Direct Lithium Extraction: Innovations for Cost Reduction

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) represents a paradigm shift in lithium production technology, emerging as an alternative to traditional extraction methods that have dominated the industry for decades. Conventional lithium extraction primarily relies on solar evaporation of brine pools or hard-rock mining, both of which present significant environmental challenges and operational inefficiencies. The evolution of DLE technologies began in the early 2000s, with substantial acceleration in research and development occurring over the past decade in response to the exponential growth in lithium demand driven by electric vehicle batteries and energy storage systems.

The technological trajectory of DLE has been characterized by progressive improvements in selectivity, efficiency, and sustainability. Early iterations focused primarily on proof-of-concept demonstrations, while recent advancements have emphasized scalability and cost reduction. The current technological landscape encompasses various approaches including adsorption, ion exchange, solvent extraction, and membrane-based processes, each with distinct advantages and limitations in different operational contexts.

The primary objective of DLE technology development is to establish economically viable processes that can extract lithium from diverse sources with significantly reduced environmental footprint compared to conventional methods. Specifically, DLE aims to decrease water consumption by 50-90%, reduce land use by up to 90%, and accelerate production timelines from years to days or weeks, while maintaining or improving recovery rates above 80%.

Cost reduction represents the most critical challenge for widespread DLE adoption. Current DLE processes typically operate at costs between $5,000-$10,000 per ton of lithium carbonate equivalent (LCE), compared to $2,500-$4,000 for traditional methods. The technological goal is to achieve cost parity by 2025 and potential cost advantages by 2030 through innovations in materials science, process optimization, and energy efficiency.

Another key objective is to expand the viable resource base for lithium production. DLE technologies potentially enable extraction from previously uneconomical sources including geothermal brines, oilfield produced water, and low-concentration continental brines, which could dramatically increase global lithium reserves and reduce supply chain vulnerabilities in the transition to clean energy systems.

The technological evolution of DLE is increasingly influenced by sustainability imperatives, with growing emphasis on developing closed-loop systems that minimize waste generation, reduce chemical consumption, and enable the co-extraction of valuable by-products such as zinc, manganese, and rare earth elements to improve overall economics.

The technological trajectory of DLE has been characterized by progressive improvements in selectivity, efficiency, and sustainability. Early iterations focused primarily on proof-of-concept demonstrations, while recent advancements have emphasized scalability and cost reduction. The current technological landscape encompasses various approaches including adsorption, ion exchange, solvent extraction, and membrane-based processes, each with distinct advantages and limitations in different operational contexts.

The primary objective of DLE technology development is to establish economically viable processes that can extract lithium from diverse sources with significantly reduced environmental footprint compared to conventional methods. Specifically, DLE aims to decrease water consumption by 50-90%, reduce land use by up to 90%, and accelerate production timelines from years to days or weeks, while maintaining or improving recovery rates above 80%.

Cost reduction represents the most critical challenge for widespread DLE adoption. Current DLE processes typically operate at costs between $5,000-$10,000 per ton of lithium carbonate equivalent (LCE), compared to $2,500-$4,000 for traditional methods. The technological goal is to achieve cost parity by 2025 and potential cost advantages by 2030 through innovations in materials science, process optimization, and energy efficiency.

Another key objective is to expand the viable resource base for lithium production. DLE technologies potentially enable extraction from previously uneconomical sources including geothermal brines, oilfield produced water, and low-concentration continental brines, which could dramatically increase global lithium reserves and reduce supply chain vulnerabilities in the transition to clean energy systems.

The technological evolution of DLE is increasingly influenced by sustainability imperatives, with growing emphasis on developing closed-loop systems that minimize waste generation, reduce chemical consumption, and enable the co-extraction of valuable by-products such as zinc, manganese, and rare earth elements to improve overall economics.

Market Demand Analysis for Lithium Extraction

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Market analysis indicates that global lithium demand is projected to increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, representing a compound annual growth rate (CAGR) of over 20%.

This surge in demand has created significant pressure on traditional lithium extraction methods, which are increasingly unable to meet market requirements in terms of both volume and cost-effectiveness. The automotive industry alone accounts for more than 75% of lithium demand, with major manufacturers committing to full electrification of their fleets within the next decade.

Battery manufacturers and technology companies are actively seeking stable, sustainable lithium supplies to support their growth strategies. This has resulted in vertical integration attempts, with companies like Tesla and CATL investing directly in lithium extraction and processing technologies to secure their supply chains.

Price volatility has been a persistent challenge in the lithium market, with prices fluctuating between $5,000 and $80,000 per metric ton in recent years. This volatility underscores the urgent need for more cost-effective and predictable extraction technologies. Direct Lithium Extraction (DLE) technologies are positioned to address this market gap by potentially reducing production costs by 30-50% compared to traditional methods.

Geographically, the demand landscape is shifting. While China currently dominates lithium processing, accounting for approximately 60% of global capacity, Western markets are rapidly developing domestic capabilities to reduce dependency on foreign supplies. The United States, European Union, and Australia have all classified lithium as a critical mineral, implementing policies to stimulate domestic production and processing.

Environmental considerations are increasingly influencing market dynamics. Traditional extraction methods face growing resistance due to their substantial water consumption and land disturbance. This has created market pull for DLE technologies, which typically reduce water usage by 50-90% compared to conventional methods.

The investment landscape reflects this growing market demand, with venture capital and corporate investment in DLE technologies exceeding $1.5 billion between 2020 and 2023. Industry analysts predict that DLE could capture 25% of global lithium production by 2030, representing a market opportunity of approximately $15 billion annually.

This surge in demand has created significant pressure on traditional lithium extraction methods, which are increasingly unable to meet market requirements in terms of both volume and cost-effectiveness. The automotive industry alone accounts for more than 75% of lithium demand, with major manufacturers committing to full electrification of their fleets within the next decade.

Battery manufacturers and technology companies are actively seeking stable, sustainable lithium supplies to support their growth strategies. This has resulted in vertical integration attempts, with companies like Tesla and CATL investing directly in lithium extraction and processing technologies to secure their supply chains.

Price volatility has been a persistent challenge in the lithium market, with prices fluctuating between $5,000 and $80,000 per metric ton in recent years. This volatility underscores the urgent need for more cost-effective and predictable extraction technologies. Direct Lithium Extraction (DLE) technologies are positioned to address this market gap by potentially reducing production costs by 30-50% compared to traditional methods.

Geographically, the demand landscape is shifting. While China currently dominates lithium processing, accounting for approximately 60% of global capacity, Western markets are rapidly developing domestic capabilities to reduce dependency on foreign supplies. The United States, European Union, and Australia have all classified lithium as a critical mineral, implementing policies to stimulate domestic production and processing.

Environmental considerations are increasingly influencing market dynamics. Traditional extraction methods face growing resistance due to their substantial water consumption and land disturbance. This has created market pull for DLE technologies, which typically reduce water usage by 50-90% compared to conventional methods.

The investment landscape reflects this growing market demand, with venture capital and corporate investment in DLE technologies exceeding $1.5 billion between 2020 and 2023. Industry analysts predict that DLE could capture 25% of global lithium production by 2030, representing a market opportunity of approximately $15 billion annually.

Current DLE Technical Challenges

Despite significant advancements in Direct Lithium Extraction (DLE) technologies, several critical technical challenges continue to impede widespread commercial adoption and cost reduction. The most pressing challenge remains the selectivity of lithium over competing ions in brine solutions. Most brines contain high concentrations of sodium, potassium, magnesium, and calcium ions that can interfere with lithium extraction processes, reducing efficiency and increasing operational costs.

Energy consumption represents another major hurdle for DLE implementation. Current technologies, particularly those utilizing electrochemical methods or thermal evaporation steps, require substantial energy inputs that significantly impact operational expenses. This energy intensity directly contradicts sustainability goals and diminishes the economic viability of DLE operations, especially in regions with high energy costs.

Water management continues to pose significant technical difficulties. Many DLE processes require substantial water inputs for regeneration cycles or produce large volumes of wastewater that must be treated. In water-scarce regions where many lithium resources are located, this creates both environmental concerns and operational constraints that increase overall extraction costs.

Sorbent durability and lifecycle performance remain problematic across various DLE approaches. Ion exchange materials, membranes, and other selective media often experience degradation after multiple extraction cycles, necessitating frequent replacement. This degradation is particularly accelerated in brines with complex chemical compositions or high levels of impurities, leading to increased operational expenditures and material waste.

Scaling challenges persist when transitioning from laboratory demonstrations to commercial operations. Many promising DLE technologies have shown excellent performance in controlled environments but encounter significant efficiency losses when scaled to industrial volumes. These scaling inefficiencies stem from flow distribution problems, pressure drop issues, and contact time limitations in larger extraction systems.

Process integration with existing operations presents additional technical barriers. Retrofitting DLE technologies into conventional extraction operations requires careful engineering to manage brine chemistry changes throughout the process chain. The interfaces between DLE units and downstream processing steps often create bottlenecks that reduce overall system efficiency.

Recovery rates for lithium remain suboptimal in many DLE implementations, typically ranging from 50-80% depending on the technology and brine composition. This incomplete recovery represents a significant economic loss and reduces the sustainability advantage of DLE compared to traditional extraction methods. Improving recovery rates without increasing energy or chemical inputs remains a critical technical challenge for cost reduction.

Energy consumption represents another major hurdle for DLE implementation. Current technologies, particularly those utilizing electrochemical methods or thermal evaporation steps, require substantial energy inputs that significantly impact operational expenses. This energy intensity directly contradicts sustainability goals and diminishes the economic viability of DLE operations, especially in regions with high energy costs.

Water management continues to pose significant technical difficulties. Many DLE processes require substantial water inputs for regeneration cycles or produce large volumes of wastewater that must be treated. In water-scarce regions where many lithium resources are located, this creates both environmental concerns and operational constraints that increase overall extraction costs.

Sorbent durability and lifecycle performance remain problematic across various DLE approaches. Ion exchange materials, membranes, and other selective media often experience degradation after multiple extraction cycles, necessitating frequent replacement. This degradation is particularly accelerated in brines with complex chemical compositions or high levels of impurities, leading to increased operational expenditures and material waste.

Scaling challenges persist when transitioning from laboratory demonstrations to commercial operations. Many promising DLE technologies have shown excellent performance in controlled environments but encounter significant efficiency losses when scaled to industrial volumes. These scaling inefficiencies stem from flow distribution problems, pressure drop issues, and contact time limitations in larger extraction systems.

Process integration with existing operations presents additional technical barriers. Retrofitting DLE technologies into conventional extraction operations requires careful engineering to manage brine chemistry changes throughout the process chain. The interfaces between DLE units and downstream processing steps often create bottlenecks that reduce overall system efficiency.

Recovery rates for lithium remain suboptimal in many DLE implementations, typically ranging from 50-80% depending on the technology and brine composition. This incomplete recovery represents a significant economic loss and reduces the sustainability advantage of DLE compared to traditional extraction methods. Improving recovery rates without increasing energy or chemical inputs remains a critical technical challenge for cost reduction.

Cost-Effective DLE Solutions

01 Improved sorbent materials for lithium extraction

Advanced sorbent materials can significantly reduce the cost of direct lithium extraction by increasing selectivity and capacity for lithium ions. These materials include novel inorganic ion exchangers, metal-organic frameworks, and functionalized polymers that can efficiently separate lithium from brines and other sources with minimal energy input. The improved selectivity reduces the need for extensive pre-treatment and post-processing, while higher capacity materials require less frequent regeneration cycles.- Improved sorbent materials for lithium extraction: Advanced sorbent materials can significantly reduce the cost of direct lithium extraction by increasing selectivity and capacity for lithium ions. These materials include novel ion exchange resins, inorganic adsorbents, and composite materials that can efficiently separate lithium from brines with minimal energy input. Improved sorbents also demonstrate enhanced durability and regeneration capabilities, reducing replacement costs and extending operational lifespans in extraction systems.

- Energy-efficient regeneration processes: Developing energy-efficient methods for regenerating extraction media represents a major cost reduction opportunity in direct lithium extraction. Advanced regeneration techniques utilize optimized elution chemistry, reduced temperature requirements, and improved fluid dynamics to minimize energy consumption. These processes can recover lithium from sorbents using less chemicals and energy, significantly lowering operational expenses while maintaining high lithium recovery rates.

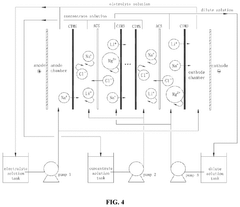

- Integrated process optimization systems: Comprehensive process optimization systems integrate multiple aspects of direct lithium extraction to reduce overall costs. These systems employ advanced control algorithms, real-time monitoring, and automated adjustments to optimize extraction parameters based on brine composition and operating conditions. By coordinating pre-treatment, extraction, and post-processing stages, these integrated approaches minimize reagent consumption, reduce waste generation, and improve lithium recovery efficiency.

- Membrane and filtration technology advancements: Advanced membrane and filtration technologies offer significant cost reductions in direct lithium extraction processes. These innovations include specialized nanofiltration membranes, selective separation barriers, and hybrid filtration systems that can efficiently separate lithium from contaminants with reduced energy requirements. By improving selectivity and throughput while decreasing fouling and maintenance needs, these technologies lower operational costs and increase the purity of extracted lithium compounds.

- Brine pre-treatment and impurity management: Effective brine pre-treatment and impurity management systems reduce downstream processing costs in direct lithium extraction. These approaches include selective precipitation of interfering elements, advanced filtration to remove suspended solids, and chemical treatments to neutralize problematic compounds. By addressing impurities before the main extraction process, these methods extend the lifespan of extraction media, reduce chemical consumption, and improve the quality of the final lithium product.

02 Energy-efficient regeneration processes

Developing energy-efficient methods for regenerating extraction media represents a major cost reduction opportunity in direct lithium extraction. Innovations include low-temperature regeneration techniques, electrochemical regeneration systems, and solar-powered regeneration processes that significantly reduce energy consumption. These approaches minimize operational expenses by decreasing electricity and heating costs while extending the lifespan of extraction materials through gentler regeneration conditions.Expand Specific Solutions03 Process intensification and system integration

Integrating multiple extraction steps into continuous, compact systems reduces capital and operational costs in direct lithium extraction. These integrated approaches combine extraction, purification, and concentration processes in modular designs that minimize footprint and equipment requirements. Process intensification techniques include membrane-assisted extraction, electrochemical systems that combine separation and concentration steps, and multi-functional reactors that perform several operations simultaneously, resulting in significant cost savings through reduced equipment needs and improved efficiency.Expand Specific Solutions04 Brine pre-treatment optimization

Optimizing pre-treatment processes for lithium-containing brines can substantially reduce overall extraction costs. Innovative approaches include selective precipitation of interfering ions, membrane filtration systems that remove contaminants while concentrating lithium, and electrochemical pre-treatment methods that modify brine chemistry to enhance subsequent extraction steps. These techniques minimize chemical consumption, reduce waste generation, and improve the efficiency of downstream extraction processes by providing cleaner feed streams with higher lithium concentrations.Expand Specific Solutions05 Direct lithium recovery from unconventional sources

Developing cost-effective methods to extract lithium from unconventional sources such as geothermal brines, oil field produced waters, and mining waste streams offers significant economic advantages. These approaches leverage existing infrastructure and waste streams to reduce capital costs while providing additional revenue streams from what would otherwise be waste materials. Technologies include selective extraction systems designed for specific challenging matrices, co-production processes that recover multiple valuable elements simultaneously, and in-situ recovery methods that minimize handling and processing requirements.Expand Specific Solutions

Key Industry Players in DLE Market

Direct Lithium Extraction (DLE) technology is currently in an early growth phase, with the global market expected to expand significantly due to increasing demand for lithium in battery production. The competitive landscape features established players like Schlumberger, BASF, and POSCO Holdings alongside innovative startups such as Lilac Solutions, Evove, and Watercycle Technologies. These companies are developing proprietary technologies to reduce extraction costs through ion-exchange materials, advanced membranes, and process optimization. Academic institutions including Cornell University, The University of Manchester, and Chinese Academy of Sciences are contributing breakthrough research. The technology is approaching commercial viability, with several pilot projects demonstrating 30-50% cost reductions compared to traditional methods, though widespread implementation remains 3-5 years away as companies work to scale operations and improve efficiency.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering at the Chinese Academy of Sciences has developed several innovative DLE technologies focusing on cost reduction through advanced materials science. Their primary approach involves electrochemical lithium extraction systems that utilize specially designed electrode materials with high lithium selectivity. These materials feature precisely engineered porous structures that enable efficient lithium ion capture while minimizing interference from competing ions like sodium, magnesium, and calcium. The institute has pioneered a pulsed electrochemical process that reduces energy consumption by up to 40% compared to continuous operation systems. Their technology incorporates a novel regeneration method that extends the lifespan of extraction materials, significantly reducing replacement costs which are a major expense in many DLE operations. Additionally, they've developed integrated systems that combine lithium extraction with valuable by-product recovery, improving overall economics. Recent research has focused on ambient temperature extraction processes that eliminate heating requirements, further reducing operational costs. The institute has demonstrated these technologies at pilot scale, achieving lithium recovery rates of 85-92% with significantly reduced processing times compared to conventional methods.

Strengths: Advanced materials science approach provides high selectivity for lithium; energy-efficient pulsed electrochemical process reduces operational costs; integrated by-product recovery improves economics; ambient temperature operation eliminates heating costs. Weaknesses: Technology may require specialized expertise for operation and maintenance; electrode materials may face degradation issues in certain brine chemistries; scaling to commercial production volumes remains to be fully demonstrated.

BASF SE

Technical Solution: BASF SE has developed a comprehensive direct lithium extraction technology platform focused on cost reduction through advanced sorbent materials and process optimization. Their approach centers on proprietary metal-organic framework (MOF) materials that offer exceptional lithium selectivity even in brines with high magnesium and calcium content. These engineered sorbents feature precisely controlled pore structures that allow for rapid lithium uptake and release, significantly reducing cycle times compared to conventional ion exchange materials. BASF's process incorporates a novel regeneration system that uses minimal chemicals and energy, addressing two major cost drivers in DLE operations. The company has integrated their extraction technology with downstream processing to produce battery-grade lithium compounds directly, eliminating several intermediate steps in traditional production chains. Their system operates at ambient temperatures and pressures, reducing energy requirements and equipment costs. BASF has demonstrated this technology at pilot scale, achieving lithium recovery rates exceeding 90% while maintaining consistent performance over thousands of extraction cycles, indicating excellent sorbent durability. The process design includes water recycling capabilities that reduce freshwater consumption by up to 95% compared to evaporation pond methods.

Strengths: Highly selective MOF sorbents reduce purification requirements; efficient regeneration system minimizes chemical and energy costs; integrated downstream processing simplifies production chain; ambient operating conditions reduce energy consumption and equipment complexity. Weaknesses: MOF materials may have higher production costs than conventional ion exchange resins; technology optimization may be required for different brine chemistries; full commercial-scale implementation remains to be demonstrated.

Core Patents in DLE Cost Reduction

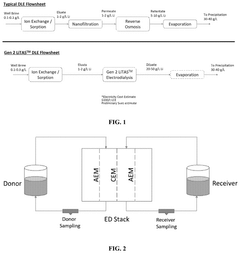

Lithium extraction method

PatentWO2025137291A1

Innovation

- A process combining separation technologies such as lithium adsorbents, nanofiltration, and reverse osmosis to selectively extract lithium from brine solutions with reduced energy consumption and improved water utilization.

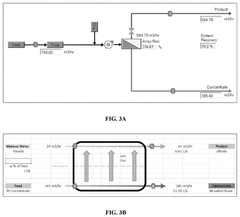

Systems and methods for direct lithium extraction

PatentPendingUS20250011957A1

Innovation

- The integration of selective membrane electrodialysis as a single step to simultaneously concentrate and purify lithium brines, reducing the number of required processing steps, capital and operating costs, and carbon footprint, while eliminating the need for large equipment at remote mining locations.

Environmental Impact Assessment

Direct Lithium Extraction (DLE) technologies present significant environmental implications that must be thoroughly assessed when evaluating cost reduction innovations. Traditional lithium extraction methods, particularly evaporation ponds, have substantial environmental footprints including high water consumption, land use disruption, and chemical contamination risks. DLE technologies offer promising alternatives with potentially reduced environmental impacts.

Water usage represents a critical environmental consideration for DLE implementation. While conventional evaporation methods can consume up to 500,000 gallons of water per ton of lithium produced, advanced DLE technologies demonstrate potential reductions of 50-90% in water requirements. This conservation aspect is particularly significant in water-stressed regions like Chile's Atacama Desert and Argentina's lithium triangle, where water scarcity affects both ecosystems and local communities.

Land disturbance metrics reveal another environmental advantage of DLE systems. These technologies typically require 90% less land area compared to traditional evaporation ponds, which can span thousands of hectares. The reduced spatial footprint minimizes habitat disruption and preserves biodiversity in sensitive ecological zones where lithium resources are often concentrated.

Carbon emissions associated with DLE processes vary significantly based on energy sources utilized. Current assessments indicate that DLE operations powered by renewable energy can achieve 30-60% lower carbon footprints compared to conventional methods. However, energy-intensive DLE variants may actually increase emissions if reliant on fossil fuel power sources, highlighting the importance of integrated renewable energy solutions in achieving true environmental benefits.

Chemical usage and waste management present ongoing environmental challenges for DLE implementation. While some DLE technologies utilize specialized sorbents and solvents that can be regenerated and reused, proper handling protocols remain essential to prevent contamination events. Recent innovations in biodegradable extraction agents and closed-loop processing systems demonstrate promising pathways for minimizing chemical risks.

Ecosystem impacts extend beyond immediate extraction sites, affecting groundwater dynamics and potentially disrupting hydrological systems. Comprehensive monitoring programs are increasingly being integrated into DLE operations to track potential impacts on aquifer levels, water quality parameters, and ecological indicators in surrounding environments. These data-driven approaches enable adaptive management strategies that can mitigate unforeseen environmental consequences.

Regulatory frameworks governing environmental aspects of DLE technologies continue to evolve globally, with varying requirements for impact assessments, monitoring protocols, and remediation standards. Companies pursuing cost reduction innovations must navigate these complex regulatory landscapes while demonstrating environmental performance improvements to secure both operational permits and social license to operate.

Water usage represents a critical environmental consideration for DLE implementation. While conventional evaporation methods can consume up to 500,000 gallons of water per ton of lithium produced, advanced DLE technologies demonstrate potential reductions of 50-90% in water requirements. This conservation aspect is particularly significant in water-stressed regions like Chile's Atacama Desert and Argentina's lithium triangle, where water scarcity affects both ecosystems and local communities.

Land disturbance metrics reveal another environmental advantage of DLE systems. These technologies typically require 90% less land area compared to traditional evaporation ponds, which can span thousands of hectares. The reduced spatial footprint minimizes habitat disruption and preserves biodiversity in sensitive ecological zones where lithium resources are often concentrated.

Carbon emissions associated with DLE processes vary significantly based on energy sources utilized. Current assessments indicate that DLE operations powered by renewable energy can achieve 30-60% lower carbon footprints compared to conventional methods. However, energy-intensive DLE variants may actually increase emissions if reliant on fossil fuel power sources, highlighting the importance of integrated renewable energy solutions in achieving true environmental benefits.

Chemical usage and waste management present ongoing environmental challenges for DLE implementation. While some DLE technologies utilize specialized sorbents and solvents that can be regenerated and reused, proper handling protocols remain essential to prevent contamination events. Recent innovations in biodegradable extraction agents and closed-loop processing systems demonstrate promising pathways for minimizing chemical risks.

Ecosystem impacts extend beyond immediate extraction sites, affecting groundwater dynamics and potentially disrupting hydrological systems. Comprehensive monitoring programs are increasingly being integrated into DLE operations to track potential impacts on aquifer levels, water quality parameters, and ecological indicators in surrounding environments. These data-driven approaches enable adaptive management strategies that can mitigate unforeseen environmental consequences.

Regulatory frameworks governing environmental aspects of DLE technologies continue to evolve globally, with varying requirements for impact assessments, monitoring protocols, and remediation standards. Companies pursuing cost reduction innovations must navigate these complex regulatory landscapes while demonstrating environmental performance improvements to secure both operational permits and social license to operate.

Supply Chain Optimization

Supply chain optimization represents a critical factor in reducing the overall costs of Direct Lithium Extraction (DLE) technologies. The lithium value chain involves multiple stages from extraction to processing, each presenting opportunities for efficiency improvements and cost reduction. Current DLE supply chains often suffer from fragmentation and geographical disconnects between extraction sites and processing facilities, leading to increased transportation costs and logistical complexities.

A key optimization strategy involves vertical integration of the lithium supply chain. Companies that control multiple stages from extraction to battery-grade lithium production can eliminate intermediary margins and reduce transaction costs. This approach has been successfully implemented by major players like Albemarle and SQM, resulting in reported cost reductions of 15-20% compared to non-integrated operations.

Localization of processing facilities near extraction sites presents another significant opportunity. By processing lithium-rich solutions closer to the source, companies can minimize transportation costs of low-value intermediate products. Analysis of recent DLE projects indicates that co-location of extraction and processing facilities can reduce overall operational expenses by 8-12%, particularly in regions with complex logistics networks.

Strategic sourcing of reagents and materials used in DLE processes offers additional cost advantages. Many DLE technologies require specific ion-exchange materials, sorbents, or membranes that constitute a substantial portion of operational costs. Developing supplier partnerships and long-term contracts for these critical materials can stabilize costs and potentially secure preferential pricing, with documented savings of 5-10% in recent industry case studies.

Digitalization of supply chain management through advanced analytics and IoT solutions enables real-time monitoring and optimization of material flows. These technologies allow for predictive maintenance of DLE equipment, inventory optimization, and demand forecasting, collectively reducing working capital requirements and minimizing downtime. Early adopters of digital supply chain solutions in the lithium sector have reported efficiency improvements of 7-15%.

Circular economy principles applied to DLE supply chains can further reduce costs through recovery and reuse of reagents, processing water, and spent materials. Closed-loop systems that recapture and regenerate extraction media have demonstrated the potential to reduce material costs by up to 30% while simultaneously addressing environmental concerns related to waste management and resource consumption.

A key optimization strategy involves vertical integration of the lithium supply chain. Companies that control multiple stages from extraction to battery-grade lithium production can eliminate intermediary margins and reduce transaction costs. This approach has been successfully implemented by major players like Albemarle and SQM, resulting in reported cost reductions of 15-20% compared to non-integrated operations.

Localization of processing facilities near extraction sites presents another significant opportunity. By processing lithium-rich solutions closer to the source, companies can minimize transportation costs of low-value intermediate products. Analysis of recent DLE projects indicates that co-location of extraction and processing facilities can reduce overall operational expenses by 8-12%, particularly in regions with complex logistics networks.

Strategic sourcing of reagents and materials used in DLE processes offers additional cost advantages. Many DLE technologies require specific ion-exchange materials, sorbents, or membranes that constitute a substantial portion of operational costs. Developing supplier partnerships and long-term contracts for these critical materials can stabilize costs and potentially secure preferential pricing, with documented savings of 5-10% in recent industry case studies.

Digitalization of supply chain management through advanced analytics and IoT solutions enables real-time monitoring and optimization of material flows. These technologies allow for predictive maintenance of DLE equipment, inventory optimization, and demand forecasting, collectively reducing working capital requirements and minimizing downtime. Early adopters of digital supply chain solutions in the lithium sector have reported efficiency improvements of 7-15%.

Circular economy principles applied to DLE supply chains can further reduce costs through recovery and reuse of reagents, processing water, and spent materials. Closed-loop systems that recapture and regenerate extraction media have demonstrated the potential to reduce material costs by up to 30% while simultaneously addressing environmental concerns related to waste management and resource consumption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!