How to Scale Direct Lithium Extraction for Industrial Applications

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology has emerged as a revolutionary approach to lithium production, diverging from traditional methods such as evaporation ponds and hard rock mining. The evolution of DLE began in the 1990s with initial laboratory-scale experiments, but significant technological advancements have only materialized in the last decade. This acceleration coincides with the exponential growth in demand for lithium-ion batteries, primarily driven by electric vehicle manufacturing and renewable energy storage systems.

DLE technologies encompass a diverse range of extraction methodologies including adsorption, ion exchange, solvent extraction, and membrane processes. Each approach offers unique advantages in terms of efficiency, environmental impact, and scalability potential. The technological trajectory has consistently moved toward solutions that minimize water usage, reduce land footprint, and accelerate production timelines compared to conventional methods.

The primary objective of scaling DLE for industrial applications is to develop economically viable processes that can extract lithium from various brine resources with high recovery rates (>90%) while maintaining product purity standards (battery-grade lithium compounds with >99.5% purity). Additionally, these processes must demonstrate operational stability over extended periods and resilience to variations in brine chemistry.

Current technological trends indicate a growing focus on selective adsorption materials with enhanced lithium selectivity, particularly in the presence of competing ions such as sodium, magnesium, and calcium. Parallel developments in process intensification and modular system design are enabling more efficient extraction operations with reduced capital expenditure requirements.

The environmental sustainability dimension has become increasingly central to DLE technology development. Modern systems aim to achieve near-zero liquid discharge, minimal chemical consumption, and significantly reduced carbon footprints compared to traditional extraction methods. These environmental considerations are not merely regulatory compliance measures but essential components of economically sustainable operations.

Looking forward, the technological roadmap for DLE includes integration with renewable energy sources, development of closed-loop systems for reagent recycling, and advancement of real-time monitoring capabilities through IoT and AI applications. The ultimate goal is to establish DLE as the predominant lithium production method, capable of meeting the projected five-fold increase in global lithium demand by 2030 while adhering to increasingly stringent environmental standards.

DLE technologies encompass a diverse range of extraction methodologies including adsorption, ion exchange, solvent extraction, and membrane processes. Each approach offers unique advantages in terms of efficiency, environmental impact, and scalability potential. The technological trajectory has consistently moved toward solutions that minimize water usage, reduce land footprint, and accelerate production timelines compared to conventional methods.

The primary objective of scaling DLE for industrial applications is to develop economically viable processes that can extract lithium from various brine resources with high recovery rates (>90%) while maintaining product purity standards (battery-grade lithium compounds with >99.5% purity). Additionally, these processes must demonstrate operational stability over extended periods and resilience to variations in brine chemistry.

Current technological trends indicate a growing focus on selective adsorption materials with enhanced lithium selectivity, particularly in the presence of competing ions such as sodium, magnesium, and calcium. Parallel developments in process intensification and modular system design are enabling more efficient extraction operations with reduced capital expenditure requirements.

The environmental sustainability dimension has become increasingly central to DLE technology development. Modern systems aim to achieve near-zero liquid discharge, minimal chemical consumption, and significantly reduced carbon footprints compared to traditional extraction methods. These environmental considerations are not merely regulatory compliance measures but essential components of economically sustainable operations.

Looking forward, the technological roadmap for DLE includes integration with renewable energy sources, development of closed-loop systems for reagent recycling, and advancement of real-time monitoring capabilities through IoT and AI applications. The ultimate goal is to establish DLE as the predominant lithium production method, capable of meeting the projected five-fold increase in global lithium demand by 2030 while adhering to increasingly stringent environmental standards.

Market Demand Analysis for Lithium Resources

The global lithium market is experiencing unprecedented growth driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current projections indicate the lithium demand will increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, representing a compound annual growth rate exceeding 20%. This exponential growth trajectory creates an urgent need for more efficient extraction technologies like Direct Lithium Extraction (DLE).

Traditional lithium production methods—evaporation ponds and hard-rock mining—cannot sustainably meet this surging demand due to their environmental impact, lengthy production timelines, and geographical limitations. The EV industry alone is expected to consume over 75% of global lithium production by 2025, with major automakers committing billions to electrification strategies that depend on stable lithium supply chains.

Battery manufacturers and energy storage developers constitute another significant market segment driving lithium demand. Grid-scale energy storage installations are projected to increase tenfold by 2030, requiring substantial lithium resources to support renewable energy integration. This sector's growth is further accelerated by government policies worldwide promoting clean energy transitions and carbon neutrality goals.

The geographical distribution of lithium demand presents notable market dynamics. While China currently dominates the lithium processing industry, accounting for over 60% of global capacity, Western economies are actively developing domestic supply chains to reduce dependency. The European Union's European Battery Alliance and the United States' critical minerals initiatives both emphasize securing lithium supplies as a strategic priority.

Price volatility remains a critical market factor, with lithium carbonate prices fluctuating between $10,000 and $80,000 per ton in recent years. This volatility underscores the need for more predictable production methods like DLE, which can potentially stabilize supply and pricing through consistent, scalable operations independent of seasonal or climatic factors.

Industrial-scale DLE implementation addresses several market pain points: reducing production lead times from years to months, enabling lithium extraction from previously uneconomical resources, and significantly lowering water consumption and environmental footprint. Market analysis indicates that companies successfully scaling DLE technology could capture premium pricing through ESG advantages and supply reliability.

The investment landscape reflects this market potential, with venture capital and corporate funding for DLE technologies exceeding $1.5 billion since 2020. Major mining companies and battery manufacturers are increasingly forming strategic partnerships with DLE technology developers, signaling strong industry confidence in these emerging extraction methods.

Traditional lithium production methods—evaporation ponds and hard-rock mining—cannot sustainably meet this surging demand due to their environmental impact, lengthy production timelines, and geographical limitations. The EV industry alone is expected to consume over 75% of global lithium production by 2025, with major automakers committing billions to electrification strategies that depend on stable lithium supply chains.

Battery manufacturers and energy storage developers constitute another significant market segment driving lithium demand. Grid-scale energy storage installations are projected to increase tenfold by 2030, requiring substantial lithium resources to support renewable energy integration. This sector's growth is further accelerated by government policies worldwide promoting clean energy transitions and carbon neutrality goals.

The geographical distribution of lithium demand presents notable market dynamics. While China currently dominates the lithium processing industry, accounting for over 60% of global capacity, Western economies are actively developing domestic supply chains to reduce dependency. The European Union's European Battery Alliance and the United States' critical minerals initiatives both emphasize securing lithium supplies as a strategic priority.

Price volatility remains a critical market factor, with lithium carbonate prices fluctuating between $10,000 and $80,000 per ton in recent years. This volatility underscores the need for more predictable production methods like DLE, which can potentially stabilize supply and pricing through consistent, scalable operations independent of seasonal or climatic factors.

Industrial-scale DLE implementation addresses several market pain points: reducing production lead times from years to months, enabling lithium extraction from previously uneconomical resources, and significantly lowering water consumption and environmental footprint. Market analysis indicates that companies successfully scaling DLE technology could capture premium pricing through ESG advantages and supply reliability.

The investment landscape reflects this market potential, with venture capital and corporate funding for DLE technologies exceeding $1.5 billion since 2020. Major mining companies and battery manufacturers are increasingly forming strategic partnerships with DLE technology developers, signaling strong industry confidence in these emerging extraction methods.

Current DLE Status and Technical Challenges

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives to traditional lithium extraction methods, offering potential solutions to address the growing global demand for lithium. Currently, DLE technologies are at various stages of development, with several pilot projects demonstrating technical feasibility but few reaching commercial-scale implementation.

The most advanced DLE technologies employ ion exchange, adsorption, or membrane processes to selectively extract lithium from brines. Companies like Standard Lithium, Lilac Solutions, and EnergyX have demonstrated extraction efficiencies of 80-90% in controlled environments, significantly higher than the 40-50% recovery rates typical of evaporation ponds. However, these results have primarily been achieved at laboratory or small pilot scales.

A critical challenge in scaling DLE technologies is maintaining selectivity for lithium over competing ions such as sodium, magnesium, and calcium when processing diverse brine compositions. Current technologies often experience performance degradation when confronted with variable feedstock quality, resulting in reduced extraction efficiency and increased operational costs at larger scales.

Material durability presents another significant hurdle. Most DLE technologies utilize specialized sorbents or membranes that must withstand thousands of cycles in harsh chemical environments. Current materials often show degradation after extended use, necessitating frequent replacement and increasing operational expenses. The development of more robust materials with longer operational lifespans is essential for economic viability at industrial scale.

Energy consumption remains prohibitively high for many DLE processes. While theoretically more efficient than evaporation ponds, the pumping, heating, and regeneration steps in DLE systems can consume 10-15 kWh per kilogram of lithium carbonate equivalent (LCE) produced. This energy intensity poses challenges for both economic feasibility and environmental sustainability when scaling to industrial production levels.

Water management represents a paradoxical challenge. While DLE promises reduced water consumption compared to evaporation ponds, industrial implementation still requires significant water volumes for processing and regeneration cycles. In water-scarce regions where many lithium resources are located, this creates tension between resource extraction and environmental stewardship.

Geographically, DLE technology development is concentrated in North America and Europe, with companies in the United States, Canada, and Germany leading innovation. However, implementation challenges vary significantly across different lithium-rich regions, including the Lithium Triangle in South America, Nevada in the US, and various sites in Australia and China, each presenting unique geological and regulatory environments that affect scalability.

The most advanced DLE technologies employ ion exchange, adsorption, or membrane processes to selectively extract lithium from brines. Companies like Standard Lithium, Lilac Solutions, and EnergyX have demonstrated extraction efficiencies of 80-90% in controlled environments, significantly higher than the 40-50% recovery rates typical of evaporation ponds. However, these results have primarily been achieved at laboratory or small pilot scales.

A critical challenge in scaling DLE technologies is maintaining selectivity for lithium over competing ions such as sodium, magnesium, and calcium when processing diverse brine compositions. Current technologies often experience performance degradation when confronted with variable feedstock quality, resulting in reduced extraction efficiency and increased operational costs at larger scales.

Material durability presents another significant hurdle. Most DLE technologies utilize specialized sorbents or membranes that must withstand thousands of cycles in harsh chemical environments. Current materials often show degradation after extended use, necessitating frequent replacement and increasing operational expenses. The development of more robust materials with longer operational lifespans is essential for economic viability at industrial scale.

Energy consumption remains prohibitively high for many DLE processes. While theoretically more efficient than evaporation ponds, the pumping, heating, and regeneration steps in DLE systems can consume 10-15 kWh per kilogram of lithium carbonate equivalent (LCE) produced. This energy intensity poses challenges for both economic feasibility and environmental sustainability when scaling to industrial production levels.

Water management represents a paradoxical challenge. While DLE promises reduced water consumption compared to evaporation ponds, industrial implementation still requires significant water volumes for processing and regeneration cycles. In water-scarce regions where many lithium resources are located, this creates tension between resource extraction and environmental stewardship.

Geographically, DLE technology development is concentrated in North America and Europe, with companies in the United States, Canada, and Germany leading innovation. However, implementation challenges vary significantly across different lithium-rich regions, including the Lithium Triangle in South America, Nevada in the US, and various sites in Australia and China, each presenting unique geological and regulatory environments that affect scalability.

Current Industrial-Scale DLE Solutions

01 Adsorption-based direct lithium extraction technologies

Adsorption-based technologies utilize specialized materials that selectively capture lithium ions from brine solutions. These materials, such as ion-exchange resins and inorganic adsorbents, can be designed with high selectivity for lithium over competing ions like sodium, potassium, and magnesium. The process typically involves passing lithium-containing brine through columns packed with these adsorbents, followed by desorption steps to recover concentrated lithium solutions. This approach enables efficient extraction from low-concentration sources and can be scaled for commercial production.- Adsorption-based extraction technologies: Direct lithium extraction technologies that utilize selective adsorption materials to capture lithium ions from brine solutions. These methods typically employ specialized ion exchange resins or inorganic adsorbents that can selectively bind to lithium ions in the presence of competing ions. The adsorption process can be scaled up through modular designs, allowing for flexible capacity expansion based on production needs. After adsorption, lithium is typically recovered through desorption processes using acid or other regeneration solutions.

- Membrane and electrochemical separation systems: Extraction systems that utilize membrane technology and electrochemical processes to separate lithium from brine or other sources. These technologies often employ ion-selective membranes, electrodialysis, or electrochemical cells to facilitate the selective transport of lithium ions. The scalability of these systems is enhanced through modular designs and the ability to increase membrane surface area or electrode capacity. These approaches typically offer advantages in energy efficiency and can be designed for continuous operation at industrial scale.

- Modular and portable extraction units: Compact, modular extraction systems designed for deployment at various scales, from pilot to commercial operations. These units are characterized by their transportability, allowing for deployment directly at lithium-rich brine sources. The modular design enables scalability through the addition of parallel processing units as production requirements increase. These systems often integrate multiple extraction technologies and can be rapidly deployed to remote locations, reducing the need for extensive permanent infrastructure.

- Process optimization for industrial scale operations: Methods and systems focused on optimizing direct lithium extraction processes for large-scale industrial implementation. These innovations address challenges related to scaling up laboratory or pilot processes to commercial production levels. Key aspects include improving lithium recovery rates, reducing chemical consumption, minimizing waste generation, and enhancing overall process efficiency. These approaches often incorporate advanced process control systems, automation, and data analytics to maintain consistent performance at scale.

- Integration with renewable energy and sustainable practices: Direct lithium extraction technologies designed to operate with renewable energy sources and incorporate sustainable practices for large-scale operations. These systems aim to reduce the environmental footprint of lithium production by utilizing solar, geothermal, or other renewable energy sources to power extraction processes. Additionally, they often include water recycling systems, waste minimization strategies, and methods to reduce or eliminate the use of evaporation ponds. The scalability of these integrated systems considers both production capacity and environmental sustainability.

02 Membrane-based lithium extraction systems

Membrane-based systems employ selective membranes to separate lithium ions from other components in brine solutions. These systems utilize technologies such as nanofiltration, electrodialysis, and membrane distillation to achieve separation. The membranes can be engineered with specific pore sizes and surface properties to enhance lithium selectivity. Membrane processes offer advantages in terms of continuous operation, reduced chemical consumption, and potential for modular scaling. These systems can be designed for various production capacities, from pilot to industrial scale.Expand Specific Solutions03 Electrochemical lithium extraction methods

Electrochemical methods utilize electrical potential to selectively extract lithium from brines and other sources. These approaches include electrochemical intercalation, capacitive deionization, and electrochemical precipitation. By applying controlled voltage or current, lithium ions can be selectively removed from solution and concentrated for recovery. Electrochemical systems offer advantages in terms of energy efficiency, reduced chemical usage, and potential for integration with renewable energy sources. These methods can be scaled from laboratory demonstrations to commercial-scale operations.Expand Specific Solutions04 Integrated direct lithium extraction process systems

Integrated systems combine multiple technologies to optimize lithium extraction efficiency and scalability. These systems typically incorporate pre-treatment steps, primary extraction processes, and downstream processing to produce battery-grade lithium compounds. Integration may include brine concentration, impurity removal, selective extraction, and conversion to final products such as lithium carbonate or hydroxide. These comprehensive approaches address challenges of scaling by optimizing energy usage, minimizing waste, and maximizing lithium recovery across the entire process chain.Expand Specific Solutions05 Modular and scalable DLE equipment designs

Modular equipment designs enable flexible scaling of direct lithium extraction operations. These approaches utilize standardized process units that can be replicated and connected to achieve desired production capacity. Modular designs facilitate phased implementation, allowing operations to start at smaller scales and expand as needed. Equipment innovations include specialized extraction vessels, automated control systems, and optimized flow configurations to enhance efficiency at various scales. These designs address challenges of remote deployment, variable feed compositions, and capital efficiency in scaling lithium production.Expand Specific Solutions

Key Industrial Players in DLE Technology

The direct lithium extraction (DLE) technology market is in its early growth phase, characterized by rapid innovation and increasing commercial interest. The global lithium market is projected to expand significantly, driven by electric vehicle battery demand, creating urgency for scaling DLE solutions. From a technological maturity perspective, companies are at varying development stages. Industry leaders like Energy Exploration Technologies, Lilac Solutions, and International Battery Metals are advancing commercial-scale implementations, while Koch Technology Solutions and Schlumberger are leveraging their industrial expertise to scale DLE processes. Academic institutions including The University of Manchester, Penn State, and Chinese universities are contributing fundamental research. The competitive landscape features both specialized startups and established corporations like BYD and Murata Manufacturing, indicating a diversifying ecosystem focused on overcoming extraction efficiency, water usage, and cost challenges to achieve industrial-scale implementation.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed a comprehensive DLE technology platform focused on industrial scalability. Their approach integrates advanced sorbent materials with optimized process engineering to create modular extraction systems. The technology employs specialized ion-exchange materials that selectively capture lithium ions from brine solutions while rejecting competing ions like sodium, magnesium, and calcium. Koch's system operates in continuous cycles of adsorption and desorption, with proprietary regeneration chemistry that maintains sorbent performance over thousands of cycles [4]. Their industrial implementation includes pre-treatment systems to handle various brine compositions, automated process control for consistent operation, and waste management solutions to minimize environmental impact. Koch has designed their systems with standardized modules that can be manufactured at scale and deployed rapidly to extraction sites, with each module capable of processing 50-200 m³/hour of brine depending on lithium concentration [5]. The company has focused on reducing energy consumption through heat integration and optimized fluid dynamics, making their solution viable for remote locations.

Strengths: Highly engineered system integration provides turnkey solutions for industrial deployment; modular design allows for phased capacity expansion; proprietary sorbent materials with demonstrated long-term stability; comprehensive approach addressing the entire extraction process from pre-treatment to final concentration. Weaknesses: System complexity requires specialized operational expertise; higher initial capital investment compared to traditional methods; performance may vary with different brine chemistries; requires reliable infrastructure for chemical supply and product transport.

Energy Exploration Technologies, Inc.

Technical Solution: Energy Exploration Technologies (EnergyX) has developed a proprietary Lithium-Ion Transport and Separation (LiTAS™) technology for direct lithium extraction. Their approach utilizes advanced membrane technology based on metal-organic frameworks (MOFs) that can selectively filter lithium ions from brine solutions. The system operates at ambient temperature and pressure, significantly reducing energy requirements compared to traditional methods. EnergyX's membrane technology creates a physical barrier that allows lithium ions to pass through while blocking larger ions like sodium, magnesium, and calcium [6]. This selective permeability enables continuous extraction without the need for chemical regeneration cycles common in ion-exchange systems. The company has designed their technology as stackable membrane modules that can be deployed in parallel to achieve industrial-scale throughput. Each module contains thousands of square meters of membrane surface area optimized for lithium transport. EnergyX claims their process can recover up to 90% of available lithium in brines while reducing water consumption by over 90% compared to evaporation ponds [7]. The system is designed to produce a concentrated lithium solution that requires minimal further processing to reach battery-grade specifications.

Strengths: Membrane-based approach eliminates or reduces chemical consumption for regeneration; continuous operation without cycling improves efficiency; lower energy requirements than many competing technologies; minimal water consumption; compact footprint enables deployment in space-constrained locations. Weaknesses: Membrane fouling may occur with certain brine compositions requiring pre-treatment; scaling up membrane production to industrial volumes presents manufacturing challenges; relatively new technology with limited long-term operational data; may require specialized maintenance for membrane replacement.

Critical Patents and Technical Innovations in DLE

Lithium extraction

PatentWO2024126601A1

Innovation

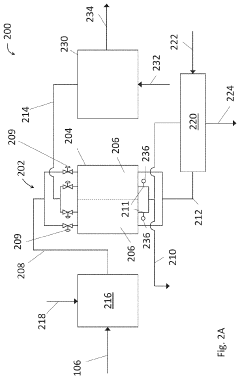

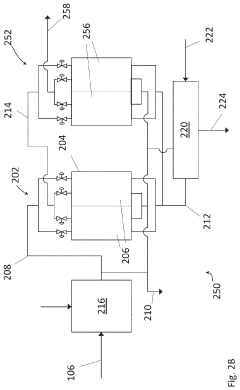

- Replacing hydrochloric acid with organic acids like oxalic or citric acid in the release step, allowing direct reaction with a non-lithium metal hydroxide to produce lithium hydroxide without intermediate lithium carbonate formation, using a lithium-selective ion exchange process with hollow fiber membranes for efficient extraction and release.

Integrated lithium extraction

PatentActiveUS20210246529A1

Innovation

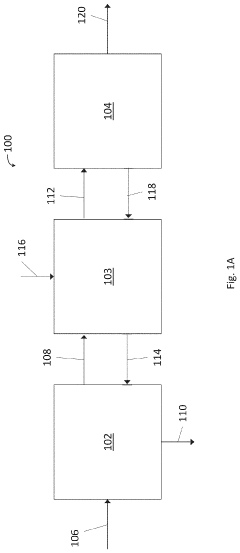

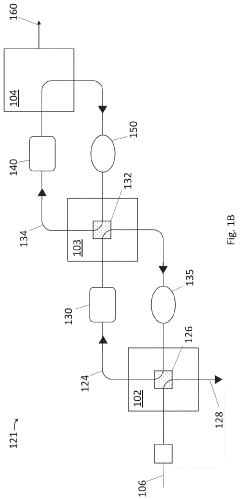

- The process involves using an intercalated resin to remove divalent ions from an aqueous source, followed by a solid adsorbent and liquid absorbent to concentrate lithium, with recycling and purification steps to maximize lithium recovery and minimize water usage.

Environmental Impact Assessment of DLE Methods

The environmental impact of Direct Lithium Extraction (DLE) methods represents a critical consideration as the industry scales toward commercial implementation. Traditional lithium extraction methods, particularly evaporation ponds, have faced significant criticism for their substantial water consumption, land use requirements, and chemical contamination risks. DLE technologies offer promising alternatives with potentially reduced environmental footprints.

Water usage metrics across various DLE methods demonstrate significant improvements compared to conventional approaches. While evaporation ponds typically consume 500-2,000 liters of water per kilogram of lithium carbonate equivalent (LCE), advanced DLE technologies have achieved reductions to 50-300 liters per kilogram. Ion exchange and adsorption-based systems show particular promise in water conservation, with some closed-loop systems reporting up to 90% water recycling capabilities.

Land disturbance assessments reveal that DLE facilities require substantially less surface area than evaporation ponds. A comparative analysis indicates that a DLE plant with equivalent production capacity occupies approximately 10-20% of the land area needed for traditional operations. This reduced footprint minimizes habitat disruption and preserves biodiversity in sensitive lithium-rich regions such as the South American "Lithium Triangle."

Chemical usage and waste generation vary significantly across DLE methodologies. Electrochemical systems typically employ fewer harsh chemicals than conventional acid leaching processes, though they may introduce concerns regarding electrode degradation and specialized material disposal. Adsorption-based systems generate spent adsorbents requiring proper management, while membrane systems produce concentrated brine streams that must be carefully handled to prevent groundwater contamination.

Carbon footprint analyses of DLE operations indicate potential advantages in greenhouse gas emissions. The accelerated extraction timeframe (hours to days versus months to years for evaporation) reduces operational energy requirements. However, this advantage may be offset by the energy-intensive nature of certain DLE technologies, particularly electrochemical approaches requiring significant electricity inputs.

Regulatory compliance frameworks for DLE environmental impacts remain underdeveloped in many jurisdictions. As industrial scaling progresses, standardized environmental impact assessment protocols specific to DLE technologies will be essential to ensure consistent evaluation and mitigation strategies across the industry. Several leading lithium producers have initiated voluntary environmental monitoring programs to establish baseline performance metrics.

Water usage metrics across various DLE methods demonstrate significant improvements compared to conventional approaches. While evaporation ponds typically consume 500-2,000 liters of water per kilogram of lithium carbonate equivalent (LCE), advanced DLE technologies have achieved reductions to 50-300 liters per kilogram. Ion exchange and adsorption-based systems show particular promise in water conservation, with some closed-loop systems reporting up to 90% water recycling capabilities.

Land disturbance assessments reveal that DLE facilities require substantially less surface area than evaporation ponds. A comparative analysis indicates that a DLE plant with equivalent production capacity occupies approximately 10-20% of the land area needed for traditional operations. This reduced footprint minimizes habitat disruption and preserves biodiversity in sensitive lithium-rich regions such as the South American "Lithium Triangle."

Chemical usage and waste generation vary significantly across DLE methodologies. Electrochemical systems typically employ fewer harsh chemicals than conventional acid leaching processes, though they may introduce concerns regarding electrode degradation and specialized material disposal. Adsorption-based systems generate spent adsorbents requiring proper management, while membrane systems produce concentrated brine streams that must be carefully handled to prevent groundwater contamination.

Carbon footprint analyses of DLE operations indicate potential advantages in greenhouse gas emissions. The accelerated extraction timeframe (hours to days versus months to years for evaporation) reduces operational energy requirements. However, this advantage may be offset by the energy-intensive nature of certain DLE technologies, particularly electrochemical approaches requiring significant electricity inputs.

Regulatory compliance frameworks for DLE environmental impacts remain underdeveloped in many jurisdictions. As industrial scaling progresses, standardized environmental impact assessment protocols specific to DLE technologies will be essential to ensure consistent evaluation and mitigation strategies across the industry. Several leading lithium producers have initiated voluntary environmental monitoring programs to establish baseline performance metrics.

Economic Feasibility of Industrial DLE Implementation

The economic viability of Direct Lithium Extraction (DLE) technologies at industrial scale remains a critical consideration for widespread adoption. Current cost analyses indicate that DLE implementation requires significant capital expenditure, with initial investments ranging from $20-50 million for medium-scale operations. These costs primarily stem from specialized adsorption materials, processing equipment, and infrastructure development necessary for handling large brine volumes.

Operating expenses present another substantial economic factor, with energy consumption being particularly significant. Most DLE technologies require between 15-40 kWh per kilogram of lithium carbonate equivalent (LCE) produced, considerably higher than traditional evaporation pond methods. However, this energy disadvantage is partially offset by DLE's dramatically reduced processing time—days versus months—enabling faster return on investment and market responsiveness.

Water management economics also factor prominently in the feasibility equation. While DLE typically consumes less water overall than evaporation ponds, the treatment and recycling of process water adds approximately $200-350 per ton of LCE to production costs. This represents a trade-off between environmental sustainability and economic efficiency that varies significantly by implementation location and available water resources.

Recovery rates significantly impact economic calculations, with current industrial DLE implementations achieving 70-90% lithium recovery compared to 40-50% for traditional methods. This efficiency improvement translates to approximately 25-30% more marketable product from the same brine resource, creating substantial long-term economic advantages despite higher upfront costs.

Scale economies present promising pathways to cost reduction. Analysis of pilot projects indicates that scaling from demonstration to commercial operations can reduce production costs by 30-40% through improved process efficiency and reduced per-unit capital costs. Industry projections suggest that at full industrial scale, DLE production costs could potentially decrease to $3,500-4,500 per ton of LCE, approaching cost parity with conventional methods.

Market positioning also influences economic feasibility. Premium pricing for environmentally responsible lithium production—estimated at 5-15% above market rates—can improve the economic case for DLE implementation. Additionally, the ability to extract lithium from previously uneconomical low-concentration brines expands the resource base, potentially transforming marginal deposits into valuable assets.

Regulatory considerations increasingly factor into economic calculations, with carbon taxation and environmental compliance costs favoring DLE technologies. In jurisdictions with stringent environmental regulations, the avoided costs of environmental remediation and regulatory penalties can improve DLE's comparative economic position by an estimated 10-20% over conventional extraction methods.

Operating expenses present another substantial economic factor, with energy consumption being particularly significant. Most DLE technologies require between 15-40 kWh per kilogram of lithium carbonate equivalent (LCE) produced, considerably higher than traditional evaporation pond methods. However, this energy disadvantage is partially offset by DLE's dramatically reduced processing time—days versus months—enabling faster return on investment and market responsiveness.

Water management economics also factor prominently in the feasibility equation. While DLE typically consumes less water overall than evaporation ponds, the treatment and recycling of process water adds approximately $200-350 per ton of LCE to production costs. This represents a trade-off between environmental sustainability and economic efficiency that varies significantly by implementation location and available water resources.

Recovery rates significantly impact economic calculations, with current industrial DLE implementations achieving 70-90% lithium recovery compared to 40-50% for traditional methods. This efficiency improvement translates to approximately 25-30% more marketable product from the same brine resource, creating substantial long-term economic advantages despite higher upfront costs.

Scale economies present promising pathways to cost reduction. Analysis of pilot projects indicates that scaling from demonstration to commercial operations can reduce production costs by 30-40% through improved process efficiency and reduced per-unit capital costs. Industry projections suggest that at full industrial scale, DLE production costs could potentially decrease to $3,500-4,500 per ton of LCE, approaching cost parity with conventional methods.

Market positioning also influences economic feasibility. Premium pricing for environmentally responsible lithium production—estimated at 5-15% above market rates—can improve the economic case for DLE implementation. Additionally, the ability to extract lithium from previously uneconomical low-concentration brines expands the resource base, potentially transforming marginal deposits into valuable assets.

Regulatory considerations increasingly factor into economic calculations, with carbon taxation and environmental compliance costs favoring DLE technologies. In jurisdictions with stringent environmental regulations, the avoided costs of environmental remediation and regulatory penalties can improve DLE's comparative economic position by an estimated 10-20% over conventional extraction methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!