE operational costs estimated between $3,500-$6,000 per ton of LCE, compared to $2,500-$3,500 for established brine operations. However, these costs are projected to decrease by 30-40% over the next five years as technologies mature and economies of scale are realized.

The most advanced DLE technologies have demonstrated lithium recovery rates of 70-90% in controlled environments, significantly higher than the 30-50% typically achieved through conventional evaporation pond methods. However, field implementation at commercial scale remains limited, with fewer than ten fully operational commercial DLE facilities worldwide as of 2023.

A primary challenge facing DLE technologies is energy intensity, with current systems requiring between 5-15 kWh per kilogram of lithium carbonate equivalent (LCE) produced. This energy requirement varies significantly based on the specific technology employed, brine chemistry, and operational parameters. For comparison, traditional evaporation methods consume approximately 2-5 kWh/kg LCE but require substantially more time and physical space.

Water consumption presents another significant challenge, particularly in water-stressed regions where many lithium resources are located. Advanced DLE systems claim water usage reductions of up to 70% compared to evaporation ponds, but actual performance data from commercial operations remains limited and inconsistent across different technologies and geographies.

Selectivity and contaminant management continue to pose technical hurdles. Most DLE technologies struggle with achieving consistent lithium purity when processing brines with high concentrations of competing ions such as magnesium, calcium, and sodium. This necessitates additional downstream processing, increasing both energy requirements and operational costs.

Geographically, DLE technology development shows distinct regional patterns. North American companies lead in ion-exchange and adsorption-based technologies, while European research institutions have made significant advances in membrane and electrochemical processes. Chinese entities have focused primarily on scaling existing technologies rather than fundamental innovation.

The regulatory landscape for DLE varies substantially across regions, with some jurisdictions expediting permitting processes for DLE projects due to their reduced environmental footprint compared to evaporation ponds, while others maintain stringent requirements that slow implementation. This regulatory inconsistency creates additional challenges for global technology standardization and deployment.

Economic viability remains a critical concern, with current DLE operational costs estimated between $3,500-$6,000 per ton of LCE, compared to $2,500-$3,500 for established brine operations. However, these costs are projected to decrease by 30-40% over the next five years as technologies mature and economies of scale are realized.

Current Energy Cost Benchmarking Methodologies

01 Energy efficiency metrics in DLE processes

Direct Lithium Extraction processes can be evaluated using specific energy efficiency metrics that measure the amount of energy consumed per unit of lithium extracted. These metrics help in comparing different DLE technologies and optimizing operational parameters. Key considerations include the energy required for pumping, heating, and regeneration of extraction media. Advanced monitoring systems can track real-time energy consumption and identify opportunities for efficiency improvements in the extraction process.- Energy efficiency metrics in DLE processes: Direct Lithium Extraction (DLE) processes can be evaluated using specific energy efficiency metrics that measure the amount of energy consumed per unit of lithium extracted. These metrics help in comparing different DLE technologies and optimizing operational parameters. Energy consumption is typically measured in kWh per kilogram of lithium carbonate equivalent (LCE) produced, with lower values indicating more efficient processes. Advanced monitoring systems can track these metrics in real-time to identify opportunities for energy optimization.

- Renewable energy integration with DLE systems: Integration of renewable energy sources with Direct Lithium Extraction systems can significantly reduce the carbon footprint and operational costs. Solar, geothermal, and wind energy can be harnessed to power various DLE processes, particularly in remote locations where lithium brine resources are abundant. Hybrid energy systems that combine multiple renewable sources can ensure continuous operation while minimizing reliance on fossil fuels. Energy storage solutions can also be incorporated to manage intermittency issues associated with renewable energy sources.

- Heat recovery and thermal energy management: Thermal energy management and heat recovery systems play a crucial role in optimizing the energy efficiency of DLE processes. Since many DLE methods involve heating and cooling cycles, recovering waste heat from various process streams can significantly reduce overall energy consumption. Advanced heat exchangers, thermal storage systems, and process integration techniques can be employed to minimize energy losses. The implementation of these thermal management strategies can reduce energy costs by 20-40% in some DLE operations.

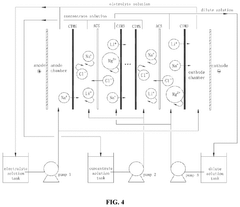

- Electrochemical energy optimization in DLE: Electrochemical processes in Direct Lithium Extraction can be optimized to reduce energy consumption through improved electrode materials, cell design, and operating conditions. Advanced electrode materials with higher selectivity for lithium ions can reduce the energy required for separation. Pulsed electric field techniques and optimized current densities can enhance energy efficiency in electrochemical DLE systems. Monitoring and controlling parameters such as voltage, current density, and temperature are essential for maintaining optimal energy performance in these systems.

- Comparative energy cost analysis frameworks: Frameworks for comparative energy cost analysis enable stakeholders to evaluate different DLE technologies based on their energy requirements and associated costs. These frameworks consider factors such as energy source availability, regional energy prices, process efficiency, and scale of operation. Life cycle assessment methodologies can be applied to determine the total energy footprint of DLE processes from extraction to product delivery. Standardized metrics and benchmarking tools help in making informed decisions when selecting the most energy-efficient DLE technology for specific lithium resources.

02 Renewable energy integration with DLE systems

Integration of renewable energy sources with Direct Lithium Extraction systems can significantly reduce operational costs and environmental impact. Solar, geothermal, and wind energy can be utilized to power various components of DLE operations, particularly in remote brine field locations. This integration requires specialized energy management systems to handle the intermittent nature of renewable sources while maintaining consistent extraction processes. The combination of renewable energy with DLE represents a sustainable approach to lithium production with lower carbon footprints.Expand Specific Solutions03 Heat recovery and thermal energy optimization in DLE

Thermal energy management is crucial in Direct Lithium Extraction processes, particularly for technologies requiring temperature control for adsorption and desorption cycles. Heat recovery systems can capture and reuse thermal energy from various stages of the extraction process, significantly reducing overall energy consumption. Innovations in heat exchanger design and thermal storage solutions allow for more efficient use of energy in heating brine solutions and regenerating extraction media. These optimizations directly impact the economic viability of DLE operations by lowering energy costs.Expand Specific Solutions04 Electrochemical energy requirements in DLE technologies

Electrochemical Direct Lithium Extraction methods have specific energy cost considerations related to the electrical current required for ion separation and concentration. These systems utilize various electrode materials and membrane technologies to selectively extract lithium ions from brine solutions. The energy consumption metrics for electrochemical DLE include voltage efficiency, current density optimization, and electrode durability. Advanced control systems can dynamically adjust electrical parameters to minimize energy usage while maintaining extraction performance across varying brine compositions.Expand Specific Solutions05 Energy consumption monitoring and optimization systems for DLE

Sophisticated monitoring and control systems are being developed specifically for tracking and optimizing energy consumption in Direct Lithium Extraction operations. These systems incorporate sensors, data analytics, and machine learning algorithms to identify energy usage patterns and recommend operational adjustments. Real-time monitoring allows for immediate response to efficiency deviations and helps in establishing baseline energy metrics for different extraction conditions. Implementation of these systems enables continuous improvement in energy efficiency and provides valuable data for scaling up DLE technologies from pilot to commercial scale.Expand Specific Solutions

Key Industry Players in DLE Technology

The Direct Lithium Extraction (DLE) technology market is currently in its early growth phase, characterized by rapid innovation and increasing commercial interest. The global market size is projected to expand significantly as demand for lithium in battery production continues to surge. From a technological maturity perspective, DLE remains in development with varying approaches being pursued. Key players include established energy companies like Schlumberger Technologies and Koch Technology Solutions who bring extensive extraction expertise, alongside specialized innovators such as Evove Ltd. with their advanced membrane technologies. Chinese entities including State Grid Corp. of China and Sunwoda Power Technology are making significant investments, while academic institutions like Penn State Research Foundation, Sichuan University, and the University of Manchester contribute fundamental research advancements. The competitive landscape reflects a mix of established industrial players and emerging technology specialists racing to develop energy-efficient, commercially viable DLE solutions.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed an advanced Direct Lithium Extraction (DLE) technology platform called "NeoLith Energy" that focuses on optimizing energy efficiency metrics in lithium extraction processes. Their approach utilizes selective adsorption materials with high lithium selectivity and rapid kinetics, significantly reducing energy consumption compared to traditional evaporation methods. The system employs a closed-loop process that minimizes water usage and recycles process fluids, further enhancing energy efficiency. Schlumberger's benchmarking methodology incorporates comprehensive energy cost metrics including kWh per kg of lithium carbonate equivalent (LCE) produced, energy intensity relative to lithium concentration in brine, and total carbon footprint analysis. Their pilot plant in Clayton Valley, Nevada has demonstrated energy consumption reductions of up to 40% compared to conventional evaporation ponds, with processing times reduced from months to weeks. The technology also features advanced process control systems that continuously optimize operational parameters based on real-time energy consumption data.

Strengths: Superior energy efficiency metrics compared to traditional methods; significantly faster extraction timeframes; reduced water consumption; scalable technology applicable to various brine compositions. Weaknesses: Higher initial capital expenditure compared to conventional methods; technology still being validated at commercial scale; performance may vary depending on specific brine chemistry and conditions.

Evove Ltd.

Technical Solution: Evove has pioneered a membrane-based Direct Lithium Extraction (DLE) technology that focuses on energy-efficient separation processes. Their proprietary "Separonics" platform utilizes precision-engineered filtration membranes with nano-scale pores specifically designed for lithium ion selectivity. The technology employs a combination of advanced materials science and electrochemical principles to achieve high lithium recovery rates while minimizing energy inputs. Evove's benchmarking framework for energy metrics includes comprehensive analysis of membrane performance under various operating conditions, measuring energy consumption per unit of lithium recovered, and optimization of pressure differentials to minimize pumping energy requirements. Their system incorporates energy recovery devices that capture and reuse pressure energy, further improving overall efficiency metrics. The company has reported energy consumption figures of approximately 2-4 kWh per kg of lithium extracted, representing a significant improvement over conventional methods that can require 5-15 kWh per kg. Evove's technology also demonstrates superior performance in handling brines with complex compositions, maintaining energy efficiency even with challenging feedstocks.

Strengths: Highly selective membrane technology minimizing energy-intensive purification steps; modular design allowing for scalable implementation; lower operational energy requirements compared to many competing technologies; ability to process complex brine compositions. Weaknesses: Membrane fouling can occur over time, potentially increasing energy requirements; higher upfront costs compared to some conventional methods; technology still being scaled to full commercial deployment.

Critical Patents and Research in DLE Energy Efficiency

Systems and methods for direct lithium extraction

PatentPendingUS20250011957A1

Innovation

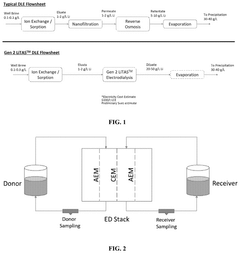

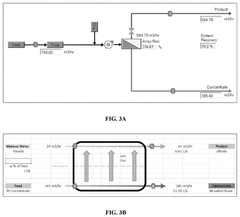

- The integration of selective membrane electrodialysis as a single step to simultaneously concentrate and purify lithium brines, reducing the number of required processing steps, capital and operating costs, and carbon footprint, while eliminating the need for large equipment at remote mining locations.

Environmental Impact Assessment of DLE Technologies

Direct Lithium Extraction (DLE) technologies present significant environmental implications that must be thoroughly assessed when benchmarking their energy cost metrics. These technologies offer potential advantages over traditional lithium extraction methods such as evaporation ponds and hard rock mining, which are known for their substantial environmental footprints.

Water usage represents a critical environmental consideration for DLE technologies. While conventional evaporation methods consume approximately 500,000 gallons of water per ton of lithium carbonate produced, advanced DLE approaches can reduce water consumption by 50-90%. This reduction is particularly significant in water-stressed regions where lithium resources are often located, such as the "Lithium Triangle" spanning Chile, Argentina, and Bolivia.

Land disturbance metrics reveal another important environmental dimension. Traditional evaporation ponds require extensive land areas—approximately 2-3 square kilometers per 1,000 tons of annual lithium production. In contrast, DLE facilities operate with a significantly smaller physical footprint, typically requiring less than 10% of the land area needed for conventional methods.

Carbon emissions associated with energy consumption vary considerably across DLE technologies. Adsorption-based systems generally demonstrate lower energy requirements (approximately 5-8 kWh per kg of lithium) compared to membrane or solvent extraction approaches (8-15 kWh per kg). This translates directly to greenhouse gas emissions, with the most efficient DLE technologies producing 5-7 tons of CO2 equivalent per ton of lithium carbonate equivalent (LCE), compared to 15-20 tons for traditional methods.

Chemical usage and waste generation present additional environmental challenges. Most DLE technologies require chemical reagents for lithium recovery and regeneration processes. Ion exchange methods typically consume 1-2 tons of acid per ton of lithium produced, while some newer technologies have reduced this to under 0.5 tons. Proper management of spent sorbents, membranes, and process chemicals is essential to prevent soil and groundwater contamination.

Ecosystem impacts must also be considered, particularly regarding brine reinjection practices. DLE technologies that return processed brine to aquifers can help maintain hydrological balance but may introduce chemical alterations. Recent field studies indicate that properly managed reinjection can maintain groundwater quality when brine chemistry is carefully monitored and controlled, with pH variations kept within 0.5 units of baseline conditions.

Water usage represents a critical environmental consideration for DLE technologies. While conventional evaporation methods consume approximately 500,000 gallons of water per ton of lithium carbonate produced, advanced DLE approaches can reduce water consumption by 50-90%. This reduction is particularly significant in water-stressed regions where lithium resources are often located, such as the "Lithium Triangle" spanning Chile, Argentina, and Bolivia.

Land disturbance metrics reveal another important environmental dimension. Traditional evaporation ponds require extensive land areas—approximately 2-3 square kilometers per 1,000 tons of annual lithium production. In contrast, DLE facilities operate with a significantly smaller physical footprint, typically requiring less than 10% of the land area needed for conventional methods.

Carbon emissions associated with energy consumption vary considerably across DLE technologies. Adsorption-based systems generally demonstrate lower energy requirements (approximately 5-8 kWh per kg of lithium) compared to membrane or solvent extraction approaches (8-15 kWh per kg). This translates directly to greenhouse gas emissions, with the most efficient DLE technologies producing 5-7 tons of CO2 equivalent per ton of lithium carbonate equivalent (LCE), compared to 15-20 tons for traditional methods.

Chemical usage and waste generation present additional environmental challenges. Most DLE technologies require chemical reagents for lithium recovery and regeneration processes. Ion exchange methods typically consume 1-2 tons of acid per ton of lithium produced, while some newer technologies have reduced this to under 0.5 tons. Proper management of spent sorbents, membranes, and process chemicals is essential to prevent soil and groundwater contamination.

Ecosystem impacts must also be considered, particularly regarding brine reinjection practices. DLE technologies that return processed brine to aquifers can help maintain hydrological balance but may introduce chemical alterations. Recent field studies indicate that properly managed reinjection can maintain groundwater quality when brine chemistry is carefully monitored and controlled, with pH variations kept within 0.5 units of baseline conditions.

Regulatory Framework for Lithium Extraction

The regulatory landscape for lithium extraction is becoming increasingly complex as governments worldwide recognize the strategic importance of this critical mineral for energy transition. At the international level, organizations such as the International Energy Agency (IEA) and the United Nations Framework Convention on Climate Change (UNFCCC) have established guidelines for sustainable mining practices that directly impact Direct Lithium Extraction (DLE) operations. These frameworks emphasize energy efficiency metrics as key performance indicators for environmental compliance.

In the United States, the regulatory environment for lithium extraction is governed by multiple agencies, including the Environmental Protection Agency (EPA), the Bureau of Land Management (BLM), and state-level environmental departments. Recent policy developments, such as the Inflation Reduction Act of 2022, have introduced tax incentives for domestic lithium production that meets specific energy efficiency benchmarks. These regulations require DLE operators to document and report energy consumption per kilogram of lithium carbonate equivalent (LCE) produced.

The European Union has implemented the European Battery Regulation, which mandates carbon footprint declarations for batteries sold within the EU market. This regulation indirectly affects DLE operations by requiring transparency in energy consumption throughout the lithium supply chain. Companies must now calculate and disclose the energy intensity of their extraction processes, creating a de facto regulatory standard for energy efficiency in DLE technologies.

In Latin America's "Lithium Triangle" (Argentina, Bolivia, and Chile), each country has developed distinct regulatory approaches. Chile's lithium governance model includes specific provisions for water and energy use in the Atacama Desert, where water conservation is paramount. The Chilean government has recently introduced energy efficiency requirements for new lithium extraction contracts, establishing maximum energy consumption thresholds per ton of lithium produced.

Australia, another major lithium producer, has incorporated energy efficiency standards into its mining approval processes. The Western Australian government now requires detailed energy management plans for lithium projects, with particular emphasis on renewable energy integration for DLE operations.

China, as both a major lithium producer and consumer, has implemented its dual-control policy on energy consumption and intensity, which applies to lithium extraction activities. Chinese regulations increasingly favor DLE technologies that demonstrate lower energy footprints compared to traditional evaporation methods.

These regulatory frameworks collectively create a global trend toward standardized energy metrics for lithium extraction. Companies developing DLE technologies must now design their processes with regulatory compliance in mind, particularly focusing on minimizing energy consumption to meet increasingly stringent international and national requirements.

In the United States, the regulatory environment for lithium extraction is governed by multiple agencies, including the Environmental Protection Agency (EPA), the Bureau of Land Management (BLM), and state-level environmental departments. Recent policy developments, such as the Inflation Reduction Act of 2022, have introduced tax incentives for domestic lithium production that meets specific energy efficiency benchmarks. These regulations require DLE operators to document and report energy consumption per kilogram of lithium carbonate equivalent (LCE) produced.

The European Union has implemented the European Battery Regulation, which mandates carbon footprint declarations for batteries sold within the EU market. This regulation indirectly affects DLE operations by requiring transparency in energy consumption throughout the lithium supply chain. Companies must now calculate and disclose the energy intensity of their extraction processes, creating a de facto regulatory standard for energy efficiency in DLE technologies.

In Latin America's "Lithium Triangle" (Argentina, Bolivia, and Chile), each country has developed distinct regulatory approaches. Chile's lithium governance model includes specific provisions for water and energy use in the Atacama Desert, where water conservation is paramount. The Chilean government has recently introduced energy efficiency requirements for new lithium extraction contracts, establishing maximum energy consumption thresholds per ton of lithium produced.

Australia, another major lithium producer, has incorporated energy efficiency standards into its mining approval processes. The Western Australian government now requires detailed energy management plans for lithium projects, with particular emphasis on renewable energy integration for DLE operations.

China, as both a major lithium producer and consumer, has implemented its dual-control policy on energy consumption and intensity, which applies to lithium extraction activities. Chinese regulations increasingly favor DLE technologies that demonstrate lower energy footprints compared to traditional evaporation methods.

These regulatory frameworks collectively create a global trend toward standardized energy metrics for lithium extraction. Companies developing DLE technologies must now design their processes with regulatory compliance in mind, particularly focusing on minimizing energy consumption to meet increasingly stringent international and national requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!