Optimizing Direct Lithium Extraction for Environmental Impact

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology has emerged as a revolutionary approach to lithium production, evolving significantly since its conceptual development in the 1990s. This technology represents a paradigm shift from traditional extraction methods such as hard rock mining and evaporative brine processing, which have dominated the lithium supply chain for decades. The fundamental objective of DLE is to extract lithium directly from brine resources with minimal environmental footprint while maximizing recovery efficiency.

The historical trajectory of DLE development has been characterized by incremental innovations in selective adsorption materials, membrane technologies, and electrochemical processes. Early DLE attempts faced challenges with selectivity, as brines typically contain numerous competing ions including sodium, potassium, magnesium, and calcium. The technological evolution has focused on developing increasingly selective extraction media capable of preferentially capturing lithium ions from complex brine compositions.

Current DLE technology aims to address several critical objectives simultaneously: reducing water consumption by 50-90% compared to evaporative methods, minimizing land disturbance by over 70%, accelerating production timelines from years to days, and increasing lithium recovery rates from approximately 40% to potentially over 90%. These objectives align with the growing global emphasis on sustainable resource extraction practices and the urgent need to expand lithium production capacity to meet escalating demand from the electric vehicle and energy storage sectors.

The technical progression of DLE has been driven by innovations in three primary approaches: adsorption-based technologies utilizing selective materials such as lithium manganese oxides and lithium titanium oxides; ion-exchange processes employing specialized resins; and membrane-based systems including nanofiltration and electrodialysis. Each approach presents distinct advantages and limitations regarding selectivity, energy requirements, and scalability.

Environmental optimization of DLE represents the next frontier in this technological evolution. Current research focuses on developing closed-loop systems that minimize waste generation, reduce chemical consumption, and enable the beneficial use of extracted by-products. The ultimate goal is to establish a circular economy approach to lithium production that maximizes resource efficiency while minimizing ecological disruption.

The technology trajectory suggests that future DLE developments will increasingly integrate renewable energy sources, advanced water recycling systems, and real-time monitoring capabilities to further reduce environmental impacts. As global lithium demand is projected to increase by 400-800% by 2030, optimizing DLE for environmental performance while maintaining economic viability represents both a significant challenge and opportunity for sustainable technological innovation in the critical minerals sector.

The historical trajectory of DLE development has been characterized by incremental innovations in selective adsorption materials, membrane technologies, and electrochemical processes. Early DLE attempts faced challenges with selectivity, as brines typically contain numerous competing ions including sodium, potassium, magnesium, and calcium. The technological evolution has focused on developing increasingly selective extraction media capable of preferentially capturing lithium ions from complex brine compositions.

Current DLE technology aims to address several critical objectives simultaneously: reducing water consumption by 50-90% compared to evaporative methods, minimizing land disturbance by over 70%, accelerating production timelines from years to days, and increasing lithium recovery rates from approximately 40% to potentially over 90%. These objectives align with the growing global emphasis on sustainable resource extraction practices and the urgent need to expand lithium production capacity to meet escalating demand from the electric vehicle and energy storage sectors.

The technical progression of DLE has been driven by innovations in three primary approaches: adsorption-based technologies utilizing selective materials such as lithium manganese oxides and lithium titanium oxides; ion-exchange processes employing specialized resins; and membrane-based systems including nanofiltration and electrodialysis. Each approach presents distinct advantages and limitations regarding selectivity, energy requirements, and scalability.

Environmental optimization of DLE represents the next frontier in this technological evolution. Current research focuses on developing closed-loop systems that minimize waste generation, reduce chemical consumption, and enable the beneficial use of extracted by-products. The ultimate goal is to establish a circular economy approach to lithium production that maximizes resource efficiency while minimizing ecological disruption.

The technology trajectory suggests that future DLE developments will increasingly integrate renewable energy sources, advanced water recycling systems, and real-time monitoring capabilities to further reduce environmental impacts. As global lithium demand is projected to increase by 400-800% by 2030, optimizing DLE for environmental performance while maintaining economic viability represents both a significant challenge and opportunity for sustainable technological innovation in the critical minerals sector.

Market Demand Analysis for Sustainable Lithium

The global lithium market is experiencing unprecedented growth driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current projections indicate the lithium market will reach approximately $8.2 billion by 2027, with a compound annual growth rate exceeding 14% between 2022 and 2027. This surge in demand has created significant pressure on traditional lithium extraction methods, which often involve extensive water usage, habitat destruction, and chemical pollution.

Sustainable lithium extraction has emerged as a critical market need, with over 80% of major automotive manufacturers publicly committing to reducing the environmental footprint of their battery supply chains. Tesla, Volkswagen, and BMW have specifically cited sustainable lithium sourcing in their ESG reports, indicating strong downstream pressure for environmentally responsible extraction methods.

Direct Lithium Extraction (DLE) technologies that minimize environmental impact are experiencing particularly strong demand growth, with investment in this sector increasing by 300% between 2019 and 2022. Market analysis reveals that lithium producers implementing sustainable extraction methods command premium pricing, with price differentials of 5-10% compared to conventionally sourced lithium.

Geographically, demand for sustainable lithium is highest in Europe, where regulatory frameworks increasingly mandate environmental impact assessments for battery materials. The European Battery Alliance has established specific targets for reducing the carbon and water footprint of lithium production, creating a market advantage for low-impact extraction technologies.

Consumer awareness regarding battery material sourcing has also risen substantially, with recent surveys indicating that 67% of EV buyers consider environmental impact in purchasing decisions. This trend has prompted major battery manufacturers like CATL, LG Energy Solution, and Samsung SDI to establish sustainable sourcing initiatives, further driving demand for environmentally optimized extraction methods.

The industrial sector beyond automotive is also contributing to market growth, with grid-scale energy storage deployments expected to increase tenfold by 2030. These applications prioritize long-term sustainability and are increasingly specifying environmentally responsible lithium sources in procurement requirements.

Water conservation represents a particularly valuable market differentiator, as conventional lithium extraction can consume up to 500,000 gallons of water per ton of lithium produced. Technologies that reduce water usage by 90% or more are attracting premium valuations and preferred supplier status among battery manufacturers with strong sustainability commitments.

Sustainable lithium extraction has emerged as a critical market need, with over 80% of major automotive manufacturers publicly committing to reducing the environmental footprint of their battery supply chains. Tesla, Volkswagen, and BMW have specifically cited sustainable lithium sourcing in their ESG reports, indicating strong downstream pressure for environmentally responsible extraction methods.

Direct Lithium Extraction (DLE) technologies that minimize environmental impact are experiencing particularly strong demand growth, with investment in this sector increasing by 300% between 2019 and 2022. Market analysis reveals that lithium producers implementing sustainable extraction methods command premium pricing, with price differentials of 5-10% compared to conventionally sourced lithium.

Geographically, demand for sustainable lithium is highest in Europe, where regulatory frameworks increasingly mandate environmental impact assessments for battery materials. The European Battery Alliance has established specific targets for reducing the carbon and water footprint of lithium production, creating a market advantage for low-impact extraction technologies.

Consumer awareness regarding battery material sourcing has also risen substantially, with recent surveys indicating that 67% of EV buyers consider environmental impact in purchasing decisions. This trend has prompted major battery manufacturers like CATL, LG Energy Solution, and Samsung SDI to establish sustainable sourcing initiatives, further driving demand for environmentally optimized extraction methods.

The industrial sector beyond automotive is also contributing to market growth, with grid-scale energy storage deployments expected to increase tenfold by 2030. These applications prioritize long-term sustainability and are increasingly specifying environmentally responsible lithium sources in procurement requirements.

Water conservation represents a particularly valuable market differentiator, as conventional lithium extraction can consume up to 500,000 gallons of water per ton of lithium produced. Technologies that reduce water usage by 90% or more are attracting premium valuations and preferred supplier status among battery manufacturers with strong sustainability commitments.

Current DLE Technologies and Environmental Challenges

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives to traditional lithium extraction methods, primarily addressing the environmental concerns associated with evaporation ponds and hard rock mining. Current DLE technologies can be categorized into several main approaches: ion exchange, adsorption, solvent extraction, and membrane processes.

Ion exchange technologies utilize specialized resins or inorganic materials that selectively capture lithium ions from brine solutions. Companies like Lilac Solutions and EnergyX have developed proprietary ion exchange materials that can extract lithium with higher efficiency and selectivity compared to conventional methods. However, these technologies often require significant amounts of water for regeneration cycles and face challenges with resin durability in high-salinity environments.

Adsorption-based DLE employs materials such as lithium manganese oxides or lithium aluminum layered double hydroxides that can selectively adsorb lithium from brines. While these methods show promising selectivity, they typically require pH adjustment of the brine, which introduces additional chemical inputs and potential environmental impacts through waste stream management.

Membrane-based processes, including nanofiltration and electrodialysis, represent another category of DLE technologies. These approaches use specialized membranes to separate lithium from other constituents in the brine. Standard Lithium and Saltworks Technologies have made notable advances in this area, though energy consumption remains a significant challenge.

The environmental challenges associated with current DLE technologies are multifaceted. Water usage remains substantial, with most processes requiring 10-20 cubic meters of water per ton of lithium carbonate equivalent produced. While this represents an improvement over evaporation ponds (which use approximately 500 cubic meters per ton), it still poses concerns in water-scarce regions like the Lithium Triangle in South America.

Chemical consumption presents another environmental challenge. Many DLE processes require acids, bases, and other reagents for operation and regeneration, creating potential for chemical waste streams that must be properly managed to prevent environmental contamination.

Energy requirements constitute a significant environmental consideration. Most DLE technologies demand substantial electricity for pumping, heating, and processing, with energy consumption ranging from 5 to 15 MWh per ton of lithium produced. This energy footprint can undermine the sustainability benefits if not sourced from renewable energy.

Land disturbance, while reduced compared to evaporation ponds, remains an issue with infrastructure requirements for DLE facilities. Additionally, the management of spent materials, including exhausted resins and membranes, presents emerging waste management challenges that have not been fully addressed in commercial implementations.

Ion exchange technologies utilize specialized resins or inorganic materials that selectively capture lithium ions from brine solutions. Companies like Lilac Solutions and EnergyX have developed proprietary ion exchange materials that can extract lithium with higher efficiency and selectivity compared to conventional methods. However, these technologies often require significant amounts of water for regeneration cycles and face challenges with resin durability in high-salinity environments.

Adsorption-based DLE employs materials such as lithium manganese oxides or lithium aluminum layered double hydroxides that can selectively adsorb lithium from brines. While these methods show promising selectivity, they typically require pH adjustment of the brine, which introduces additional chemical inputs and potential environmental impacts through waste stream management.

Membrane-based processes, including nanofiltration and electrodialysis, represent another category of DLE technologies. These approaches use specialized membranes to separate lithium from other constituents in the brine. Standard Lithium and Saltworks Technologies have made notable advances in this area, though energy consumption remains a significant challenge.

The environmental challenges associated with current DLE technologies are multifaceted. Water usage remains substantial, with most processes requiring 10-20 cubic meters of water per ton of lithium carbonate equivalent produced. While this represents an improvement over evaporation ponds (which use approximately 500 cubic meters per ton), it still poses concerns in water-scarce regions like the Lithium Triangle in South America.

Chemical consumption presents another environmental challenge. Many DLE processes require acids, bases, and other reagents for operation and regeneration, creating potential for chemical waste streams that must be properly managed to prevent environmental contamination.

Energy requirements constitute a significant environmental consideration. Most DLE technologies demand substantial electricity for pumping, heating, and processing, with energy consumption ranging from 5 to 15 MWh per ton of lithium produced. This energy footprint can undermine the sustainability benefits if not sourced from renewable energy.

Land disturbance, while reduced compared to evaporation ponds, remains an issue with infrastructure requirements for DLE facilities. Additionally, the management of spent materials, including exhausted resins and membranes, presents emerging waste management challenges that have not been fully addressed in commercial implementations.

Current Environmental Optimization Solutions

01 Water usage and management in DLE processes

Direct Lithium Extraction processes impact water resources in lithium-rich regions. Advanced DLE technologies focus on reducing freshwater consumption through closed-loop systems, water recycling mechanisms, and efficient brine management. These approaches minimize water footprint compared to traditional evaporation methods, addressing concerns about water scarcity in arid regions where lithium extraction often occurs. Sustainable water management practices are essential for reducing environmental impact while maintaining extraction efficiency.- Water usage and conservation in DLE processes: Direct Lithium Extraction technologies impact water resources in lithium-rich regions. Advanced DLE methods focus on reducing freshwater consumption through closed-loop systems, water recycling technologies, and minimizing evaporation losses compared to traditional extraction methods. These innovations help preserve local water tables and reduce competition with agricultural and community needs in often water-stressed regions where lithium deposits are found.

- Chemical usage and waste management: Environmental concerns in DLE operations include the management of chemicals used in extraction processes and resulting waste streams. Modern DLE technologies incorporate biodegradable solvents, ion-exchange resins with minimal environmental footprint, and advanced waste treatment systems. These approaches reduce the risk of soil and groundwater contamination while minimizing the generation of hazardous byproducts compared to conventional extraction methods.

- Energy efficiency and carbon footprint: The energy requirements of DLE processes significantly impact their overall environmental footprint. Innovations focus on reducing energy consumption through optimized extraction cycles, heat recovery systems, and integration of renewable energy sources. These improvements help decrease greenhouse gas emissions associated with lithium production, making DLE potentially more climate-friendly than traditional brine evaporation or hard-rock mining methods when properly implemented.

- Land use and ecosystem preservation: DLE technologies offer advantages in land use efficiency compared to traditional extraction methods. By utilizing smaller physical footprints than evaporation ponds or open-pit mining, DLE systems help preserve natural habitats and reduce ecosystem disruption. Advanced approaches incorporate site restoration plans, minimize surface disturbance, and implement monitoring systems to protect biodiversity in lithium-rich regions, addressing concerns about habitat fragmentation and species displacement.

- Sustainable DLE monitoring and regulatory compliance: Environmental impact assessment and monitoring systems are crucial for sustainable DLE operations. These include real-time environmental monitoring technologies, comprehensive lifecycle assessments, and regulatory compliance frameworks specific to lithium extraction. Advanced monitoring approaches track water quality, air emissions, and ecological indicators to ensure operations remain within environmental parameters, while facilitating transparent reporting to stakeholders and regulatory bodies.

02 Chemical usage and waste reduction in DLE

Environmental concerns related to chemical usage in Direct Lithium Extraction include potential contamination from solvents, resins, and processing agents. Innovative DLE technologies focus on developing biodegradable reagents, minimizing hazardous chemical use, and implementing closed-loop chemical recovery systems. These advancements reduce waste generation and prevent harmful substances from entering surrounding ecosystems. Proper chemical management and waste treatment protocols are critical for minimizing the environmental footprint of lithium extraction operations.Expand Specific Solutions03 Energy efficiency and carbon footprint reduction

Energy consumption represents a significant environmental concern in Direct Lithium Extraction processes. Modern DLE technologies incorporate energy-efficient designs, renewable energy integration, and heat recovery systems to reduce carbon emissions. Compared to traditional evaporation pond methods, advanced DLE approaches can significantly lower the carbon footprint of lithium production. Innovations focus on optimizing extraction processes to minimize energy requirements while maintaining or improving lithium recovery rates.Expand Specific Solutions04 Land use and ecosystem preservation

Direct Lithium Extraction technologies offer significant advantages over conventional methods regarding land disturbance and ecosystem impact. DLE processes require substantially smaller physical footprints compared to traditional evaporation ponds, reducing habitat disruption and landscape alteration. Advanced systems incorporate design elements that minimize surface disturbance, protect biodiversity, and enable more efficient land use. These approaches help preserve natural ecosystems while allowing for sustainable lithium production to meet growing demand for battery materials.Expand Specific Solutions05 Brine restoration and subsurface impact mitigation

Environmental concerns regarding subsurface impacts of Direct Lithium Extraction include potential aquifer disruption and geochemical alterations. Advanced DLE technologies focus on brine restoration techniques that return processed brine to its source with minimal compositional changes. These approaches maintain hydrogeological balance, prevent subsidence, and protect groundwater quality. Monitoring systems track subsurface conditions to ensure long-term sustainability of extraction operations and minimize impacts on geological formations and groundwater resources.Expand Specific Solutions

Key Industry Players in DLE Technology

The Direct Lithium Extraction (DLE) market is in its early growth phase, characterized by rapid technological innovation and increasing commercial deployment. With global lithium demand projected to triple by 2025, DLE represents a significant opportunity for sustainable lithium production. Companies like Lilac Solutions, Evove, and Watercycle Technologies are pioneering membrane and ion-exchange technologies that reduce environmental footprint compared to traditional evaporation methods. Koch Technology Solutions and Schlumberger are leveraging their industrial expertise to scale DLE solutions, while academic institutions such as MIT and The University of Manchester contribute fundamental research. POSCO Holdings and Ningbo Ronbay are integrating DLE into broader battery material supply chains. The technology is approaching commercial maturity with several pilot projects transitioning to full-scale operations, though optimization for specific brine chemistries remains a challenge.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has commercialized a membrane-based Direct Lithium Extraction (DLE) technology that utilizes advanced selective separation membranes to isolate lithium from brine resources. Their process employs a combination of nanofiltration and electrodialysis techniques that allow for selective lithium passage while rejecting competing ions. The system operates under moderate pressure conditions and utilizes specialized membrane stacks that can be tailored to specific brine compositions. This approach reduces water consumption by approximately 80% compared to evaporation methods and eliminates the need for large evaporation ponds. Koch's technology integrates with downstream processing to produce battery-grade lithium compounds directly. The system is designed with energy recovery mechanisms to minimize operational costs, with reported energy consumption of 4-6 kWh per kg of lithium carbonate equivalent produced. Field implementations have demonstrated lithium recovery rates of 85-90% across various brine chemistries while maintaining consistent product quality[3][4].

Strengths: Lower chemical consumption compared to many competing DLE technologies; modular and scalable design; reduced water footprint; ability to handle varying brine compositions. Weaknesses: Membrane fouling may require periodic maintenance; energy requirements for pressure-driven processes; potential challenges with highly concentrated brines; membrane replacement costs over time.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed an advanced Direct Lithium Extraction (DLE) technology called NeoLith Energy that combines selective adsorption with proprietary fluid handling systems derived from their extensive experience in oilfield operations. Their approach utilizes specialized adsorbent materials that selectively capture lithium ions from brine resources. The system operates in a continuous flow configuration with multiple extraction columns that cycle between adsorption and desorption phases, ensuring uninterrupted production. Schlumberger's technology incorporates sophisticated process control systems that optimize operational parameters based on real-time monitoring of brine chemistry and system performance. This results in consistent lithium recovery rates exceeding 90% while minimizing reagent consumption. The NeoLith Energy platform reduces water usage by approximately 85% compared to evaporation ponds and features a closed-loop water recycling system that further minimizes environmental impact. Field pilots have demonstrated the ability to process various brine types, including those from geothermal sources and oilfield produced water, with lithium concentration times of less than 24 hours compared to 18-24 months for traditional methods[7][8].

Strengths: Leverages extensive experience in fluid handling from oil and gas operations; advanced process control systems; adaptable to various brine sources; significant reduction in processing time. Weaknesses: Relatively high energy requirements; complex system integration; potential challenges with scaling to very large production volumes; proprietary technology may limit third-party improvements.

Critical Patents and Innovations in DLE

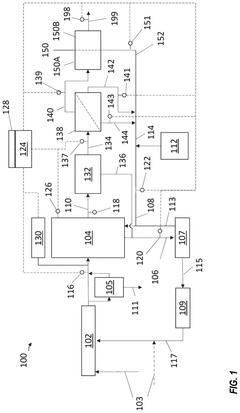

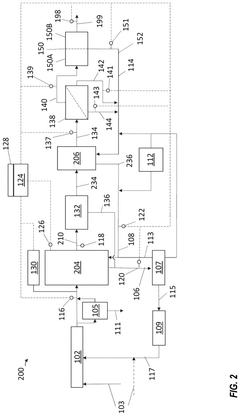

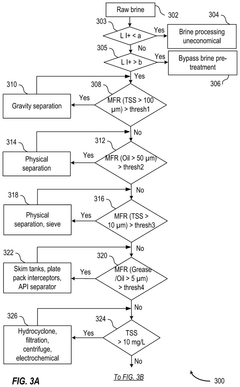

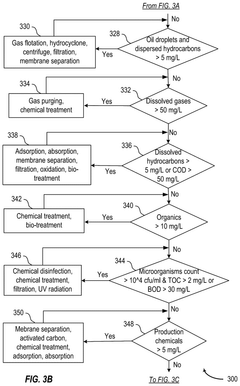

Flexible brine pre-treatment for direct lithium extraction

PatentPendingUS20250145497A1

Innovation

- A flexible brine pre-treatment process that involves measuring properties of a sample brine, comparing them to specified thresholds, and selecting appropriate pre-treatment stages to modify the brine properties, thereby optimizing the DLE process.

process

PatentWO2025106417A1

Innovation

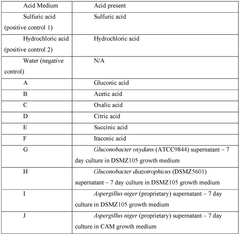

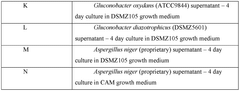

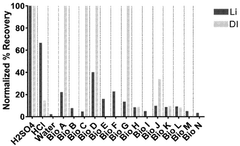

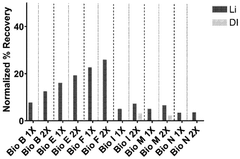

- The use of an acid medium comprising organic acids with a lowest pKa value of at least 4 or dicarboxylic acids with 3 or more carbon atoms and a lowest pKa value of at least 3.5 for desorbing lithium from adsorbents, which minimizes adsorbent damage and allows for environmentally friendly production of these acids through microorganisms.

Water Conservation Strategies in DLE Processes

Water conservation represents a critical dimension in the optimization of Direct Lithium Extraction (DLE) processes, particularly as global water scarcity intensifies. Traditional lithium extraction methods, such as evaporation ponds, consume between 500,000 to 2 million gallons of water per ton of lithium produced. DLE technologies offer promising alternatives with significantly reduced water footprints, yet strategic water management remains essential for maximizing environmental benefits.

Closed-loop water systems have emerged as a foundational strategy in DLE operations, enabling up to 90% water recycling rates. These systems capture, treat, and reuse process water, dramatically reducing freshwater withdrawal requirements. Advanced membrane filtration technologies, including reverse osmosis and nanofiltration, play crucial roles in these systems by efficiently separating lithium from other dissolved solids while preserving water quality for reuse.

Real-time monitoring systems equipped with IoT sensors provide continuous data on water quality parameters, flow rates, and system performance. This enables precise control of water usage and immediate identification of inefficiencies or leaks. Machine learning algorithms increasingly complement these systems by predicting maintenance needs and optimizing water treatment cycles, further reducing consumption by an estimated 15-20%.

Selective adsorption materials represent another frontier in water conservation for DLE. Novel materials such as metal-organic frameworks (MOFs) and functionalized polymers demonstrate high selectivity for lithium ions while minimizing water requirements. Research indicates that these advanced sorbents can reduce process water needs by up to 30% compared to first-generation DLE technologies.

Integration with renewable energy systems further enhances water conservation potential. Solar-powered desalination units can provide supplementary water sources in arid regions, while waste heat recovery systems reduce evaporative losses during thermal treatment phases. These integrated approaches have demonstrated water savings of 25-40% in pilot projects across various geographical contexts.

Geographically tailored water management strategies recognize that optimal approaches vary by location. In water-stressed regions like Chile's Atacama Desert, DLE facilities increasingly implement zero-liquid discharge systems, while operations in water-rich areas focus on minimizing contamination risks to local watersheds. This context-specific optimization ensures that water conservation measures align with local environmental conditions and regulatory frameworks.

Closed-loop water systems have emerged as a foundational strategy in DLE operations, enabling up to 90% water recycling rates. These systems capture, treat, and reuse process water, dramatically reducing freshwater withdrawal requirements. Advanced membrane filtration technologies, including reverse osmosis and nanofiltration, play crucial roles in these systems by efficiently separating lithium from other dissolved solids while preserving water quality for reuse.

Real-time monitoring systems equipped with IoT sensors provide continuous data on water quality parameters, flow rates, and system performance. This enables precise control of water usage and immediate identification of inefficiencies or leaks. Machine learning algorithms increasingly complement these systems by predicting maintenance needs and optimizing water treatment cycles, further reducing consumption by an estimated 15-20%.

Selective adsorption materials represent another frontier in water conservation for DLE. Novel materials such as metal-organic frameworks (MOFs) and functionalized polymers demonstrate high selectivity for lithium ions while minimizing water requirements. Research indicates that these advanced sorbents can reduce process water needs by up to 30% compared to first-generation DLE technologies.

Integration with renewable energy systems further enhances water conservation potential. Solar-powered desalination units can provide supplementary water sources in arid regions, while waste heat recovery systems reduce evaporative losses during thermal treatment phases. These integrated approaches have demonstrated water savings of 25-40% in pilot projects across various geographical contexts.

Geographically tailored water management strategies recognize that optimal approaches vary by location. In water-stressed regions like Chile's Atacama Desert, DLE facilities increasingly implement zero-liquid discharge systems, while operations in water-rich areas focus on minimizing contamination risks to local watersheds. This context-specific optimization ensures that water conservation measures align with local environmental conditions and regulatory frameworks.

Regulatory Compliance and ESG Considerations

Direct Lithium Extraction (DLE) operations are subject to a complex web of regulatory frameworks that vary significantly across jurisdictions. In the United States, the Environmental Protection Agency (EPA) regulates water discharge through the Clean Water Act, while the Bureau of Land Management oversees extraction activities on federal lands. The EU's more stringent approach is embodied in the European Green Deal, which emphasizes sustainable resource extraction with minimal environmental footprint.

Companies engaged in DLE must navigate these regulatory landscapes while simultaneously addressing growing Environmental, Social, and Governance (ESG) expectations from investors and stakeholders. The lithium industry faces particular scrutiny regarding water usage, as traditional evaporative methods consume between 500,000 to 2 million gallons of water per ton of lithium produced. DLE technologies that demonstrate significant reductions in water consumption gain favorable regulatory treatment and stronger ESG profiles.

Carbon footprint considerations represent another critical regulatory and ESG factor. Jurisdictions with carbon pricing mechanisms or emissions trading schemes create direct financial incentives for companies to adopt low-carbon DLE technologies. The EU's Carbon Border Adjustment Mechanism, scheduled for full implementation by 2026, will further impact the economics of lithium imports based on their embedded carbon content.

Indigenous rights and community engagement have emerged as essential components of regulatory compliance for extraction projects. In Latin America's "Lithium Triangle," companies must secure Free, Prior, and Informed Consent (FPIC) from indigenous communities before project development. Companies with robust community engagement processes not only ensure regulatory compliance but also strengthen their social license to operate.

Waste management regulations are becoming increasingly stringent, with particular focus on the disposal of spent sorbents, membranes, and process chemicals used in DLE. Circular economy principles are being incorporated into regulatory frameworks, requiring companies to develop comprehensive end-of-life management plans for materials and equipment.

Transparency in ESG reporting is transitioning from voluntary to mandatory in many jurisdictions. The EU's Corporate Sustainability Reporting Directive and the SEC's proposed climate disclosure rules will require detailed reporting on environmental impacts, including those from lithium extraction activities. Companies implementing DLE technologies must develop robust monitoring and reporting systems to track key environmental performance indicators.

Forward-looking companies are adopting a proactive approach to regulatory compliance, engaging with regulators during technology development phases rather than after deployment. This collaborative approach helps shape reasonable regulatory expectations while demonstrating corporate commitment to responsible resource development.

Companies engaged in DLE must navigate these regulatory landscapes while simultaneously addressing growing Environmental, Social, and Governance (ESG) expectations from investors and stakeholders. The lithium industry faces particular scrutiny regarding water usage, as traditional evaporative methods consume between 500,000 to 2 million gallons of water per ton of lithium produced. DLE technologies that demonstrate significant reductions in water consumption gain favorable regulatory treatment and stronger ESG profiles.

Carbon footprint considerations represent another critical regulatory and ESG factor. Jurisdictions with carbon pricing mechanisms or emissions trading schemes create direct financial incentives for companies to adopt low-carbon DLE technologies. The EU's Carbon Border Adjustment Mechanism, scheduled for full implementation by 2026, will further impact the economics of lithium imports based on their embedded carbon content.

Indigenous rights and community engagement have emerged as essential components of regulatory compliance for extraction projects. In Latin America's "Lithium Triangle," companies must secure Free, Prior, and Informed Consent (FPIC) from indigenous communities before project development. Companies with robust community engagement processes not only ensure regulatory compliance but also strengthen their social license to operate.

Waste management regulations are becoming increasingly stringent, with particular focus on the disposal of spent sorbents, membranes, and process chemicals used in DLE. Circular economy principles are being incorporated into regulatory frameworks, requiring companies to develop comprehensive end-of-life management plans for materials and equipment.

Transparency in ESG reporting is transitioning from voluntary to mandatory in many jurisdictions. The EU's Corporate Sustainability Reporting Directive and the SEC's proposed climate disclosure rules will require detailed reporting on environmental impacts, including those from lithium extraction activities. Companies implementing DLE technologies must develop robust monitoring and reporting systems to track key environmental performance indicators.

Forward-looking companies are adopting a proactive approach to regulatory compliance, engaging with regulators during technology development phases rather than after deployment. This collaborative approach helps shape reasonable regulatory expectations while demonstrating corporate commitment to responsible resource development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!