Case Evaluation: Direct Lithium Extraction in Low-Grade Ores

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology has emerged as a revolutionary approach to lithium production, evolving significantly since its conceptual development in the 1970s. Traditional lithium extraction methods primarily relied on evaporative processes in salt flats or hard-rock mining, both characterized by extensive land use, high water consumption, and lengthy production timelines. The technological evolution of DLE represents a paradigm shift in addressing these limitations, particularly for low-grade ore deposits previously deemed economically unviable.

The lithium industry has witnessed accelerated development in response to the exponential growth of the electric vehicle market and renewable energy storage systems. Global lithium demand is projected to increase by 400-500% by 2030, creating urgent pressure to develop more efficient extraction technologies. This trajectory has catalyzed significant investment in DLE research and development, with notable advancements occurring in selective adsorption materials, membrane technologies, and electrochemical processes.

DLE technologies aim to extract lithium directly from brines, geothermal waters, and low-grade ores with significantly reduced environmental impact compared to conventional methods. The primary technical objectives include achieving higher lithium recovery rates (>90% compared to 40-50% in traditional methods), substantially reducing water consumption, minimizing land disturbance, and dramatically shortening production timelines from years to days or hours.

For low-grade ores specifically, DLE technology seeks to overcome the economic barriers that have historically rendered these resources unexploitable. These ores, typically containing less than 0.5% lithium content, represent a vast untapped resource that could significantly expand global lithium production capacity if efficiently accessed. The technical challenge lies in developing selective extraction processes that can economically separate lithium from complex mineral matrices with minimal energy input and chemical consumption.

Recent technological breakthroughs have demonstrated promising results in laboratory and pilot-scale operations, with several companies reporting successful lithium extraction from previously uneconomical sources. These advancements include novel sorbent materials with high lithium selectivity, improved ion exchange resins, and innovative electrochemical separation techniques specifically designed for low-grade ore processing.

The ultimate goal of DLE technology development for low-grade ores is to establish economically viable and environmentally sustainable processes that can supplement traditional lithium sources, thereby addressing the anticipated supply gap in the rapidly expanding lithium market. This would not only diversify the global lithium supply chain but also potentially redistribute production geographically, reducing concentration risk in the current lithium market.

The lithium industry has witnessed accelerated development in response to the exponential growth of the electric vehicle market and renewable energy storage systems. Global lithium demand is projected to increase by 400-500% by 2030, creating urgent pressure to develop more efficient extraction technologies. This trajectory has catalyzed significant investment in DLE research and development, with notable advancements occurring in selective adsorption materials, membrane technologies, and electrochemical processes.

DLE technologies aim to extract lithium directly from brines, geothermal waters, and low-grade ores with significantly reduced environmental impact compared to conventional methods. The primary technical objectives include achieving higher lithium recovery rates (>90% compared to 40-50% in traditional methods), substantially reducing water consumption, minimizing land disturbance, and dramatically shortening production timelines from years to days or hours.

For low-grade ores specifically, DLE technology seeks to overcome the economic barriers that have historically rendered these resources unexploitable. These ores, typically containing less than 0.5% lithium content, represent a vast untapped resource that could significantly expand global lithium production capacity if efficiently accessed. The technical challenge lies in developing selective extraction processes that can economically separate lithium from complex mineral matrices with minimal energy input and chemical consumption.

Recent technological breakthroughs have demonstrated promising results in laboratory and pilot-scale operations, with several companies reporting successful lithium extraction from previously uneconomical sources. These advancements include novel sorbent materials with high lithium selectivity, improved ion exchange resins, and innovative electrochemical separation techniques specifically designed for low-grade ore processing.

The ultimate goal of DLE technology development for low-grade ores is to establish economically viable and environmentally sustainable processes that can supplement traditional lithium sources, thereby addressing the anticipated supply gap in the rapidly expanding lithium market. This would not only diversify the global lithium supply chain but also potentially redistribute production geographically, reducing concentration risk in the current lithium market.

Market Analysis for Low-Grade Lithium Resources

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Traditional lithium extraction has focused on high-grade resources such as brine deposits in South America and hard rock mines in Australia. However, as demand continues to outpace supply, attention is increasingly shifting toward previously overlooked low-grade lithium resources.

Market projections indicate that lithium demand will increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030. This represents a compound annual growth rate (CAGR) of over 20%, creating significant supply pressure on existing resources. The current market valuation of lithium stands at around $50 billion, with forecasts suggesting it could reach $150 billion by 2030.

Low-grade lithium resources, defined as those containing less than 0.5% lithium content, represent over 70% of global lithium reserves but account for less than 10% of current production. These resources include clay deposits, oil field brines, geothermal brines, and low-concentration hard rock formations. The economic viability of these resources has historically been limited by technological constraints and high processing costs.

Recent market analysis reveals growing interest from major battery manufacturers and automotive companies in securing lithium supply chains through direct investment in extraction technologies for low-grade resources. Companies like Tesla, CATL, and LG Energy Solution have established strategic partnerships with mining companies and technology developers focused on innovative extraction methods for these previously uneconomical deposits.

Regional market distribution shows North America possessing significant untapped low-grade lithium resources, particularly in Nevada's clay deposits and Arkansas' bromine-rich brines. Europe has limited primary lithium resources but is investing heavily in recycling technologies and alternative extraction methods. China dominates the processing landscape but faces resource constraints, driving its companies to secure overseas assets.

Price volatility in the lithium market has created additional incentives for developing low-grade resources. Lithium carbonate prices have fluctuated between $6,000 and $80,000 per ton over the past five years, with current prices stabilizing around $30,000 per ton. This price level makes many previously uneconomical low-grade resources potentially viable with improved extraction technologies.

Market barriers for low-grade lithium resources include high capital expenditure requirements, water usage concerns, environmental permitting challenges, and technological uncertainties. However, the strategic importance of lithium for energy transition and national security considerations is prompting governmental support through research funding, tax incentives, and streamlined regulatory pathways in many jurisdictions.

Market projections indicate that lithium demand will increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030. This represents a compound annual growth rate (CAGR) of over 20%, creating significant supply pressure on existing resources. The current market valuation of lithium stands at around $50 billion, with forecasts suggesting it could reach $150 billion by 2030.

Low-grade lithium resources, defined as those containing less than 0.5% lithium content, represent over 70% of global lithium reserves but account for less than 10% of current production. These resources include clay deposits, oil field brines, geothermal brines, and low-concentration hard rock formations. The economic viability of these resources has historically been limited by technological constraints and high processing costs.

Recent market analysis reveals growing interest from major battery manufacturers and automotive companies in securing lithium supply chains through direct investment in extraction technologies for low-grade resources. Companies like Tesla, CATL, and LG Energy Solution have established strategic partnerships with mining companies and technology developers focused on innovative extraction methods for these previously uneconomical deposits.

Regional market distribution shows North America possessing significant untapped low-grade lithium resources, particularly in Nevada's clay deposits and Arkansas' bromine-rich brines. Europe has limited primary lithium resources but is investing heavily in recycling technologies and alternative extraction methods. China dominates the processing landscape but faces resource constraints, driving its companies to secure overseas assets.

Price volatility in the lithium market has created additional incentives for developing low-grade resources. Lithium carbonate prices have fluctuated between $6,000 and $80,000 per ton over the past five years, with current prices stabilizing around $30,000 per ton. This price level makes many previously uneconomical low-grade resources potentially viable with improved extraction technologies.

Market barriers for low-grade lithium resources include high capital expenditure requirements, water usage concerns, environmental permitting challenges, and technological uncertainties. However, the strategic importance of lithium for energy transition and national security considerations is prompting governmental support through research funding, tax incentives, and streamlined regulatory pathways in many jurisdictions.

Technical Challenges in Low-Grade Lithium Extraction

Direct Lithium Extraction (DLE) from low-grade ores presents significant technical challenges that must be overcome to make these resources economically viable. The primary obstacle lies in the low concentration of lithium in these deposits, typically ranging from 0.05% to 0.5% Li2O, which necessitates processing large volumes of material for relatively small yields.

Conventional extraction methods face efficiency barriers when applied to low-grade ores. Traditional acid leaching processes consume excessive reagents and energy when lithium content is minimal, resulting in unfavorable economics and environmental impacts. The presence of impurities such as iron, aluminum, magnesium, and calcium further complicates extraction, as these elements compete with lithium during separation processes.

Mineralogical complexity represents another significant challenge. Low-grade lithium deposits often contain the element distributed across multiple mineral phases with varying dissolution properties. This heterogeneity makes it difficult to design a single-step extraction process that effectively targets all lithium-bearing components, necessitating multi-stage approaches that increase operational complexity and cost.

Water consumption poses a critical constraint, particularly as many lithium deposits are located in water-scarce regions. Current extraction methods require 500-2,000 liters of water per kilogram of lithium carbonate produced, creating sustainability concerns and potential conflicts with local communities and other industries competing for water resources.

Energy requirements for processing low-grade ores are substantially higher per unit of lithium recovered compared to higher-grade resources. The additional crushing, grinding, and concentration steps needed to process larger volumes of material translate to increased carbon footprints and operational costs, challenging the economic viability of these projects.

Waste management presents ongoing difficulties, as low-grade ore processing generates significantly larger volumes of tailings and spent materials. These wastes often contain residual chemicals and require careful handling to prevent environmental contamination, adding to project costs and complexity.

Recovery rates remain suboptimal, with current technologies typically achieving only 30-70% lithium recovery from low-grade sources. This inefficiency means valuable resources are left unrecovered, further challenging economic feasibility. Additionally, the quality of lithium products from these sources often requires additional purification steps to meet battery-grade specifications.

Scaling laboratory successes to industrial operations introduces additional engineering challenges. Promising bench-scale technologies frequently encounter unforeseen complications when scaled up, including issues with material handling, reagent recycling, and process control that weren't apparent in smaller-scale testing.

Conventional extraction methods face efficiency barriers when applied to low-grade ores. Traditional acid leaching processes consume excessive reagents and energy when lithium content is minimal, resulting in unfavorable economics and environmental impacts. The presence of impurities such as iron, aluminum, magnesium, and calcium further complicates extraction, as these elements compete with lithium during separation processes.

Mineralogical complexity represents another significant challenge. Low-grade lithium deposits often contain the element distributed across multiple mineral phases with varying dissolution properties. This heterogeneity makes it difficult to design a single-step extraction process that effectively targets all lithium-bearing components, necessitating multi-stage approaches that increase operational complexity and cost.

Water consumption poses a critical constraint, particularly as many lithium deposits are located in water-scarce regions. Current extraction methods require 500-2,000 liters of water per kilogram of lithium carbonate produced, creating sustainability concerns and potential conflicts with local communities and other industries competing for water resources.

Energy requirements for processing low-grade ores are substantially higher per unit of lithium recovered compared to higher-grade resources. The additional crushing, grinding, and concentration steps needed to process larger volumes of material translate to increased carbon footprints and operational costs, challenging the economic viability of these projects.

Waste management presents ongoing difficulties, as low-grade ore processing generates significantly larger volumes of tailings and spent materials. These wastes often contain residual chemicals and require careful handling to prevent environmental contamination, adding to project costs and complexity.

Recovery rates remain suboptimal, with current technologies typically achieving only 30-70% lithium recovery from low-grade sources. This inefficiency means valuable resources are left unrecovered, further challenging economic feasibility. Additionally, the quality of lithium products from these sources often requires additional purification steps to meet battery-grade specifications.

Scaling laboratory successes to industrial operations introduces additional engineering challenges. Promising bench-scale technologies frequently encounter unforeseen complications when scaled up, including issues with material handling, reagent recycling, and process control that weren't apparent in smaller-scale testing.

Current DLE Solutions for Low-Grade Ores

01 Adsorption-based extraction methods

Adsorption-based methods utilize specialized materials to selectively capture lithium ions from brine solutions. These methods typically employ ion exchange resins, inorganic adsorbents, or functionalized polymers that have high selectivity for lithium over competing ions like sodium, potassium, and magnesium. The efficiency of these methods depends on factors such as adsorbent capacity, selectivity, regeneration capability, and kinetics of adsorption. Recent advancements focus on developing novel adsorbent materials with improved lithium uptake and reduced regeneration costs.- Adsorption-based extraction methods: Adsorption-based methods for direct lithium extraction utilize specialized adsorbents that selectively capture lithium ions from brine solutions. These methods typically employ ion-exchange materials, lithium-selective sorbents, or functionalized membranes that can efficiently separate lithium from other elements present in the brine. The efficiency of these processes depends on factors such as adsorbent selectivity, adsorption capacity, and regeneration capabilities, which collectively determine the overall lithium recovery rate.

- Electrochemical extraction techniques: Electrochemical methods for direct lithium extraction involve the use of electrical potential to selectively extract lithium ions from brine solutions. These techniques include electrochemical cells, capacitive deionization, and electrodialysis systems specifically designed for lithium recovery. The extraction efficiency is influenced by factors such as electrode materials, applied voltage, current density, and solution chemistry. These methods often offer advantages in terms of energy efficiency and environmental impact compared to traditional evaporation techniques.

- Membrane-based separation systems: Membrane-based systems for direct lithium extraction utilize specialized membranes that allow selective passage of lithium ions while blocking other elements. These systems may employ nanofiltration, reverse osmosis, or ion-selective membranes to achieve high lithium recovery rates. The extraction efficiency depends on membrane properties such as selectivity, permeability, and fouling resistance. Optimization of operating parameters like pressure, flow rate, and solution pre-treatment can significantly enhance the overall lithium recovery efficiency.

- Chemical precipitation and extraction methods: Chemical precipitation methods for direct lithium extraction involve the addition of specific reagents to brine solutions to selectively precipitate lithium compounds. These methods may utilize pH adjustment, addition of complexing agents, or specific chemical reactions to separate lithium from other elements. The extraction efficiency is determined by factors such as reagent selectivity, reaction kinetics, and precipitation conditions. These methods can achieve high lithium recovery rates but may require additional purification steps to obtain battery-grade lithium compounds.

- Process optimization and efficiency enhancement: Various approaches to optimize direct lithium extraction processes focus on enhancing overall efficiency through system design improvements, process integration, and operational parameter optimization. These approaches include multi-stage extraction systems, hybrid processes combining different extraction methods, advanced process control strategies, and energy recovery systems. Efficiency enhancement techniques may also involve pre-treatment of brine solutions, recycling of process streams, and optimization of regeneration procedures to maximize lithium recovery while minimizing resource consumption.

02 Membrane-based separation technologies

Membrane-based technologies employ selective barriers to separate lithium from other components in brine solutions. These include nanofiltration, electrodialysis, and other membrane processes that exploit differences in ion size, charge, or mobility. The extraction efficiency is influenced by membrane properties such as permeability, selectivity, fouling resistance, and durability. Recent innovations focus on developing composite membranes with enhanced lithium selectivity and reduced energy consumption, as well as optimizing operating conditions to maximize lithium recovery while minimizing impurities.Expand Specific Solutions03 Electrochemical extraction processes

Electrochemical methods utilize electrical potential to selectively extract lithium from brines or other sources. These processes include electrochemical intercalation, electrolysis, and capacitive deionization techniques. The efficiency of these methods is determined by factors such as electrode materials, cell design, applied potential, and solution chemistry. Recent developments focus on novel electrode materials with high lithium selectivity, improved cycling stability, and reduced energy requirements, as well as optimizing process parameters to enhance lithium recovery rates.Expand Specific Solutions04 Solvent extraction and chemical precipitation

Solvent extraction and chemical precipitation methods involve the use of specific chemicals to selectively extract or precipitate lithium from solution. These methods typically employ organic solvents, complexing agents, or precipitating reagents that interact preferentially with lithium ions. The efficiency depends on factors such as reagent selectivity, reaction kinetics, and separation efficiency. Recent innovations focus on developing environmentally friendly solvents, improving phase separation, and optimizing reaction conditions to maximize lithium recovery while minimizing chemical consumption and waste generation.Expand Specific Solutions05 Process optimization and integrated systems

Process optimization approaches focus on enhancing the overall efficiency of direct lithium extraction through system integration, process intensification, and advanced control strategies. These methods involve combining multiple extraction techniques, optimizing process parameters, and implementing real-time monitoring and control systems. The efficiency improvements come from synergistic effects between different extraction stages, reduced energy and reagent consumption, and minimized waste generation. Recent developments include hybrid extraction systems, continuous processing technologies, and AI-based process optimization to maximize lithium recovery rates while minimizing operational costs.Expand Specific Solutions

Key Industry Players in DLE Technology

Direct Lithium Extraction (DLE) in low-grade ores represents an emerging market in the early growth phase, with global lithium demand projected to reach $9.4 billion by 2027. The technology maturity varies significantly among key players. Companies like CATL and BYD are leveraging their battery manufacturing expertise to integrate backward into lithium extraction, while specialized technology developers such as Lilac Solutions and Novalith Technologies are pioneering innovative ion-exchange and CO2-based extraction methods. Academic institutions including Penn State Research Foundation and The University of Manchester are contributing fundamental research advances. The competitive landscape is diversifying with traditional mining companies, battery manufacturers, and technology startups all vying for position in this strategically important sector that bridges mining, chemical processing, and clean energy applications.

Novalith Technologies Pty Ltd.

Technical Solution: Novalith Technologies has pioneered a CO2-driven direct lithium extraction process specifically targeting low-grade lithium ores. Their LiCAL™ technology uses carbon dioxide as a reagent to selectively leach lithium from various lithium-bearing minerals, including spodumene, lepidolite, and clay deposits. The process involves contacting crushed ore with carbonated water under controlled conditions, where CO2 forms carbonic acid that selectively dissolves lithium while leaving most impurities in the solid phase. This creates a lithium bicarbonate solution that can be directly converted to battery-grade lithium chemicals. The technology integrates carbon capture, utilizing CO2 as both a reagent and sequestering it in the process. Novalith's approach eliminates the need for high-temperature calcination and aggressive reagents typically used in conventional processing, reducing energy requirements by up to 70% compared to traditional methods while enabling economic extraction from ores with lithium concentrations as low as 0.4%.

Strengths: Significantly reduced carbon footprint through CO2 utilization; lower chemical and energy consumption; elimination of sodium-based reagents; ability to process various low-grade ore types; production of fewer waste streams. Weaknesses: Relatively new technology with limited large-scale implementation; potential challenges in achieving consistent extraction rates across heterogeneous ore bodies; may require specific ore preparation steps; CO2 sourcing logistics in remote locations.

Lilac Solutions, Inc.

Technical Solution: Lilac Solutions has developed an innovative ion exchange technology specifically designed for direct lithium extraction (DLE) from low-grade ores and brines. Their proprietary ceramic ion exchange beads selectively absorb lithium ions from brine solutions while rejecting other elements. The process operates in a continuous flow system where lithium-rich brines pass through columns containing these beads, which capture lithium and release it into a small volume of fresh solution, creating a concentrated lithium product. This technology achieves concentration factors of 100-10,000x, significantly reducing the physical footprint compared to traditional evaporation ponds. Lilac's system can process brines with lithium concentrations as low as 100 ppm, making previously uneconomical resources viable. The modular design allows for scalable implementation and can be deployed directly at brine sources, minimizing transportation costs and environmental impact.

Strengths: High selectivity for lithium over competing ions; rapid processing time (hours vs. months for evaporation ponds); significantly reduced water consumption; ability to process low-grade resources; modular and scalable design. Weaknesses: Requires electricity and some chemical inputs; higher capital costs compared to traditional methods; technology still being proven at commercial scale; potential for ion exchange material degradation over multiple cycles.

Critical Patents and Innovations in DLE

Recovery of lithium from low-grade ores

PatentInactiveUS4285914A

Innovation

- The process involves adding CaO or CaCO3 to the clay and using a gaseous H2O-HCl mixture at elevated temperatures to form non-reactive calcium silicate, allowing for efficient lithium recovery without preliminary beneficiation, using a low-cost chlorination reagent and optimizing CaO/CaCO3 amounts to achieve maximum efficiency.

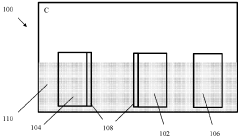

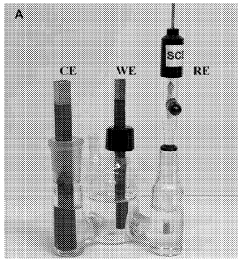

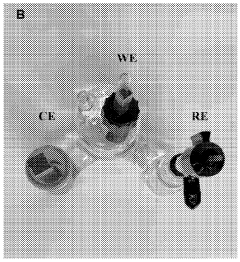

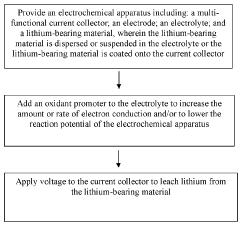

Direct electrochemical extraction of lithium from ores

PatentWO2023224970A1

Innovation

- A direct electrochemical method using a carbon-based or metal/alloy-based current collector with an electrolyte and an oxidant promoter to leach lithium from lithium-bearing materials like spodumene without phase transformation, applying voltage to increase extraction efficiency and reduce energy consumption.

Environmental Impact Assessment of DLE Methods

Direct Lithium Extraction (DLE) technologies present both significant environmental advantages and challenges compared to traditional lithium extraction methods. When applied to low-grade ores, DLE methods substantially reduce land disturbance by eliminating the need for large evaporation ponds that characterize conventional brine operations. This reduction in physical footprint can decrease habitat destruction and preserve biodiversity in sensitive ecosystems where lithium deposits are often found.

Water consumption represents a critical environmental consideration for DLE implementation. While traditional evaporative methods can consume up to 500,000 gallons of water per ton of lithium produced, advanced DLE technologies demonstrate potential water usage reductions of 50-90%. However, when processing low-grade ores, the increased volume of material handling may partially offset these water conservation benefits, necessitating careful water management strategies in water-stressed regions.

Chemical usage in DLE processes introduces another environmental dimension requiring assessment. Most DLE methods employ sorbents, solvents, or membranes that require periodic regeneration using acids, bases, or other chemicals. The environmental impact depends largely on closed-loop implementation efficiency and chemical recovery rates. Recent advancements in bio-based sorbents and environmentally benign regeneration agents show promise for reducing the chemical footprint of these operations.

Energy consumption patterns differ significantly between DLE methods. Adsorption-based technologies typically require 5-15 kWh per kilogram of lithium extracted, while membrane and solvent extraction approaches may consume 10-25 kWh/kg. This energy intensity must be evaluated against the carbon footprint of the regional electricity grid where implementation occurs. Renewable energy integration presents a viable pathway to mitigate these impacts, with several pilot projects demonstrating successful solar-powered DLE operations.

Waste management constitutes perhaps the most significant environmental challenge for DLE in low-grade ore processing. The increased volume of processed material generates substantial solid waste streams that require proper handling and disposal. Advanced waste valorization approaches, including the recovery of valuable by-products like magnesium, calcium, and rare earth elements, can transform waste management from an environmental liability into a potential economic opportunity while reducing overall environmental impact.

Lifecycle assessment studies indicate that despite these challenges, DLE methods applied to low-grade ores generally maintain a 30-45% lower overall environmental impact compared to conventional extraction techniques when properly implemented with appropriate mitigation measures and technological optimizations.

Water consumption represents a critical environmental consideration for DLE implementation. While traditional evaporative methods can consume up to 500,000 gallons of water per ton of lithium produced, advanced DLE technologies demonstrate potential water usage reductions of 50-90%. However, when processing low-grade ores, the increased volume of material handling may partially offset these water conservation benefits, necessitating careful water management strategies in water-stressed regions.

Chemical usage in DLE processes introduces another environmental dimension requiring assessment. Most DLE methods employ sorbents, solvents, or membranes that require periodic regeneration using acids, bases, or other chemicals. The environmental impact depends largely on closed-loop implementation efficiency and chemical recovery rates. Recent advancements in bio-based sorbents and environmentally benign regeneration agents show promise for reducing the chemical footprint of these operations.

Energy consumption patterns differ significantly between DLE methods. Adsorption-based technologies typically require 5-15 kWh per kilogram of lithium extracted, while membrane and solvent extraction approaches may consume 10-25 kWh/kg. This energy intensity must be evaluated against the carbon footprint of the regional electricity grid where implementation occurs. Renewable energy integration presents a viable pathway to mitigate these impacts, with several pilot projects demonstrating successful solar-powered DLE operations.

Waste management constitutes perhaps the most significant environmental challenge for DLE in low-grade ore processing. The increased volume of processed material generates substantial solid waste streams that require proper handling and disposal. Advanced waste valorization approaches, including the recovery of valuable by-products like magnesium, calcium, and rare earth elements, can transform waste management from an environmental liability into a potential economic opportunity while reducing overall environmental impact.

Lifecycle assessment studies indicate that despite these challenges, DLE methods applied to low-grade ores generally maintain a 30-45% lower overall environmental impact compared to conventional extraction techniques when properly implemented with appropriate mitigation measures and technological optimizations.

Economic Feasibility of Low-Grade Lithium Extraction

The economic feasibility of Direct Lithium Extraction (DLE) from low-grade ores represents a critical consideration for industry stakeholders. Current market analyses indicate that traditional lithium extraction methods become economically unviable when ore grades fall below 0.6%, creating a significant opportunity for innovative DLE technologies that can profitably process lower concentrations.

Cost modeling reveals that DLE technologies can potentially reduce production costs by 30-50% compared to conventional evaporation pond methods when applied to low-grade resources. This cost advantage stems primarily from reduced land requirements, accelerated extraction timeframes, and diminished water consumption. However, these savings must be balanced against higher initial capital expenditures for specialized equipment and increased energy requirements.

Break-even analysis suggests that with current lithium carbonate prices hovering around $15,000-$20,000 per ton, DLE becomes economically viable for ores with lithium concentrations as low as 0.1-0.2%, depending on specific geological conditions and extraction efficiency. This represents a significant expansion of the economically recoverable lithium resource base globally.

Return on investment calculations indicate potential payback periods of 3-5 years for DLE projects targeting low-grade ores, assuming stable commodity prices and operational efficiency. This timeline compares favorably with conventional extraction methods that may require 5-7 years to achieve profitability when working with premium-grade resources.

Energy consumption remains a significant cost factor, with DLE processes requiring approximately 1.5-2.5 MWh per ton of lithium carbonate equivalent produced. Renewable energy integration presents an opportunity to both reduce operational costs and enhance environmental sustainability metrics, potentially improving project economics by 10-15% in regions with favorable renewable resources.

Scale economies play a crucial role in determining feasibility, with minimum economically viable processing volumes estimated at 5,000-10,000 tons of lithium carbonate equivalent annually. This threshold necessitates substantial initial investment but enables competitive unit economics once operational.

Market volatility represents a significant risk factor, as lithium price fluctuations of ±30% have been observed in recent years. Sensitivity analysis indicates that DLE projects maintain economic viability even with 20% price decreases, provided that extraction efficiencies remain above 80% and energy costs are effectively managed.

Cost modeling reveals that DLE technologies can potentially reduce production costs by 30-50% compared to conventional evaporation pond methods when applied to low-grade resources. This cost advantage stems primarily from reduced land requirements, accelerated extraction timeframes, and diminished water consumption. However, these savings must be balanced against higher initial capital expenditures for specialized equipment and increased energy requirements.

Break-even analysis suggests that with current lithium carbonate prices hovering around $15,000-$20,000 per ton, DLE becomes economically viable for ores with lithium concentrations as low as 0.1-0.2%, depending on specific geological conditions and extraction efficiency. This represents a significant expansion of the economically recoverable lithium resource base globally.

Return on investment calculations indicate potential payback periods of 3-5 years for DLE projects targeting low-grade ores, assuming stable commodity prices and operational efficiency. This timeline compares favorably with conventional extraction methods that may require 5-7 years to achieve profitability when working with premium-grade resources.

Energy consumption remains a significant cost factor, with DLE processes requiring approximately 1.5-2.5 MWh per ton of lithium carbonate equivalent produced. Renewable energy integration presents an opportunity to both reduce operational costs and enhance environmental sustainability metrics, potentially improving project economics by 10-15% in regions with favorable renewable resources.

Scale economies play a crucial role in determining feasibility, with minimum economically viable processing volumes estimated at 5,000-10,000 tons of lithium carbonate equivalent annually. This threshold necessitates substantial initial investment but enables competitive unit economics once operational.

Market volatility represents a significant risk factor, as lithium price fluctuations of ±30% have been observed in recent years. Sensitivity analysis indicates that DLE projects maintain economic viability even with 20% price decreases, provided that extraction efficiencies remain above 80% and energy costs are effectively managed.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!