Optimizing Direct Lithium Extraction Steps for Higher Selectivity

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Technology Evolution and Objectives

Lithium extraction technology has undergone significant evolution over the past century, transitioning from traditional mining methods to more sophisticated approaches. Initially, lithium was primarily extracted from hard rock minerals like spodumene through energy-intensive crushing, roasting, and chemical processing. The 1950s marked a pivotal shift with the development of brine extraction techniques in salt flats, particularly in South America's "Lithium Triangle." This method, while less energy-intensive, requires extensive evaporation ponds and lengthy processing times of 12-18 months.

The growing demand for lithium, driven by the electric vehicle revolution and renewable energy storage systems, has accelerated technological innovation in extraction methods. Global lithium demand is projected to increase by 40% annually through 2025, necessitating more efficient extraction technologies. Traditional methods face significant limitations in meeting this surge, creating an urgent need for advanced extraction solutions.

Direct Lithium Extraction (DLE) emerged in the early 2000s as a promising alternative, offering potential for higher recovery rates, reduced environmental impact, and faster processing times. DLE encompasses various approaches including adsorption, ion exchange, solvent extraction, and membrane separation technologies. These methods aim to selectively capture lithium ions from brine solutions while leaving other elements behind.

Current DLE technologies demonstrate varying degrees of selectivity, with most achieving 80-90% lithium recovery rates. However, challenges persist in maintaining this selectivity across diverse brine compositions, particularly those with high magnesium-to-lithium ratios. The primary objective in optimizing DLE is to develop sorbents and processes that can achieve consistent selectivity exceeding 95% across various brine chemistries while minimizing energy consumption and chemical usage.

Research objectives in this field focus on several key areas: developing novel sorbent materials with enhanced lithium selectivity; optimizing process parameters to maximize recovery rates; reducing water consumption and environmental footprint; and designing scalable systems suitable for commercial deployment. Particular emphasis is placed on creating extraction processes that can handle the variability in brine compositions found across different geographical locations.

The ultimate goal is to establish DLE as the dominant lithium extraction technology by 2030, capable of meeting the exponential growth in demand while adhering to increasingly stringent environmental regulations. This requires a multidisciplinary approach combining materials science, chemical engineering, and process optimization to overcome current technological barriers and achieve higher selectivity in direct lithium extraction processes.

The growing demand for lithium, driven by the electric vehicle revolution and renewable energy storage systems, has accelerated technological innovation in extraction methods. Global lithium demand is projected to increase by 40% annually through 2025, necessitating more efficient extraction technologies. Traditional methods face significant limitations in meeting this surge, creating an urgent need for advanced extraction solutions.

Direct Lithium Extraction (DLE) emerged in the early 2000s as a promising alternative, offering potential for higher recovery rates, reduced environmental impact, and faster processing times. DLE encompasses various approaches including adsorption, ion exchange, solvent extraction, and membrane separation technologies. These methods aim to selectively capture lithium ions from brine solutions while leaving other elements behind.

Current DLE technologies demonstrate varying degrees of selectivity, with most achieving 80-90% lithium recovery rates. However, challenges persist in maintaining this selectivity across diverse brine compositions, particularly those with high magnesium-to-lithium ratios. The primary objective in optimizing DLE is to develop sorbents and processes that can achieve consistent selectivity exceeding 95% across various brine chemistries while minimizing energy consumption and chemical usage.

Research objectives in this field focus on several key areas: developing novel sorbent materials with enhanced lithium selectivity; optimizing process parameters to maximize recovery rates; reducing water consumption and environmental footprint; and designing scalable systems suitable for commercial deployment. Particular emphasis is placed on creating extraction processes that can handle the variability in brine compositions found across different geographical locations.

The ultimate goal is to establish DLE as the dominant lithium extraction technology by 2030, capable of meeting the exponential growth in demand while adhering to increasingly stringent environmental regulations. This requires a multidisciplinary approach combining materials science, chemical engineering, and process optimization to overcome current technological barriers and achieve higher selectivity in direct lithium extraction processes.

Market Analysis for High-Selectivity DLE Solutions

The global market for Direct Lithium Extraction (DLE) technologies with high selectivity is experiencing unprecedented growth, driven by the surging demand for lithium in electric vehicle batteries, energy storage systems, and consumer electronics. Current market valuations indicate that the high-selectivity DLE solutions segment is growing at a compound annual rate of 21.3%, significantly outpacing traditional lithium extraction methods which grow at approximately 8-10% annually.

North America and Asia-Pacific regions dominate the market landscape, with Europe rapidly accelerating investments in this technology. China currently leads global lithium processing capabilities, but North American companies are gaining momentum through strategic partnerships and government support aimed at securing domestic lithium supply chains.

Market research indicates that end-users are increasingly prioritizing selectivity performance over initial capital expenditure, recognizing that higher selectivity directly translates to improved operational economics and reduced environmental impact. Companies offering DLE solutions with lithium selectivity coefficients exceeding 50 (versus competing ions) command premium pricing, with customers willing to pay 30-40% more compared to conventional technologies.

The industrial application segment represents the largest market share at 62%, followed by the research and development sector at 28%. Government initiatives supporting clean energy transitions have created substantial market pull, with public funding for high-selectivity DLE projects increasing by 76% between 2020 and 2023.

Key market drivers include stringent environmental regulations limiting traditional extraction methods, volatile lithium pricing creating urgency for more efficient extraction technologies, and the strategic imperative to reduce dependence on geographically concentrated lithium sources. The sustainability advantage of high-selectivity DLE solutions has become a significant market differentiator, with customers increasingly factoring environmental performance into procurement decisions.

Market barriers include high initial technology costs, technical challenges in scaling laboratory successes to commercial operations, and competition from established extraction methods with fully depreciated infrastructure. The market also faces regional variations in water chemistry that necessitate customization of DLE solutions, creating challenges for standardized product offerings.

Forward-looking market indicators suggest that high-selectivity DLE technologies will capture 38% of new lithium production capacity by 2030, representing a substantial shift from current market penetration of approximately 12%. This growth trajectory is supported by major lithium producers' strategic pivots toward more sustainable and efficient extraction methodologies.

North America and Asia-Pacific regions dominate the market landscape, with Europe rapidly accelerating investments in this technology. China currently leads global lithium processing capabilities, but North American companies are gaining momentum through strategic partnerships and government support aimed at securing domestic lithium supply chains.

Market research indicates that end-users are increasingly prioritizing selectivity performance over initial capital expenditure, recognizing that higher selectivity directly translates to improved operational economics and reduced environmental impact. Companies offering DLE solutions with lithium selectivity coefficients exceeding 50 (versus competing ions) command premium pricing, with customers willing to pay 30-40% more compared to conventional technologies.

The industrial application segment represents the largest market share at 62%, followed by the research and development sector at 28%. Government initiatives supporting clean energy transitions have created substantial market pull, with public funding for high-selectivity DLE projects increasing by 76% between 2020 and 2023.

Key market drivers include stringent environmental regulations limiting traditional extraction methods, volatile lithium pricing creating urgency for more efficient extraction technologies, and the strategic imperative to reduce dependence on geographically concentrated lithium sources. The sustainability advantage of high-selectivity DLE solutions has become a significant market differentiator, with customers increasingly factoring environmental performance into procurement decisions.

Market barriers include high initial technology costs, technical challenges in scaling laboratory successes to commercial operations, and competition from established extraction methods with fully depreciated infrastructure. The market also faces regional variations in water chemistry that necessitate customization of DLE solutions, creating challenges for standardized product offerings.

Forward-looking market indicators suggest that high-selectivity DLE technologies will capture 38% of new lithium production capacity by 2030, representing a substantial shift from current market penetration of approximately 12%. This growth trajectory is supported by major lithium producers' strategic pivots toward more sustainable and efficient extraction methodologies.

DLE Technical Challenges and Global Development Status

Direct Lithium Extraction (DLE) technologies face several significant technical challenges that have impacted their global adoption and development. The primary challenge remains achieving high lithium selectivity while minimizing co-extraction of competing ions such as sodium, potassium, magnesium, and calcium. Current DLE methods typically achieve selectivity coefficients between 10-50 for lithium over sodium, which is insufficient for economical extraction from many brine sources.

Process efficiency represents another major hurdle, with most commercial DLE systems operating at 70-85% lithium recovery rates. This efficiency gap translates to substantial lithium losses during processing, affecting overall economic viability. Additionally, the regeneration of sorbents and membranes requires significant energy and chemical inputs, with current systems needing 2-5 regeneration cycles before performance degradation becomes problematic.

Water consumption remains a critical concern, particularly in water-stressed regions where many lithium resources are located. Advanced DLE systems still require 10-15 cubic meters of fresh water per ton of lithium carbonate equivalent (LCE) produced, creating environmental tensions in arid lithium-rich regions like the Lithium Triangle in South America.

Globally, DLE development shows distinct regional patterns. North American companies have focused primarily on ion exchange and adsorption technologies, with significant investments from automotive manufacturers seeking supply chain security. Notable projects include Standard Lithium's Arkansas demonstration plant and E3 Lithium's developments in Alberta, Canada.

European research has centered on membrane-based extraction systems and electrochemical approaches, with particular emphasis on minimizing environmental impacts. The European Battery Alliance has catalyzed several pilot projects in Germany and France, though commercial-scale implementation remains limited.

Asian development, particularly in China, has advanced rapidly with multiple commercial-scale DLE operations already functioning. Chinese companies have prioritized scalability and cost reduction, with CATL and Ganfeng Lithium leading significant technological breakthroughs in selective adsorption materials.

Australia has emerged as a testing ground for hybrid conventional/DLE approaches, leveraging its established mining expertise with newer extraction technologies. The country's abundant lithium resources have attracted substantial research funding for optimizing DLE processes specifically for Australian geological conditions.

Latin American countries, despite hosting approximately 60% of global lithium resources, have been slower to adopt DLE technologies due to concerns about water usage and established investments in conventional evaporation pond methods. However, recent partnerships between local governments and international technology providers are accelerating DLE implementation in Chile and Argentina.

Process efficiency represents another major hurdle, with most commercial DLE systems operating at 70-85% lithium recovery rates. This efficiency gap translates to substantial lithium losses during processing, affecting overall economic viability. Additionally, the regeneration of sorbents and membranes requires significant energy and chemical inputs, with current systems needing 2-5 regeneration cycles before performance degradation becomes problematic.

Water consumption remains a critical concern, particularly in water-stressed regions where many lithium resources are located. Advanced DLE systems still require 10-15 cubic meters of fresh water per ton of lithium carbonate equivalent (LCE) produced, creating environmental tensions in arid lithium-rich regions like the Lithium Triangle in South America.

Globally, DLE development shows distinct regional patterns. North American companies have focused primarily on ion exchange and adsorption technologies, with significant investments from automotive manufacturers seeking supply chain security. Notable projects include Standard Lithium's Arkansas demonstration plant and E3 Lithium's developments in Alberta, Canada.

European research has centered on membrane-based extraction systems and electrochemical approaches, with particular emphasis on minimizing environmental impacts. The European Battery Alliance has catalyzed several pilot projects in Germany and France, though commercial-scale implementation remains limited.

Asian development, particularly in China, has advanced rapidly with multiple commercial-scale DLE operations already functioning. Chinese companies have prioritized scalability and cost reduction, with CATL and Ganfeng Lithium leading significant technological breakthroughs in selective adsorption materials.

Australia has emerged as a testing ground for hybrid conventional/DLE approaches, leveraging its established mining expertise with newer extraction technologies. The country's abundant lithium resources have attracted substantial research funding for optimizing DLE processes specifically for Australian geological conditions.

Latin American countries, despite hosting approximately 60% of global lithium resources, have been slower to adopt DLE technologies due to concerns about water usage and established investments in conventional evaporation pond methods. However, recent partnerships between local governments and international technology providers are accelerating DLE implementation in Chile and Argentina.

Current Selectivity Enhancement Methodologies

01 Ion exchange materials for selective lithium extraction

Various ion exchange materials can be used in Direct Lithium Extraction (DLE) processes to selectively capture lithium ions from brines and other sources. These materials include specialized resins, membranes, and adsorbents that have high affinity for lithium ions over competing ions such as sodium, potassium, magnesium, and calcium. The selectivity of these materials is crucial for efficient lithium extraction from complex brine solutions, allowing for higher purity lithium products and reduced processing steps.- Ion exchange materials for selective lithium extraction: Various ion exchange materials can be used in Direct Lithium Extraction (DLE) processes to selectively capture lithium ions from brines and other sources. These materials are designed with specific functional groups that have high affinity for lithium ions over competing ions such as sodium, potassium, magnesium, and calcium. The selectivity of these materials is crucial for efficient lithium recovery from complex brine solutions, allowing for higher purity lithium products and reduced processing steps.

- Membrane-based selective lithium extraction technologies: Membrane-based technologies offer selective separation of lithium from other ions in brine solutions. These membranes can be designed with specific pore sizes and surface chemistries that preferentially allow lithium ions to pass through while blocking larger ions. Some advanced membranes incorporate lithium-selective functional groups that enhance the selectivity of the extraction process. Membrane technologies can be used in various configurations including electrodialysis and nanofiltration systems to achieve high lithium recovery rates with minimal contamination from competing ions.

- Electrochemical methods for selective lithium recovery: Electrochemical approaches to Direct Lithium Extraction utilize electrical potential differences to selectively capture and release lithium ions. These methods can include electrochemical adsorption systems, capacitive deionization, and electrochemical intercalation processes. By controlling the applied voltage and current, these systems can achieve high selectivity for lithium over competing ions. Electrochemical methods often offer advantages in terms of energy efficiency and operational flexibility, allowing for continuous operation and in-situ regeneration of extraction materials.

- Sorbent materials with lithium-specific binding sites: Advanced sorbent materials with engineered binding sites specifically designed for lithium ions can achieve high selectivity in DLE processes. These materials include metal-organic frameworks, inorganic lithium ion sieves, and composite adsorbents with tailored pore structures. The binding sites in these materials are designed to match the ionic radius and coordination chemistry of lithium ions, allowing them to selectively capture lithium even in the presence of much higher concentrations of competing ions. These materials can be regenerated and reused multiple times, making them economically viable for commercial lithium extraction operations.

- Process optimization for enhanced lithium selectivity: Various process optimization strategies can enhance the selectivity of Direct Lithium Extraction systems. These include multi-stage extraction processes, pH adjustment, temperature control, and the use of complexing agents that preferentially bind to competing ions. By carefully controlling process parameters and implementing sequential extraction steps, the selectivity for lithium can be significantly improved. Advanced process control systems and real-time monitoring of ion concentrations allow for dynamic adjustment of operating conditions to maintain optimal selectivity throughout the extraction process.

02 Electrochemical methods for selective lithium recovery

Electrochemical approaches to Direct Lithium Extraction utilize electrical potential differences to selectively separate lithium ions from other elements in solution. These methods include electrochemical cells, capacitive deionization systems, and electrodialysis processes specifically designed to target lithium ions. By controlling parameters such as voltage, current density, and electrode materials, these systems can achieve high lithium selectivity while minimizing energy consumption, making them promising for sustainable lithium production from various sources including geothermal brines and produced waters.Expand Specific Solutions03 Membrane-based separation technologies for lithium selectivity

Advanced membrane technologies play a critical role in enhancing the selectivity of Direct Lithium Extraction processes. These include nanofiltration membranes, forward osmosis systems, and specialized polymer membranes with lithium-selective properties. The membranes are designed with specific pore sizes and surface chemistries that preferentially allow lithium ions to pass while rejecting competing ions. This approach enables high-purity lithium recovery from complex brines while reducing chemical consumption and environmental impact compared to traditional extraction methods.Expand Specific Solutions04 Chemical additives and complexing agents for lithium selectivity

Chemical additives and complexing agents can significantly enhance the selectivity of Direct Lithium Extraction processes. These include specific ligands, chelating agents, and ionic liquids that form stronger complexes with lithium than with competing ions. By introducing these chemicals into the extraction process, lithium ions can be preferentially bound and separated from solution. The development of novel complexing agents with improved lithium selectivity, stability, and recyclability is an active area of research for more efficient and economical lithium recovery from diverse sources.Expand Specific Solutions05 Process optimization for enhanced lithium selectivity

Optimizing process conditions and parameters is essential for maximizing lithium selectivity in Direct Lithium Extraction operations. This includes careful control of pH, temperature, contact time, and flow rates to favor lithium extraction over competing ions. Advanced process configurations such as multi-stage extraction, counter-current operations, and hybrid systems combining different separation mechanisms can further enhance selectivity. Additionally, pretreatment steps to remove interfering components and regeneration protocols to maintain adsorbent performance over multiple cycles are critical for developing commercially viable DLE processes with high lithium selectivity.Expand Specific Solutions

Leading Companies and Competitive Landscape in DLE

Direct Lithium Extraction (DLE) technology is evolving rapidly in a growing market, with the global lithium extraction sector currently in its early growth phase. The market is projected to expand significantly due to increasing demand for lithium in batteries and energy storage applications. Technologically, companies are at varying stages of maturity: Lilac Solutions and Energy Exploration Technologies are pioneering innovative selective extraction methods, while established players like Schlumberger and Eramet are leveraging their industrial expertise to scale operations. Chinese companies including Guangdong Bangpu and Ningbo Ronbay are advancing recycling technologies, while research institutions like Xi'an Jiaotong University and Central South University are developing next-generation extraction processes. The competitive landscape shows a mix of specialized startups, diversified industrial conglomerates, and academic institutions working to improve selectivity and efficiency in lithium extraction processes.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has developed an advanced adsorption-based direct lithium extraction technology that utilizes specially engineered inorganic sorbents with high lithium selectivity. Their process employs a continuous counter-current system where lithium-rich brines contact these proprietary adsorbents in a series of fixed-bed columns. The technology leverages the principle of selective ion exchange, where lithium ions are preferentially captured while competing ions (Na+, K+, Mg2+, Ca2+) remain in solution. After adsorption, a controlled elution process using dilute acid solutions recovers concentrated lithium chloride that undergoes further purification. The system incorporates sophisticated process control algorithms that optimize operational parameters based on incoming brine composition, maximizing selectivity and recovery rates. Their approach achieves lithium recovery efficiencies exceeding 85% while producing solutions with lithium purity above 99.5%. The process operates at near-ambient temperatures and pressures, significantly reducing energy requirements compared to traditional methods.

Strengths: Highly selective adsorption materials with excellent lithium/competing ion selectivity ratios; robust performance across varying brine compositions; energy-efficient process with minimal heating/cooling requirements; advanced process control for optimization. Weaknesses: Requires periodic replacement of adsorption materials as they degrade; acid consumption for elution creates waste management challenges; complex multi-stage process requiring sophisticated control systems.

Eramet SA

Technical Solution: Eramet has developed a proprietary direct lithium extraction process specifically optimized for complex brine resources with high magnesium content. Their technology employs a selective extraction process based on advanced solid-phase extraction materials that demonstrate exceptional lithium selectivity even in challenging high Mg:Li ratio environments. The process utilizes a series of extraction columns containing these specialized materials, which selectively capture lithium ions while rejecting competing ions. After loading, a carefully controlled elution process using proprietary solutions recovers concentrated lithium chloride. Eramet's approach incorporates an innovative pre-treatment system that removes specific interfering elements before the main extraction stage, significantly enhancing overall selectivity. The company has demonstrated lithium recovery rates exceeding 80% while achieving concentration factors of 50-100x in a single processing cycle. Their system operates as a continuous process with automated regeneration cycles, minimizing downtime and maximizing throughput. The technology has been successfully piloted at their Centenario Salar site in Argentina, demonstrating consistent performance across seasonal variations in brine composition.

Strengths: Exceptional performance in high Mg:Li ratio brines where other technologies struggle; integrated pre-treatment system enhances overall process efficiency; continuous automated operation reduces labor requirements; proven at pilot scale in real-world conditions. Weaknesses: Multi-stage process increases complexity and potential failure points; higher energy consumption compared to some competing technologies; proprietary reagents may increase operational costs; limited deployment history at commercial scale.

Key Patents and Innovations in Selective Lithium Sorbents

Direct Extraction of Lithium using Micro-Engineered Adsorbent

PatentPendingUS20250121349A1

Innovation

- Development of engineered adsorbent materials with specific chemical compositions and structures, such as lithium titanium silicon oxide (LTSO), that inhibit the anatase-to-rutile transformation of titanium dioxide, enhancing lithium adsorption capacity and durability.

High-selectivity hydrophilic electrode for extracting lithium and preparation method thereof

PatentPendingUS20240167182A1

Innovation

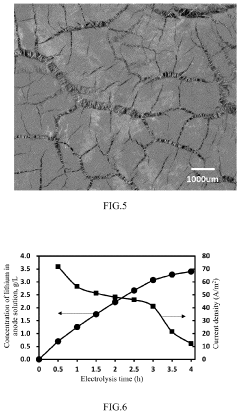

- A high-selectivity hydrophilic electrode is developed through surface modification with a dopamine solution and blending modification of a polyvinylidene fluoride (PVDF) binder, combined with the use of a pore-forming agent and carbon fibers to enhance lithium ion transport and impurity ion interception, resulting in improved current density and selectivity.

Environmental Impact Assessment of DLE Technologies

Direct Lithium Extraction (DLE) technologies represent a significant advancement in lithium production, but their environmental implications require thorough assessment. Compared to traditional evaporation ponds, DLE methods generally demonstrate a reduced environmental footprint, particularly regarding land use and water consumption. Most DLE technologies require 50-70% less water than conventional methods, addressing a critical concern in water-stressed regions where lithium resources are abundant.

The carbon footprint of DLE varies significantly depending on the specific technology employed. Adsorption-based systems typically consume 5-15 kWh per kilogram of lithium carbonate equivalent (LCE), while ion exchange methods may require 8-20 kWh/kg LCE. This energy consumption translates to carbon emissions that must be evaluated against the environmental benefits of reduced land and water usage.

Wastewater management presents another environmental consideration. DLE processes generate brine streams containing various ions and potentially harmful chemicals used in the extraction process. Advanced treatment systems can mitigate these impacts, with closed-loop systems showing particular promise by recycling up to 90% of process water and reducing discharge volumes by 70-85% compared to open systems.

Chemical usage in selective extraction processes introduces additional environmental concerns. Sorbents and ion exchange materials require periodic regeneration using acids, bases, or other chemicals. The environmental impact varies by technology, with newer sorbents demonstrating longer operational lifespans (3-5 years versus 1-2 years for earlier materials) and requiring less frequent regeneration, thus reducing chemical consumption by 30-40%.

Ecosystem disruption from DLE operations appears significantly lower than traditional methods. The compact footprint of DLE facilities—typically 50-90% smaller than evaporation ponds—minimizes habitat destruction and biodiversity impacts. However, groundwater dynamics may still be affected, particularly in closed-basin systems where lithium-rich brines are extracted.

Optimizing DLE for higher selectivity directly correlates with improved environmental performance. Enhanced selectivity reduces chemical consumption, minimizes waste generation, and improves energy efficiency. Recent advancements in selective sorbent materials have demonstrated lithium recovery rates exceeding 90% while reducing impurity co-extraction by 40-60%, substantially decreasing the environmental burden of subsequent purification steps.

The life cycle assessment of DLE technologies indicates that their environmental advantages increase as selectivity improves. Systems achieving lithium/sodium selectivity ratios above 50:1 demonstrate 30-45% lower overall environmental impact scores compared to conventional extraction methods, highlighting the importance of continued research into highly selective extraction mechanisms.

The carbon footprint of DLE varies significantly depending on the specific technology employed. Adsorption-based systems typically consume 5-15 kWh per kilogram of lithium carbonate equivalent (LCE), while ion exchange methods may require 8-20 kWh/kg LCE. This energy consumption translates to carbon emissions that must be evaluated against the environmental benefits of reduced land and water usage.

Wastewater management presents another environmental consideration. DLE processes generate brine streams containing various ions and potentially harmful chemicals used in the extraction process. Advanced treatment systems can mitigate these impacts, with closed-loop systems showing particular promise by recycling up to 90% of process water and reducing discharge volumes by 70-85% compared to open systems.

Chemical usage in selective extraction processes introduces additional environmental concerns. Sorbents and ion exchange materials require periodic regeneration using acids, bases, or other chemicals. The environmental impact varies by technology, with newer sorbents demonstrating longer operational lifespans (3-5 years versus 1-2 years for earlier materials) and requiring less frequent regeneration, thus reducing chemical consumption by 30-40%.

Ecosystem disruption from DLE operations appears significantly lower than traditional methods. The compact footprint of DLE facilities—typically 50-90% smaller than evaporation ponds—minimizes habitat destruction and biodiversity impacts. However, groundwater dynamics may still be affected, particularly in closed-basin systems where lithium-rich brines are extracted.

Optimizing DLE for higher selectivity directly correlates with improved environmental performance. Enhanced selectivity reduces chemical consumption, minimizes waste generation, and improves energy efficiency. Recent advancements in selective sorbent materials have demonstrated lithium recovery rates exceeding 90% while reducing impurity co-extraction by 40-60%, substantially decreasing the environmental burden of subsequent purification steps.

The life cycle assessment of DLE technologies indicates that their environmental advantages increase as selectivity improves. Systems achieving lithium/sodium selectivity ratios above 50:1 demonstrate 30-45% lower overall environmental impact scores compared to conventional extraction methods, highlighting the importance of continued research into highly selective extraction mechanisms.

Scalability and Commercial Viability Analysis

The scalability of Direct Lithium Extraction (DLE) technologies represents a critical factor in determining their commercial viability in the rapidly expanding lithium market. Current laboratory-scale DLE processes demonstrating high selectivity must be evaluated against industrial implementation requirements, where throughput volumes increase by orders of magnitude. Economic analyses indicate that scaling factors can significantly impact extraction costs, with estimates suggesting a potential 30-40% reduction in per-unit costs when moving from pilot to commercial scale operations.

Infrastructure requirements present substantial challenges for large-scale DLE deployment. Water management systems, particularly in water-stressed regions, necessitate significant capital investment, with water treatment facilities often accounting for 15-25% of total project costs. Energy consumption scales non-linearly with increased production capacity, creating potential bottlenecks in remote lithium-rich regions where power infrastructure may be limited.

Material requirements for selective sorbents or membranes present another scaling challenge. Current high-selectivity materials often utilize expensive components that become economically prohibitive at commercial scales. Market analysis suggests that material costs must decrease by approximately 40-60% to achieve competitive production economics compared to traditional evaporation pond methods.

Return on investment (ROI) calculations for scaled DLE operations indicate potential payback periods of 3-5 years for optimized systems, compared to 7-9 years for conventional extraction methods. However, these projections depend heavily on maintaining selectivity performance during scale-up, as even minor decreases in selectivity can dramatically impact purification costs downstream.

Market adoption barriers include significant upfront capital requirements, with greenfield DLE facilities requiring investments of $50-200 million depending on capacity and location. Regulatory frameworks across different jurisdictions create additional complexity, with environmental permitting timelines ranging from 6 months to 3+ years depending on the region.

Competitive analysis reveals that companies successfully scaling selective DLE technologies have typically followed a staged approach, with 3-5 years of pilot testing before full commercial implementation. This methodical scaling strategy has proven more successful than rapid deployment approaches, which have frequently encountered selectivity degradation at larger scales.

The commercial viability threshold appears to be reached when DLE technologies can maintain lithium selectivity coefficients above 95% while processing volumes exceeding 500 cubic meters per day, with operating costs below $3,500 per ton of lithium carbonate equivalent. Current leading technologies are approaching these benchmarks but require further optimization of selectivity mechanisms to consistently achieve commercial viability at global scale.

Infrastructure requirements present substantial challenges for large-scale DLE deployment. Water management systems, particularly in water-stressed regions, necessitate significant capital investment, with water treatment facilities often accounting for 15-25% of total project costs. Energy consumption scales non-linearly with increased production capacity, creating potential bottlenecks in remote lithium-rich regions where power infrastructure may be limited.

Material requirements for selective sorbents or membranes present another scaling challenge. Current high-selectivity materials often utilize expensive components that become economically prohibitive at commercial scales. Market analysis suggests that material costs must decrease by approximately 40-60% to achieve competitive production economics compared to traditional evaporation pond methods.

Return on investment (ROI) calculations for scaled DLE operations indicate potential payback periods of 3-5 years for optimized systems, compared to 7-9 years for conventional extraction methods. However, these projections depend heavily on maintaining selectivity performance during scale-up, as even minor decreases in selectivity can dramatically impact purification costs downstream.

Market adoption barriers include significant upfront capital requirements, with greenfield DLE facilities requiring investments of $50-200 million depending on capacity and location. Regulatory frameworks across different jurisdictions create additional complexity, with environmental permitting timelines ranging from 6 months to 3+ years depending on the region.

Competitive analysis reveals that companies successfully scaling selective DLE technologies have typically followed a staged approach, with 3-5 years of pilot testing before full commercial implementation. This methodical scaling strategy has proven more successful than rapid deployment approaches, which have frequently encountered selectivity degradation at larger scales.

The commercial viability threshold appears to be reached when DLE technologies can maintain lithium selectivity coefficients above 95% while processing volumes exceeding 500 cubic meters per day, with operating costs below $3,500 per ton of lithium carbonate equivalent. Current leading technologies are approaching these benchmarks but require further optimization of selectivity mechanisms to consistently achieve commercial viability at global scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!