Direct Lithium Extraction: Innovation in Equipment Efficiency

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) represents a paradigm shift in lithium production technology, emerging as an alternative to traditional extraction methods that have dominated the industry for decades. Conventional lithium extraction primarily relies on solar evaporation of brine resources or hard-rock mining, both characterized by lengthy production cycles, significant environmental footprints, and geographical limitations. The evolution of DLE technology began in the early 2000s, with substantial acceleration in development occurring over the past decade in response to the exponential growth in lithium demand driven by electric vehicle batteries and energy storage systems.

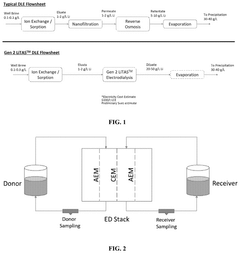

The technological trajectory of DLE has been marked by progressive improvements in selectivity, efficiency, and scalability. Early iterations focused primarily on proof-of-concept demonstrations, while recent advancements have emphasized commercial viability and process optimization. The current technological landscape encompasses various approaches including adsorption, ion exchange, solvent extraction, and membrane-based separation, each with distinct operational characteristics and efficiency profiles.

The primary objective of DLE technology development is to establish extraction processes that can achieve high lithium recovery rates (>90%) while minimizing water consumption, chemical usage, and energy requirements. Additionally, DLE aims to reduce the production timeline from months to days or hours, enabling more responsive supply chains that can adapt to market fluctuations. Equipment efficiency stands as a critical factor in realizing these objectives, as it directly impacts operational costs, environmental sustainability, and economic viability.

Current research and development efforts are increasingly focused on enhancing equipment efficiency through innovations in materials science, process engineering, and system integration. These initiatives target improvements in several key performance indicators, including energy consumption per ton of lithium produced, selectivity for lithium over competing ions, adsorbent capacity and regeneration cycles, and overall process intensification.

The technological goals for next-generation DLE equipment include developing systems capable of processing diverse brine chemistries with consistent performance, minimizing pre-treatment requirements, reducing mechanical complexity to enhance reliability, and implementing advanced control systems for optimized operation. Furthermore, there is growing emphasis on designing modular and scalable equipment that can be deployed across various geographical contexts, from high-altitude salars to geothermal brines and oilfield produced waters.

As the lithium market continues to expand at a compound annual growth rate exceeding 20%, the imperative for efficient DLE technology becomes increasingly pronounced. Industry projections suggest that by 2030, DLE could account for up to 25% of global lithium production, representing a significant shift in the resource landscape and highlighting the strategic importance of continued innovation in equipment efficiency.

The technological trajectory of DLE has been marked by progressive improvements in selectivity, efficiency, and scalability. Early iterations focused primarily on proof-of-concept demonstrations, while recent advancements have emphasized commercial viability and process optimization. The current technological landscape encompasses various approaches including adsorption, ion exchange, solvent extraction, and membrane-based separation, each with distinct operational characteristics and efficiency profiles.

The primary objective of DLE technology development is to establish extraction processes that can achieve high lithium recovery rates (>90%) while minimizing water consumption, chemical usage, and energy requirements. Additionally, DLE aims to reduce the production timeline from months to days or hours, enabling more responsive supply chains that can adapt to market fluctuations. Equipment efficiency stands as a critical factor in realizing these objectives, as it directly impacts operational costs, environmental sustainability, and economic viability.

Current research and development efforts are increasingly focused on enhancing equipment efficiency through innovations in materials science, process engineering, and system integration. These initiatives target improvements in several key performance indicators, including energy consumption per ton of lithium produced, selectivity for lithium over competing ions, adsorbent capacity and regeneration cycles, and overall process intensification.

The technological goals for next-generation DLE equipment include developing systems capable of processing diverse brine chemistries with consistent performance, minimizing pre-treatment requirements, reducing mechanical complexity to enhance reliability, and implementing advanced control systems for optimized operation. Furthermore, there is growing emphasis on designing modular and scalable equipment that can be deployed across various geographical contexts, from high-altitude salars to geothermal brines and oilfield produced waters.

As the lithium market continues to expand at a compound annual growth rate exceeding 20%, the imperative for efficient DLE technology becomes increasingly pronounced. Industry projections suggest that by 2030, DLE could account for up to 25% of global lithium production, representing a significant shift in the resource landscape and highlighting the strategic importance of continued innovation in equipment efficiency.

Market Analysis for Lithium Extraction Solutions

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. The market value for lithium extraction solutions reached approximately $4.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 12.8% through 2030. This remarkable growth trajectory underscores the critical importance of developing more efficient Direct Lithium Extraction (DLE) technologies.

Demand for lithium is heavily concentrated in three main sectors: electric mobility (accounting for 51% of global demand), energy storage systems (27%), and consumer electronics (18%). The remaining 4% serves various industrial applications. This distribution highlights the transformative impact of transportation electrification on lithium market dynamics, with automotive manufacturers increasingly securing direct lithium supply chains to mitigate volatility risks.

Geographically, the Asia-Pacific region dominates lithium consumption, representing 68% of global demand, followed by Europe (19%) and North America (11%). China alone accounts for 39% of worldwide lithium utilization, primarily due to its dominant position in battery manufacturing. However, recent policy initiatives in the United States and European Union aim to reduce dependency on Asian supply chains, potentially reshaping regional demand patterns over the next decade.

The market for DLE technologies specifically has emerged as a high-growth segment within the broader lithium extraction landscape. Traditional extraction methods—evaporation ponds and hard-rock mining—face increasing scrutiny due to environmental concerns and operational inefficiencies. DLE solutions address these challenges by offering reduced water consumption (up to 90% less than evaporation methods), smaller physical footprints, and accelerated production timelines.

End-users increasingly prioritize equipment efficiency metrics when evaluating lithium extraction solutions. Recovery rates, energy consumption per ton of lithium carbonate equivalent (LCE), and operational expenditure have become key decision factors. Market research indicates that solutions delivering recovery rates above 85% while maintaining energy consumption below 5 MWh per ton of LCE command premium pricing, typically 15-20% above industry averages.

The competitive landscape features established mining companies investing heavily in DLE technologies alongside specialized technology providers and startups. This market fragmentation presents significant opportunities for innovation-driven companies that can demonstrate superior equipment efficiency metrics. Industry analysts project that companies achieving breakthrough improvements in extraction efficiency could capture market share rapidly, as lithium producers face mounting pressure to expand production while minimizing environmental impacts.

Demand for lithium is heavily concentrated in three main sectors: electric mobility (accounting for 51% of global demand), energy storage systems (27%), and consumer electronics (18%). The remaining 4% serves various industrial applications. This distribution highlights the transformative impact of transportation electrification on lithium market dynamics, with automotive manufacturers increasingly securing direct lithium supply chains to mitigate volatility risks.

Geographically, the Asia-Pacific region dominates lithium consumption, representing 68% of global demand, followed by Europe (19%) and North America (11%). China alone accounts for 39% of worldwide lithium utilization, primarily due to its dominant position in battery manufacturing. However, recent policy initiatives in the United States and European Union aim to reduce dependency on Asian supply chains, potentially reshaping regional demand patterns over the next decade.

The market for DLE technologies specifically has emerged as a high-growth segment within the broader lithium extraction landscape. Traditional extraction methods—evaporation ponds and hard-rock mining—face increasing scrutiny due to environmental concerns and operational inefficiencies. DLE solutions address these challenges by offering reduced water consumption (up to 90% less than evaporation methods), smaller physical footprints, and accelerated production timelines.

End-users increasingly prioritize equipment efficiency metrics when evaluating lithium extraction solutions. Recovery rates, energy consumption per ton of lithium carbonate equivalent (LCE), and operational expenditure have become key decision factors. Market research indicates that solutions delivering recovery rates above 85% while maintaining energy consumption below 5 MWh per ton of LCE command premium pricing, typically 15-20% above industry averages.

The competitive landscape features established mining companies investing heavily in DLE technologies alongside specialized technology providers and startups. This market fragmentation presents significant opportunities for innovation-driven companies that can demonstrate superior equipment efficiency metrics. Industry analysts project that companies achieving breakthrough improvements in extraction efficiency could capture market share rapidly, as lithium producers face mounting pressure to expand production while minimizing environmental impacts.

Current DLE Technical Challenges and Limitations

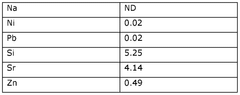

Despite the promising potential of Direct Lithium Extraction (DLE) technologies, several significant technical challenges and limitations currently impede widespread commercial adoption and optimal equipment efficiency. The primary challenge lies in the selectivity of ion exchange materials and sorbents, which often struggle to effectively separate lithium from other ions present in brine solutions, particularly sodium, potassium, magnesium, and calcium. This selectivity issue directly impacts equipment design and operational efficiency, requiring complex pre-treatment systems that increase capital expenditure and operational costs.

Energy consumption represents another critical limitation, as most current DLE processes require substantial energy inputs for pumping, heating, and regeneration cycles. This high energy demand not only affects operational economics but also contradicts the sustainability goals associated with lithium production for green technologies. Equipment designed for these processes must balance energy efficiency with extraction performance, creating engineering trade-offs that have not been optimally resolved.

Water usage efficiency presents a significant challenge, particularly in arid regions where many lithium resources are located. Conventional DLE systems can require substantial water volumes for regeneration and washing cycles, creating a paradoxical situation where water-intensive processes are deployed in water-scarce environments. Equipment innovations that minimize water consumption while maintaining extraction efficiency remain underdeveloped.

Durability and lifespan of extraction materials constitute another limitation, as ion exchange resins and adsorbents often degrade after multiple regeneration cycles, especially when exposed to impurities in brine solutions. This degradation necessitates frequent replacement, increasing operational costs and creating equipment downtime that reduces overall process efficiency.

Scalability challenges persist across the industry, with many promising laboratory-scale technologies failing to maintain performance metrics when scaled to commercial operations. The engineering complexity of maintaining uniform flow distribution, contact time, and extraction efficiency in large-scale equipment has proven particularly problematic.

Process integration represents a final significant hurdle, as DLE technologies must seamlessly integrate with existing brine processing operations or be designed as standalone systems with their own pre-treatment and post-processing capabilities. Current equipment designs often create bottlenecks at these integration points, reducing overall system efficiency and increasing complexity.

These technical challenges collectively contribute to higher capital and operational costs compared to traditional evaporation pond methods, creating economic barriers to adoption despite the environmental and time advantages that DLE technologies offer.

Energy consumption represents another critical limitation, as most current DLE processes require substantial energy inputs for pumping, heating, and regeneration cycles. This high energy demand not only affects operational economics but also contradicts the sustainability goals associated with lithium production for green technologies. Equipment designed for these processes must balance energy efficiency with extraction performance, creating engineering trade-offs that have not been optimally resolved.

Water usage efficiency presents a significant challenge, particularly in arid regions where many lithium resources are located. Conventional DLE systems can require substantial water volumes for regeneration and washing cycles, creating a paradoxical situation where water-intensive processes are deployed in water-scarce environments. Equipment innovations that minimize water consumption while maintaining extraction efficiency remain underdeveloped.

Durability and lifespan of extraction materials constitute another limitation, as ion exchange resins and adsorbents often degrade after multiple regeneration cycles, especially when exposed to impurities in brine solutions. This degradation necessitates frequent replacement, increasing operational costs and creating equipment downtime that reduces overall process efficiency.

Scalability challenges persist across the industry, with many promising laboratory-scale technologies failing to maintain performance metrics when scaled to commercial operations. The engineering complexity of maintaining uniform flow distribution, contact time, and extraction efficiency in large-scale equipment has proven particularly problematic.

Process integration represents a final significant hurdle, as DLE technologies must seamlessly integrate with existing brine processing operations or be designed as standalone systems with their own pre-treatment and post-processing capabilities. Current equipment designs often create bottlenecks at these integration points, reducing overall system efficiency and increasing complexity.

These technical challenges collectively contribute to higher capital and operational costs compared to traditional evaporation pond methods, creating economic barriers to adoption despite the environmental and time advantages that DLE technologies offer.

Current Equipment Solutions for Direct Lithium Extraction

01 Adsorption-based extraction systems

Adsorption-based direct lithium extraction systems utilize specialized adsorbent materials to selectively capture lithium ions from brine solutions. These systems typically employ ion exchange resins or inorganic adsorbents that have high selectivity for lithium over competing ions. The efficiency of these systems depends on the adsorption capacity, selectivity, and regeneration capabilities of the adsorbent materials. Advanced designs incorporate optimized flow patterns and contact time to maximize lithium recovery while minimizing energy consumption.- Adsorption-based extraction systems: Direct lithium extraction systems utilizing selective adsorption materials to efficiently capture lithium ions from brine solutions. These systems typically employ specialized ion exchange resins or inorganic adsorbents that can selectively bind lithium while rejecting competing ions. The efficiency of these systems depends on the selectivity of the adsorbent material, contact time, and regeneration processes. Advanced adsorption systems can achieve higher recovery rates and reduced processing times compared to traditional evaporation methods.

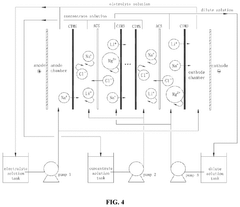

- Membrane and electrochemical separation technologies: Electrochemical systems and membrane technologies designed to separate lithium from brine solutions through electrical potential differences or selective membrane filtration. These technologies include electrodialysis, membrane electrolysis, and electrochemical cells specifically designed for lithium extraction. The efficiency of these systems is measured by energy consumption per unit of lithium recovered, membrane selectivity, and operational lifespan. These methods typically offer faster extraction rates than traditional methods and can operate continuously with lower environmental impact.

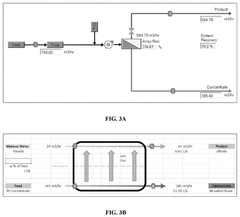

- Process optimization and control systems: Advanced control systems and process optimization technologies that enhance the efficiency of direct lithium extraction equipment. These include automated monitoring systems, real-time analytics, and feedback control mechanisms that adjust operational parameters based on input conditions. Machine learning algorithms and AI-based control systems can predict optimal operating conditions and prevent efficiency losses. These systems can significantly improve lithium recovery rates, reduce energy consumption, and extend equipment lifespan through precise control of extraction parameters.

- Energy-efficient extraction equipment design: Innovative equipment designs focused on reducing energy consumption in direct lithium extraction processes. These designs incorporate energy recovery systems, optimized flow patterns, and thermally efficient components to minimize energy losses. Heat exchangers, pressure recovery devices, and low-energy pumping systems are integrated to reduce the overall energy footprint of the extraction process. The efficiency improvements come from both mechanical design optimizations and novel materials that reduce friction, heat loss, and fluid resistance throughout the system.

- Modular and scalable extraction systems: Modular direct lithium extraction systems designed for scalability and deployment flexibility across different brine resources. These systems feature standardized components that can be easily transported, assembled, and scaled according to resource characteristics and production requirements. The modular approach allows for incremental capacity expansion and adaptation to varying brine chemistries without complete system redesign. Efficiency is improved through standardization, rapid deployment capabilities, and the ability to optimize individual modules for specific operating conditions.

02 Membrane-based separation technologies

Membrane-based technologies for direct lithium extraction utilize specialized membranes that selectively allow lithium ions to pass through while blocking other elements. These systems may employ nanofiltration, electrodialysis, or other membrane separation techniques to achieve high lithium recovery rates. The efficiency of membrane-based systems is determined by factors such as membrane selectivity, fouling resistance, and operational lifetime. Recent innovations focus on developing composite membranes with enhanced lithium selectivity and reduced energy requirements.Expand Specific Solutions03 Electrochemical extraction methods

Electrochemical methods for direct lithium extraction utilize electrical potential differences to selectively extract lithium from brine solutions. These systems may employ electrochemical cells with specialized electrodes that capture lithium ions during charging cycles and release them during discharge. The efficiency of electrochemical extraction systems depends on factors such as electrode materials, cell design, and operating parameters. Advanced systems incorporate energy recovery mechanisms to reduce overall power consumption and improve extraction economics.Expand Specific Solutions04 Integrated extraction and processing systems

Integrated direct lithium extraction systems combine multiple processing steps into unified equipment designs to improve overall efficiency. These systems may incorporate extraction, purification, and concentration stages within a single process train, reducing transfer losses and energy requirements. The efficiency of integrated systems is enhanced through heat recovery, process intensification, and automated control systems. Such designs minimize footprint requirements while maximizing lithium recovery rates and product purity.Expand Specific Solutions05 Modular and scalable extraction equipment

Modular direct lithium extraction equipment is designed for scalability and deployment flexibility across various brine resources. These systems utilize standardized components that can be easily transported, assembled, and expanded to match production requirements. The efficiency of modular systems is optimized through parallel processing configurations and adaptive control systems that respond to variations in feed composition. This approach enables rapid deployment and operational adjustments to maximize lithium recovery while minimizing capital expenditure.Expand Specific Solutions

Key Industry Players in DLE Technology Development

Direct Lithium Extraction (DLE) technology is currently in an early growth phase, with the global market expected to expand significantly due to increasing demand for lithium in battery applications. The market size is projected to reach several billion dollars by 2030, driven by the need for more efficient extraction methods compared to traditional evaporation ponds. Technologically, the field shows varying maturity levels, with companies like Lilac Solutions and International Battery Metals leading with ion-exchange technologies, while Koch Technology Solutions and Evove are advancing membrane-based approaches. Research institutions such as Penn State Research Foundation and Fraunhofer-Gesellschaft are contributing fundamental innovations, while established players like Schlumberger are leveraging their industrial expertise to scale solutions. The competitive landscape reflects a mix of specialized startups, research organizations, and industrial conglomerates working to improve equipment efficiency and environmental sustainability.

Lilac Solutions, Inc.

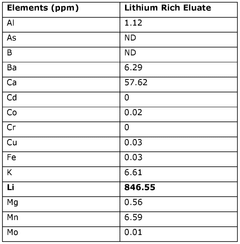

Technical Solution: Lilac Solutions has developed an ion-exchange technology platform specifically designed for lithium extraction from brines. Their proprietary ion-exchange beads selectively absorb lithium from brine resources while rejecting other elements. The process operates in a continuous flow system where brine passes through modules containing the beads, which capture lithium ions. Once saturated, the beads are regenerated using a water-based solution, producing a concentrated lithium solution ready for further processing. This technology significantly reduces the physical footprint compared to traditional evaporation ponds, with extraction facilities requiring only 1% of the land area. Lilac's system achieves lithium recovery rates of over 90% compared to approximately 40% for conventional methods, while operating at much faster speeds - hours versus the 18+ months required for evaporation ponds.

Strengths: Superior lithium selectivity with 90%+ recovery rates; dramatically reduced processing time (hours vs months); minimal environmental footprint; works with low-grade and complex brines. Weaknesses: Requires specialized ion-exchange materials that may have limited lifespan; regeneration process creates additional waste streams that require management; higher upfront capital costs compared to traditional evaporation methods.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed an advanced membrane-based Direct Lithium Extraction (DLE) technology that utilizes specialized nanofiltration and selective separation processes. Their system employs proprietary membrane technology that allows for selective lithium ion passage while rejecting competing ions such as sodium, magnesium, and calcium. The process operates under optimized pressure and flow conditions to maximize lithium recovery efficiency while minimizing energy consumption. Koch's approach integrates pre-treatment systems to handle varying brine compositions and post-extraction concentration steps to produce battery-grade lithium compounds. Their modular design enables scalable implementation from pilot to commercial scale, with reported lithium recovery rates exceeding 85% across diverse brine chemistries. The technology significantly reduces water consumption compared to evaporation pond methods, with up to 90% less freshwater usage in some implementations.

Strengths: Highly selective membrane technology with minimal chemical consumption; modular and scalable design allowing for flexible deployment; reduced water footprint compared to conventional methods; faster extraction timeframe than evaporation ponds. Weaknesses: Membrane fouling can occur with certain brine compositions requiring additional pre-treatment; higher energy requirements for pressure-driven processes; membranes may require periodic replacement, increasing operational costs over time.

Core Patents and Innovations in DLE Equipment Design

Systems and methods for direct lithium extraction

PatentPendingUS20250011957A1

Innovation

- The integration of selective membrane electrodialysis as a single step to simultaneously concentrate and purify lithium brines, reducing the number of required processing steps, capital and operating costs, and carbon footprint, while eliminating the need for large equipment at remote mining locations.

Process and product

PatentWO2025105970A1

Innovation

- A DLE process using a lithium sorbent with a high specific surface area, combined with ultrafiltration or nanofiltration membranes for separation, and a pH-controlled upload step to optimize lithium absorption and reduce impurity carryover.

Environmental Impact Assessment of DLE Technologies

The environmental footprint of Direct Lithium Extraction (DLE) technologies represents a critical consideration in their industrial adoption. Traditional lithium extraction methods, particularly evaporation ponds, consume vast quantities of water—approximately 500,000 gallons per ton of lithium—and occupy extensive land areas, disrupting local ecosystems. In contrast, DLE technologies demonstrate significant potential for reducing these environmental impacts.

Water consumption metrics reveal that advanced DLE systems can reduce freshwater usage by 50-65% compared to conventional methods. This efficiency is particularly valuable in water-stressed regions like Chile's Atacama Desert and Argentina's lithium triangle, where water resources are already under pressure from competing agricultural and community needs.

Land disturbance analysis indicates that DLE facilities require only 10-20% of the land area needed for traditional evaporation pond operations. This dramatic reduction minimizes habitat fragmentation and preserves biodiversity in sensitive ecological zones where lithium deposits are often located.

Carbon emissions assessments of DLE operations show varied results depending on energy sources. When powered by renewable energy, DLE can reduce the carbon footprint of lithium production by up to 30%. However, implementations relying on fossil fuels may partially offset these gains, highlighting the importance of integrated renewable energy solutions in DLE facility design.

Chemical usage presents both challenges and opportunities. While some DLE technologies employ sorbents and solvents that require careful handling and disposal, newer ion-exchange materials demonstrate improved environmental profiles with lower toxicity and greater reusability. Closed-loop systems that recycle processing chemicals have shown 85-90% reduction in chemical waste generation.

Groundwater impact studies indicate that DLE technologies, particularly those using selective adsorption methods, pose significantly lower risks of brine contamination and aquifer disruption compared to traditional extraction. Monitoring data from pilot installations shows minimal changes in groundwater chemistry when proper containment systems are implemented.

Waste management remains an evolving aspect of DLE environmental assessment. The concentrated brine and spent sorbent materials require specialized disposal protocols, though emerging technologies for beneficial reuse of these byproducts show promise for further reducing environmental liabilities.

Water consumption metrics reveal that advanced DLE systems can reduce freshwater usage by 50-65% compared to conventional methods. This efficiency is particularly valuable in water-stressed regions like Chile's Atacama Desert and Argentina's lithium triangle, where water resources are already under pressure from competing agricultural and community needs.

Land disturbance analysis indicates that DLE facilities require only 10-20% of the land area needed for traditional evaporation pond operations. This dramatic reduction minimizes habitat fragmentation and preserves biodiversity in sensitive ecological zones where lithium deposits are often located.

Carbon emissions assessments of DLE operations show varied results depending on energy sources. When powered by renewable energy, DLE can reduce the carbon footprint of lithium production by up to 30%. However, implementations relying on fossil fuels may partially offset these gains, highlighting the importance of integrated renewable energy solutions in DLE facility design.

Chemical usage presents both challenges and opportunities. While some DLE technologies employ sorbents and solvents that require careful handling and disposal, newer ion-exchange materials demonstrate improved environmental profiles with lower toxicity and greater reusability. Closed-loop systems that recycle processing chemicals have shown 85-90% reduction in chemical waste generation.

Groundwater impact studies indicate that DLE technologies, particularly those using selective adsorption methods, pose significantly lower risks of brine contamination and aquifer disruption compared to traditional extraction. Monitoring data from pilot installations shows minimal changes in groundwater chemistry when proper containment systems are implemented.

Waste management remains an evolving aspect of DLE environmental assessment. The concentrated brine and spent sorbent materials require specialized disposal protocols, though emerging technologies for beneficial reuse of these byproducts show promise for further reducing environmental liabilities.

Supply Chain Considerations for DLE Implementation

The implementation of Direct Lithium Extraction (DLE) technologies requires careful consideration of supply chain dynamics to ensure operational efficiency and sustainability. The supply chain for DLE encompasses raw material sourcing, equipment manufacturing, chemical reagent procurement, and distribution networks for the extracted lithium products.

Critical to DLE implementation is the availability of specialized equipment components, including ion-exchange resins, selective adsorbents, and membrane materials. These materials often require advanced manufacturing capabilities and may face supply constraints as DLE adoption increases globally. Companies implementing DLE must establish reliable procurement channels for these specialized components to avoid operational disruptions.

Chemical reagents used in DLE processes represent another crucial supply chain consideration. Many DLE methods require specific acids, bases, or solvents for regeneration cycles. The consistent availability, quality, and pricing of these chemicals directly impact operational costs and extraction efficiency. Strategic partnerships with chemical suppliers and potential on-site production capabilities should be evaluated to mitigate supply risks.

Water management presents a significant supply chain challenge for DLE operations. While DLE generally uses less water than traditional evaporation methods, the quality and quantity of water required for processing must be secured, particularly in water-stressed regions. Infrastructure for water treatment and recycling becomes an integral part of the DLE supply chain, necessitating investment in complementary technologies.

Energy supply reliability constitutes another critical factor in the DLE supply chain. Many innovative DLE technologies require consistent electricity for pumping, heating, or electrochemical processes. The integration of renewable energy sources can enhance sustainability but adds complexity to supply chain planning and may require energy storage solutions to ensure operational continuity.

Transportation logistics for both incoming materials and outgoing lithium products must be optimized for DLE facilities. The location of processing facilities relative to lithium sources, chemical suppliers, and end markets significantly impacts overall operational efficiency. Multi-modal transportation options and strategic facility placement can reduce costs and carbon footprint.

As DLE technologies evolve, supply chain resilience becomes increasingly important. Diversification of suppliers, vertical integration strategies, and development of alternative material sources can help mitigate risks associated with geopolitical tensions or market volatility. Companies implementing DLE should conduct comprehensive supply chain vulnerability assessments and develop contingency plans for critical components.

Critical to DLE implementation is the availability of specialized equipment components, including ion-exchange resins, selective adsorbents, and membrane materials. These materials often require advanced manufacturing capabilities and may face supply constraints as DLE adoption increases globally. Companies implementing DLE must establish reliable procurement channels for these specialized components to avoid operational disruptions.

Chemical reagents used in DLE processes represent another crucial supply chain consideration. Many DLE methods require specific acids, bases, or solvents for regeneration cycles. The consistent availability, quality, and pricing of these chemicals directly impact operational costs and extraction efficiency. Strategic partnerships with chemical suppliers and potential on-site production capabilities should be evaluated to mitigate supply risks.

Water management presents a significant supply chain challenge for DLE operations. While DLE generally uses less water than traditional evaporation methods, the quality and quantity of water required for processing must be secured, particularly in water-stressed regions. Infrastructure for water treatment and recycling becomes an integral part of the DLE supply chain, necessitating investment in complementary technologies.

Energy supply reliability constitutes another critical factor in the DLE supply chain. Many innovative DLE technologies require consistent electricity for pumping, heating, or electrochemical processes. The integration of renewable energy sources can enhance sustainability but adds complexity to supply chain planning and may require energy storage solutions to ensure operational continuity.

Transportation logistics for both incoming materials and outgoing lithium products must be optimized for DLE facilities. The location of processing facilities relative to lithium sources, chemical suppliers, and end markets significantly impacts overall operational efficiency. Multi-modal transportation options and strategic facility placement can reduce costs and carbon footprint.

As DLE technologies evolve, supply chain resilience becomes increasingly important. Diversification of suppliers, vertical integration strategies, and development of alternative material sources can help mitigate risks associated with geopolitical tensions or market volatility. Companies implementing DLE should conduct comprehensive supply chain vulnerability assessments and develop contingency plans for critical components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!