Direct Lithium Extraction vs Traditional Methods: Cost Analysis

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Lithium extraction technologies have evolved significantly over the past century, with traditional methods dominating the industry until recent decades. Conventional lithium production primarily relies on two approaches: solar evaporation of brine resources and hard-rock mining of lithium-bearing minerals such as spodumene. These traditional methods, while established, present considerable challenges including lengthy production timelines, substantial land and water requirements, and variable recovery rates typically ranging from 30-50%.

Direct Lithium Extraction (DLE) represents a paradigm shift in lithium production technology, emerging as a response to the limitations of conventional methods. DLE encompasses a family of technologies that selectively extract lithium from brine solutions using advanced materials science and chemical engineering principles. The fundamental objective of DLE development is to establish more efficient, environmentally sustainable, and economically viable methods for lithium recovery to meet rapidly escalating global demand.

The technological evolution of DLE has accelerated particularly since 2010, driven by the exponential growth in lithium-ion battery applications for electric vehicles and energy storage systems. Industry projections indicate lithium demand could increase by 400-500% by 2030, creating urgent pressure for more efficient extraction technologies. This market dynamic has catalyzed significant research and development investment in DLE technologies across both academic institutions and commercial enterprises.

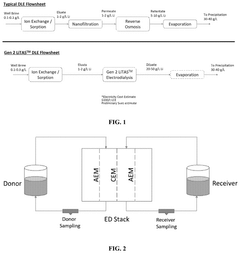

DLE technologies generally employ one of three core mechanisms: adsorption using lithium-selective materials, ion exchange processes, or solvent extraction methodologies. Each approach offers distinct advantages and limitations regarding selectivity, recovery rates, operational costs, and environmental impact profiles. The technical objectives for DLE development focus on achieving lithium recovery rates exceeding 80%, reducing water consumption by 50-70% compared to evaporation methods, and shortening production timelines from years to days or weeks.

Cost considerations represent a critical dimension in DLE technology development. While traditional methods benefit from established infrastructure and operational experience, they suffer from high capital intensity and significant operational expenses related to land acquisition, pond construction, and lengthy production cycles. The primary economic objective of DLE innovation is to demonstrate competitive cost structures through higher recovery rates, reduced production timelines, and decreased resource intensity, ultimately targeting production costs below $5,000 per ton of lithium carbonate equivalent.

Recent technological breakthroughs in selective adsorption materials and process optimization have positioned certain DLE technologies at inflection points where they may achieve cost parity with traditional methods while offering superior environmental performance. This cost-performance balance represents the central focus of current DLE research and development efforts, with significant implications for the future structure of global lithium supply chains and the broader clean energy transition.

Direct Lithium Extraction (DLE) represents a paradigm shift in lithium production technology, emerging as a response to the limitations of conventional methods. DLE encompasses a family of technologies that selectively extract lithium from brine solutions using advanced materials science and chemical engineering principles. The fundamental objective of DLE development is to establish more efficient, environmentally sustainable, and economically viable methods for lithium recovery to meet rapidly escalating global demand.

The technological evolution of DLE has accelerated particularly since 2010, driven by the exponential growth in lithium-ion battery applications for electric vehicles and energy storage systems. Industry projections indicate lithium demand could increase by 400-500% by 2030, creating urgent pressure for more efficient extraction technologies. This market dynamic has catalyzed significant research and development investment in DLE technologies across both academic institutions and commercial enterprises.

DLE technologies generally employ one of three core mechanisms: adsorption using lithium-selective materials, ion exchange processes, or solvent extraction methodologies. Each approach offers distinct advantages and limitations regarding selectivity, recovery rates, operational costs, and environmental impact profiles. The technical objectives for DLE development focus on achieving lithium recovery rates exceeding 80%, reducing water consumption by 50-70% compared to evaporation methods, and shortening production timelines from years to days or weeks.

Cost considerations represent a critical dimension in DLE technology development. While traditional methods benefit from established infrastructure and operational experience, they suffer from high capital intensity and significant operational expenses related to land acquisition, pond construction, and lengthy production cycles. The primary economic objective of DLE innovation is to demonstrate competitive cost structures through higher recovery rates, reduced production timelines, and decreased resource intensity, ultimately targeting production costs below $5,000 per ton of lithium carbonate equivalent.

Recent technological breakthroughs in selective adsorption materials and process optimization have positioned certain DLE technologies at inflection points where they may achieve cost parity with traditional methods while offering superior environmental performance. This cost-performance balance represents the central focus of current DLE research and development efforts, with significant implications for the future structure of global lithium supply chains and the broader clean energy transition.

Market Demand for Lithium Extraction Solutions

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Market analysis indicates that lithium demand is projected to increase by 500% by 2030, with the EV sector alone accounting for approximately 75% of this demand. This exponential growth trajectory has created an urgent need for more efficient and cost-effective lithium extraction technologies.

Traditional lithium extraction methods, including evaporation ponds and hard rock mining, are increasingly unable to meet this surging demand due to their lengthy production timelines and geographical limitations. Evaporation ponds typically require 18-24 months to produce battery-grade lithium, creating significant supply chain bottlenecks that cannot accommodate the accelerating EV manufacturing schedules.

The battery manufacturing industry has been particularly vocal about supply constraints, with major producers reporting lithium supply shortages affecting production targets. These market pressures have driven lithium prices to historic highs, with spot prices reaching $78,000 per metric ton in 2022, representing a 400% increase from 2020 levels. While prices have moderated somewhat in 2023, they remain significantly elevated compared to historical averages.

Environmental and social considerations are also reshaping market demand patterns. Consumers and regulatory bodies are increasingly prioritizing sustainably sourced materials, creating market preference for extraction methods with reduced water consumption, land disturbance, and carbon emissions. This trend is particularly evident in Europe and North America, where ESG (Environmental, Social, and Governance) considerations heavily influence purchasing decisions and investment flows.

Geopolitical factors further complicate the market landscape, with lithium resources concentrated in a limited number of countries. This concentration has prompted many nations to classify lithium as a critical mineral and develop strategies to secure domestic supply chains. The resulting government initiatives, including substantial research grants and tax incentives, have created a favorable environment for investment in novel extraction technologies.

Industry forecasts suggest that the market for advanced lithium extraction solutions could reach $25 billion by 2028, with Direct Lithium Extraction (DLE) technologies potentially capturing 30% of new production capacity additions. This represents a significant opportunity for technology providers who can demonstrate cost-effective solutions that address both the economic and sustainability challenges of traditional methods.

Traditional lithium extraction methods, including evaporation ponds and hard rock mining, are increasingly unable to meet this surging demand due to their lengthy production timelines and geographical limitations. Evaporation ponds typically require 18-24 months to produce battery-grade lithium, creating significant supply chain bottlenecks that cannot accommodate the accelerating EV manufacturing schedules.

The battery manufacturing industry has been particularly vocal about supply constraints, with major producers reporting lithium supply shortages affecting production targets. These market pressures have driven lithium prices to historic highs, with spot prices reaching $78,000 per metric ton in 2022, representing a 400% increase from 2020 levels. While prices have moderated somewhat in 2023, they remain significantly elevated compared to historical averages.

Environmental and social considerations are also reshaping market demand patterns. Consumers and regulatory bodies are increasingly prioritizing sustainably sourced materials, creating market preference for extraction methods with reduced water consumption, land disturbance, and carbon emissions. This trend is particularly evident in Europe and North America, where ESG (Environmental, Social, and Governance) considerations heavily influence purchasing decisions and investment flows.

Geopolitical factors further complicate the market landscape, with lithium resources concentrated in a limited number of countries. This concentration has prompted many nations to classify lithium as a critical mineral and develop strategies to secure domestic supply chains. The resulting government initiatives, including substantial research grants and tax incentives, have created a favorable environment for investment in novel extraction technologies.

Industry forecasts suggest that the market for advanced lithium extraction solutions could reach $25 billion by 2028, with Direct Lithium Extraction (DLE) technologies potentially capturing 30% of new production capacity additions. This represents a significant opportunity for technology providers who can demonstrate cost-effective solutions that address both the economic and sustainability challenges of traditional methods.

Current State and Challenges in Lithium Extraction

The global lithium extraction industry is currently dominated by traditional methods, primarily brine evaporation and hard rock mining. Brine evaporation accounts for approximately 58% of global production, concentrated in the "Lithium Triangle" of Chile, Argentina, and Bolivia, while hard rock mining represents about 42%, with Australia as the leading producer. These conventional methods, though well-established, face significant challenges in meeting the exponentially growing demand driven by electric vehicle batteries and energy storage systems.

Traditional brine evaporation, while relatively low-cost at $2,000-$3,500 per ton of lithium carbonate equivalent (LCE), suffers from lengthy production timelines of 18-24 months and low recovery rates of only 30-50%. The process is also highly water-intensive, consuming approximately 500,000 gallons per ton of lithium in regions already experiencing water scarcity. Environmental concerns include disruption of local ecosystems and potential contamination of groundwater resources.

Hard rock mining, primarily of spodumene, offers faster production cycles but at substantially higher costs ranging from $4,000-$6,000 per ton of LCE. The energy-intensive nature of this method results in a considerably larger carbon footprint, with estimates suggesting emissions of 15-20 tons of CO2 per ton of lithium produced, compared to 5-10 tons for brine operations.

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives, with over 60 different processes under development globally. These methods promise recovery rates of 70-90%, dramatically reduced water usage (up to 70% less), and production timelines measured in days rather than months. However, DLE faces its own set of challenges, including high capital expenditure requirements, technological immaturity, and limited commercial-scale implementation.

Current DLE cost estimates range widely from $3,000-$7,000 per ton of LCE, reflecting the nascent state of these technologies. Energy requirements remain a significant concern, with some DLE methods requiring 5-15 kWh per kilogram of lithium produced, potentially offsetting environmental benefits if powered by non-renewable sources.

The geographical distribution of lithium extraction capabilities is highly concentrated, with just four countries—Australia, Chile, China, and Argentina—controlling over 90% of global production. This concentration creates geopolitical vulnerabilities in the supply chain, particularly as demand is projected to triple by 2025, reaching approximately 1.5 million metric tons of LCE annually.

Technical barriers to scaling DLE include selective ion exchange efficiency, membrane fouling in filtration systems, and the challenge of processing diverse brine chemistries. Additionally, the industry faces regulatory uncertainties regarding water rights, environmental impacts, and indigenous community concerns, particularly in the Lithium Triangle region.

Traditional brine evaporation, while relatively low-cost at $2,000-$3,500 per ton of lithium carbonate equivalent (LCE), suffers from lengthy production timelines of 18-24 months and low recovery rates of only 30-50%. The process is also highly water-intensive, consuming approximately 500,000 gallons per ton of lithium in regions already experiencing water scarcity. Environmental concerns include disruption of local ecosystems and potential contamination of groundwater resources.

Hard rock mining, primarily of spodumene, offers faster production cycles but at substantially higher costs ranging from $4,000-$6,000 per ton of LCE. The energy-intensive nature of this method results in a considerably larger carbon footprint, with estimates suggesting emissions of 15-20 tons of CO2 per ton of lithium produced, compared to 5-10 tons for brine operations.

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives, with over 60 different processes under development globally. These methods promise recovery rates of 70-90%, dramatically reduced water usage (up to 70% less), and production timelines measured in days rather than months. However, DLE faces its own set of challenges, including high capital expenditure requirements, technological immaturity, and limited commercial-scale implementation.

Current DLE cost estimates range widely from $3,000-$7,000 per ton of LCE, reflecting the nascent state of these technologies. Energy requirements remain a significant concern, with some DLE methods requiring 5-15 kWh per kilogram of lithium produced, potentially offsetting environmental benefits if powered by non-renewable sources.

The geographical distribution of lithium extraction capabilities is highly concentrated, with just four countries—Australia, Chile, China, and Argentina—controlling over 90% of global production. This concentration creates geopolitical vulnerabilities in the supply chain, particularly as demand is projected to triple by 2025, reaching approximately 1.5 million metric tons of LCE annually.

Technical barriers to scaling DLE include selective ion exchange efficiency, membrane fouling in filtration systems, and the challenge of processing diverse brine chemistries. Additionally, the industry faces regulatory uncertainties regarding water rights, environmental impacts, and indigenous community concerns, particularly in the Lithium Triangle region.

Cost Analysis of DLE vs Traditional Methods

01 Cost-effective extraction methods

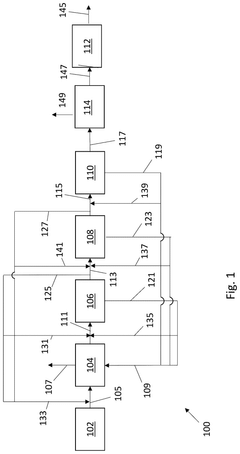

Various cost-effective methods for direct lithium extraction have been developed to reduce operational expenses. These methods focus on optimizing the extraction process through innovative techniques that minimize energy consumption, reduce chemical usage, and improve recovery rates. By implementing these cost-effective approaches, the overall economic viability of lithium extraction projects can be significantly enhanced, making them more competitive in the global market.- Cost reduction through improved extraction methods: Various improved extraction methods have been developed to reduce the cost of direct lithium extraction. These methods focus on enhancing efficiency, reducing energy consumption, and minimizing chemical usage. Innovations include optimized adsorption processes, advanced membrane technologies, and novel electrochemical approaches that can significantly lower operational expenses compared to traditional extraction methods.

- Economic analysis of DLE processes: Economic analyses of direct lithium extraction processes reveal various cost factors including capital expenditure, operational expenses, and return on investment. These analyses compare different extraction technologies based on their economic viability, scalability, and market competitiveness. Comprehensive cost models help in identifying the most cost-effective approaches for commercial implementation of DLE technologies.

- Sustainable and environmentally friendly extraction techniques: Sustainable extraction techniques aim to reduce environmental impact while maintaining cost-effectiveness. These approaches include water recycling systems, reduced chemical consumption, and minimized waste generation. By implementing environmentally friendly practices, companies can avoid regulatory penalties and remediation costs while potentially accessing green financing options, thereby improving the overall economic profile of lithium extraction operations.

- Equipment and infrastructure cost optimization: Optimization of equipment and infrastructure costs is crucial for economical direct lithium extraction. Innovations include modular plant designs, equipment with dual functionality, and simplified processing systems. These advancements reduce initial capital expenditure and maintenance costs while increasing operational flexibility, allowing for more cost-effective scaling of lithium production facilities.

- Energy efficiency improvements in DLE: Energy efficiency improvements significantly impact the cost structure of direct lithium extraction operations. Innovations include low-energy sorbents, optimized heating and cooling systems, and renewable energy integration. By reducing energy consumption, these technologies lower operational expenses and make lithium extraction more economically viable, particularly in regions with high energy costs or limited energy infrastructure.

02 Adsorption and membrane technologies

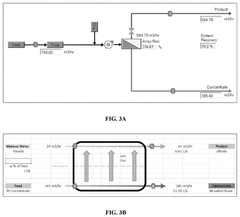

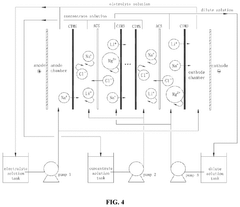

Advanced adsorption materials and membrane technologies have been developed to improve the efficiency and reduce the cost of direct lithium extraction. These technologies utilize selective ion exchange materials and specialized membranes that can separate lithium from other elements in brine solutions with high selectivity. The implementation of these technologies results in higher lithium recovery rates while reducing water consumption and processing time, thereby lowering the overall extraction costs.Expand Specific Solutions03 Energy optimization in extraction processes

Energy consumption represents a significant portion of direct lithium extraction costs. Innovations in energy optimization include the use of renewable energy sources, heat recovery systems, and process integration techniques to minimize energy requirements. Some methods incorporate solar evaporation in combination with advanced extraction technologies, while others utilize waste heat from adjacent industrial processes. These energy optimization strategies can substantially reduce operational costs and improve the sustainability of lithium extraction operations.Expand Specific Solutions04 Chemical reagent reduction and recycling

The cost of chemical reagents used in direct lithium extraction processes can be significant. Innovative approaches focus on reducing reagent consumption through more efficient extraction methods, as well as implementing reagent recycling systems. These techniques include closed-loop processes that recover and reuse chemicals, development of more efficient precipitating agents, and alternative extraction methods that require fewer or less expensive chemicals. By minimizing chemical usage and implementing effective recycling, operational costs can be substantially reduced.Expand Specific Solutions05 Economic analysis and cost modeling

Comprehensive economic analysis and cost modeling frameworks have been developed to evaluate and optimize direct lithium extraction processes. These models consider capital expenditures, operational costs, market conditions, and environmental factors to provide a holistic view of project economics. By utilizing these analytical tools, lithium extraction operations can identify cost drivers, optimize process parameters, and make informed decisions regarding technology selection and project implementation. This systematic approach to cost analysis helps maximize the economic performance of lithium extraction projects.Expand Specific Solutions

Key Industry Players in Lithium Extraction

Direct Lithium Extraction (DLE) technology is emerging as a disruptive force in the lithium extraction market, currently in its early growth phase. The global lithium market, valued at approximately $7.5 billion, is projected to expand significantly due to increasing demand for electric vehicles and energy storage systems. DLE offers substantial advantages over traditional methods, with companies like Energy Exploration Technologies, POSCO Holdings, and Schlumberger developing proprietary technologies that reduce water usage by up to 90% and land footprint by 70%. While traditional evaporation ponds remain dominant, DLE is rapidly maturing with International Battery Metals and Koch Technology Solutions advancing commercial-scale implementations. Contemporary Amperex Technology and Evove are focusing on membrane-based extraction technologies, while academic institutions like The University of Manchester and Penn State Research Foundation are contributing breakthrough research to accelerate industry-wide adoption.

Energy Exploration Technologies, Inc.

Technical Solution: EnergyX has developed a proprietary Lithium Ion Transport and Separation (LiTAS™) technology for direct lithium extraction (DLE). Their approach uses metal-organic framework (MOF) based membranes that selectively extract lithium ions from brine solutions. The technology operates at ambient temperature and pressure, requiring significantly less land and water compared to traditional evaporation ponds. EnergyX's process can extract lithium in days rather than months, with recovery rates exceeding 90% compared to 30-40% for traditional methods[1]. Their cost analysis indicates operational expenses approximately 40% lower than conventional evaporation techniques, primarily due to reduced water consumption and faster processing times[3]. The company has successfully demonstrated their technology in pilot projects in the Lithium Triangle of South America, showing promising results for commercial scalability.

Strengths: Higher lithium recovery rates (>90%), significantly reduced processing time (days vs. months), lower water consumption, and smaller physical footprint. Weaknesses: Requires initial capital investment for specialized membrane technology, still working toward full commercial-scale implementation, and may face challenges with membrane fouling in certain brine compositions.

RIST (Research Institute of Industrial Science & Technology)

Technical Solution: RIST has developed a novel direct lithium extraction (DLE) technology in collaboration with POSCO Holdings, focusing on adsorption-based selective lithium recovery. Their proprietary Li-Catcher™ technology utilizes specialized inorganic adsorbents that selectively capture lithium ions from diverse brine sources. The process operates through a continuous adsorption-desorption cycle that can extract lithium from brines with concentrations as low as 20 ppm. RIST's economic analysis demonstrates their technology reduces the lithium production timeline from 12-18 months (traditional evaporation) to just 8 hours, while achieving recovery rates of approximately 80-90%[8]. Their cost modeling indicates a 40-50% reduction in operational expenses compared to conventional methods, primarily through water conservation (90% less water usage) and dramatically reduced land requirements (less than 10% of the area needed for evaporation ponds)[9]. The technology has been successfully demonstrated at commercial scale in South Korea and Argentina, processing various brine compositions with consistent results.

Strengths: Exceptional processing speed (hours vs. months), ability to extract from low-concentration sources, minimal land and water requirements, and proven commercial-scale implementation. Weaknesses: Higher energy consumption than evaporation methods, requires periodic replacement of specialized adsorbent materials, and initial capital costs exceed traditional approaches.

Technical Innovations in DLE Processes

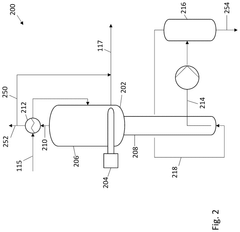

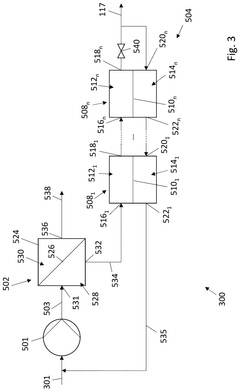

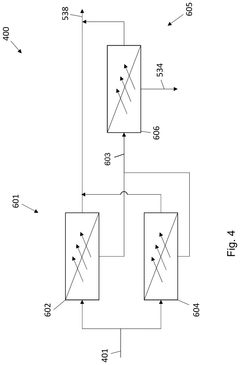

Systems and methods for direct lithium extraction

PatentPendingUS20250011957A1

Innovation

- The integration of selective membrane electrodialysis as a single step to simultaneously concentrate and purify lithium brines, reducing the number of required processing steps, capital and operating costs, and carbon footprint, while eliminating the need for large equipment at remote mining locations.

Method of recovering lithium from a lithium source

PatentPendingUS20250177923A1

Innovation

- The method involves direct lithium extraction using techniques such as electrochemical separation, solvent extraction, ion withdrawal, or membrane separation, followed by purification, concentration, and removal of monovalent impurities to yield a purified lithium concentrate.

Environmental Impact Assessment

The environmental impact of lithium extraction methods represents a critical consideration in the evaluation of Direct Lithium Extraction (DLE) versus traditional methods. Traditional extraction techniques, particularly evaporation ponds, require extensive land use—approximately 2,000 hectares for a typical operation—resulting in significant habitat disruption and biodiversity loss in sensitive ecosystems like the salt flats of South America's "Lithium Triangle."

Water consumption presents another major environmental concern, with conventional evaporation methods consuming between 500,000 to 1.9 million liters of water per ton of lithium carbonate produced. This intensive water usage has led to documented groundwater depletion in regions like Chile's Salar de Atacama, where lithium operations compete with agricultural needs and indigenous communities for scarce water resources.

Chemical usage in traditional methods introduces additional environmental risks through potential soil contamination and water pollution. The evaporation process typically employs various reagents including lime, sodium carbonate, and sulfuric acid, which can lead to localized chemical imbalances in surrounding ecosystems when improperly managed.

DLE technologies offer promising environmental advantages through significantly reduced land footprint requirements—typically 90% less than evaporation ponds—and substantially lower water consumption, with some advanced systems achieving up to 70% water recovery rates. These improvements directly address two of the most pressing environmental concerns associated with lithium production.

Carbon emissions profiles differ markedly between extraction methods. While traditional evaporation ponds have relatively low energy requirements (primarily for pumping), they operate over extended timeframes of 18-24 months. In contrast, DLE processes require higher energy inputs but operate continuously with much shorter processing times, creating different carbon footprint considerations depending on the energy source utilized.

Waste management represents another environmental dimension where DLE may offer advantages. Traditional methods generate substantial solid waste in the form of salt tailings and spent chemicals, while many DLE technologies produce more concentrated waste streams that may be easier to manage, treat, or potentially valorize as secondary products.

Ecosystem restoration potential also differs between methods. Evaporation ponds create long-term landscape alterations that are difficult to remediate, while DLE facilities generally allow for more straightforward site rehabilitation after operations cease, potentially enabling better post-mining land use options.

Water consumption presents another major environmental concern, with conventional evaporation methods consuming between 500,000 to 1.9 million liters of water per ton of lithium carbonate produced. This intensive water usage has led to documented groundwater depletion in regions like Chile's Salar de Atacama, where lithium operations compete with agricultural needs and indigenous communities for scarce water resources.

Chemical usage in traditional methods introduces additional environmental risks through potential soil contamination and water pollution. The evaporation process typically employs various reagents including lime, sodium carbonate, and sulfuric acid, which can lead to localized chemical imbalances in surrounding ecosystems when improperly managed.

DLE technologies offer promising environmental advantages through significantly reduced land footprint requirements—typically 90% less than evaporation ponds—and substantially lower water consumption, with some advanced systems achieving up to 70% water recovery rates. These improvements directly address two of the most pressing environmental concerns associated with lithium production.

Carbon emissions profiles differ markedly between extraction methods. While traditional evaporation ponds have relatively low energy requirements (primarily for pumping), they operate over extended timeframes of 18-24 months. In contrast, DLE processes require higher energy inputs but operate continuously with much shorter processing times, creating different carbon footprint considerations depending on the energy source utilized.

Waste management represents another environmental dimension where DLE may offer advantages. Traditional methods generate substantial solid waste in the form of salt tailings and spent chemicals, while many DLE technologies produce more concentrated waste streams that may be easier to manage, treat, or potentially valorize as secondary products.

Ecosystem restoration potential also differs between methods. Evaporation ponds create long-term landscape alterations that are difficult to remediate, while DLE facilities generally allow for more straightforward site rehabilitation after operations cease, potentially enabling better post-mining land use options.

Supply Chain Considerations

The supply chain for lithium extraction represents a critical component in the cost analysis between Direct Lithium Extraction (DLE) and traditional methods. Traditional extraction methods rely heavily on extensive transportation networks, as brine pools and hard rock mining operations are typically located in remote areas of South America, Australia, and China. This geographical distribution necessitates complex logistics systems that significantly impact overall costs, with transportation expenses often accounting for 15-20% of the total production cost.

DLE technologies offer potential advantages in supply chain optimization by enabling lithium extraction from previously untapped sources closer to manufacturing facilities. This proximity effect could reduce transportation distances by up to 60% in some regions, particularly when implemented near battery manufacturing hubs. The reduced geographical constraints of DLE may lead to more distributed production models, potentially decreasing supply chain vulnerabilities and price volatility that have historically plagued the lithium market.

Raw material requirements present another significant supply chain consideration. Traditional methods demand substantial quantities of reagents like sodium carbonate for brine operations or sulfuric acid for hard rock processing. These dependencies create additional supply chain complexities and exposure to price fluctuations in chemical markets. DLE technologies generally require specialized adsorbents, ion exchange resins, or membranes, which represent a shift in supply chain dependencies rather than their elimination.

Equipment sourcing represents a divergent aspect between the methodologies. Traditional extraction relies on conventional mining and evaporation equipment with established global supply networks. In contrast, DLE systems incorporate more specialized components that currently have limited supplier bases, creating potential bottlenecks as adoption scales. This supplier concentration risk could temporarily constrain DLE implementation until manufacturing capacity expands.

Water and energy infrastructure access significantly influences supply chain decisions. Traditional methods require extensive water resources in often water-stressed regions, necessitating complex water rights negotiations and infrastructure development. DLE operations typically have lower water requirements but higher energy demands, shifting infrastructure dependencies toward electrical grid capacity and reliability rather than water access.

The recyclability of materials presents an emerging supply chain consideration. DLE technologies potentially offer superior recovery and reuse of processing materials, with some systems demonstrating 90%+ reusability of adsorbents across multiple extraction cycles. This circular approach could reduce ongoing supply requirements and mitigate exposure to supply disruptions, though it requires establishing new reverse logistics systems not present in traditional extraction methods.

DLE technologies offer potential advantages in supply chain optimization by enabling lithium extraction from previously untapped sources closer to manufacturing facilities. This proximity effect could reduce transportation distances by up to 60% in some regions, particularly when implemented near battery manufacturing hubs. The reduced geographical constraints of DLE may lead to more distributed production models, potentially decreasing supply chain vulnerabilities and price volatility that have historically plagued the lithium market.

Raw material requirements present another significant supply chain consideration. Traditional methods demand substantial quantities of reagents like sodium carbonate for brine operations or sulfuric acid for hard rock processing. These dependencies create additional supply chain complexities and exposure to price fluctuations in chemical markets. DLE technologies generally require specialized adsorbents, ion exchange resins, or membranes, which represent a shift in supply chain dependencies rather than their elimination.

Equipment sourcing represents a divergent aspect between the methodologies. Traditional extraction relies on conventional mining and evaporation equipment with established global supply networks. In contrast, DLE systems incorporate more specialized components that currently have limited supplier bases, creating potential bottlenecks as adoption scales. This supplier concentration risk could temporarily constrain DLE implementation until manufacturing capacity expands.

Water and energy infrastructure access significantly influences supply chain decisions. Traditional methods require extensive water resources in often water-stressed regions, necessitating complex water rights negotiations and infrastructure development. DLE operations typically have lower water requirements but higher energy demands, shifting infrastructure dependencies toward electrical grid capacity and reliability rather than water access.

The recyclability of materials presents an emerging supply chain consideration. DLE technologies potentially offer superior recovery and reuse of processing materials, with some systems demonstrating 90%+ reusability of adsorbents across multiple extraction cycles. This circular approach could reduce ongoing supply requirements and mitigate exposure to supply disruptions, though it requires establishing new reverse logistics systems not present in traditional extraction methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!