Reducing Energy Consumption in Direct Lithium Extraction

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology has emerged as a revolutionary approach to lithium production, offering significant advantages over traditional methods such as evaporation ponds and hard rock mining. The development of DLE can be traced back to the early 2000s, with substantial advancements occurring in the past decade as global demand for lithium has surged due to the electric vehicle revolution and renewable energy storage requirements.

The evolution of DLE technology has been driven by the inherent limitations of conventional extraction methods, which are characterized by lengthy production cycles, substantial land and water requirements, and considerable environmental impacts. Traditional brine evaporation processes typically require 18-24 months for lithium recovery and achieve extraction efficiencies of only 30-40%, while consuming vast quantities of water in often water-stressed regions.

DLE technologies aim to selectively extract lithium from brines, geothermal waters, and even seawater using various mechanisms including adsorption, ion exchange, solvent extraction, and membrane processes. The primary technological trajectory has been toward developing more selective sorbents and membranes that can efficiently separate lithium ions from other elements present in solution, particularly sodium, magnesium, and calcium.

A critical challenge in the DLE landscape is the high energy consumption associated with many current processes. Pumping, heating, regeneration of sorbents, and downstream processing all contribute to the energy footprint of DLE operations. This energy intensity not only impacts the economic viability of these technologies but also potentially undermines their environmental benefits compared to conventional methods.

The technical objectives for advancing DLE technology center on significantly reducing energy requirements while maintaining or improving extraction efficiency and selectivity. Specific goals include developing sorbents that can operate at ambient temperatures, require less aggressive regeneration conditions, and demonstrate longer operational lifespans before replacement is necessary.

Additionally, there is a focus on integrating renewable energy sources to power DLE operations, implementing energy recovery systems, and optimizing process configurations to minimize pumping and heating requirements. The ultimate aim is to establish DLE as not only the most environmentally sustainable approach to lithium production but also the most economically competitive.

Success in reducing energy consumption in DLE would address a critical bottleneck in scaling these technologies to meet projected lithium demand, which is expected to increase by 400-800% by 2030. This would enable more widespread deployment of DLE systems, potentially unlocking previously uneconomical lithium resources and diversifying the global supply chain for this strategic metal.

The evolution of DLE technology has been driven by the inherent limitations of conventional extraction methods, which are characterized by lengthy production cycles, substantial land and water requirements, and considerable environmental impacts. Traditional brine evaporation processes typically require 18-24 months for lithium recovery and achieve extraction efficiencies of only 30-40%, while consuming vast quantities of water in often water-stressed regions.

DLE technologies aim to selectively extract lithium from brines, geothermal waters, and even seawater using various mechanisms including adsorption, ion exchange, solvent extraction, and membrane processes. The primary technological trajectory has been toward developing more selective sorbents and membranes that can efficiently separate lithium ions from other elements present in solution, particularly sodium, magnesium, and calcium.

A critical challenge in the DLE landscape is the high energy consumption associated with many current processes. Pumping, heating, regeneration of sorbents, and downstream processing all contribute to the energy footprint of DLE operations. This energy intensity not only impacts the economic viability of these technologies but also potentially undermines their environmental benefits compared to conventional methods.

The technical objectives for advancing DLE technology center on significantly reducing energy requirements while maintaining or improving extraction efficiency and selectivity. Specific goals include developing sorbents that can operate at ambient temperatures, require less aggressive regeneration conditions, and demonstrate longer operational lifespans before replacement is necessary.

Additionally, there is a focus on integrating renewable energy sources to power DLE operations, implementing energy recovery systems, and optimizing process configurations to minimize pumping and heating requirements. The ultimate aim is to establish DLE as not only the most environmentally sustainable approach to lithium production but also the most economically competitive.

Success in reducing energy consumption in DLE would address a critical bottleneck in scaling these technologies to meet projected lithium demand, which is expected to increase by 400-800% by 2030. This would enable more widespread deployment of DLE systems, potentially unlocking previously uneconomical lithium resources and diversifying the global supply chain for this strategic metal.

Market Analysis for Energy-Efficient DLE Solutions

The global market for energy-efficient Direct Lithium Extraction (DLE) solutions is experiencing rapid growth, driven by the increasing demand for lithium in battery production for electric vehicles and renewable energy storage systems. Current market valuations indicate that the DLE technology sector is expected to reach $1.2 billion by 2025, with a compound annual growth rate of 29.3% from 2021 to 2025.

Energy consumption represents approximately 30-40% of operational costs in traditional lithium extraction processes, creating a significant economic incentive for energy-efficient alternatives. Companies implementing energy-optimized DLE solutions report cost reductions of 15-25% in their extraction operations, translating to millions in annual savings for large-scale producers.

Market segmentation reveals three primary customer categories for energy-efficient DLE technologies: established lithium producers seeking to optimize existing operations, new market entrants requiring cost-effective extraction methods, and technology providers developing integrated solutions. The largest market share currently belongs to North America (38%), followed by Asia-Pacific (32%), Europe (21%), and other regions (9%).

Demand forecasts indicate particularly strong growth in regions with significant lithium deposits but challenging extraction conditions, such as South America's lithium triangle (Argentina, Bolivia, and Chile) and Australia's hard rock deposits. These markets are especially receptive to energy-efficient technologies that can reduce operational costs while minimizing environmental impact.

Consumer preference analysis shows increasing prioritization of sustainability metrics alongside cost efficiency. End users in the battery manufacturing sector are willing to pay a 5-8% premium for lithium sourced through energy-efficient and environmentally responsible extraction methods, creating additional market incentives for technology development.

Regulatory trends further support market growth for energy-efficient DLE solutions. Several major lithium-producing countries have implemented or announced carbon pricing mechanisms and environmental standards that penalize energy-intensive extraction methods. For instance, Chile's new mining regulations include specific energy efficiency requirements, while the European Union's battery passport initiative will require disclosure of energy consumption in material sourcing.

Market barriers include high initial capital expenditure requirements for implementing new DLE technologies, with typical installation costs ranging from $20-50 million depending on scale. However, return on investment analyses demonstrate payback periods of 3-5 years for most energy-efficient systems, making them increasingly attractive as energy prices continue to rise globally.

Energy consumption represents approximately 30-40% of operational costs in traditional lithium extraction processes, creating a significant economic incentive for energy-efficient alternatives. Companies implementing energy-optimized DLE solutions report cost reductions of 15-25% in their extraction operations, translating to millions in annual savings for large-scale producers.

Market segmentation reveals three primary customer categories for energy-efficient DLE technologies: established lithium producers seeking to optimize existing operations, new market entrants requiring cost-effective extraction methods, and technology providers developing integrated solutions. The largest market share currently belongs to North America (38%), followed by Asia-Pacific (32%), Europe (21%), and other regions (9%).

Demand forecasts indicate particularly strong growth in regions with significant lithium deposits but challenging extraction conditions, such as South America's lithium triangle (Argentina, Bolivia, and Chile) and Australia's hard rock deposits. These markets are especially receptive to energy-efficient technologies that can reduce operational costs while minimizing environmental impact.

Consumer preference analysis shows increasing prioritization of sustainability metrics alongside cost efficiency. End users in the battery manufacturing sector are willing to pay a 5-8% premium for lithium sourced through energy-efficient and environmentally responsible extraction methods, creating additional market incentives for technology development.

Regulatory trends further support market growth for energy-efficient DLE solutions. Several major lithium-producing countries have implemented or announced carbon pricing mechanisms and environmental standards that penalize energy-intensive extraction methods. For instance, Chile's new mining regulations include specific energy efficiency requirements, while the European Union's battery passport initiative will require disclosure of energy consumption in material sourcing.

Market barriers include high initial capital expenditure requirements for implementing new DLE technologies, with typical installation costs ranging from $20-50 million depending on scale. However, return on investment analyses demonstrate payback periods of 3-5 years for most energy-efficient systems, making them increasingly attractive as energy prices continue to rise globally.

Current DLE Energy Challenges and Limitations

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives to traditional evaporation ponds for lithium recovery, offering faster extraction rates and reduced environmental footprint. However, current DLE methods face significant energy consumption challenges that limit their widespread commercial adoption and sustainability.

The primary energy challenge in DLE processes stems from the pumping requirements for brine circulation through adsorption columns or membranes. These systems typically require continuous pumping of large volumes of lithium-containing brines, consuming substantial electrical energy. For instance, adsorption-based DLE systems can require between 15-40 kWh per kilogram of lithium carbonate equivalent (LCE) produced solely for pumping operations.

Thermal energy demands represent another major limitation. Many DLE technologies require heating during desorption phases to release captured lithium from sorbents or membranes. These thermal regeneration processes often operate at temperatures between 60-90°C, necessitating significant energy inputs, particularly in cold climate regions. This thermal requirement can add an additional 10-25 kWh per kilogram of LCE to the energy footprint.

Concentration and purification stages following extraction also contribute substantially to energy consumption. Processes like reverse osmosis, nanofiltration, and electrodialysis used to concentrate lithium solutions require 5-15 kWh/kg LCE. Subsequent evaporation and crystallization steps for final product formation can demand an additional 8-20 kWh/kg LCE, depending on process efficiency and environmental conditions.

The energy intensity of current DLE technologies creates economic barriers, with energy costs representing 30-50% of operational expenses for many systems. This high energy burden directly impacts the cost competitiveness of DLE against traditional extraction methods in regions with high electricity prices or limited renewable energy access.

Scale-up challenges further exacerbate energy concerns. Laboratory-scale DLE processes often demonstrate promising energy efficiencies that prove difficult to maintain at commercial scales. Pilot plants frequently report 20-40% higher energy consumption per unit of lithium produced compared to laboratory predictions due to pumping inefficiencies, heat losses, and suboptimal process integration.

Geographical constraints also play a significant role in energy limitations. Many lithium-rich brines are located in remote areas with limited grid infrastructure, necessitating on-site power generation that often relies on fossil fuels. This dependency not only increases operational costs but also undermines the environmental benefits that DLE technologies aim to deliver compared to traditional extraction methods.

Addressing these energy challenges requires innovative approaches to process design, energy recovery systems, and integration with renewable energy sources to ensure DLE technologies can fulfill their promise of more sustainable lithium production.

The primary energy challenge in DLE processes stems from the pumping requirements for brine circulation through adsorption columns or membranes. These systems typically require continuous pumping of large volumes of lithium-containing brines, consuming substantial electrical energy. For instance, adsorption-based DLE systems can require between 15-40 kWh per kilogram of lithium carbonate equivalent (LCE) produced solely for pumping operations.

Thermal energy demands represent another major limitation. Many DLE technologies require heating during desorption phases to release captured lithium from sorbents or membranes. These thermal regeneration processes often operate at temperatures between 60-90°C, necessitating significant energy inputs, particularly in cold climate regions. This thermal requirement can add an additional 10-25 kWh per kilogram of LCE to the energy footprint.

Concentration and purification stages following extraction also contribute substantially to energy consumption. Processes like reverse osmosis, nanofiltration, and electrodialysis used to concentrate lithium solutions require 5-15 kWh/kg LCE. Subsequent evaporation and crystallization steps for final product formation can demand an additional 8-20 kWh/kg LCE, depending on process efficiency and environmental conditions.

The energy intensity of current DLE technologies creates economic barriers, with energy costs representing 30-50% of operational expenses for many systems. This high energy burden directly impacts the cost competitiveness of DLE against traditional extraction methods in regions with high electricity prices or limited renewable energy access.

Scale-up challenges further exacerbate energy concerns. Laboratory-scale DLE processes often demonstrate promising energy efficiencies that prove difficult to maintain at commercial scales. Pilot plants frequently report 20-40% higher energy consumption per unit of lithium produced compared to laboratory predictions due to pumping inefficiencies, heat losses, and suboptimal process integration.

Geographical constraints also play a significant role in energy limitations. Many lithium-rich brines are located in remote areas with limited grid infrastructure, necessitating on-site power generation that often relies on fossil fuels. This dependency not only increases operational costs but also undermines the environmental benefits that DLE technologies aim to deliver compared to traditional extraction methods.

Addressing these energy challenges requires innovative approaches to process design, energy recovery systems, and integration with renewable energy sources to ensure DLE technologies can fulfill their promise of more sustainable lithium production.

Current Energy Optimization Approaches in DLE

01 Energy-efficient extraction methods

Various energy-efficient methods have been developed for direct lithium extraction to reduce overall energy consumption. These methods include optimized adsorption/desorption cycles, improved membrane technologies, and novel electrochemical processes that operate at lower energy thresholds. By implementing these energy-efficient extraction techniques, the overall carbon footprint and operational costs of lithium extraction can be significantly reduced while maintaining high recovery rates.- Energy-efficient extraction methods: Various energy-efficient methods have been developed for direct lithium extraction to reduce overall energy consumption. These methods include optimized electrochemical processes, advanced membrane technologies, and innovative sorbent materials that can operate at lower energy requirements. These approaches focus on minimizing the energy needed for lithium separation while maintaining high recovery rates and purity levels.

- Renewable energy integration: Integration of renewable energy sources such as solar, wind, and geothermal power into direct lithium extraction processes significantly reduces the carbon footprint and operational costs. These systems can be designed to operate during periods of peak renewable energy availability, utilizing excess energy that might otherwise be wasted. This approach addresses both energy consumption concerns and environmental sustainability in lithium production.

- Heat recovery and thermal management: Advanced heat recovery systems and thermal management techniques can substantially reduce the energy consumption in direct lithium extraction processes. These systems capture and reuse waste heat from various stages of the extraction process, improving overall energy efficiency. Thermal optimization includes careful process integration, heat exchangers, and insulation technologies that minimize energy losses throughout the extraction cycle.

- Electrochemical optimization: Optimized electrochemical systems for direct lithium extraction focus on reducing energy requirements through improved electrode materials, cell designs, and operating parameters. These innovations include low-resistance membranes, high-surface-area electrodes, and precise control of current densities and voltages. By minimizing electrical resistance and maximizing extraction efficiency, these systems significantly reduce the energy needed per unit of lithium produced.

- Process automation and control systems: Advanced automation and control systems play a crucial role in optimizing energy consumption during direct lithium extraction. These systems utilize real-time monitoring, artificial intelligence, and machine learning algorithms to continuously adjust process parameters for maximum energy efficiency. Smart control systems can predict optimal operating conditions, manage energy distribution, and identify opportunities for further efficiency improvements, resulting in significant energy savings across the extraction process.

02 Renewable energy integration in DLE processes

Integration of renewable energy sources such as solar, wind, and geothermal power into direct lithium extraction operations can substantially decrease fossil fuel dependency and energy costs. These systems are designed to utilize renewable energy for powering extraction pumps, heating solutions, and electrochemical processes. The combination of renewable energy with lithium extraction creates more sustainable operations and helps mitigate environmental impacts associated with traditional energy-intensive extraction methods.Expand Specific Solutions03 Heat recovery and thermal management systems

Advanced heat recovery and thermal management systems have been developed to capture and reuse thermal energy in direct lithium extraction processes. These systems include heat exchangers, thermal storage solutions, and process integration techniques that minimize energy waste. By recovering heat from various stages of the extraction process and optimizing thermal flows, overall energy consumption can be reduced significantly while maintaining extraction efficiency.Expand Specific Solutions04 Electrochemical optimization for energy reduction

Electrochemical optimization techniques focus on reducing the energy requirements of direct lithium extraction through improved electrode materials, cell designs, and operating parameters. These innovations include low-resistance membranes, high-efficiency catalysts, and precise control systems that minimize energy losses. By optimizing electrochemical processes, the energy consumption per unit of lithium extracted can be substantially decreased while maintaining high purity levels.Expand Specific Solutions05 AI and automation for energy efficiency

Artificial intelligence and automation technologies are being implemented to optimize energy usage in direct lithium extraction operations. These systems use real-time monitoring, predictive analytics, and machine learning algorithms to adjust process parameters for maximum energy efficiency. By continuously optimizing operational conditions based on data analysis, these smart systems can significantly reduce energy consumption while improving extraction yields and reducing downtime.Expand Specific Solutions

Key Industry Players in DLE Innovation

The direct lithium extraction (DLE) market is in its early growth phase, characterized by rapid technological innovation and increasing commercial deployment. The global market size is projected to expand significantly due to rising lithium demand for electric vehicle batteries and energy storage systems. Technologically, companies are at varying stages of maturity, with established players like Schlumberger Technologies and Koch Technology Solutions leading commercial implementations, while innovative startups such as Lilac Solutions, Evove, and Watercycle Technologies are advancing novel extraction methods. Academic institutions including Xi'an Jiaotong University and The University of Manchester are contributing fundamental research to reduce energy requirements. The competitive landscape features both oil and gas companies leveraging their expertise in fluid processing and specialized technology providers focused on membrane technology, ion exchange, and electrochemical processes to improve energy efficiency in lithium extraction.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed an advanced direct lithium extraction (DLE) technology called EnerLi that focuses on energy efficiency and sustainability. Their approach combines selective adsorption materials with sophisticated process engineering to minimize energy consumption. The EnerLi system utilizes proprietary ceramic adsorbents with high lithium selectivity that operate in a continuous countercurrent process. Brine flows through multiple adsorption columns where lithium is captured while other elements pass through. The lithium-loaded adsorbents are then regenerated using a carefully optimized elution process that minimizes reagent consumption and waste generation. Schlumberger's system incorporates heat recovery mechanisms that capture and reuse thermal energy throughout the process, reducing overall energy requirements by up to 60% compared to conventional methods. Their technology also features advanced process control systems that continuously optimize operating parameters based on real-time data, further enhancing energy efficiency. The modular design allows for deployment across various brine resources with minimal site preparation.

Strengths: Significant energy reduction through heat recovery and process optimization; high lithium recovery rates (85-95%); extensive experience in fluid handling and processing from oil and gas operations; robust engineering suitable for remote locations. Weaknesses: Higher initial capital investment; requires specialized technical expertise for operation; ceramic adsorbents may have limited lifespan requiring periodic replacement.

International Battery Metals Ltd.

Technical Solution: International Battery Metals (IBAT) has developed a modular, mobile direct lithium extraction technology that prioritizes energy efficiency and rapid deployment. Their system utilizes selective absorption technology based on proprietary chemical formulations that specifically target lithium ions in brine solutions. The IBAT approach employs a continuous counter-current extraction process where lithium-rich brine flows through absorption columns containing their selective media. After lithium capture, a carefully optimized elution process recovers concentrated lithium chloride solution while regenerating the absorption media. A key innovation in IBAT's technology is their focus on mobility and modularity - their extraction units are built into standard shipping containers that can be rapidly deployed to remote locations, reducing construction energy requirements. The system incorporates advanced heat exchangers and energy recovery systems that capture and reuse thermal energy throughout the process, significantly reducing overall energy consumption. IBAT claims their technology can reduce energy usage by up to 66% compared to traditional evaporation methods while achieving lithium recovery rates exceeding 90%.

Strengths: Highly mobile and modular design allows for rapid deployment; energy-efficient operation through heat recovery systems; minimal site preparation requirements; continuous operation capability; high lithium selectivity and recovery rates. Weaknesses: Limited track record of large-scale commercial operations; potential challenges in scaling to very high production volumes; requires specialized technical expertise for optimal operation.

Critical Patents and Research in Low-Energy DLE

Direct electrochemical extraction of lithium from ores

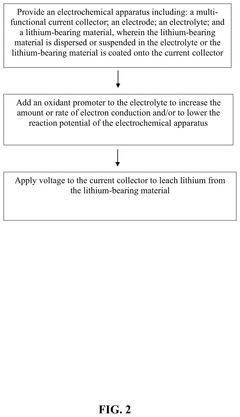

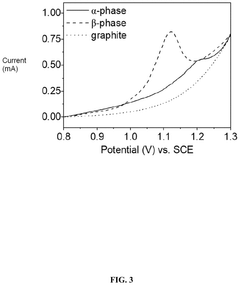

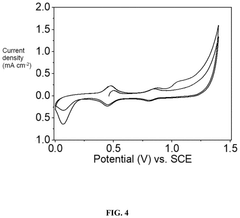

PatentPendingUS20250109517A1

Innovation

- An electrochemical leaching method using a multi-functional current collector with a carbon-based or metal-based framework, graphene oxide aerogel foam, and catalysts, along with an electrolyte and oxidant promoters, allows direct extraction of lithium from α-spodumene without phase transformation, enhancing energy efficiency and reducing environmental impact.

Lithium recovery thermal management

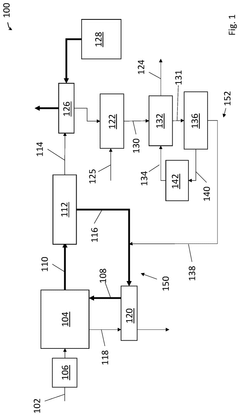

PatentActiveUS20240336490A1

Innovation

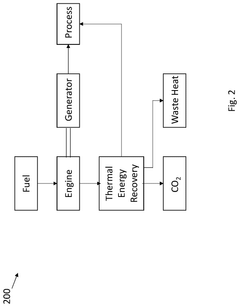

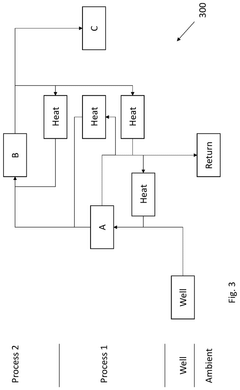

- A method involving a sorption/desorption process using ion withdrawal and thermal energy recovery, where lithium is extracted from brine sources using modular, dynamically scalable energy sources, including electric heaters and heat exchangers, to minimize energy use and environmental impact by optimizing energy coupling and thermal management.

Environmental Impact Assessment of DLE Methods

Direct Lithium Extraction (DLE) technologies, while promising for lithium production, carry significant environmental implications that require thorough assessment. Current DLE methods demonstrate varying degrees of environmental impact across multiple ecological dimensions, necessitating comprehensive evaluation frameworks to guide sustainable implementation.

Water usage represents a primary environmental concern for DLE operations. Traditional lithium extraction from brines typically consumes 500,000 to 750,000 gallons of water per ton of lithium carbonate produced. Advanced DLE technologies have demonstrated potential reductions of 50-90% in water consumption compared to evaporative methods, though actual performance varies significantly between specific technologies and implementation contexts.

Chemical usage in DLE processes presents another critical environmental consideration. Ion exchange and adsorption-based methods often require substantial quantities of acids, bases, and regeneration chemicals that may contaminate surrounding ecosystems if improperly managed. Recent advancements in selective adsorption materials have shown promise in reducing chemical requirements by 30-40%, though these improvements remain inconsistent across different technological approaches.

Land disturbance metrics reveal substantial advantages for DLE compared to traditional methods. While evaporation pond-based extraction typically requires 3,000-4,000 hectares per 20,000 tons of annual lithium carbonate production, modern DLE facilities can achieve similar output with less than 400 hectares of land disturbance, representing a 90% reduction in physical footprint.

Carbon emissions associated with DLE vary considerably based on energy sources and process efficiency. Current estimates indicate energy requirements of 5-15 kWh per kilogram of lithium extracted, translating to approximately 2.5-7.5 tons of CO₂ emissions per ton of lithium carbonate when using conventional energy sources. Integration of renewable energy can potentially reduce this carbon footprint by 60-80%.

Waste management challenges persist across DLE implementations. The generation of spent adsorbents, contaminated process water, and chemical residues requires dedicated treatment protocols. Life cycle assessments indicate that advanced DLE methods produce approximately 30-50% less hazardous waste than conventional extraction techniques, though proper disposal infrastructure remains underdeveloped in many production regions.

Ecosystem disruption potential varies significantly between DLE implementations. While avoiding the extensive surface disturbance of evaporation ponds, potential groundwater contamination and brine chemistry alterations may impact local hydrological systems. Recent monitoring studies suggest that properly engineered DLE systems can maintain ecosystem integrity when operated within established environmental parameters, though long-term ecological effects require further investigation.

Water usage represents a primary environmental concern for DLE operations. Traditional lithium extraction from brines typically consumes 500,000 to 750,000 gallons of water per ton of lithium carbonate produced. Advanced DLE technologies have demonstrated potential reductions of 50-90% in water consumption compared to evaporative methods, though actual performance varies significantly between specific technologies and implementation contexts.

Chemical usage in DLE processes presents another critical environmental consideration. Ion exchange and adsorption-based methods often require substantial quantities of acids, bases, and regeneration chemicals that may contaminate surrounding ecosystems if improperly managed. Recent advancements in selective adsorption materials have shown promise in reducing chemical requirements by 30-40%, though these improvements remain inconsistent across different technological approaches.

Land disturbance metrics reveal substantial advantages for DLE compared to traditional methods. While evaporation pond-based extraction typically requires 3,000-4,000 hectares per 20,000 tons of annual lithium carbonate production, modern DLE facilities can achieve similar output with less than 400 hectares of land disturbance, representing a 90% reduction in physical footprint.

Carbon emissions associated with DLE vary considerably based on energy sources and process efficiency. Current estimates indicate energy requirements of 5-15 kWh per kilogram of lithium extracted, translating to approximately 2.5-7.5 tons of CO₂ emissions per ton of lithium carbonate when using conventional energy sources. Integration of renewable energy can potentially reduce this carbon footprint by 60-80%.

Waste management challenges persist across DLE implementations. The generation of spent adsorbents, contaminated process water, and chemical residues requires dedicated treatment protocols. Life cycle assessments indicate that advanced DLE methods produce approximately 30-50% less hazardous waste than conventional extraction techniques, though proper disposal infrastructure remains underdeveloped in many production regions.

Ecosystem disruption potential varies significantly between DLE implementations. While avoiding the extensive surface disturbance of evaporation ponds, potential groundwater contamination and brine chemistry alterations may impact local hydrological systems. Recent monitoring studies suggest that properly engineered DLE systems can maintain ecosystem integrity when operated within established environmental parameters, though long-term ecological effects require further investigation.

Supply Chain Considerations for Sustainable DLE

The sustainable implementation of Direct Lithium Extraction (DLE) technologies requires careful consideration of supply chain dynamics to ensure both economic viability and environmental responsibility. DLE supply chains encompass raw material sourcing, processing equipment manufacturing, chemical reagent supply, and waste management infrastructure, all of which impact the overall energy footprint of lithium production.

Proximity of DLE operations to lithium sources significantly affects energy consumption in transportation. Locating processing facilities near brine fields or mineral deposits can reduce the energy required for moving materials, particularly important given the often remote locations of lithium resources in regions like the South American Lithium Triangle and Western Australia. Companies implementing DLE should conduct comprehensive logistics analyses to optimize facility placement and transportation routes.

Chemical reagent supply chains represent another critical energy consideration. Many DLE processes rely on specialized sorbents, ion exchange resins, or solvents that require energy-intensive manufacturing processes. Developing regional supply networks for these materials can reduce transportation-related energy consumption while supporting local economies. Additionally, establishing closed-loop systems for reagent recycling and regeneration within DLE facilities minimizes the need for continuous new material production.

Equipment manufacturing for DLE systems presents opportunities for energy optimization through design innovations. Modular, standardized equipment designs facilitate more efficient manufacturing processes and enable easier maintenance and component replacement, extending operational lifespans. Partnerships between DLE technology developers and equipment manufacturers can drive innovations in energy-efficient designs specifically tailored to lithium extraction requirements.

Water management within the DLE supply chain deserves particular attention, as water pumping and treatment constitute significant energy demands. Implementing water recycling systems and utilizing renewable energy for pumping operations can substantially reduce the overall energy footprint. In water-scarce regions, the energy-water nexus becomes especially critical to sustainable operations.

Waste management infrastructure represents the final key component of sustainable DLE supply chains. Developing efficient systems for handling spent materials, processing residues, and by-products requires careful planning to minimize transportation distances and energy requirements. Co-location of complementary industries that can utilize DLE by-products creates industrial symbiosis opportunities, reducing overall energy consumption across the broader supply network.

Proximity of DLE operations to lithium sources significantly affects energy consumption in transportation. Locating processing facilities near brine fields or mineral deposits can reduce the energy required for moving materials, particularly important given the often remote locations of lithium resources in regions like the South American Lithium Triangle and Western Australia. Companies implementing DLE should conduct comprehensive logistics analyses to optimize facility placement and transportation routes.

Chemical reagent supply chains represent another critical energy consideration. Many DLE processes rely on specialized sorbents, ion exchange resins, or solvents that require energy-intensive manufacturing processes. Developing regional supply networks for these materials can reduce transportation-related energy consumption while supporting local economies. Additionally, establishing closed-loop systems for reagent recycling and regeneration within DLE facilities minimizes the need for continuous new material production.

Equipment manufacturing for DLE systems presents opportunities for energy optimization through design innovations. Modular, standardized equipment designs facilitate more efficient manufacturing processes and enable easier maintenance and component replacement, extending operational lifespans. Partnerships between DLE technology developers and equipment manufacturers can drive innovations in energy-efficient designs specifically tailored to lithium extraction requirements.

Water management within the DLE supply chain deserves particular attention, as water pumping and treatment constitute significant energy demands. Implementing water recycling systems and utilizing renewable energy for pumping operations can substantially reduce the overall energy footprint. In water-scarce regions, the energy-water nexus becomes especially critical to sustainable operations.

Waste management infrastructure represents the final key component of sustainable DLE supply chains. Developing efficient systems for handling spent materials, processing residues, and by-products requires careful planning to minimize transportation distances and energy requirements. Co-location of complementary industries that can utilize DLE by-products creates industrial symbiosis opportunities, reducing overall energy consumption across the broader supply network.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!