Optimize Direct Lithium Extraction to Minimize Water Loss

SEP 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a revolutionary approach to lithium production, evolving significantly since its conceptual development in the 1990s. Traditional lithium extraction methods, primarily evaporation ponds and hard rock mining, have dominated the industry for decades but present substantial environmental challenges, particularly regarding water consumption. DLE technologies represent a paradigm shift, offering potential solutions to address the growing global demand for lithium while minimizing environmental impact.

The evolution of DLE has accelerated in recent years, driven by the exponential growth in lithium demand for electric vehicle batteries and energy storage systems. Early DLE approaches focused primarily on ion exchange and adsorption technologies, with limited commercial implementation. However, technological advancements in selective sorbents, membrane systems, and electrochemical processes have expanded the DLE landscape significantly since 2010.

Current DLE technologies can be categorized into several main approaches: ion exchange, adsorption, solvent extraction, and membrane-based processes. Each methodology offers distinct advantages and limitations regarding selectivity, recovery rates, and water efficiency. The technical trajectory indicates a clear movement toward systems that can process diverse brine chemistries while reducing freshwater requirements and minimizing waste generation.

The primary objective of optimizing DLE technologies is to develop commercially viable processes that can extract lithium efficiently while dramatically reducing water consumption compared to conventional methods. This optimization aims to achieve lithium recovery rates exceeding 90% while returning over 95% of process water to source aquifers, maintaining hydrological balance in sensitive ecosystems.

Secondary objectives include reducing energy requirements, minimizing chemical inputs, shortening processing times, and developing systems adaptable to varying brine chemistries across different geographical locations. These improvements would enable DLE to become economically competitive with traditional extraction methods while offering superior environmental performance.

The technological goals extend to developing closed-loop systems that effectively manage not only water but also other valuable minerals present in brines. This holistic approach seeks to transform lithium extraction from a water-intensive, environmentally problematic process into a sustainable operation that contributes positively to resource stewardship while meeting the growing global demand for battery materials.

As the lithium market continues its projected growth trajectory, with demand expected to increase by 500% by 2030, optimizing DLE represents not merely a technological challenge but a strategic imperative for ensuring sustainable supply chains for the clean energy transition.

The evolution of DLE has accelerated in recent years, driven by the exponential growth in lithium demand for electric vehicle batteries and energy storage systems. Early DLE approaches focused primarily on ion exchange and adsorption technologies, with limited commercial implementation. However, technological advancements in selective sorbents, membrane systems, and electrochemical processes have expanded the DLE landscape significantly since 2010.

Current DLE technologies can be categorized into several main approaches: ion exchange, adsorption, solvent extraction, and membrane-based processes. Each methodology offers distinct advantages and limitations regarding selectivity, recovery rates, and water efficiency. The technical trajectory indicates a clear movement toward systems that can process diverse brine chemistries while reducing freshwater requirements and minimizing waste generation.

The primary objective of optimizing DLE technologies is to develop commercially viable processes that can extract lithium efficiently while dramatically reducing water consumption compared to conventional methods. This optimization aims to achieve lithium recovery rates exceeding 90% while returning over 95% of process water to source aquifers, maintaining hydrological balance in sensitive ecosystems.

Secondary objectives include reducing energy requirements, minimizing chemical inputs, shortening processing times, and developing systems adaptable to varying brine chemistries across different geographical locations. These improvements would enable DLE to become economically competitive with traditional extraction methods while offering superior environmental performance.

The technological goals extend to developing closed-loop systems that effectively manage not only water but also other valuable minerals present in brines. This holistic approach seeks to transform lithium extraction from a water-intensive, environmentally problematic process into a sustainable operation that contributes positively to resource stewardship while meeting the growing global demand for battery materials.

As the lithium market continues its projected growth trajectory, with demand expected to increase by 500% by 2030, optimizing DLE represents not merely a technological challenge but a strategic imperative for ensuring sustainable supply chains for the clean energy transition.

Market Analysis for Water-Efficient Lithium Extraction

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Market projections indicate that lithium demand will increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, representing a compound annual growth rate (CAGR) of 25%. This explosive growth trajectory creates an urgent need for more efficient extraction technologies that minimize environmental impact, particularly water consumption.

Traditional lithium extraction methods, especially evaporative ponds used in South America's "Lithium Triangle" (Argentina, Bolivia, and Chile), consume between 500,000 to 2 million gallons of water per ton of lithium produced. This intensive water usage has created significant environmental concerns and social conflicts in regions already experiencing water scarcity. Market research indicates that approximately 65% of global lithium production currently relies on these water-intensive methods.

The market for water-efficient Direct Lithium Extraction (DLE) technologies is emerging as a high-growth segment within the broader lithium supply chain. Current market size estimates for DLE technologies range from $250 million to $400 million, but this is projected to reach $1.5 billion by 2028 as adoption accelerates. Early adopters of these technologies report water consumption reductions of 50-90% compared to traditional methods, creating both environmental and economic advantages.

Regional market analysis reveals varying degrees of interest and investment in water-efficient lithium extraction. North America leads in DLE technology development, with significant investments from both established mining companies and technology startups. The European market shows strong demand for sustainably sourced lithium, with automotive manufacturers increasingly requiring environmental impact disclosures from suppliers. In Asia, particularly China, the focus remains predominantly on securing lithium supply regardless of extraction method, though this is gradually shifting as environmental regulations tighten.

End-user segmentation indicates that premium EV manufacturers are willing to pay 5-15% price premiums for lithium sourced through water-efficient methods, creating market incentives for technology adoption. Battery manufacturers are increasingly incorporating environmental impact metrics into supplier evaluation criteria, with water usage emerging as a key performance indicator.

Market barriers include the higher capital expenditure requirements for DLE technologies compared to traditional methods, technological uncertainties regarding long-term performance, and resistance from established industry players with significant investments in conventional extraction infrastructure. However, regulatory trends globally are increasingly favoring water-efficient technologies through permitting advantages and potential tax incentives, creating market tailwinds for innovative extraction approaches.

Traditional lithium extraction methods, especially evaporative ponds used in South America's "Lithium Triangle" (Argentina, Bolivia, and Chile), consume between 500,000 to 2 million gallons of water per ton of lithium produced. This intensive water usage has created significant environmental concerns and social conflicts in regions already experiencing water scarcity. Market research indicates that approximately 65% of global lithium production currently relies on these water-intensive methods.

The market for water-efficient Direct Lithium Extraction (DLE) technologies is emerging as a high-growth segment within the broader lithium supply chain. Current market size estimates for DLE technologies range from $250 million to $400 million, but this is projected to reach $1.5 billion by 2028 as adoption accelerates. Early adopters of these technologies report water consumption reductions of 50-90% compared to traditional methods, creating both environmental and economic advantages.

Regional market analysis reveals varying degrees of interest and investment in water-efficient lithium extraction. North America leads in DLE technology development, with significant investments from both established mining companies and technology startups. The European market shows strong demand for sustainably sourced lithium, with automotive manufacturers increasingly requiring environmental impact disclosures from suppliers. In Asia, particularly China, the focus remains predominantly on securing lithium supply regardless of extraction method, though this is gradually shifting as environmental regulations tighten.

End-user segmentation indicates that premium EV manufacturers are willing to pay 5-15% price premiums for lithium sourced through water-efficient methods, creating market incentives for technology adoption. Battery manufacturers are increasingly incorporating environmental impact metrics into supplier evaluation criteria, with water usage emerging as a key performance indicator.

Market barriers include the higher capital expenditure requirements for DLE technologies compared to traditional methods, technological uncertainties regarding long-term performance, and resistance from established industry players with significant investments in conventional extraction infrastructure. However, regulatory trends globally are increasingly favoring water-efficient technologies through permitting advantages and potential tax incentives, creating market tailwinds for innovative extraction approaches.

Current DLE Challenges and Water Conservation Barriers

Direct Lithium Extraction (DLE) technologies face significant challenges in water conservation despite their promise as more sustainable alternatives to traditional evaporation methods. Current DLE processes typically require substantial water inputs for the regeneration of sorbents and processing of lithium-rich solutions, resulting in water consumption rates that can reach 10-15 cubic meters per ton of lithium carbonate equivalent (LCE) produced.

A primary barrier to water conservation in DLE operations is the inherent trade-off between extraction efficiency and water usage. Higher lithium recovery rates often correlate with increased water requirements, creating a technical dilemma for operators seeking to optimize both metrics simultaneously. This relationship is particularly problematic in arid regions where lithium resources are abundant but water is scarce.

The chemistry of lithium-selective sorbents presents another significant challenge. Current ion-exchange materials and adsorbents typically require multiple washing cycles with fresh water to remove impurities and regenerate binding sites. These washing processes account for approximately 30-40% of total water consumption in DLE operations, yet few commercially viable alternatives exist that maintain extraction performance while reducing water needs.

Brine management represents a third critical barrier. After lithium extraction, the remaining brine contains concentrated levels of other minerals and potential contaminants. Responsible disposal or reinjection of this brine requires additional water for dilution or treatment, creating a cascading water demand that is often overlooked in efficiency calculations.

Energy-water nexus considerations further complicate water conservation efforts. Many DLE technologies employ energy-intensive processes such as membrane filtration or electrodialysis, which indirectly increase water footprints through cooling requirements and operational needs. This hidden water consumption can add 15-20% to the total water balance of a DLE facility.

Scale formation and equipment fouling constitute persistent operational challenges that impact water usage. Mineral precipitation on equipment surfaces necessitates frequent cleaning cycles, each consuming additional water resources. Current anti-scaling technologies offer only partial solutions and often introduce chemical additives that may complicate downstream water recovery efforts.

Regulatory frameworks present non-technical barriers to water conservation innovation. In many jurisdictions, water rights and discharge permits are structured around traditional extraction methods, creating compliance challenges for novel DLE approaches that might otherwise achieve better water efficiency through closed-loop systems or alternative water sources.

The economic incentive structure of the lithium market also impedes water conservation progress. With lithium prices fluctuating significantly, producers prioritize production volume and speed over resource efficiency, particularly when water costs are artificially low or externalized. This market dynamic has historically limited investment in water-saving DLE technologies despite their long-term sustainability benefits.

A primary barrier to water conservation in DLE operations is the inherent trade-off between extraction efficiency and water usage. Higher lithium recovery rates often correlate with increased water requirements, creating a technical dilemma for operators seeking to optimize both metrics simultaneously. This relationship is particularly problematic in arid regions where lithium resources are abundant but water is scarce.

The chemistry of lithium-selective sorbents presents another significant challenge. Current ion-exchange materials and adsorbents typically require multiple washing cycles with fresh water to remove impurities and regenerate binding sites. These washing processes account for approximately 30-40% of total water consumption in DLE operations, yet few commercially viable alternatives exist that maintain extraction performance while reducing water needs.

Brine management represents a third critical barrier. After lithium extraction, the remaining brine contains concentrated levels of other minerals and potential contaminants. Responsible disposal or reinjection of this brine requires additional water for dilution or treatment, creating a cascading water demand that is often overlooked in efficiency calculations.

Energy-water nexus considerations further complicate water conservation efforts. Many DLE technologies employ energy-intensive processes such as membrane filtration or electrodialysis, which indirectly increase water footprints through cooling requirements and operational needs. This hidden water consumption can add 15-20% to the total water balance of a DLE facility.

Scale formation and equipment fouling constitute persistent operational challenges that impact water usage. Mineral precipitation on equipment surfaces necessitates frequent cleaning cycles, each consuming additional water resources. Current anti-scaling technologies offer only partial solutions and often introduce chemical additives that may complicate downstream water recovery efforts.

Regulatory frameworks present non-technical barriers to water conservation innovation. In many jurisdictions, water rights and discharge permits are structured around traditional extraction methods, creating compliance challenges for novel DLE approaches that might otherwise achieve better water efficiency through closed-loop systems or alternative water sources.

The economic incentive structure of the lithium market also impedes water conservation progress. With lithium prices fluctuating significantly, producers prioritize production volume and speed over resource efficiency, particularly when water costs are artificially low or externalized. This market dynamic has historically limited investment in water-saving DLE technologies despite their long-term sustainability benefits.

Current Water-Saving DLE Solutions

01 Water recycling systems in DLE processes

Water recycling systems are implemented in Direct Lithium Extraction (DLE) processes to minimize water loss. These systems capture, treat, and reuse water from various stages of the extraction process. By implementing closed-loop water systems, operators can significantly reduce freshwater consumption and minimize environmental impact. Advanced filtration and purification technologies ensure that recycled water meets the quality requirements for reuse in the extraction process.- Water recycling and conservation systems in DLE processes: Direct Lithium Extraction (DLE) processes can be optimized to reduce water loss through implementation of closed-loop water recycling systems. These systems capture, treat, and reuse process water, significantly reducing freshwater consumption. Advanced filtration, membrane technologies, and evaporation control mechanisms help minimize water losses during extraction operations, making the overall process more environmentally sustainable while maintaining extraction efficiency.

- Membrane-based technologies for water recovery: Specialized membrane technologies are employed in DLE processes to separate lithium from brine while recovering water. These membranes allow selective passage of certain ions while retaining others, enabling efficient water recovery. Forward osmosis, reverse osmosis, and nanofiltration membranes can be integrated into DLE systems to minimize water loss. The recovered water can be reused in the extraction process or returned to the environment, reducing the overall water footprint of lithium production.

- Evaporation reduction techniques for brine pools: Innovative approaches to reduce evaporation in brine pools and reservoirs used in DLE operations include floating covers, chemical additives, and physical barriers. These techniques significantly decrease water loss due to natural evaporation, which is particularly important in arid regions where lithium extraction often occurs. By minimizing evaporative losses, these methods help conserve water resources while maintaining the concentration of lithium in the brine, improving overall extraction efficiency.

- Advanced monitoring and control systems for water management: Sophisticated monitoring and control systems are implemented to track and manage water usage throughout the DLE process. These systems utilize sensors, IoT devices, and AI-driven analytics to detect leaks, optimize water flow, and predict maintenance needs. Real-time monitoring enables immediate response to water loss incidents and helps maintain optimal operating conditions. By precisely controlling water usage at each stage of the extraction process, these systems significantly reduce unnecessary water consumption and losses.

- Alternative solvents and extraction media to reduce water dependency: Research into alternative solvents and extraction media aims to reduce or eliminate water dependency in lithium extraction processes. These include ionic liquids, organic solvents, and solid sorbents that can selectively capture lithium with minimal or no water usage. By developing water-free or water-efficient extraction methods, the industry can significantly reduce water loss concerns. These alternative approaches often offer additional benefits such as higher selectivity for lithium and reduced processing time compared to traditional water-intensive methods.

02 Membrane-based water recovery technologies

Membrane-based technologies are employed to recover water during Direct Lithium Extraction processes. These technologies include reverse osmosis, nanofiltration, and ultrafiltration systems that separate water from lithium-rich solutions. The membranes selectively allow water molecules to pass through while retaining lithium ions and other valuable components. This approach significantly reduces water loss by enabling the recovery and reuse of process water, making the overall extraction process more sustainable.Expand Specific Solutions03 Evaporation control strategies

Evaporation control strategies are implemented to minimize water loss during Direct Lithium Extraction operations. These include the use of covered extraction ponds, floating covers, and enclosed processing systems that prevent water from evaporating into the atmosphere. Additionally, operating in controlled environments with optimized temperature and humidity conditions helps reduce evaporative losses. These strategies are particularly important in arid regions where water resources are scarce and evaporation rates are high.Expand Specific Solutions04 Advanced sorbent materials for efficient extraction

Advanced sorbent materials are developed to improve the efficiency of Direct Lithium Extraction while reducing water consumption. These materials have high selectivity for lithium ions and can be regenerated with minimal water usage. The sorbents enable more efficient lithium recovery from brines, reducing the volume of water needed for processing and minimizing water loss. Some innovative sorbents can operate effectively even with lower-quality water sources, further conserving freshwater resources.Expand Specific Solutions05 Integrated water management systems

Integrated water management systems are implemented to holistically address water loss in Direct Lithium Extraction operations. These systems combine real-time monitoring, predictive analytics, and automated control mechanisms to optimize water usage throughout the extraction process. By integrating water management with overall process control, operators can identify inefficiencies, detect leaks, and implement immediate corrective actions. These systems often incorporate weather forecasting to anticipate environmental conditions that might affect water consumption and loss.Expand Specific Solutions

Key Industry Players in DLE Innovation

The direct lithium extraction (DLE) market is in an early growth phase, characterized by rapid technological innovation and increasing commercial deployment. The global market size is projected to expand significantly due to rising lithium demand for electric vehicle batteries and energy storage systems. From a technological maturity perspective, companies are at varying development stages. Industry leaders like Lilac Solutions and Energy Exploration Technologies have developed advanced selective extraction technologies that significantly reduce water consumption compared to traditional evaporation methods. Established players such as POSCO Holdings and Schlumberger are leveraging their industrial expertise to scale DLE solutions, while research institutions including the Chinese Academy of Sciences and Central South University are advancing fundamental extraction science. Newer entrants like Adionics, Pure Lithium, and Watercycle Technologies are introducing innovative approaches focused specifically on water conservation in the extraction process.

Lilac Solutions, Inc.

Technical Solution: Lilac Solutions has developed an ion-exchange technology platform specifically designed to optimize Direct Lithium Extraction while minimizing water loss. Their proprietary ceramic ion-exchange beads selectively absorb lithium from brine solutions while leaving other elements behind. The process operates in a closed-loop system where over 98% of water is returned to the source aquifer, dramatically reducing water consumption compared to traditional evaporation ponds. Lilac's technology enables lithium recovery in hours rather than months, with their modular system design allowing for scalable deployment across various brine resources. The company's ion-exchange material demonstrates exceptional durability with thousands of absorption/desorption cycles without significant degradation, and their process operates at ambient temperature and pressure, further reducing energy requirements and environmental impact.

Strengths: Superior water efficiency with 98%+ water return to source; rapid extraction timeframe (hours vs months); modular and scalable system design; selective lithium extraction with minimal impurities; operates at ambient conditions reducing energy requirements. Weaknesses: Requires specialized ion-exchange materials that may have high initial capital costs; technology still scaling to commercial production levels; performance may vary depending on specific brine chemistry.

Evove Ltd.

Technical Solution: Evove has developed advanced filtration technology that can be applied to Direct Lithium Extraction processes to minimize water loss. Their Separonics™ platform utilizes precision-engineered membranes with tunable nanoscale pores that can selectively filter lithium ions while rejecting contaminants. The company's approach combines 3D printing and advanced materials science to create membranes specifically designed for lithium extraction applications. Evove's filtration systems operate in a closed-loop configuration that enables water recycling rates exceeding 95%, dramatically reducing freshwater requirements compared to conventional methods. Their technology addresses membrane fouling issues through specialized surface treatments and flow patterns, extending operational lifetimes and maintaining consistent performance. The modular design allows for scalable implementation across various brine resources, with their systems demonstrating significant reductions in both water consumption and energy usage compared to traditional evaporation-based extraction.

Strengths: Precision-engineered membranes with tunable selectivity; high water recycling capability; reduced fouling compared to conventional membranes; modular and scalable design; lower energy consumption than traditional methods. Weaknesses: May require pretreatment for certain brine compositions; higher initial capital costs; technology still being optimized for specific lithium extraction applications; membrane replacement costs over operational lifetime.

Critical Patents in Water-Efficient Lithium Extraction

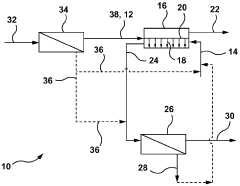

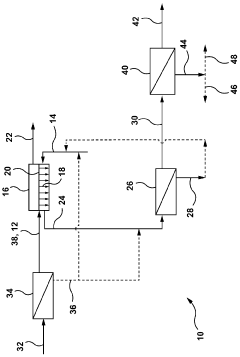

Lithium extraction method

PatentWO2025137291A1

Innovation

- A process combining separation technologies such as lithium adsorbents, nanofiltration, and reverse osmosis to selectively extract lithium from brine solutions with reduced energy consumption and improved water utilization.

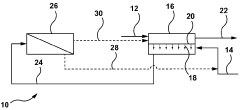

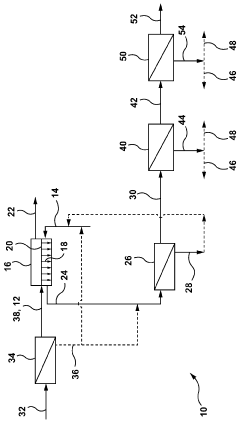

Methods of processing brine comprising lithium

PatentWO2023200653A1

Innovation

- A method involving a combination of forward osmosis (FO) and nanofiltration (NF) processes, where a feed brine and draw brine are processed through multiple FO and NF modules to concentrate lithium, reduce osmotic pressure, and remove divalent ions, allowing for the treatment of high TDS brines and recovery of lithium that would otherwise be unrecoverable.

Environmental Impact Assessment

Direct Lithium Extraction (DLE) technologies present significant environmental implications that must be thoroughly assessed. While traditional lithium extraction methods like evaporation ponds consume massive water volumes in water-stressed regions, DLE promises substantial water conservation benefits. However, comprehensive environmental impact assessment reveals several critical considerations beyond water usage alone.

Water conservation achievements through optimized DLE systems demonstrate potential reductions of 50-90% compared to conventional methods, particularly significant in arid lithium-rich regions like the "Lithium Triangle" spanning Chile, Argentina, and Bolivia. These improvements stem from closed-loop systems and advanced selective adsorption materials that minimize freshwater requirements.

Despite these improvements, DLE operations still generate wastewater containing various contaminants including residual chemicals, heavy metals, and concentrated brine solutions. The disposal and treatment of these byproducts require careful management to prevent soil contamination and groundwater pollution. Advanced treatment technologies including membrane filtration, chemical precipitation, and ion exchange systems are being implemented to mitigate these risks.

Energy consumption represents another significant environmental factor, as most DLE processes require substantial electricity for pumping, heating, and regeneration cycles. Life cycle assessments indicate that without renewable energy integration, the carbon footprint of some DLE operations may offset their water conservation benefits. Projects incorporating solar, geothermal, or wind power demonstrate more favorable overall environmental profiles.

Land disturbance from DLE facilities, while generally smaller than evaporation ponds, still impacts local ecosystems. Site selection and facility design must consider biodiversity protection, particularly in sensitive desert environments where many lithium deposits exist. Restoration planning and minimized footprint designs are becoming standard practice among leading operators.

Groundwater dynamics present perhaps the most complex environmental challenge, as extraction can alter subsurface hydrological patterns even with water-efficient technologies. Monitoring systems tracking aquifer levels, flow patterns, and water quality are essential to prevent long-term ecological damage. Several projects now implement real-time sensor networks and predictive modeling to anticipate and mitigate potential impacts.

Regulatory frameworks governing DLE environmental impacts vary significantly across jurisdictions, creating challenges for standardized assessment methodologies. Industry leaders are increasingly adopting voluntary environmental standards exceeding local requirements, recognizing that sustainable practices ultimately determine social license to operate and long-term project viability.

Water conservation achievements through optimized DLE systems demonstrate potential reductions of 50-90% compared to conventional methods, particularly significant in arid lithium-rich regions like the "Lithium Triangle" spanning Chile, Argentina, and Bolivia. These improvements stem from closed-loop systems and advanced selective adsorption materials that minimize freshwater requirements.

Despite these improvements, DLE operations still generate wastewater containing various contaminants including residual chemicals, heavy metals, and concentrated brine solutions. The disposal and treatment of these byproducts require careful management to prevent soil contamination and groundwater pollution. Advanced treatment technologies including membrane filtration, chemical precipitation, and ion exchange systems are being implemented to mitigate these risks.

Energy consumption represents another significant environmental factor, as most DLE processes require substantial electricity for pumping, heating, and regeneration cycles. Life cycle assessments indicate that without renewable energy integration, the carbon footprint of some DLE operations may offset their water conservation benefits. Projects incorporating solar, geothermal, or wind power demonstrate more favorable overall environmental profiles.

Land disturbance from DLE facilities, while generally smaller than evaporation ponds, still impacts local ecosystems. Site selection and facility design must consider biodiversity protection, particularly in sensitive desert environments where many lithium deposits exist. Restoration planning and minimized footprint designs are becoming standard practice among leading operators.

Groundwater dynamics present perhaps the most complex environmental challenge, as extraction can alter subsurface hydrological patterns even with water-efficient technologies. Monitoring systems tracking aquifer levels, flow patterns, and water quality are essential to prevent long-term ecological damage. Several projects now implement real-time sensor networks and predictive modeling to anticipate and mitigate potential impacts.

Regulatory frameworks governing DLE environmental impacts vary significantly across jurisdictions, creating challenges for standardized assessment methodologies. Industry leaders are increasingly adopting voluntary environmental standards exceeding local requirements, recognizing that sustainable practices ultimately determine social license to operate and long-term project viability.

Regulatory Framework for Sustainable Lithium Mining

The regulatory landscape for lithium extraction is evolving rapidly as governments worldwide recognize the strategic importance of lithium resources while acknowledging environmental concerns. Current regulatory frameworks vary significantly across major lithium-producing regions, with countries like Chile, Australia, and Argentina implementing different approaches to balance economic benefits with environmental protection. Chile's regulatory system, for instance, requires mining companies to obtain water rights separately from mining concessions, creating a dual-permitting process that addresses water conservation directly.

Environmental impact assessments (EIAs) have become mandatory prerequisites for lithium extraction projects in most jurisdictions, with increasing emphasis on water usage metrics. These assessments typically require detailed analysis of potential impacts on local water tables, surrounding ecosystems, and indigenous communities. The trend toward more stringent water-specific regulations is evident in recent policy updates, with some regions implementing volumetric limits on water extraction per ton of lithium produced.

International standards and certification schemes are emerging as complementary regulatory mechanisms. The Initiative for Responsible Mining Assurance (IRMA) and similar frameworks provide voluntary certification standards that often exceed national regulatory requirements, particularly regarding water stewardship. These standards are increasingly influencing corporate behavior as downstream manufacturers seek responsibly sourced materials for their supply chains.

Water rights allocation represents a particularly complex regulatory challenge in lithium-rich regions, which often coincide with water-scarce environments. Legal frameworks governing water access vary from prior appropriation systems to public ownership models, creating regulatory complexity for Direct Lithium Extraction (DLE) implementation. Some jurisdictions have begun developing lithium-specific regulatory provisions that recognize the unique water challenges associated with extraction technologies.

Emerging regulatory trends include mandatory water recycling targets, requirements for closed-loop systems, and financial guarantees for environmental remediation. Several countries are exploring regulatory incentives for companies deploying water-efficient DLE technologies, including expedited permitting processes and reduced royalty rates for operations demonstrating superior water conservation metrics.

Indigenous rights and consultation requirements constitute another critical regulatory dimension, particularly relevant to water usage in lithium extraction. The UN Declaration on the Rights of Indigenous Peoples and ILO Convention 169 establish international standards for consultation and consent that increasingly influence national regulatory frameworks, especially regarding shared water resources.

Environmental impact assessments (EIAs) have become mandatory prerequisites for lithium extraction projects in most jurisdictions, with increasing emphasis on water usage metrics. These assessments typically require detailed analysis of potential impacts on local water tables, surrounding ecosystems, and indigenous communities. The trend toward more stringent water-specific regulations is evident in recent policy updates, with some regions implementing volumetric limits on water extraction per ton of lithium produced.

International standards and certification schemes are emerging as complementary regulatory mechanisms. The Initiative for Responsible Mining Assurance (IRMA) and similar frameworks provide voluntary certification standards that often exceed national regulatory requirements, particularly regarding water stewardship. These standards are increasingly influencing corporate behavior as downstream manufacturers seek responsibly sourced materials for their supply chains.

Water rights allocation represents a particularly complex regulatory challenge in lithium-rich regions, which often coincide with water-scarce environments. Legal frameworks governing water access vary from prior appropriation systems to public ownership models, creating regulatory complexity for Direct Lithium Extraction (DLE) implementation. Some jurisdictions have begun developing lithium-specific regulatory provisions that recognize the unique water challenges associated with extraction technologies.

Emerging regulatory trends include mandatory water recycling targets, requirements for closed-loop systems, and financial guarantees for environmental remediation. Several countries are exploring regulatory incentives for companies deploying water-efficient DLE technologies, including expedited permitting processes and reduced royalty rates for operations demonstrating superior water conservation metrics.

Indigenous rights and consultation requirements constitute another critical regulatory dimension, particularly relevant to water usage in lithium extraction. The UN Declaration on the Rights of Indigenous Peoples and ILO Convention 169 establish international standards for consultation and consent that increasingly influence national regulatory frameworks, especially regarding shared water resources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!