Direct Lithium Extraction vs Membrane Technology: Cost Comparison

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE and Membrane Technology Background and Objectives

Direct Lithium Extraction (DLE) and membrane technologies represent two significant approaches in the evolving landscape of lithium production. The lithium industry has traditionally relied on evaporation ponds and hard rock mining, methods that are time-consuming, land-intensive, and often environmentally problematic. As global demand for lithium continues to surge, driven primarily by the electric vehicle and energy storage sectors, the need for more efficient and sustainable extraction methods has become increasingly apparent.

DLE technologies emerged in the early 2000s as a potential solution to address the limitations of conventional methods. These technologies aim to selectively extract lithium from brines using various mechanisms such as adsorption, ion exchange, and solvent extraction. The fundamental objective of DLE is to reduce processing time from months to days while minimizing environmental footprint and maximizing recovery rates.

Membrane technologies, on the other hand, have evolved from broader water treatment and desalination applications. These systems utilize selective barriers that allow certain ions to pass while blocking others, potentially enabling the concentration and purification of lithium from various sources. The development of specialized membranes for lithium separation represents a significant technological advancement with applications extending beyond traditional brine resources.

Both technologies aim to address several critical industry challenges: reducing water consumption, minimizing land disturbance, increasing lithium recovery rates, and enabling extraction from previously uneconomical resources. Additionally, these approaches seek to decrease production costs and carbon footprints associated with lithium production, aligning with global sustainability goals.

The technical evolution of these methods has accelerated significantly since 2015, with numerous startups and established companies investing in pilot plants and demonstration facilities. This acceleration coincides with projections indicating that lithium demand could increase by 400-800% by 2030, creating urgency for more efficient production methods.

The comparative cost structure between DLE and membrane technologies represents a crucial factor in determining their commercial viability and potential for industry adoption. Capital expenditure, operational costs, energy requirements, and scalability all factor into this economic equation, with regional variations in resource characteristics further complicating the analysis.

This technical assessment aims to provide a comprehensive comparison of these competing approaches, examining their respective technological maturity, cost structures, and potential for addressing the growing global demand for lithium in an economically viable and environmentally responsible manner.

DLE technologies emerged in the early 2000s as a potential solution to address the limitations of conventional methods. These technologies aim to selectively extract lithium from brines using various mechanisms such as adsorption, ion exchange, and solvent extraction. The fundamental objective of DLE is to reduce processing time from months to days while minimizing environmental footprint and maximizing recovery rates.

Membrane technologies, on the other hand, have evolved from broader water treatment and desalination applications. These systems utilize selective barriers that allow certain ions to pass while blocking others, potentially enabling the concentration and purification of lithium from various sources. The development of specialized membranes for lithium separation represents a significant technological advancement with applications extending beyond traditional brine resources.

Both technologies aim to address several critical industry challenges: reducing water consumption, minimizing land disturbance, increasing lithium recovery rates, and enabling extraction from previously uneconomical resources. Additionally, these approaches seek to decrease production costs and carbon footprints associated with lithium production, aligning with global sustainability goals.

The technical evolution of these methods has accelerated significantly since 2015, with numerous startups and established companies investing in pilot plants and demonstration facilities. This acceleration coincides with projections indicating that lithium demand could increase by 400-800% by 2030, creating urgency for more efficient production methods.

The comparative cost structure between DLE and membrane technologies represents a crucial factor in determining their commercial viability and potential for industry adoption. Capital expenditure, operational costs, energy requirements, and scalability all factor into this economic equation, with regional variations in resource characteristics further complicating the analysis.

This technical assessment aims to provide a comprehensive comparison of these competing approaches, examining their respective technological maturity, cost structures, and potential for addressing the growing global demand for lithium in an economically viable and environmentally responsible manner.

Market Analysis for Lithium Extraction Solutions

The global lithium extraction market is experiencing unprecedented growth, driven primarily by the expanding electric vehicle (EV) industry and renewable energy storage systems. Current market valuations place the lithium extraction sector at approximately $4 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 14.8% through 2030, potentially reaching $12.6 billion. This remarkable expansion underscores the critical importance of efficient and cost-effective lithium extraction technologies.

Direct Lithium Extraction (DLE) and membrane technologies represent two distinct approaches competing for market dominance. DLE solutions currently account for about 10% of global lithium production but are gaining significant traction due to their reduced environmental footprint and accelerated production timelines. Industry analysts predict DLE market share could reach 25% by 2030, representing a substantial shift in extraction methodologies.

Membrane technologies, while less established in commercial applications, are attracting considerable investment with over $300 million in venture capital funding allocated to membrane-based lithium extraction startups in the past three years. This emerging technology segment is expected to capture 5-8% of the market by 2028, with growth contingent upon technological maturation and demonstration of cost advantages.

Regional market dynamics reveal interesting patterns, with North America leading DLE adoption due to substantial lithium brine resources in Nevada and Arkansas. Asian markets, particularly China and South Korea, are heavily investing in membrane technology development, leveraging their established expertise in membrane manufacturing for other industries. Latin America, home to the "Lithium Triangle" (Argentina, Bolivia, and Chile), represents the largest potential market for both technologies, with several pilot projects currently underway.

Customer segmentation analysis indicates that large mining corporations prefer DLE technologies due to their scalability and compatibility with existing operations. Meanwhile, newer market entrants and technology-focused companies are more likely to adopt membrane solutions, attracted by their potential for superior selectivity and reduced water consumption.

Price sensitivity varies significantly across market segments. Traditional lithium producers operating at scale demonstrate high price sensitivity, requiring new technologies to demonstrate clear cost advantages over conventional methods. Conversely, companies focused on ESG (Environmental, Social, and Governance) metrics show greater willingness to adopt higher-cost solutions if they deliver substantial environmental benefits, particularly regarding water usage and land disturbance.

Direct Lithium Extraction (DLE) and membrane technologies represent two distinct approaches competing for market dominance. DLE solutions currently account for about 10% of global lithium production but are gaining significant traction due to their reduced environmental footprint and accelerated production timelines. Industry analysts predict DLE market share could reach 25% by 2030, representing a substantial shift in extraction methodologies.

Membrane technologies, while less established in commercial applications, are attracting considerable investment with over $300 million in venture capital funding allocated to membrane-based lithium extraction startups in the past three years. This emerging technology segment is expected to capture 5-8% of the market by 2028, with growth contingent upon technological maturation and demonstration of cost advantages.

Regional market dynamics reveal interesting patterns, with North America leading DLE adoption due to substantial lithium brine resources in Nevada and Arkansas. Asian markets, particularly China and South Korea, are heavily investing in membrane technology development, leveraging their established expertise in membrane manufacturing for other industries. Latin America, home to the "Lithium Triangle" (Argentina, Bolivia, and Chile), represents the largest potential market for both technologies, with several pilot projects currently underway.

Customer segmentation analysis indicates that large mining corporations prefer DLE technologies due to their scalability and compatibility with existing operations. Meanwhile, newer market entrants and technology-focused companies are more likely to adopt membrane solutions, attracted by their potential for superior selectivity and reduced water consumption.

Price sensitivity varies significantly across market segments. Traditional lithium producers operating at scale demonstrate high price sensitivity, requiring new technologies to demonstrate clear cost advantages over conventional methods. Conversely, companies focused on ESG (Environmental, Social, and Governance) metrics show greater willingness to adopt higher-cost solutions if they deliver substantial environmental benefits, particularly regarding water usage and land disturbance.

Technical Challenges in DLE and Membrane Technologies

Despite significant advancements in both Direct Lithium Extraction (DLE) and membrane technologies, several technical challenges persist that impact their cost-effectiveness and widespread adoption. These challenges represent critical barriers that researchers and industry players must overcome to make lithium extraction more economically viable and environmentally sustainable.

For DLE technologies, selectivity remains a primary challenge. Current sorbents and ion exchange materials often struggle to selectively capture lithium ions while excluding competing ions such as sodium, magnesium, and calcium that are abundant in brine resources. This low selectivity necessitates additional purification steps, significantly increasing operational costs and reducing overall efficiency.

Durability of DLE materials presents another substantial hurdle. The harsh chemical environments of lithium-rich brines, which often contain high concentrations of various salts and exhibit extreme pH conditions, accelerate the degradation of sorbent materials. This degradation reduces the operational lifespan of extraction systems and increases replacement frequency, directly impacting the economic viability of DLE operations.

Membrane technologies face their own set of technical limitations. Fouling and scaling represent persistent issues that reduce membrane performance over time. Mineral deposits accumulate on membrane surfaces during operation, particularly in high-salinity environments, necessitating frequent cleaning or replacement cycles that increase maintenance costs and operational downtime.

Energy consumption poses a significant challenge for membrane-based systems, particularly for electrodialysis and reverse osmosis approaches. The electrical energy required to drive ion transport across membranes contributes substantially to operational expenses, making energy efficiency a critical factor in cost comparisons between different extraction methods.

Water recovery rates also impact the economic feasibility of membrane technologies. Current systems often struggle to achieve high recovery rates without compromising membrane integrity or increasing energy requirements, resulting in trade-offs between water conservation and operational costs.

Both technologies face scalability challenges when transitioning from laboratory demonstrations to industrial-scale operations. The performance metrics achieved in controlled environments often deteriorate when scaled up, due to flow distribution issues, pressure drop considerations, and heat transfer limitations. These scaling factors can significantly alter the economic calculations that determine technology selection.

Material costs represent another shared challenge. Advanced sorbents for DLE and specialized membranes both require sophisticated manufacturing processes and often incorporate expensive materials. The development of lower-cost alternatives with comparable performance characteristics remains an active area of research that could substantially impact the cost comparison between these competing technologies.

For DLE technologies, selectivity remains a primary challenge. Current sorbents and ion exchange materials often struggle to selectively capture lithium ions while excluding competing ions such as sodium, magnesium, and calcium that are abundant in brine resources. This low selectivity necessitates additional purification steps, significantly increasing operational costs and reducing overall efficiency.

Durability of DLE materials presents another substantial hurdle. The harsh chemical environments of lithium-rich brines, which often contain high concentrations of various salts and exhibit extreme pH conditions, accelerate the degradation of sorbent materials. This degradation reduces the operational lifespan of extraction systems and increases replacement frequency, directly impacting the economic viability of DLE operations.

Membrane technologies face their own set of technical limitations. Fouling and scaling represent persistent issues that reduce membrane performance over time. Mineral deposits accumulate on membrane surfaces during operation, particularly in high-salinity environments, necessitating frequent cleaning or replacement cycles that increase maintenance costs and operational downtime.

Energy consumption poses a significant challenge for membrane-based systems, particularly for electrodialysis and reverse osmosis approaches. The electrical energy required to drive ion transport across membranes contributes substantially to operational expenses, making energy efficiency a critical factor in cost comparisons between different extraction methods.

Water recovery rates also impact the economic feasibility of membrane technologies. Current systems often struggle to achieve high recovery rates without compromising membrane integrity or increasing energy requirements, resulting in trade-offs between water conservation and operational costs.

Both technologies face scalability challenges when transitioning from laboratory demonstrations to industrial-scale operations. The performance metrics achieved in controlled environments often deteriorate when scaled up, due to flow distribution issues, pressure drop considerations, and heat transfer limitations. These scaling factors can significantly alter the economic calculations that determine technology selection.

Material costs represent another shared challenge. Advanced sorbents for DLE and specialized membranes both require sophisticated manufacturing processes and often incorporate expensive materials. The development of lower-cost alternatives with comparable performance characteristics remains an active area of research that could substantially impact the cost comparison between these competing technologies.

Current Cost Structures of DLE vs Membrane Technologies

01 Membrane-based direct lithium extraction technologies

Membrane technologies are increasingly used in direct lithium extraction (DLE) processes due to their selectivity and efficiency. These technologies utilize specialized membranes that allow lithium ions to pass through while blocking other elements, resulting in higher purity lithium products. The cost factors include membrane materials, durability, fouling resistance, and replacement frequency. Advanced membrane designs can significantly reduce operational costs by improving selectivity and reducing energy consumption in the extraction process.- Cost-effective membrane technologies for lithium extraction: Various membrane technologies have been developed to reduce the cost of direct lithium extraction processes. These include specialized ion-selective membranes that can efficiently separate lithium from other elements in brine solutions. The cost-effectiveness is achieved through improved membrane materials that offer higher selectivity, longer operational lifetimes, and reduced energy consumption during the extraction process. These advancements significantly lower the overall operational expenses compared to traditional extraction methods.

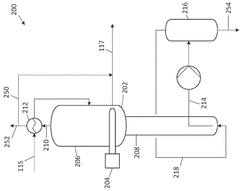

- Economic aspects of electrochemical lithium extraction systems: Electrochemical systems for direct lithium extraction offer economic advantages through reduced chemical consumption and energy requirements. These systems utilize specialized electrodes and membrane configurations to selectively capture lithium ions from brines and other sources. The cost analysis includes considerations for electrode materials, membrane durability, energy consumption, and system maintenance. Recent innovations have focused on improving the economic viability by enhancing the efficiency of electrochemical processes and reducing the associated capital and operational expenditures.

- Adsorption-based lithium extraction cost factors: Adsorption-based technologies for lithium extraction involve specialized materials that selectively capture lithium ions from solution. The cost structure of these systems depends on the adsorbent material properties, regeneration requirements, and operational parameters. Recent developments have focused on creating more durable and selective adsorbents that can be regenerated multiple times, thereby reducing the overall cost of the extraction process. The economic analysis includes considerations for adsorbent production, system design, and operational efficiency.

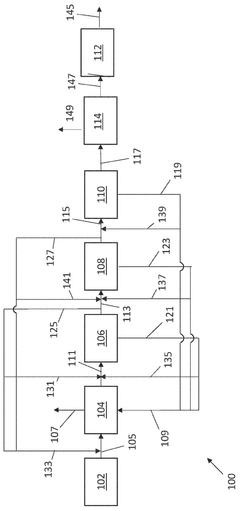

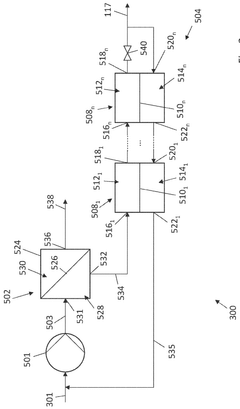

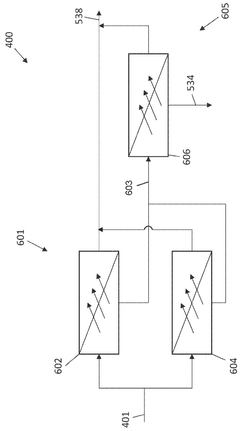

- Integrated process systems for cost optimization: Integrated process systems combine multiple technologies to optimize the cost-effectiveness of direct lithium extraction. These systems may incorporate membrane filtration, adsorption, and electrochemical processes in sequence to maximize lithium recovery while minimizing energy and chemical consumption. The economic benefits include reduced waste generation, improved resource utilization, and enhanced process efficiency. Cost optimization is achieved through careful process integration and control strategies that balance capital investment against operational expenses.

- Scaling and commercialization cost considerations: The scaling and commercialization of direct lithium extraction technologies involve significant cost considerations related to equipment sizing, infrastructure requirements, and market factors. Economic analyses focus on the capital expenditure needed for commercial-scale implementation and the operational costs associated with maintaining consistent production. Factors affecting commercialization costs include location-specific variables, regulatory compliance, supply chain logistics, and market demand. Recent innovations have addressed these challenges by developing modular systems that can be scaled according to production needs while maintaining cost efficiency.

02 Cost optimization in DLE through process integration

Process integration approaches can substantially reduce the overall cost of direct lithium extraction operations. By combining membrane filtration with other technologies such as adsorption or ion exchange, the efficiency of lithium recovery can be improved while reducing reagent consumption and waste generation. Integrated systems that optimize energy usage, water recycling, and process automation help minimize operational expenses. These integrated approaches can lower capital expenditure by reducing equipment redundancy and footprint requirements.Expand Specific Solutions03 Economic analysis of novel sorbent materials for lithium extraction

Novel sorbent materials represent a significant cost component in modern DLE systems. These materials, designed to selectively capture lithium ions from brines and other sources, vary widely in cost based on their composition, manufacturing complexity, and reusability. Advanced sorbents with higher selectivity for lithium can justify their higher initial cost through improved extraction efficiency and reduced processing steps. The economic viability of these materials depends on their cycle life, regeneration requirements, and selectivity in the presence of competing ions.Expand Specific Solutions04 Energy consumption and sustainability factors in DLE cost analysis

Energy consumption represents a major operational cost in direct lithium extraction processes. Membrane-based systems typically require energy for pumping, pressure maintenance, and in some cases, electrical potential application. Innovations focused on reducing energy requirements include low-pressure membrane operations, energy recovery systems, and renewable energy integration. The sustainability aspects of DLE technologies, including water usage efficiency and environmental impact, increasingly factor into total cost assessments as regulatory requirements become more stringent.Expand Specific Solutions05 Scaling and commercialization challenges affecting DLE economics

The transition from laboratory-scale to commercial-scale direct lithium extraction operations presents significant cost challenges. Scaling factors affect membrane performance, system reliability, and maintenance requirements. Commercial viability depends on achieving consistent extraction rates and product quality while managing variable feedstock conditions. Capital costs for full-scale implementation include specialized equipment, infrastructure development, and process control systems. The economic assessment must account for production ramp-up periods, market volatility, and supply chain considerations for critical components.Expand Specific Solutions

Key Industry Players in Lithium Extraction Market

Direct Lithium Extraction (DLE) and membrane technology are emerging as competitive approaches in the lithium extraction market, which is currently in a growth phase with expanding market size driven by electric vehicle battery demand. The technology maturity landscape shows varied development stages among key players. Energy Exploration Technologies has developed a suite of DLE technologies adaptable to various brine types, while Evove specializes in advanced graphene-based membranes that reduce environmental impact. Established companies like Schlumberger and Sinopec are leveraging their industrial expertise to scale these technologies, while International Battery Metals and Vulcan Energy are focusing on zero-carbon lithium production methods. Academic institutions including The University of Manchester and KAUST are contributing fundamental research, indicating the field remains in active development with significant cost optimization potential.

Energy Exploration Technologies, Inc.

Technical Solution: EnergyX has developed a proprietary LiTAS™ (Lithium Ionic Transport and Separation) platform based on mixed matrix membranes (MMMs) for Direct Lithium Extraction (DLE). Their technology utilizes solid-state materials with lithium-selective transport channels that allow for highly efficient extraction directly from brine resources. The system operates at ambient temperature and pressure, requiring minimal pre-treatment of brine. EnergyX's approach combines membrane technology with DLE principles, achieving lithium recovery rates of over 90% in field tests compared to traditional evaporation pond methods that typically recover only 30-50%. The company claims their process reduces water consumption by approximately 90% versus conventional methods while operating at costs estimated to be 30-50% lower than traditional extraction. Their modular design allows for scalable implementation across various brine compositions and concentrations.

Strengths: High selectivity for lithium ions with minimal contamination; significantly reduced water usage; modular and scalable design suitable for various brine sources; lower energy requirements than conventional methods. Weaknesses: Technology still being scaled to commercial levels; performance may vary with different brine chemistries; requires initial capital investment that may be higher than some competing DLE technologies.

Evove Ltd.

Technical Solution: Evove has pioneered advanced filtration technology specifically designed for lithium extraction applications through their Separonics™ platform. Their approach utilizes precision-engineered membranes with controlled pore structures at the nanoscale level, enabling highly selective separation of lithium ions from complex brine solutions. The company's membrane technology incorporates 3D-printed precision filters with enhanced fouling resistance, addressing one of the major challenges in membrane-based lithium extraction. Evove's system operates at lower pressures than conventional membrane processes, reducing energy consumption by approximately 35-40%. Their technology achieves lithium concentration factors of 10-50x from initial brine concentrations while maintaining high recovery rates above 85%. The company has demonstrated cost advantages through reduced energy requirements, minimal chemical usage, and extended membrane lifespans that can reach 3-5 years compared to industry standards of 1-2 years for conventional membranes in harsh brine environments.

Strengths: Superior fouling resistance extending operational lifetime; precision-engineered selectivity for lithium ions; lower energy consumption than conventional membrane systems; adaptable to various brine compositions. Weaknesses: May require specific pre-treatment depending on brine chemistry; higher initial capital costs compared to some conventional methods; technology still being validated at commercial scale for different brine sources.

Critical Patents and Innovations in Lithium Extraction

Process and product

PatentPendingUS20250161879A1

Innovation

- The process involves contacting an aqueous lithium solution with a lithium sorbent to absorb lithium, followed by separation of the loaded sorbent and depleted solution, and subsequent treatment to regenerate the sorbent. This process utilizes pH control to maintain the lithium depleted solution at a pH of about 3 to 7 and employs ultrafiltration or nanofiltration membranes for separation.

A method of recovering lithium from a lithium source

PatentWO2025117953A1

Innovation

- The method involves direct lithium extraction using techniques such as electrochemical separation, solvent extraction, ion withdrawal, or membrane separation, followed by purification, concentration, and removal of monovalent impurities to yield a purified lithium concentrate.

Environmental Impact Assessment of Extraction Technologies

The environmental impact of lithium extraction technologies represents a critical dimension in evaluating their overall sustainability and long-term viability. Direct Lithium Extraction (DLE) and membrane technologies present distinctly different environmental footprints that warrant comprehensive assessment.

DLE technologies generally demonstrate reduced land disturbance compared to traditional evaporation ponds, which can span thousands of acres. The spatial efficiency of DLE installations translates to significantly lower habitat disruption and ecosystem fragmentation in sensitive brine-rich regions such as the Lithium Triangle in South America.

Water consumption metrics reveal substantial differences between these technologies. Conventional evaporation methods consume approximately 500,000 gallons of water per ton of lithium produced, whereas advanced DLE systems can reduce this figure by 50-90%. Membrane technologies further optimize water efficiency through selective ion transport mechanisms that minimize freshwater requirements and enable potential water recovery.

Chemical usage patterns also diverge significantly. DLE typically employs selective adsorbents or ion exchange materials that can be regenerated, though regeneration processes often require acids or bases. Membrane technologies generally utilize fewer harsh chemicals but may require specific cleaning compounds to prevent fouling and scaling, which must be properly managed to prevent environmental contamination.

Carbon footprint analysis indicates that DLE processes consume 5-15 MWh of energy per ton of lithium carbonate equivalent (LCE), while membrane technologies typically range from 4-12 MWh per ton LCE. These energy requirements translate to varying greenhouse gas emissions depending on regional energy sources, with renewable-powered operations demonstrating substantially lower climate impacts.

Waste management considerations reveal that DLE produces concentrated brine streams that require responsible disposal or further processing. Membrane technologies generate spent membranes that present end-of-life disposal challenges, though emerging recycling methods show promise for reducing this impact.

Groundwater and aquifer impacts remain a significant concern for both technologies. DLE operations can alter local hydrogeology if extraction rates exceed natural recharge, while membrane technologies may present fewer risks to groundwater systems due to their closed-loop potential. Recent monitoring data from pilot projects suggests that properly managed DLE operations can maintain hydrogeological balance when implemented with appropriate safeguards.

Biodiversity conservation outcomes differ markedly between these approaches. The reduced spatial footprint of both technologies compared to evaporation ponds offers improved prospects for habitat preservation, though the specific chemical processes employed must be carefully managed to prevent localized impacts on sensitive species in extraction regions.

DLE technologies generally demonstrate reduced land disturbance compared to traditional evaporation ponds, which can span thousands of acres. The spatial efficiency of DLE installations translates to significantly lower habitat disruption and ecosystem fragmentation in sensitive brine-rich regions such as the Lithium Triangle in South America.

Water consumption metrics reveal substantial differences between these technologies. Conventional evaporation methods consume approximately 500,000 gallons of water per ton of lithium produced, whereas advanced DLE systems can reduce this figure by 50-90%. Membrane technologies further optimize water efficiency through selective ion transport mechanisms that minimize freshwater requirements and enable potential water recovery.

Chemical usage patterns also diverge significantly. DLE typically employs selective adsorbents or ion exchange materials that can be regenerated, though regeneration processes often require acids or bases. Membrane technologies generally utilize fewer harsh chemicals but may require specific cleaning compounds to prevent fouling and scaling, which must be properly managed to prevent environmental contamination.

Carbon footprint analysis indicates that DLE processes consume 5-15 MWh of energy per ton of lithium carbonate equivalent (LCE), while membrane technologies typically range from 4-12 MWh per ton LCE. These energy requirements translate to varying greenhouse gas emissions depending on regional energy sources, with renewable-powered operations demonstrating substantially lower climate impacts.

Waste management considerations reveal that DLE produces concentrated brine streams that require responsible disposal or further processing. Membrane technologies generate spent membranes that present end-of-life disposal challenges, though emerging recycling methods show promise for reducing this impact.

Groundwater and aquifer impacts remain a significant concern for both technologies. DLE operations can alter local hydrogeology if extraction rates exceed natural recharge, while membrane technologies may present fewer risks to groundwater systems due to their closed-loop potential. Recent monitoring data from pilot projects suggests that properly managed DLE operations can maintain hydrogeological balance when implemented with appropriate safeguards.

Biodiversity conservation outcomes differ markedly between these approaches. The reduced spatial footprint of both technologies compared to evaporation ponds offers improved prospects for habitat preservation, though the specific chemical processes employed must be carefully managed to prevent localized impacts on sensitive species in extraction regions.

Scalability and Implementation Considerations

Scaling up Direct Lithium Extraction (DLE) technologies presents different challenges compared to membrane-based systems. DLE technologies typically require significant initial capital investment but offer advantages in terms of modular deployment. These systems can be implemented in phases, allowing companies to start with smaller production capacities and expand as demand increases or as operational experience grows. This scalability feature makes DLE particularly attractive for mining operations in remote locations where traditional evaporation ponds would be impractical or environmentally problematic.

Membrane technologies, while often less capital-intensive initially, face scaling limitations related to membrane fouling and replacement cycles. As systems grow larger, the operational complexity increases exponentially, requiring more sophisticated monitoring and maintenance protocols. However, membrane systems generally have smaller physical footprints than DLE installations of comparable capacity, making them suitable for operations with space constraints.

Implementation considerations for both technologies extend beyond mere technical feasibility. Regulatory compliance represents a significant factor, with DLE technologies often facing fewer environmental hurdles due to their reduced water consumption and land use compared to traditional methods. Membrane technologies may require additional permitting related to waste disposal, particularly in environmentally sensitive areas.

Infrastructure requirements differ substantially between the two approaches. DLE systems typically demand robust power supplies, as energy consumption scales with production volume. Many commercial DLE installations require 50-70 kWh per kilogram of lithium carbonate equivalent produced. Membrane technologies generally have lower energy demands but may require specialized water pre-treatment facilities to prevent premature membrane degradation.

Workforce considerations also impact implementation decisions. DLE technologies increasingly incorporate automation and remote monitoring capabilities, potentially reducing on-site staffing requirements but necessitating specialized technical expertise. Membrane operations typically require more hands-on maintenance and regular intervention, translating to higher ongoing labor costs but potentially lower specialized training requirements.

Time-to-market represents another critical implementation factor. DLE installations can often be commissioned more rapidly than traditional extraction methods, with some modular systems operational within 12-18 months of project initiation. Membrane technologies may offer even faster deployment in certain contexts, particularly for smaller-scale operations, with some systems becoming operational in under 12 months.

Membrane technologies, while often less capital-intensive initially, face scaling limitations related to membrane fouling and replacement cycles. As systems grow larger, the operational complexity increases exponentially, requiring more sophisticated monitoring and maintenance protocols. However, membrane systems generally have smaller physical footprints than DLE installations of comparable capacity, making them suitable for operations with space constraints.

Implementation considerations for both technologies extend beyond mere technical feasibility. Regulatory compliance represents a significant factor, with DLE technologies often facing fewer environmental hurdles due to their reduced water consumption and land use compared to traditional methods. Membrane technologies may require additional permitting related to waste disposal, particularly in environmentally sensitive areas.

Infrastructure requirements differ substantially between the two approaches. DLE systems typically demand robust power supplies, as energy consumption scales with production volume. Many commercial DLE installations require 50-70 kWh per kilogram of lithium carbonate equivalent produced. Membrane technologies generally have lower energy demands but may require specialized water pre-treatment facilities to prevent premature membrane degradation.

Workforce considerations also impact implementation decisions. DLE technologies increasingly incorporate automation and remote monitoring capabilities, potentially reducing on-site staffing requirements but necessitating specialized technical expertise. Membrane operations typically require more hands-on maintenance and regular intervention, translating to higher ongoing labor costs but potentially lower specialized training requirements.

Time-to-market represents another critical implementation factor. DLE installations can often be commissioned more rapidly than traditional extraction methods, with some modular systems operational within 12-18 months of project initiation. Membrane technologies may offer even faster deployment in certain contexts, particularly for smaller-scale operations, with some systems becoming operational in under 12 months.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!