Direct Lithium Extraction vs Conventional Drilling: Efficiency Metrics

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Lithium extraction technologies have evolved significantly over the past century, with conventional brine evaporation and hard rock mining dominating the industry for decades. Direct Lithium Extraction (DLE) represents a paradigm shift in this landscape, emerging as a promising alternative to address the growing global demand for lithium driven by the electric vehicle revolution and renewable energy storage systems.

The historical trajectory of lithium extraction began with mineral mining in the early 20th century, followed by the development of brine extraction methods in the 1950s. These conventional methods have sustained the industry but face increasing scrutiny due to their environmental impact, water consumption, and lengthy production timelines. DLE technologies began emerging in the 1990s but have gained significant momentum only in the past decade as lithium demand forecasts have skyrocketed.

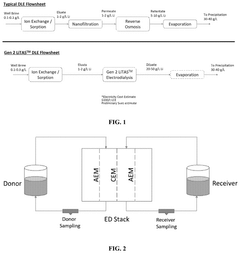

DLE encompasses a diverse set of technologies including adsorption, ion exchange, solvent extraction, and membrane processes, all aimed at selectively extracting lithium from brines with greater efficiency than traditional methods. The fundamental innovation lies in the ability to extract lithium directly from brine without extensive evaporation ponds, potentially reducing production time from 18 months to mere days.

The technical objectives of DLE development center around five key metrics: recovery efficiency, selectivity, processing speed, water consumption, and environmental footprint. Current research aims to achieve lithium recovery rates exceeding 90% (compared to 40-50% in conventional methods), processing times of hours rather than months, and water usage reductions of up to 90%.

Industry projections suggest that by 2030, DLE could account for 25-30% of global lithium production, representing a transformative shift in supply chain dynamics. This transition is particularly significant given forecasts indicating lithium demand may increase by 400-500% by 2030, primarily driven by battery applications.

The technological evolution continues with emerging research focused on enhancing sorbent materials, developing more energy-efficient processes, and creating closed-loop systems that minimize waste. Recent breakthroughs in selective adsorption materials and electrochemical extraction methods have demonstrated promising results in laboratory settings, with several pilot plants now operational across North America and South America.

The ultimate goal of DLE technology development extends beyond mere extraction efficiency to creating sustainable, economically viable processes that can operate across diverse brine chemistries and geological settings, thereby expanding the global lithium resource base and reducing dependency on geographically concentrated conventional resources.

The historical trajectory of lithium extraction began with mineral mining in the early 20th century, followed by the development of brine extraction methods in the 1950s. These conventional methods have sustained the industry but face increasing scrutiny due to their environmental impact, water consumption, and lengthy production timelines. DLE technologies began emerging in the 1990s but have gained significant momentum only in the past decade as lithium demand forecasts have skyrocketed.

DLE encompasses a diverse set of technologies including adsorption, ion exchange, solvent extraction, and membrane processes, all aimed at selectively extracting lithium from brines with greater efficiency than traditional methods. The fundamental innovation lies in the ability to extract lithium directly from brine without extensive evaporation ponds, potentially reducing production time from 18 months to mere days.

The technical objectives of DLE development center around five key metrics: recovery efficiency, selectivity, processing speed, water consumption, and environmental footprint. Current research aims to achieve lithium recovery rates exceeding 90% (compared to 40-50% in conventional methods), processing times of hours rather than months, and water usage reductions of up to 90%.

Industry projections suggest that by 2030, DLE could account for 25-30% of global lithium production, representing a transformative shift in supply chain dynamics. This transition is particularly significant given forecasts indicating lithium demand may increase by 400-500% by 2030, primarily driven by battery applications.

The technological evolution continues with emerging research focused on enhancing sorbent materials, developing more energy-efficient processes, and creating closed-loop systems that minimize waste. Recent breakthroughs in selective adsorption materials and electrochemical extraction methods have demonstrated promising results in laboratory settings, with several pilot plants now operational across North America and South America.

The ultimate goal of DLE technology development extends beyond mere extraction efficiency to creating sustainable, economically viable processes that can operate across diverse brine chemistries and geological settings, thereby expanding the global lithium resource base and reducing dependency on geographically concentrated conventional resources.

Lithium Market Demand Analysis

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Market analysis indicates that global lithium demand reached approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2022, with projections suggesting this figure could triple by 2030, reaching 1.5 million metric tons annually.

The EV sector represents the largest demand driver, accounting for over 70% of lithium consumption. This trend is accelerating as major automotive manufacturers commit to electrification targets, with companies like Volkswagen, GM, and Ford announcing plans to phase out internal combustion engines entirely within the next 10-15 years. Battery production capacity is expanding at a compound annual growth rate (CAGR) of 25%, necessitating substantial increases in lithium supply.

Energy storage systems represent the second-largest growth segment, with utility-scale battery installations increasing by 160% year-over-year in 2022. As renewable energy penetration increases globally, the demand for large-scale energy storage solutions continues to rise, further straining lithium supply chains.

Consumer electronics, traditionally a major lithium consumer, now represents a smaller but still significant market share of approximately 14%. While growth in this sector has moderated compared to automotive applications, the absolute volume continues to increase steadily at 5-7% annually.

Regional demand analysis reveals China dominates global lithium processing, accounting for 75% of all battery-grade lithium production. However, demand growth is accelerating in North America and Europe as these regions establish domestic battery supply chains to reduce dependence on Asian manufacturers.

Price volatility has been extreme, with lithium carbonate prices surging from $10,000 per ton in early 2021 to over $80,000 per ton in late 2022, before moderating to $30,000-40,000 range in 2023. This volatility underscores the critical supply-demand imbalance in the market.

The efficiency gap between Direct Lithium Extraction (DLE) and conventional extraction methods becomes particularly significant when viewed against this market backdrop. Conventional methods struggle to scale production quickly enough to meet surging demand, while DLE technologies promise faster time-to-market and potentially lower production costs at scale, addressing the market's need for rapid supply expansion.

The EV sector represents the largest demand driver, accounting for over 70% of lithium consumption. This trend is accelerating as major automotive manufacturers commit to electrification targets, with companies like Volkswagen, GM, and Ford announcing plans to phase out internal combustion engines entirely within the next 10-15 years. Battery production capacity is expanding at a compound annual growth rate (CAGR) of 25%, necessitating substantial increases in lithium supply.

Energy storage systems represent the second-largest growth segment, with utility-scale battery installations increasing by 160% year-over-year in 2022. As renewable energy penetration increases globally, the demand for large-scale energy storage solutions continues to rise, further straining lithium supply chains.

Consumer electronics, traditionally a major lithium consumer, now represents a smaller but still significant market share of approximately 14%. While growth in this sector has moderated compared to automotive applications, the absolute volume continues to increase steadily at 5-7% annually.

Regional demand analysis reveals China dominates global lithium processing, accounting for 75% of all battery-grade lithium production. However, demand growth is accelerating in North America and Europe as these regions establish domestic battery supply chains to reduce dependence on Asian manufacturers.

Price volatility has been extreme, with lithium carbonate prices surging from $10,000 per ton in early 2021 to over $80,000 per ton in late 2022, before moderating to $30,000-40,000 range in 2023. This volatility underscores the critical supply-demand imbalance in the market.

The efficiency gap between Direct Lithium Extraction (DLE) and conventional extraction methods becomes particularly significant when viewed against this market backdrop. Conventional methods struggle to scale production quickly enough to meet surging demand, while DLE technologies promise faster time-to-market and potentially lower production costs at scale, addressing the market's need for rapid supply expansion.

DLE vs Conventional Extraction: Current Status and Challenges

The global lithium extraction landscape is currently experiencing a significant technological transition. Conventional lithium extraction methods, primarily evaporation ponds and hard rock mining, have dominated the industry for decades. These traditional approaches, while established, present considerable challenges including lengthy production timelines (12-18 months for evaporation ponds), substantial water consumption (approximately 500,000 gallons per ton of lithium), and relatively low recovery rates (typically 30-50%).

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives, with various approaches being developed and tested worldwide. These include adsorption-based systems, ion exchange membranes, solvent extraction methods, and electrochemical processes. Current DLE implementations demonstrate significantly improved efficiency metrics, with extraction times reduced to hours or days rather than months, water usage decreased by up to 90%, and recovery rates potentially reaching 70-90%.

Despite these advantages, DLE technologies face several critical challenges. Technical barriers include selectivity issues in complex brine compositions, adsorbent durability concerns, and scaling challenges when transitioning from laboratory to commercial production. The geographical distribution of DLE development shows concentration in North America, particularly the United States and Canada, with growing research activities in Australia, China, and parts of Europe.

Economic factors present additional hurdles, as many DLE technologies require substantial capital investment and have yet to demonstrate long-term economic viability at commercial scale. Current cost estimates suggest operational expenses of $3,000-$7,000 per ton of lithium carbonate equivalent (LCE) for DLE methods, compared to $2,000-$5,000 for conventional approaches, though this gap is narrowing as technologies mature.

Environmental considerations reveal a complex picture. While DLE significantly reduces water consumption and physical footprint compared to evaporation ponds, some processes require considerable energy input or chemical reagents, creating different environmental trade-offs that vary by specific technology and implementation.

Regulatory frameworks worldwide are still adapting to these emerging technologies, with inconsistent approaches across different jurisdictions creating uncertainty for technology developers and potential adopters. This regulatory landscape is particularly challenging in regions with established conventional extraction operations where existing permitting processes may not adequately address novel DLE approaches.

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives, with various approaches being developed and tested worldwide. These include adsorption-based systems, ion exchange membranes, solvent extraction methods, and electrochemical processes. Current DLE implementations demonstrate significantly improved efficiency metrics, with extraction times reduced to hours or days rather than months, water usage decreased by up to 90%, and recovery rates potentially reaching 70-90%.

Despite these advantages, DLE technologies face several critical challenges. Technical barriers include selectivity issues in complex brine compositions, adsorbent durability concerns, and scaling challenges when transitioning from laboratory to commercial production. The geographical distribution of DLE development shows concentration in North America, particularly the United States and Canada, with growing research activities in Australia, China, and parts of Europe.

Economic factors present additional hurdles, as many DLE technologies require substantial capital investment and have yet to demonstrate long-term economic viability at commercial scale. Current cost estimates suggest operational expenses of $3,000-$7,000 per ton of lithium carbonate equivalent (LCE) for DLE methods, compared to $2,000-$5,000 for conventional approaches, though this gap is narrowing as technologies mature.

Environmental considerations reveal a complex picture. While DLE significantly reduces water consumption and physical footprint compared to evaporation ponds, some processes require considerable energy input or chemical reagents, creating different environmental trade-offs that vary by specific technology and implementation.

Regulatory frameworks worldwide are still adapting to these emerging technologies, with inconsistent approaches across different jurisdictions creating uncertainty for technology developers and potential adopters. This regulatory landscape is particularly challenging in regions with established conventional extraction operations where existing permitting processes may not adequately address novel DLE approaches.

Current DLE Technical Solutions and Methodologies

01 Direct Lithium Extraction (DLE) Technologies

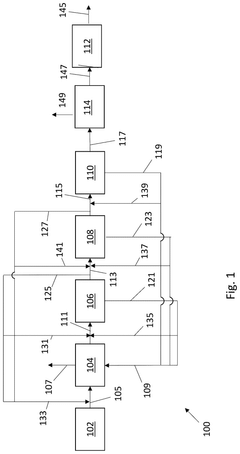

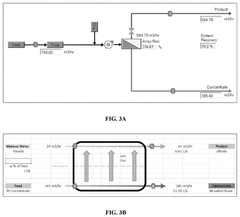

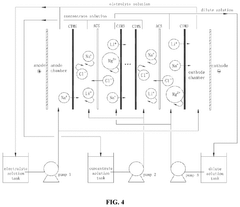

Direct Lithium Extraction technologies represent innovative methods for extracting lithium from brine resources without traditional evaporation ponds. These technologies utilize selective adsorption, ion exchange, or membrane processes to efficiently separate lithium from other elements in brine solutions. DLE methods significantly reduce water consumption, processing time, and environmental footprint compared to conventional extraction methods, while potentially increasing lithium recovery rates.- Direct Lithium Extraction (DLE) Technologies: Various technologies for directly extracting lithium from brine resources without traditional evaporation ponds. These methods include adsorption, ion exchange, solvent extraction, and membrane processes that can selectively capture lithium ions from brines. DLE technologies offer advantages such as reduced environmental footprint, faster extraction times, and higher recovery rates compared to conventional evaporation methods.

- Drilling Efficiency Measurement and Optimization: Systems and methods for measuring and optimizing drilling efficiency in conventional oil, gas, and geothermal operations. These include real-time monitoring tools, performance metrics calculation, and analytical methods to evaluate drilling parameters such as rate of penetration, mechanical specific energy, and drilling cost per foot. Advanced sensors and data analytics help optimize drilling operations by reducing non-productive time and improving overall operational efficiency.

- Integration of Lithium Extraction with Existing Well Infrastructure: Methods for integrating lithium extraction processes with existing oil and gas well infrastructure to improve economic efficiency. These approaches leverage abandoned or producing wells to access lithium-rich brines, utilizing existing boreholes and surface facilities to reduce capital expenditure. The integration enables simultaneous production of hydrocarbons and lithium, creating new revenue streams from existing assets while minimizing environmental impact.

- Monitoring and Analysis Systems for Resource Extraction: Advanced monitoring and analysis systems designed specifically for resource extraction operations, including lithium production and conventional drilling. These systems incorporate sensors, data acquisition tools, and analytical software to provide real-time information on operational parameters. Machine learning algorithms and artificial intelligence are employed to process large datasets, identify patterns, and optimize extraction processes for improved efficiency and reduced environmental impact.

- Environmental Impact Assessment and Reduction Methods: Technologies and methodologies for assessing and reducing the environmental impact of both direct lithium extraction and conventional drilling operations. These include water conservation techniques, carbon footprint reduction strategies, and waste management solutions. Comparative metrics are developed to evaluate the sustainability of different extraction methods, helping operators select approaches that balance economic efficiency with environmental responsibility.

02 Drilling Efficiency Metrics and Optimization

Various metrics and methodologies are employed to measure and optimize conventional drilling efficiency in resource extraction operations. These include rate of penetration (ROP), mechanical specific energy (MSE), drilling cost per foot, and non-productive time analysis. Advanced monitoring systems collect real-time data on drilling parameters such as weight on bit, torque, and rotational speed to optimize drilling performance, reduce operational costs, and minimize environmental impact.Expand Specific Solutions03 Integration of Sensor Technologies and Data Analytics

Modern extraction operations increasingly rely on integrated sensor technologies and advanced data analytics to enhance both direct lithium extraction and conventional drilling processes. These systems employ real-time monitoring, machine learning algorithms, and predictive maintenance capabilities to optimize operational parameters, detect anomalies, and prevent equipment failures. The integration of these technologies enables more precise resource targeting, improved extraction efficiency, and reduced environmental impact.Expand Specific Solutions04 Environmental Impact Assessment and Sustainability Metrics

Environmental impact assessment frameworks and sustainability metrics are being developed specifically for lithium extraction and drilling operations. These metrics evaluate water usage, carbon footprint, land disturbance, waste generation, and energy consumption across different extraction methodologies. Comparative analyses between DLE and conventional extraction techniques help quantify environmental benefits and support more sustainable operational decisions in the lithium industry.Expand Specific Solutions05 Economic Efficiency Comparison Frameworks

Economic efficiency comparison frameworks provide comprehensive methodologies for evaluating the financial performance of different lithium extraction techniques against conventional drilling operations. These frameworks incorporate capital expenditure, operational costs, recovery rates, processing time, and market factors to determine the most economically viable extraction methods for specific geological conditions. Such analyses help stakeholders make informed investment decisions by balancing technological innovation with economic feasibility.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Direct Lithium Extraction (DLE) technology is emerging as a disruptive alternative to conventional lithium drilling, with the market currently in its early growth phase. The global lithium extraction market is projected to expand significantly, driven by increasing demand for lithium-ion batteries. Technologically, DLE is advancing rapidly with companies like Energy Exploration Technologies, International Battery Metals, and Koch Technology Solutions leading innovation in membrane-based extraction methods. Schlumberger and Baker Hughes are leveraging their oil industry expertise to develop competitive DLE solutions, while academic institutions such as Central South University and The University of Manchester are contributing breakthrough research. Chinese companies including BYD and CATL are vertically integrating extraction capabilities to secure supply chains, indicating the technology's strategic importance in the clean energy transition.

Koch Technology Solutions LLC

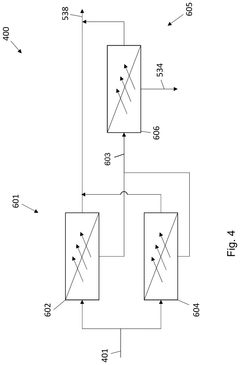

Technical Solution: Koch Technology Solutions has developed an advanced direct lithium extraction (DLE) technology that utilizes a selective ion exchange process to extract lithium from various brine resources. Their proprietary system employs specialized adsorbent materials that selectively capture lithium ions while rejecting competing elements. The process operates in a continuous flow configuration that can extract lithium in hours rather than the months required by traditional evaporation methods. Koch's technology achieves lithium recovery rates of approximately 85-95%, significantly outperforming conventional approaches that typically recover only 30-50%. Their system features a closed-loop design that recycles approximately 98% of process water, dramatically reducing environmental impact. The technology can effectively process brines with lithium concentrations as low as 25ppm, expanding the range of economically viable lithium resources. Koch leverages its extensive experience in separation technologies and industrial-scale operations to optimize the extraction process, including advanced process control systems and energy recovery mechanisms that reduce overall energy consumption by approximately 40% compared to other DLE methods.

Strengths: Achieves exceptional lithium recovery rates of 85-95%; processes lithium in hours versus months; minimal environmental footprint with 98% water recycling; can economically extract from low-concentration brines; leverages Koch's extensive industrial-scale separation expertise. Weaknesses: Requires specialized adsorbent materials that need periodic regeneration or replacement; higher initial capital costs than traditional evaporation methods; energy requirements vary based on brine chemistry and may be significant for certain applications.

Schlumberger Technologies, Inc.

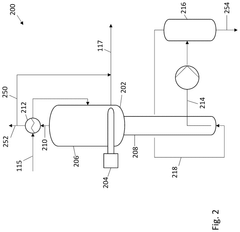

Technical Solution: Schlumberger has developed NeoLith Energy, an advanced direct lithium extraction (DLE) technology designed to transform lithium production from brines. Their process employs a selective extraction method that utilizes proprietary sorbent materials to capture lithium ions while rejecting competing elements like sodium, magnesium, and calcium. The NeoLith system operates as a continuous process that can extract lithium from brines in hours rather than the months required by solar evaporation. Schlumberger's technology achieves lithium recovery rates of approximately 90%, significantly higher than conventional methods that typically recover 30-50%. Their pilot plant in Clayton Valley, Nevada, processes lithium in a closed-loop system that returns over 90% of water to the aquifer, dramatically reducing environmental impact. The technology is designed to work with various brine chemistries and can be scaled modularly to accommodate different production requirements. Schlumberger leverages its extensive experience in oilfield technologies to optimize the extraction process, including advanced filtration, fluid handling, and process control systems.

Strengths: Achieves approximately 90% lithium recovery efficiency versus 30-50% for conventional methods; reduces water consumption by over 90% through recycling; modular design enables flexible deployment; leverages Schlumberger's extensive subsurface expertise and global operational capabilities. Weaknesses: Higher initial capital expenditure than traditional evaporation ponds; requires specialized technical expertise to operate; technology still being proven at commercial scale; energy requirements may be higher than conventional methods depending on brine chemistry.

Critical Patents and Innovations in DLE Technology

Method of recovering lithium from a lithium source

PatentPendingUS20250177923A1

Innovation

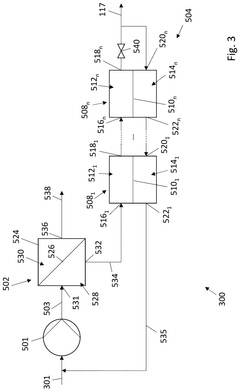

- The method involves direct lithium extraction using techniques such as electrochemical separation, solvent extraction, ion withdrawal, or membrane separation, followed by purification, concentration, and removal of monovalent impurities to yield a purified lithium concentrate.

Systems and methods for direct lithium extraction

PatentPendingUS20250011957A1

Innovation

- The integration of selective membrane electrodialysis as a single step to simultaneously concentrate and purify lithium brines, reducing the number of required processing steps, capital and operating costs, and carbon footprint, while eliminating the need for large equipment at remote mining locations.

Environmental Impact Assessment of Extraction Methods

The environmental impact of lithium extraction methods represents a critical dimension in evaluating the sustainability of energy transition technologies. Conventional lithium extraction through evaporation ponds demonstrates significant environmental drawbacks, primarily excessive water consumption in water-scarce regions. These operations typically require 500,000 to 750,000 gallons of water per metric ton of lithium produced, exacerbating water stress in arid regions like Chile's Atacama Desert, where 65% of the region's water resources are diverted to mining operations.

Direct Lithium Extraction (DLE) technologies offer substantial environmental advantages through dramatically reduced water requirements, with some advanced systems achieving up to 90% reduction in water consumption compared to conventional methods. Additionally, DLE significantly minimizes land disturbance, requiring approximately 90% less land area than traditional evaporation ponds, thereby preserving natural habitats and biodiversity.

Chemical contamination presents another environmental concern with conventional extraction, as evaporation ponds utilize toxic chemicals including hydrochloric acid, sodium carbonate, and sodium hydroxide that can leach into soil and groundwater. DLE technologies employ more selective extraction processes that reduce chemical usage and minimize contamination risks, though specific chemical requirements vary by technology type.

Carbon footprint analysis reveals that conventional extraction methods generate approximately 15 tons of CO2 per ton of lithium carbonate equivalent (LCE), primarily from energy-intensive evaporation processes. In contrast, DLE technologies demonstrate variable emissions profiles depending on implementation, with estimates ranging from 5 to 13 tons of CO2 per ton of LCE, representing potential reductions of 13-67% in greenhouse gas emissions.

Waste management considerations further differentiate these approaches. Conventional methods produce substantial solid waste in the form of salt tailings and processing residues that require long-term management. DLE technologies generate different waste streams, primarily spent sorbents and process solutions, but typically in smaller volumes and with greater potential for recycling or responsible disposal.

Ecosystem disruption assessment indicates that evaporation ponds significantly alter local hydrology and habitat availability, affecting flamingo populations and other wildlife in sensitive regions. DLE operations maintain a smaller physical footprint but may introduce different ecological pressures through infrastructure development and operational activities, though these impacts appear more contained and manageable with proper planning.

Direct Lithium Extraction (DLE) technologies offer substantial environmental advantages through dramatically reduced water requirements, with some advanced systems achieving up to 90% reduction in water consumption compared to conventional methods. Additionally, DLE significantly minimizes land disturbance, requiring approximately 90% less land area than traditional evaporation ponds, thereby preserving natural habitats and biodiversity.

Chemical contamination presents another environmental concern with conventional extraction, as evaporation ponds utilize toxic chemicals including hydrochloric acid, sodium carbonate, and sodium hydroxide that can leach into soil and groundwater. DLE technologies employ more selective extraction processes that reduce chemical usage and minimize contamination risks, though specific chemical requirements vary by technology type.

Carbon footprint analysis reveals that conventional extraction methods generate approximately 15 tons of CO2 per ton of lithium carbonate equivalent (LCE), primarily from energy-intensive evaporation processes. In contrast, DLE technologies demonstrate variable emissions profiles depending on implementation, with estimates ranging from 5 to 13 tons of CO2 per ton of LCE, representing potential reductions of 13-67% in greenhouse gas emissions.

Waste management considerations further differentiate these approaches. Conventional methods produce substantial solid waste in the form of salt tailings and processing residues that require long-term management. DLE technologies generate different waste streams, primarily spent sorbents and process solutions, but typically in smaller volumes and with greater potential for recycling or responsible disposal.

Ecosystem disruption assessment indicates that evaporation ponds significantly alter local hydrology and habitat availability, affecting flamingo populations and other wildlife in sensitive regions. DLE operations maintain a smaller physical footprint but may introduce different ecological pressures through infrastructure development and operational activities, though these impacts appear more contained and manageable with proper planning.

Economic Viability and ROI Analysis

The economic viability of Direct Lithium Extraction (DLE) compared to conventional drilling methods represents a critical consideration for industry stakeholders. Initial capital expenditure for DLE technologies typically ranges between $15,000-$30,000 per ton of annual production capacity, whereas conventional evaporation ponds require $10,000-$20,000 per ton. However, this higher upfront investment for DLE is counterbalanced by significantly reduced operational timeframes, with production cycles of weeks rather than the 18-24 months required for traditional methods.

Operational expenditure analysis reveals that DLE technologies consume approximately 50-150 kWh of energy per kilogram of lithium carbonate equivalent (LCE), representing a substantial cost factor. Yet, when factoring in water conservation benefits—DLE uses 50-300 times less water than evaporation methods—the economic equation shifts favorably in regions with water scarcity or high water pricing.

Return on investment calculations demonstrate that DLE projects can achieve breakeven points within 3-5 years, compared to 5-8 years for conventional operations. This accelerated ROI timeline is particularly attractive to investors seeking quicker capital recovery in the volatile lithium market. Furthermore, DLE facilities demonstrate greater adaptability to market fluctuations, allowing production scaling with minimal additional investment.

Environmental compliance costs represent another significant economic factor. Conventional evaporation methods incur increasing regulatory expenses related to water usage, land disturbance, and waste management. DLE technologies, with their reduced environmental footprint, face fewer regulatory hurdles and associated compliance costs, potentially saving 5-15% in long-term operational expenses.

Market responsiveness provides DLE with another economic advantage. The ability to rapidly adjust production volumes in response to market demand fluctuations allows DLE operations to optimize revenue generation during peak pricing periods. Conventional operations, constrained by their lengthy production cycles, cannot capitalize on short-term market opportunities with the same agility.

Sensitivity analysis indicates that DLE economics improve substantially with increasing lithium prices, showing 30-40% higher profitability than conventional methods when prices exceed $15,000 per ton. Conversely, at prices below $10,000 per ton, conventional methods may retain economic advantages in regions with abundant water and favorable climatic conditions.

Operational expenditure analysis reveals that DLE technologies consume approximately 50-150 kWh of energy per kilogram of lithium carbonate equivalent (LCE), representing a substantial cost factor. Yet, when factoring in water conservation benefits—DLE uses 50-300 times less water than evaporation methods—the economic equation shifts favorably in regions with water scarcity or high water pricing.

Return on investment calculations demonstrate that DLE projects can achieve breakeven points within 3-5 years, compared to 5-8 years for conventional operations. This accelerated ROI timeline is particularly attractive to investors seeking quicker capital recovery in the volatile lithium market. Furthermore, DLE facilities demonstrate greater adaptability to market fluctuations, allowing production scaling with minimal additional investment.

Environmental compliance costs represent another significant economic factor. Conventional evaporation methods incur increasing regulatory expenses related to water usage, land disturbance, and waste management. DLE technologies, with their reduced environmental footprint, face fewer regulatory hurdles and associated compliance costs, potentially saving 5-15% in long-term operational expenses.

Market responsiveness provides DLE with another economic advantage. The ability to rapidly adjust production volumes in response to market demand fluctuations allows DLE operations to optimize revenue generation during peak pricing periods. Conventional operations, constrained by their lengthy production cycles, cannot capitalize on short-term market opportunities with the same agility.

Sensitivity analysis indicates that DLE economics improve substantially with increasing lithium prices, showing 30-40% higher profitability than conventional methods when prices exceed $15,000 per ton. Conversely, at prices below $10,000 per ton, conventional methods may retain economic advantages in regions with abundant water and favorable climatic conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!