Maximize Direct Lithium Extraction Efficiency in Closed-Loop Systems

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a revolutionary approach to lithium production, evolving significantly since its conceptual development in the 1990s. Traditional lithium extraction methods primarily relied on evaporation ponds and hard-rock mining, both characterized by extensive land use, high water consumption, and considerable environmental impact. The growing global demand for lithium, driven by the rapid expansion of electric vehicle markets and energy storage systems, has accelerated the need for more efficient and sustainable extraction technologies.

DLE technologies represent a paradigm shift in lithium production by enabling selective extraction of lithium ions from brine resources while leaving other elements behind. This approach offers significant advantages including reduced environmental footprint, accelerated production timelines, and higher recovery rates compared to conventional methods. The evolution of DLE has been marked by progressive improvements in sorbent materials, process efficiency, and system integration capabilities.

The primary objective of maximizing DLE efficiency in closed-loop systems centers on creating sustainable lithium production pathways that minimize resource consumption while maximizing yield. Closed-loop DLE systems aim to recirculate process fluids, recover reagents, and minimize waste generation, thereby addressing the environmental and economic challenges associated with traditional extraction methods. This approach aligns with broader industry goals of establishing carbon-neutral lithium production capabilities to support the clean energy transition.

Technical objectives for advanced DLE systems include achieving lithium recovery rates exceeding 90%, reducing water consumption by over 70% compared to evaporation methods, and minimizing chemical reagent use through effective regeneration processes. Additionally, these systems aim to accommodate varying brine chemistries, enabling application across diverse geographical locations and resource types.

The technological trajectory of DLE has been characterized by continuous innovation in selective adsorption materials, including ion-exchange resins, inorganic ion sieves, and membrane technologies. Recent developments have focused on enhancing selectivity for lithium over competing ions such as sodium, magnesium, and calcium, which has been a persistent challenge in brine processing operations.

Looking forward, the evolution of DLE technology is expected to focus on integration with renewable energy sources, development of more durable and selective extraction media, and implementation of advanced process control systems to optimize performance across varying operating conditions. The ultimate goal is to establish DLE as the predominant lithium production method, capable of meeting growing global demand while adhering to increasingly stringent environmental standards and sustainability requirements.

DLE technologies represent a paradigm shift in lithium production by enabling selective extraction of lithium ions from brine resources while leaving other elements behind. This approach offers significant advantages including reduced environmental footprint, accelerated production timelines, and higher recovery rates compared to conventional methods. The evolution of DLE has been marked by progressive improvements in sorbent materials, process efficiency, and system integration capabilities.

The primary objective of maximizing DLE efficiency in closed-loop systems centers on creating sustainable lithium production pathways that minimize resource consumption while maximizing yield. Closed-loop DLE systems aim to recirculate process fluids, recover reagents, and minimize waste generation, thereby addressing the environmental and economic challenges associated with traditional extraction methods. This approach aligns with broader industry goals of establishing carbon-neutral lithium production capabilities to support the clean energy transition.

Technical objectives for advanced DLE systems include achieving lithium recovery rates exceeding 90%, reducing water consumption by over 70% compared to evaporation methods, and minimizing chemical reagent use through effective regeneration processes. Additionally, these systems aim to accommodate varying brine chemistries, enabling application across diverse geographical locations and resource types.

The technological trajectory of DLE has been characterized by continuous innovation in selective adsorption materials, including ion-exchange resins, inorganic ion sieves, and membrane technologies. Recent developments have focused on enhancing selectivity for lithium over competing ions such as sodium, magnesium, and calcium, which has been a persistent challenge in brine processing operations.

Looking forward, the evolution of DLE technology is expected to focus on integration with renewable energy sources, development of more durable and selective extraction media, and implementation of advanced process control systems to optimize performance across varying operating conditions. The ultimate goal is to establish DLE as the predominant lithium production method, capable of meeting growing global demand while adhering to increasingly stringent environmental standards and sustainability requirements.

Lithium Market Demand Analysis

The global lithium market is experiencing unprecedented growth, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Annual demand for lithium is projected to increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, representing a compound annual growth rate (CAGR) of 25-30%.

Electric vehicle batteries constitute the largest demand segment, accounting for nearly 80% of lithium consumption. This dominance is expected to continue as major automotive manufacturers commit to electrification targets, with several pledging to phase out internal combustion engines entirely by 2035-2040. The International Energy Agency forecasts that EVs will represent 60% of new vehicle sales by 2030, up from roughly 9% in 2021.

Energy storage systems represent the second-largest growth sector for lithium demand. Grid-scale storage installations are projected to increase tenfold by 2030, driven by the integration of intermittent renewable energy sources into power grids worldwide. This application alone could consume 400,000-500,000 metric tons of LCE annually by 2030.

Consumer electronics, while a mature market segment, continues to provide stable demand for lithium. The proliferation of portable devices, wearable technology, and smart home systems maintains a steady consumption baseline of approximately 100,000 metric tons of LCE annually.

The supply-demand imbalance has created significant price volatility in lithium markets. Spot prices for battery-grade lithium carbonate increased by over 400% between 2020 and 2022, though they have since moderated. Industry analysts predict sustained high prices through 2030, with potential supply shortages emerging as early as 2025 if production capacity expansion fails to keep pace with demand growth.

Traditional lithium production methods—evaporative brine ponds and hard-rock mining—face increasing scrutiny due to their environmental impact and resource inefficiency. This market dynamic creates a compelling opportunity for Direct Lithium Extraction (DLE) technologies, particularly closed-loop systems that promise higher recovery rates, reduced environmental footprint, and faster production cycles.

Geographically, demand is concentrated in manufacturing hubs in East Asia, particularly China, Japan, and South Korea, which collectively account for over 85% of lithium-ion battery production. However, significant manufacturing capacity is being developed in Europe and North America as part of strategic initiatives to secure domestic battery supply chains, potentially reshaping regional demand patterns by 2030.

Electric vehicle batteries constitute the largest demand segment, accounting for nearly 80% of lithium consumption. This dominance is expected to continue as major automotive manufacturers commit to electrification targets, with several pledging to phase out internal combustion engines entirely by 2035-2040. The International Energy Agency forecasts that EVs will represent 60% of new vehicle sales by 2030, up from roughly 9% in 2021.

Energy storage systems represent the second-largest growth sector for lithium demand. Grid-scale storage installations are projected to increase tenfold by 2030, driven by the integration of intermittent renewable energy sources into power grids worldwide. This application alone could consume 400,000-500,000 metric tons of LCE annually by 2030.

Consumer electronics, while a mature market segment, continues to provide stable demand for lithium. The proliferation of portable devices, wearable technology, and smart home systems maintains a steady consumption baseline of approximately 100,000 metric tons of LCE annually.

The supply-demand imbalance has created significant price volatility in lithium markets. Spot prices for battery-grade lithium carbonate increased by over 400% between 2020 and 2022, though they have since moderated. Industry analysts predict sustained high prices through 2030, with potential supply shortages emerging as early as 2025 if production capacity expansion fails to keep pace with demand growth.

Traditional lithium production methods—evaporative brine ponds and hard-rock mining—face increasing scrutiny due to their environmental impact and resource inefficiency. This market dynamic creates a compelling opportunity for Direct Lithium Extraction (DLE) technologies, particularly closed-loop systems that promise higher recovery rates, reduced environmental footprint, and faster production cycles.

Geographically, demand is concentrated in manufacturing hubs in East Asia, particularly China, Japan, and South Korea, which collectively account for over 85% of lithium-ion battery production. However, significant manufacturing capacity is being developed in Europe and North America as part of strategic initiatives to secure domestic battery supply chains, potentially reshaping regional demand patterns by 2030.

Current DLE Technologies and Challenges

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives to traditional evaporation pond methods, offering potential for higher recovery rates, reduced environmental impact, and accelerated production timelines. Current DLE approaches can be categorized into three primary types: adsorption-based, ion exchange, and solvent extraction technologies.

Adsorption-based technologies utilize specialized materials with high selectivity for lithium ions. These materials, including lithium aluminum layered double hydroxides (LDH), lithium manganese oxides, and lithium titanium oxides, can effectively capture lithium from brines. While offering good selectivity, these systems often struggle with regeneration efficiency and material stability over multiple extraction cycles.

Ion exchange technologies employ engineered resins or inorganic materials that preferentially exchange lithium ions for other ions. Companies like EnergyX and Lilac Solutions have developed proprietary ion exchange materials claiming 90%+ lithium recovery rates. However, challenges persist in managing competing ions (particularly magnesium and calcium), resin fouling, and maintaining performance consistency in varying brine compositions.

Solvent extraction methods use specialized organic compounds that selectively bind with lithium in an immiscible phase. Though effective in laboratory settings, scaling these systems has proven difficult due to solvent loss, phase separation issues, and environmental concerns regarding organic chemical usage in closed-loop systems.

Membrane technologies, including nanofiltration and electrodialysis, represent another emerging approach. These systems use electrical potential or specialized membranes to separate lithium from other constituents. While promising for their low chemical consumption, they typically require significant energy input and face membrane fouling challenges in high-salinity environments.

The primary technical challenges across all DLE technologies in closed-loop systems include: maintaining extraction efficiency over multiple cycles; managing impurity build-up; minimizing reagent consumption; reducing energy requirements; and ensuring water conservation. Most commercial DLE systems currently achieve lithium recovery rates between 70-90%, significantly higher than traditional evaporation methods (30-50%), but still below theoretical maximums.

Water management represents a particular challenge for closed-loop DLE systems. While these technologies promise reduced water consumption compared to evaporation ponds, practical implementations often require substantial freshwater for regeneration and washing steps. This creates a critical tension between extraction efficiency and water conservation, especially in water-scarce regions where many lithium resources are located.

Material durability and lifecycle performance remain significant hurdles, with most systems showing degradation in selectivity and capacity after repeated extraction-regeneration cycles. This necessitates periodic material replacement, increasing operational costs and creating potential waste management challenges.

Adsorption-based technologies utilize specialized materials with high selectivity for lithium ions. These materials, including lithium aluminum layered double hydroxides (LDH), lithium manganese oxides, and lithium titanium oxides, can effectively capture lithium from brines. While offering good selectivity, these systems often struggle with regeneration efficiency and material stability over multiple extraction cycles.

Ion exchange technologies employ engineered resins or inorganic materials that preferentially exchange lithium ions for other ions. Companies like EnergyX and Lilac Solutions have developed proprietary ion exchange materials claiming 90%+ lithium recovery rates. However, challenges persist in managing competing ions (particularly magnesium and calcium), resin fouling, and maintaining performance consistency in varying brine compositions.

Solvent extraction methods use specialized organic compounds that selectively bind with lithium in an immiscible phase. Though effective in laboratory settings, scaling these systems has proven difficult due to solvent loss, phase separation issues, and environmental concerns regarding organic chemical usage in closed-loop systems.

Membrane technologies, including nanofiltration and electrodialysis, represent another emerging approach. These systems use electrical potential or specialized membranes to separate lithium from other constituents. While promising for their low chemical consumption, they typically require significant energy input and face membrane fouling challenges in high-salinity environments.

The primary technical challenges across all DLE technologies in closed-loop systems include: maintaining extraction efficiency over multiple cycles; managing impurity build-up; minimizing reagent consumption; reducing energy requirements; and ensuring water conservation. Most commercial DLE systems currently achieve lithium recovery rates between 70-90%, significantly higher than traditional evaporation methods (30-50%), but still below theoretical maximums.

Water management represents a particular challenge for closed-loop DLE systems. While these technologies promise reduced water consumption compared to evaporation ponds, practical implementations often require substantial freshwater for regeneration and washing steps. This creates a critical tension between extraction efficiency and water conservation, especially in water-scarce regions where many lithium resources are located.

Material durability and lifecycle performance remain significant hurdles, with most systems showing degradation in selectivity and capacity after repeated extraction-regeneration cycles. This necessitates periodic material replacement, increasing operational costs and creating potential waste management challenges.

Closed-Loop DLE System Solutions

01 Adsorption-based extraction methods

Adsorption-based methods utilize specialized materials to selectively capture lithium ions from brine solutions. These methods typically employ ion-exchange resins, inorganic adsorbents, or engineered materials with high selectivity for lithium over competing ions like sodium, magnesium, and calcium. The efficiency of these processes depends on factors such as adsorbent capacity, selectivity, regeneration capability, and cycle stability. Advanced adsorbents can significantly reduce extraction time compared to traditional evaporation methods while improving overall lithium recovery rates.- Adsorption-based extraction methods: Adsorption-based technologies utilize specialized materials to selectively capture lithium ions from brine solutions. These methods employ ion-exchange materials, lithium-selective adsorbents, or engineered sorbents that can efficiently separate lithium from other elements present in the brine. The efficiency of these processes depends on the selectivity of the adsorbent material, contact time, and regeneration capabilities. Advanced adsorbents can significantly reduce extraction time compared to traditional evaporation methods while maintaining high recovery rates.

- Membrane and electrochemical extraction technologies: Membrane and electrochemical technologies employ selective barriers or electrical potential differences to separate lithium from other ions in solution. These methods include electrodialysis, nanofiltration, and electrochemical cells specifically designed for lithium extraction. The efficiency of these processes is determined by membrane selectivity, energy consumption, and system design. These technologies can operate continuously and often require less physical space than traditional methods, making them suitable for deployment in various geographical locations.

- Process optimization and control systems: Advanced control systems and process optimization techniques can significantly enhance the efficiency of direct lithium extraction operations. These include real-time monitoring of extraction parameters, automated adjustment of process conditions, and integration of machine learning algorithms to optimize extraction rates. By implementing sophisticated control strategies, operators can maintain optimal conditions throughout the extraction process, resulting in higher lithium recovery rates, reduced reagent consumption, and improved energy efficiency.

- Novel extraction media and materials: Innovative materials specifically engineered for lithium extraction can dramatically improve efficiency metrics. These include functionalized polymers, composite materials with enhanced selectivity, and nanostructured adsorbents with high surface area. The development of these materials focuses on increasing lithium selectivity over competing ions (particularly sodium, magnesium, and calcium), improving kinetics of adsorption/desorption cycles, and enhancing durability for multiple extraction cycles. These advanced materials can operate effectively across a wider range of brine compositions and temperatures.

- Integrated extraction and recovery systems: Integrated systems that combine extraction, purification, and recovery processes can maximize overall lithium production efficiency. These systems incorporate multiple technologies working in sequence to optimize each stage of the lithium recovery process. By integrating various unit operations such as pre-treatment, selective extraction, purification, and concentration, these systems can achieve higher lithium recovery rates while minimizing waste generation and energy consumption. The integration also allows for better heat and material recovery between process steps, further enhancing overall efficiency.

02 Membrane and electrochemical separation technologies

Membrane and electrochemical technologies employ selective barriers or electrical potential differences to separate lithium from other elements in brine solutions. These methods include electrodialysis, capacitive deionization, and selective membrane filtration. The efficiency of these processes is determined by membrane selectivity, energy consumption, and system design. These technologies can operate continuously and often require less physical footprint than traditional methods, making them suitable for deployment in various geographical locations while maintaining high lithium recovery rates.Expand Specific Solutions03 Solvent extraction and chemical precipitation

Solvent extraction and chemical precipitation methods involve the use of specific chemicals to selectively extract or precipitate lithium from brine solutions. These processes typically use organic solvents, complexing agents, or precipitating reagents that interact preferentially with lithium ions. The efficiency of these methods depends on reagent selectivity, reaction kinetics, and separation efficiency. These approaches can achieve high purity lithium products in fewer steps than traditional methods, though considerations must be made for chemical consumption and environmental impact.Expand Specific Solutions04 Process optimization and integration

Process optimization and integration approaches focus on combining multiple extraction technologies or optimizing process parameters to enhance overall lithium extraction efficiency. These methods may involve sequential processing steps, hybrid systems, or novel process configurations designed to maximize lithium recovery while minimizing energy and resource consumption. Key factors affecting efficiency include process flow design, operating conditions, and system integration. Advanced control systems and real-time monitoring can further improve performance by enabling adaptive operation based on feed composition variations.Expand Specific Solutions05 Novel materials and nanotechnology applications

Novel materials and nanotechnology applications involve the development of advanced materials with enhanced lithium selectivity and capacity. These include engineered nanostructured adsorbents, composite materials, metal-organic frameworks, and functionalized polymers specifically designed for lithium extraction. The efficiency improvements come from increased surface area, optimized binding sites, and tailored pore structures that enhance lithium selectivity and kinetics. These materials can significantly reduce processing time and increase lithium recovery rates while operating under milder conditions than conventional methods.Expand Specific Solutions

Key Industry Players in DLE Technology

The direct lithium extraction (DLE) market is currently in its early growth phase, characterized by rapid technological innovation and increasing commercial deployment. The global market size is projected to expand significantly, driven by the surging demand for lithium in electric vehicle batteries and energy storage systems. From a technological maturity perspective, several key players are advancing closed-loop DLE systems with varying approaches. Koch Technology Solutions and Schlumberger are leveraging their industrial expertise to scale up commercial operations, while Lilac Solutions and International Battery Metals are pioneering ion-exchange and selective adsorption technologies. Academic institutions like Tianjin University and Xi'an Jiaotong University are contributing fundamental research, while emerging companies such as Pure Lithium, Evove, and Watercycle Technologies are developing novel membrane and electrochemical processes to maximize efficiency and minimize environmental impact.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed an advanced membrane-based direct lithium extraction (DLE) technology operating within a closed-loop system. Their approach integrates selective separation membranes with electrochemical processes to efficiently extract lithium from various brine sources. The technology employs specialized ion-selective membranes that allow lithium ions to pass through while rejecting competing ions such as sodium, magnesium, and calcium. In their closed-loop configuration, brine is pre-treated to remove potential foulants before entering a multi-stage membrane system where an applied electrical potential drives lithium ion transport across the membranes into a sweep solution. This concentrated lithium solution is then further processed to produce battery-grade lithium compounds. The system achieves lithium recovery rates of approximately 85-95%[5], significantly outperforming traditional evaporation methods. A key innovation in Koch's approach is their membrane fouling prevention system, which extends operational life and maintains consistent performance even with challenging brine compositions. The closed-loop design recirculates process water and chemicals, minimizing waste generation and environmental impact. Their system can process a wide range of brine concentrations and operates continuously with minimal downtime for maintenance, enabling consistent production rates regardless of weather conditions.

Strengths: High selectivity for lithium using advanced membrane technology; reduced environmental footprint through water recycling; weather-independent operation unlike solar evaporation; rapid processing time measured in days rather than months; scalable modular design. Weaknesses: Membrane fouling can still occur with certain brine compositions requiring additional pre-treatment; energy consumption for electrochemical processes; specialized membranes may have limited operational lifespan requiring periodic replacement; higher capital costs compared to traditional evaporation methods.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering at the Chinese Academy of Sciences has developed an innovative electrochemical direct lithium extraction technology operating in a closed-loop system. Their approach combines electrochemical intercalation materials with precise process control to achieve high lithium selectivity and recovery rates. The technology employs specially designed lithium-selective electrodes containing manganese oxide-based intercalation compounds that preferentially capture lithium ions during the charging cycle. In their closed-loop configuration, brine flows through electrochemical cells where lithium ions are selectively intercalated into the electrode material while other ions remain in solution. During the discharge cycle, the captured lithium is released into a small volume of fresh water or recovery solution, creating a concentrated lithium stream for further processing. This electrochemical approach achieves lithium recovery rates of 80-90%[8] while maintaining high selectivity over competing ions such as sodium, magnesium, and calcium. A distinctive feature of their technology is the ability to operate effectively across a wide temperature range (10-60°C), making it suitable for various geographical locations. The system incorporates advanced monitoring and control systems that optimize energy consumption by adjusting electrical parameters based on brine composition and concentration. Their research has demonstrated successful operation with minimal degradation of electrode materials over hundreds of cycles, addressing a key challenge in electrochemical DLE approaches.

Strengths: High selectivity for lithium through electrochemical mechanisms; ability to operate across wide temperature ranges; minimal chemical consumption compared to adsorption methods; precise control over extraction parameters; effective with varying brine compositions. Weaknesses: Energy requirements for electrochemical processes; potential electrode degradation over extended operation requiring periodic replacement; complexity of system control and optimization; scaling challenges when processing high volumes of brine; potential for electrode fouling in certain brine chemistries.

Critical Patents in DLE Efficiency Enhancement

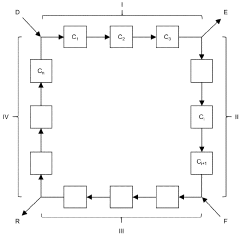

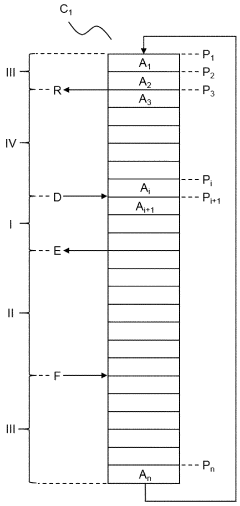

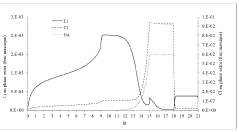

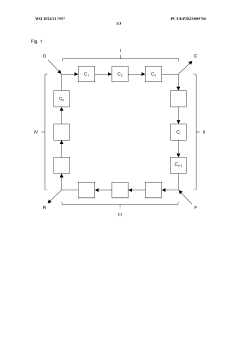

Method and device for simulated moving bed extraction by lithium adsorption

PatentWO2023117597A1

Innovation

- A simulated moving bed process using lithiated aluminum oxyhydroxide or aluminum hydroxide as an adsorbent, with a closed-loop system and specific zone distributions, allows for efficient lithium adsorption and desorption, reducing impurities and desorbent consumption, and enhancing lithium concentration.

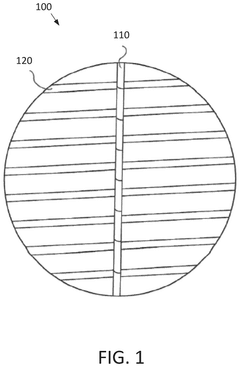

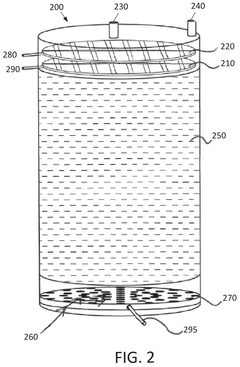

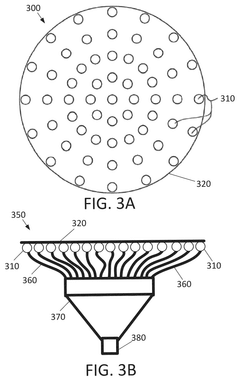

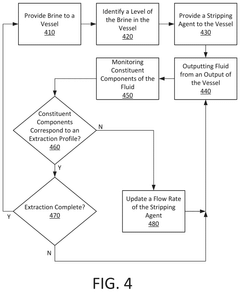

Ion extraction column for brine

PatentPendingUS20250092490A1

Innovation

- A method and apparatus for direct lithium extraction (DLE) using a porous media bed with a uniform extractant material that absorbs target ions like lithium, followed by a stripping solution to separate and regenerate the extractant, maintaining a sharp interface between brine and stripping solution to maximize extraction efficiency.

Environmental Impact Assessment

The environmental impact of Direct Lithium Extraction (DLE) in closed-loop systems represents a critical consideration for sustainable lithium production. Traditional lithium extraction methods, particularly evaporation ponds, consume vast quantities of water—approximately 500,000 gallons per ton of lithium—and occupy extensive land areas, disrupting local ecosystems and biodiversity. In contrast, closed-loop DLE systems demonstrate significant environmental advantages through substantial reduction in water consumption, with some advanced systems achieving up to 90% water recycling rates.

Land use impact assessments reveal that DLE technologies require merely 10% of the surface area compared to conventional evaporation methods, minimizing habitat disruption and preserving natural landscapes. This reduced footprint is particularly valuable in ecologically sensitive regions where lithium brine resources often coincide with fragile ecosystems.

Carbon footprint analysis indicates that optimized closed-loop DLE systems can reduce greenhouse gas emissions by 30-50% compared to traditional extraction methods. This reduction stems from decreased energy requirements for water pumping, treatment, and the elimination of extensive evaporation periods. Furthermore, when powered by renewable energy sources, certain DLE operations have demonstrated potential for near-carbon-neutral lithium production.

Waste management represents another environmental dimension where closed-loop systems excel. By implementing advanced filtration and selective adsorption technologies, these systems minimize chemical reagent usage and produce significantly less hazardous waste. The precipitation of impurities can be controlled more precisely, allowing for potential recovery of valuable by-products like magnesium and potassium compounds.

Groundwater protection is enhanced through closed-loop operation, as these systems substantially reduce the risk of brine leakage and aquifer contamination. Monitoring data from pilot projects indicates minimal impact on groundwater quality when proper containment protocols are implemented, contrasting sharply with the documented groundwater depletion associated with traditional methods.

Biodiversity conservation benefits from DLE closed-loop systems through reduced habitat destruction and decreased wildlife exposure to concentrated brine solutions. Environmental monitoring at operational DLE facilities has documented significantly lower impacts on local flora and fauna compared to conventional extraction sites, particularly regarding migratory bird populations that often suffer high mortality rates at traditional evaporation ponds.

Land use impact assessments reveal that DLE technologies require merely 10% of the surface area compared to conventional evaporation methods, minimizing habitat disruption and preserving natural landscapes. This reduced footprint is particularly valuable in ecologically sensitive regions where lithium brine resources often coincide with fragile ecosystems.

Carbon footprint analysis indicates that optimized closed-loop DLE systems can reduce greenhouse gas emissions by 30-50% compared to traditional extraction methods. This reduction stems from decreased energy requirements for water pumping, treatment, and the elimination of extensive evaporation periods. Furthermore, when powered by renewable energy sources, certain DLE operations have demonstrated potential for near-carbon-neutral lithium production.

Waste management represents another environmental dimension where closed-loop systems excel. By implementing advanced filtration and selective adsorption technologies, these systems minimize chemical reagent usage and produce significantly less hazardous waste. The precipitation of impurities can be controlled more precisely, allowing for potential recovery of valuable by-products like magnesium and potassium compounds.

Groundwater protection is enhanced through closed-loop operation, as these systems substantially reduce the risk of brine leakage and aquifer contamination. Monitoring data from pilot projects indicates minimal impact on groundwater quality when proper containment protocols are implemented, contrasting sharply with the documented groundwater depletion associated with traditional methods.

Biodiversity conservation benefits from DLE closed-loop systems through reduced habitat destruction and decreased wildlife exposure to concentrated brine solutions. Environmental monitoring at operational DLE facilities has documented significantly lower impacts on local flora and fauna compared to conventional extraction sites, particularly regarding migratory bird populations that often suffer high mortality rates at traditional evaporation ponds.

Water Conservation Strategies in DLE Systems

Water conservation represents a critical component in optimizing Direct Lithium Extraction (DLE) systems, particularly within closed-loop frameworks. The traditional lithium extraction methods typically consume between 500,000 to 2 million gallons of water per ton of lithium carbonate equivalent (LCE), creating significant environmental challenges in water-scarce regions where lithium deposits are often found.

Advanced DLE systems have begun implementing multi-stage water recovery processes that can reclaim up to 90% of process water. These systems utilize reverse osmosis and multi-effect evaporation technologies to separate pure water from brine solutions after lithium extraction, allowing for continuous reuse within the operational cycle.

Membrane distillation technology has emerged as a promising advancement, operating at lower temperatures than conventional evaporation methods and reducing energy requirements by 30-40%. This technology enables effective water recovery even from highly concentrated brines where traditional methods become inefficient due to scaling and fouling issues.

Real-time monitoring systems equipped with IoT sensors now track water quality parameters throughout the extraction process, optimizing water usage through automated adjustments based on lithium concentration, impurity levels, and system performance metrics. These smart systems have demonstrated water consumption reductions of 15-25% in pilot implementations.

Hybrid precipitation-adsorption techniques represent another innovative approach, combining selective precipitation of impurities with adsorption processes to minimize water requirements during purification stages. This methodology has shown potential to reduce freshwater intake by up to 60% compared to conventional processing routes.

Several leading DLE operations have implemented zero liquid discharge (ZLD) configurations, where all wastewater is treated and recycled, with solid waste being the only output. While capital-intensive, these systems eliminate environmental discharge and reduce regulatory compliance costs, offering long-term operational benefits in environmentally sensitive areas.

Emerging research focuses on selective ion exchange materials that can operate effectively in higher TDS (Total Dissolved Solids) environments, potentially allowing for fewer regeneration cycles and consequently reducing water requirements for sorbent washing and regeneration phases by approximately 20-30%.

AI-driven predictive maintenance systems are being deployed to anticipate scaling and fouling issues before they impact system efficiency, thereby extending operational cycles between cleaning procedures and minimizing associated water consumption for maintenance activities.

Advanced DLE systems have begun implementing multi-stage water recovery processes that can reclaim up to 90% of process water. These systems utilize reverse osmosis and multi-effect evaporation technologies to separate pure water from brine solutions after lithium extraction, allowing for continuous reuse within the operational cycle.

Membrane distillation technology has emerged as a promising advancement, operating at lower temperatures than conventional evaporation methods and reducing energy requirements by 30-40%. This technology enables effective water recovery even from highly concentrated brines where traditional methods become inefficient due to scaling and fouling issues.

Real-time monitoring systems equipped with IoT sensors now track water quality parameters throughout the extraction process, optimizing water usage through automated adjustments based on lithium concentration, impurity levels, and system performance metrics. These smart systems have demonstrated water consumption reductions of 15-25% in pilot implementations.

Hybrid precipitation-adsorption techniques represent another innovative approach, combining selective precipitation of impurities with adsorption processes to minimize water requirements during purification stages. This methodology has shown potential to reduce freshwater intake by up to 60% compared to conventional processing routes.

Several leading DLE operations have implemented zero liquid discharge (ZLD) configurations, where all wastewater is treated and recycled, with solid waste being the only output. While capital-intensive, these systems eliminate environmental discharge and reduce regulatory compliance costs, offering long-term operational benefits in environmentally sensitive areas.

Emerging research focuses on selective ion exchange materials that can operate effectively in higher TDS (Total Dissolved Solids) environments, potentially allowing for fewer regeneration cycles and consequently reducing water requirements for sorbent washing and regeneration phases by approximately 20-30%.

AI-driven predictive maintenance systems are being deployed to anticipate scaling and fouling issues before they impact system efficiency, thereby extending operational cycles between cleaning procedures and minimizing associated water consumption for maintenance activities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!