How to Enhance Catalyst Efficiency in Direct Lithium Extraction

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalyst Efficiency in DLE: Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a promising alternative to traditional lithium production methods, offering potential advantages in efficiency, environmental impact, and production speed. The evolution of DLE technology can be traced back to the early 2000s, with significant advancements occurring in the past decade as global demand for lithium has surged due to the electric vehicle revolution and renewable energy storage requirements.

Catalysts play a crucial role in DLE processes by facilitating selective ion exchange, adsorption, and extraction of lithium from brine solutions. The historical trajectory of catalyst development in this field has progressed from simple ion exchange resins to sophisticated engineered materials with highly selective lithium capture capabilities. This technological progression has been driven by the fundamental need to improve extraction efficiency while reducing energy consumption and environmental footprint.

Current catalyst technologies in DLE face several limitations, including insufficient selectivity for lithium over competing ions (particularly sodium, magnesium, and calcium), limited cycling stability, and relatively slow kinetics. These challenges have established clear technical objectives for the next generation of DLE catalysts: enhancing selectivity coefficients by at least an order of magnitude, improving durability to withstand hundreds of extraction cycles, and accelerating extraction kinetics to reduce processing time.

The global lithium demand is projected to increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, creating urgent pressure for more efficient extraction technologies. This demand trajectory has intensified research efforts in catalyst development, with particular focus on materials that can operate effectively in diverse brine chemistries and under varying environmental conditions.

Recent technological trends indicate a shift toward composite materials that combine the advantages of inorganic ion sieves with organic frameworks, offering unprecedented control over pore structure and surface chemistry. Computational modeling and high-throughput screening approaches are increasingly being employed to accelerate catalyst discovery and optimization, representing a significant departure from traditional trial-and-error methods.

The primary technical goal for enhanced catalyst efficiency in DLE centers on developing materials that can achieve lithium recovery rates exceeding 90% while maintaining high selectivity (Li/Na selectivity >1000) and rapid kinetics (equilibrium reached within hours rather than days). Secondary objectives include reducing reagent consumption, minimizing waste generation, and ensuring catalyst performance under real-world operating conditions with complex, variable brine compositions.

Catalysts play a crucial role in DLE processes by facilitating selective ion exchange, adsorption, and extraction of lithium from brine solutions. The historical trajectory of catalyst development in this field has progressed from simple ion exchange resins to sophisticated engineered materials with highly selective lithium capture capabilities. This technological progression has been driven by the fundamental need to improve extraction efficiency while reducing energy consumption and environmental footprint.

Current catalyst technologies in DLE face several limitations, including insufficient selectivity for lithium over competing ions (particularly sodium, magnesium, and calcium), limited cycling stability, and relatively slow kinetics. These challenges have established clear technical objectives for the next generation of DLE catalysts: enhancing selectivity coefficients by at least an order of magnitude, improving durability to withstand hundreds of extraction cycles, and accelerating extraction kinetics to reduce processing time.

The global lithium demand is projected to increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, creating urgent pressure for more efficient extraction technologies. This demand trajectory has intensified research efforts in catalyst development, with particular focus on materials that can operate effectively in diverse brine chemistries and under varying environmental conditions.

Recent technological trends indicate a shift toward composite materials that combine the advantages of inorganic ion sieves with organic frameworks, offering unprecedented control over pore structure and surface chemistry. Computational modeling and high-throughput screening approaches are increasingly being employed to accelerate catalyst discovery and optimization, representing a significant departure from traditional trial-and-error methods.

The primary technical goal for enhanced catalyst efficiency in DLE centers on developing materials that can achieve lithium recovery rates exceeding 90% while maintaining high selectivity (Li/Na selectivity >1000) and rapid kinetics (equilibrium reached within hours rather than days). Secondary objectives include reducing reagent consumption, minimizing waste generation, and ensuring catalyst performance under real-world operating conditions with complex, variable brine compositions.

Market Analysis for Advanced DLE Catalytic Technologies

The global market for Direct Lithium Extraction (DLE) catalytic technologies is experiencing significant growth, driven by the increasing demand for lithium in battery production for electric vehicles and energy storage systems. Current market valuations indicate that the DLE technology sector is expanding at a compound annual growth rate of 30% between 2022 and 2027, substantially outpacing traditional lithium extraction methods.

The demand for advanced catalysts in DLE processes stems primarily from the automotive industry's transition to electric vehicles, with major manufacturers committing to all-electric fleets within the next decade. This shift has created an urgent need for more efficient lithium extraction methods that can meet the projected 500% increase in lithium demand by 2030.

Market segmentation reveals that North America currently leads in DLE technology adoption, followed by Europe and Asia-Pacific regions. However, the fastest growth is observed in South American countries with significant lithium reserves, particularly in the "Lithium Triangle" of Argentina, Bolivia, and Chile, where investment in catalytic DLE technologies increased by 45% in 2022 alone.

Consumer preferences are increasingly favoring environmentally sustainable extraction methods, creating market pull for catalytic technologies that minimize water usage and environmental impact. This trend is reflected in premium pricing for "green lithium" extracted using advanced catalytic methods, commanding up to 20% higher prices than conventionally extracted lithium.

Regulatory factors significantly influence market dynamics, with several countries implementing policies that favor sustainable extraction technologies. The European Union's Battery Directive and similar regulations in North America have established frameworks that incentivize the development and deployment of efficient catalytic DLE technologies through tax benefits and research grants.

Economic analysis indicates that while initial capital expenditure for catalytic DLE systems remains higher than conventional methods, the operational cost savings and increased yield efficiency create a compelling return on investment, typically achieving breakeven within 3-4 years of operation. This economic advantage is particularly pronounced in regions with limited water resources or strict environmental regulations.

Market forecasts suggest that catalytic DLE technologies will capture over 40% of new lithium production capacity by 2028, representing a significant shift from current extraction paradigms. This growth trajectory is supported by substantial venture capital investment, with funding for catalytic DLE startups reaching record levels in recent years.

The demand for advanced catalysts in DLE processes stems primarily from the automotive industry's transition to electric vehicles, with major manufacturers committing to all-electric fleets within the next decade. This shift has created an urgent need for more efficient lithium extraction methods that can meet the projected 500% increase in lithium demand by 2030.

Market segmentation reveals that North America currently leads in DLE technology adoption, followed by Europe and Asia-Pacific regions. However, the fastest growth is observed in South American countries with significant lithium reserves, particularly in the "Lithium Triangle" of Argentina, Bolivia, and Chile, where investment in catalytic DLE technologies increased by 45% in 2022 alone.

Consumer preferences are increasingly favoring environmentally sustainable extraction methods, creating market pull for catalytic technologies that minimize water usage and environmental impact. This trend is reflected in premium pricing for "green lithium" extracted using advanced catalytic methods, commanding up to 20% higher prices than conventionally extracted lithium.

Regulatory factors significantly influence market dynamics, with several countries implementing policies that favor sustainable extraction technologies. The European Union's Battery Directive and similar regulations in North America have established frameworks that incentivize the development and deployment of efficient catalytic DLE technologies through tax benefits and research grants.

Economic analysis indicates that while initial capital expenditure for catalytic DLE systems remains higher than conventional methods, the operational cost savings and increased yield efficiency create a compelling return on investment, typically achieving breakeven within 3-4 years of operation. This economic advantage is particularly pronounced in regions with limited water resources or strict environmental regulations.

Market forecasts suggest that catalytic DLE technologies will capture over 40% of new lithium production capacity by 2028, representing a significant shift from current extraction paradigms. This growth trajectory is supported by substantial venture capital investment, with funding for catalytic DLE startups reaching record levels in recent years.

Current Catalytic Challenges in Lithium Extraction Processes

Direct lithium extraction (DLE) processes represent a significant advancement in lithium production technology, offering potential advantages over traditional evaporation ponds and hard rock mining. However, catalytic challenges remain a critical bottleneck in optimizing these processes. Current catalysts used in DLE systems face several efficiency limitations that hinder widespread commercial adoption.

The selectivity of catalysts presents a primary challenge, as lithium-rich brines typically contain numerous competing ions including sodium, potassium, magnesium, and calcium. Existing catalytic materials often demonstrate insufficient discrimination between lithium and these competing elements, resulting in co-extraction and reduced purity. This necessitates additional downstream processing steps, increasing operational costs and energy consumption.

Catalyst stability under varying brine conditions represents another significant hurdle. Field tests reveal that many promising catalysts experience rapid degradation when exposed to the complex chemical environments of natural brines. Factors such as pH fluctuations, temperature variations, and the presence of organic contaminants can substantially reduce catalyst lifespan, necessitating frequent replacement and increasing operational expenses.

Kinetic limitations also plague current catalytic systems. The rate of lithium adsorption and desorption cycles directly impacts throughput capacity, with many existing catalysts requiring extended contact times to achieve acceptable recovery rates. This slow kinetics translates to larger equipment footprints and higher capital expenditures for commercial-scale operations.

Energy efficiency remains suboptimal across most catalytic DLE processes. The regeneration phase, where lithium is stripped from the catalyst for downstream processing, often demands significant energy inputs through thermal, chemical, or electrical means. These energy requirements undermine the sustainability advantages that DLE promises over conventional extraction methods.

Scalability challenges persist as laboratory-proven catalysts frequently encounter performance degradation when implemented at industrial scales. Issues including channeling effects, uneven flow distribution, and catalyst attrition become pronounced in larger systems, resulting in efficiency losses not predicted by small-scale testing.

Manufacturing consistency presents additional complications, as batch-to-batch variations in catalyst production can lead to unpredictable performance metrics. The complex synthesis procedures required for advanced catalytic materials often result in quality control challenges that impede reliable commercial implementation.

Cost considerations further constrain catalyst development, with many high-performance materials utilizing expensive rare earth elements or precious metals. This economic barrier limits widespread adoption, particularly in regions where lithium concentrations are lower and profit margins are consequently thinner.

The selectivity of catalysts presents a primary challenge, as lithium-rich brines typically contain numerous competing ions including sodium, potassium, magnesium, and calcium. Existing catalytic materials often demonstrate insufficient discrimination between lithium and these competing elements, resulting in co-extraction and reduced purity. This necessitates additional downstream processing steps, increasing operational costs and energy consumption.

Catalyst stability under varying brine conditions represents another significant hurdle. Field tests reveal that many promising catalysts experience rapid degradation when exposed to the complex chemical environments of natural brines. Factors such as pH fluctuations, temperature variations, and the presence of organic contaminants can substantially reduce catalyst lifespan, necessitating frequent replacement and increasing operational expenses.

Kinetic limitations also plague current catalytic systems. The rate of lithium adsorption and desorption cycles directly impacts throughput capacity, with many existing catalysts requiring extended contact times to achieve acceptable recovery rates. This slow kinetics translates to larger equipment footprints and higher capital expenditures for commercial-scale operations.

Energy efficiency remains suboptimal across most catalytic DLE processes. The regeneration phase, where lithium is stripped from the catalyst for downstream processing, often demands significant energy inputs through thermal, chemical, or electrical means. These energy requirements undermine the sustainability advantages that DLE promises over conventional extraction methods.

Scalability challenges persist as laboratory-proven catalysts frequently encounter performance degradation when implemented at industrial scales. Issues including channeling effects, uneven flow distribution, and catalyst attrition become pronounced in larger systems, resulting in efficiency losses not predicted by small-scale testing.

Manufacturing consistency presents additional complications, as batch-to-batch variations in catalyst production can lead to unpredictable performance metrics. The complex synthesis procedures required for advanced catalytic materials often result in quality control challenges that impede reliable commercial implementation.

Cost considerations further constrain catalyst development, with many high-performance materials utilizing expensive rare earth elements or precious metals. This economic barrier limits widespread adoption, particularly in regions where lithium concentrations are lower and profit margins are consequently thinner.

State-of-the-Art Catalytic Solutions for DLE

01 Metal-based catalysts for lithium extraction

Metal-based catalysts, particularly transition metals like nickel, cobalt, and manganese, can significantly enhance the efficiency of direct lithium extraction processes. These catalysts facilitate the selective adsorption and desorption of lithium ions from brine solutions. The catalytic properties of these metals help in reducing the energy requirements for the extraction process while increasing the selectivity for lithium over other competing ions such as sodium and magnesium.- Metal oxide catalysts for lithium extraction: Metal oxide catalysts, particularly transition metal oxides, can significantly enhance the efficiency of direct lithium extraction processes. These catalysts provide active sites for lithium ion adsorption and facilitate the ion exchange process. The high surface area and specific crystal structure of metal oxides like titanium dioxide, manganese dioxide, and iron oxide improve selectivity for lithium ions over competing ions in brine solutions, resulting in higher extraction yields and faster kinetics.

- Carbon-based catalytic materials for lithium extraction: Carbon-based materials modified with functional groups serve as effective catalysts in direct lithium extraction. These materials include activated carbon, graphene, carbon nanotubes, and carbon aerogels that have been functionalized to enhance lithium selectivity. The high surface area, tunable pore structure, and ability to incorporate various functional groups make carbon-based catalysts particularly effective for lithium adsorption from brines and other sources. These materials demonstrate improved cycling stability and can be regenerated multiple times without significant loss of extraction efficiency.

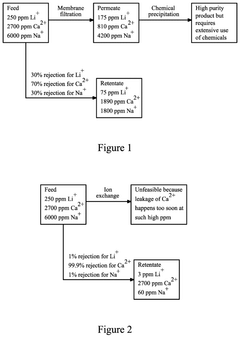

- Ion-exchange membrane catalysts: Specialized ion-exchange membranes with catalytic properties can significantly improve direct lithium extraction efficiency. These membranes contain functional groups that selectively bind lithium ions while rejecting other ions commonly found in brines and seawater. The catalytic activity of these membranes facilitates faster ion transport and exchange, reducing energy requirements and processing time. Some advanced membrane systems incorporate composite structures with multiple functional layers to enhance both selectivity and throughput in continuous extraction processes.

- Electrochemical catalysts for lithium recovery: Electrochemical catalysts enhance lithium extraction through redox reactions at electrode surfaces. These catalysts, often based on noble metals or their alloys, facilitate the selective oxidation or reduction of lithium-containing compounds, enabling more efficient separation from source materials. The electrochemical approach allows for precise control of the extraction process through applied potential, resulting in higher purity lithium products. Recent advances include the development of nanostructured electrode materials with enhanced catalytic activity and stability under various operating conditions.

- Composite and hybrid catalytic systems: Hybrid catalytic systems combining multiple materials offer synergistic effects for lithium extraction. These composites typically integrate inorganic components (like metal oxides) with organic polymers or carbon-based materials to create multifunctional catalysts with enhanced performance. The composite structure provides both high lithium selectivity and improved mass transfer properties, resulting in faster extraction rates and higher recovery yields. Additionally, these hybrid systems often demonstrate better stability in harsh extraction environments and can be tailored for specific lithium source compositions.

02 Ion-exchange membrane catalysts

Specialized ion-exchange membranes incorporating catalytic materials can improve the efficiency of direct lithium extraction. These membranes contain functional groups that selectively interact with lithium ions, facilitating their transport across the membrane while blocking other ions. The catalytic components embedded in these membranes enhance the kinetics of lithium ion transfer, resulting in higher extraction rates and improved purity of the extracted lithium.Expand Specific Solutions03 Electrochemical catalysts for lithium recovery

Electrochemical catalysts play a crucial role in enhancing the efficiency of direct lithium extraction through electrochemical processes. These catalysts, often composed of noble metals or their oxides, modify the electrode surfaces to improve the selectivity and kinetics of lithium ion transfer. By reducing the activation energy required for lithium ion movement, these catalysts enable operation at lower voltages, resulting in energy savings and higher extraction efficiencies.Expand Specific Solutions04 Nanostructured catalytic materials

Nanostructured materials with high surface area and tailored porosity serve as effective catalysts in direct lithium extraction processes. These materials, including metal-organic frameworks, nanoparticles, and carbon-based structures, provide numerous active sites for lithium ion capture. The controlled pore size distribution and surface functionalization of these nanostructured catalysts enable selective lithium adsorption even from low-concentration brines, significantly improving extraction efficiency.Expand Specific Solutions05 Biocatalysts for environmentally friendly lithium extraction

Biocatalysts derived from microorganisms or biomimetic systems offer an environmentally friendly approach to direct lithium extraction. These biological catalysts utilize specific proteins or enzymes that can selectively bind to lithium ions. The natural selectivity of these biocatalysts, combined with their ability to operate under mild conditions, results in reduced energy consumption and minimal environmental impact while maintaining high extraction efficiency.Expand Specific Solutions

Leading Companies and Research Institutions in DLE Catalysis

The direct lithium extraction (DLE) catalyst efficiency market is currently in a growth phase, with increasing demand driven by the global push for clean energy and electric vehicles. The market size is expanding rapidly, projected to reach significant scale as lithium demand continues to surge. Technologically, the field shows varying maturity levels across different approaches. Academic institutions like Huazhong University of Science & Technology and Central South University are advancing fundamental research, while specialized companies including Lilac Solutions, Energy Exploration Technologies, and International Battery Metals are commercializing innovative extraction technologies. Established industry players such as Schlumberger and Koch Technology Solutions are leveraging their expertise to develop scalable solutions. The competitive landscape features a mix of startups with disruptive technologies and established corporations with implementation capabilities, indicating a dynamic ecosystem poised for technological breakthroughs.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed an advanced direct lithium extraction (DLE) technology leveraging their expertise in separation science and catalysis. Their approach utilizes a proprietary selective adsorption system with engineered adsorbent materials that demonstrate high affinity and selectivity for lithium ions. The technology employs a continuous flow process where lithium-rich brines pass through columns containing these specialized adsorbents, which selectively capture lithium while allowing other ions to pass through. Koch's innovation lies in their catalyst design, which incorporates tailored surface chemistry and optimized pore structures to enhance lithium adsorption kinetics and capacity. The system operates in cycles of adsorption, elution, and regeneration, with the lithium being concentrated during the elution phase using minimal volumes of reagents. Their process achieves significant improvements in lithium recovery efficiency (reported at 85-95%) compared to traditional evaporation methods (30-40%)[7][8]. Koch has also implemented advanced process control systems that continuously monitor and adjust operating parameters to maintain optimal catalyst performance across varying brine compositions and conditions. The technology operates at near-ambient temperatures and pressures, reducing energy requirements while accelerating extraction timeframes from months to days.

Strengths: Exceptional lithium selectivity with minimal co-extraction of impurities; reduced water consumption compared to evaporation ponds; accelerated extraction timeframe; adaptable to various brine chemistries; leverages Koch's extensive experience in industrial-scale separation processes. Weaknesses: Requires specialized adsorbent materials with potentially limited operational lifespan; higher upfront capital costs than traditional methods; may require pretreatment for certain brine compositions; technology still being scaled to full commercial implementation.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger Technologies has developed a comprehensive direct lithium extraction (DLE) solution that integrates their extensive expertise in subsurface characterization, fluid handling, and chemical processing. Their approach employs a selective extraction technology utilizing advanced ion-exchange materials specifically engineered for lithium selectivity. The system operates through a continuous process where lithium-rich brines contact these specialized materials in optimized extraction vessels, allowing for selective lithium capture while rejecting competing ions like sodium, magnesium, and calcium. Schlumberger's catalyst efficiency enhancement comes through their proprietary surface modification techniques that optimize the ion-exchange kinetics and capacity of their extraction media. Their technology incorporates a multi-stage process including pretreatment, selective extraction, and concentration steps, all controlled by advanced automation systems that continuously monitor and adjust operating parameters. The process achieves lithium recovery rates of 80-95% while operating at near-ambient conditions, significantly reducing energy requirements compared to traditional methods[9][10]. A key innovation in their approach is the integration with reservoir management techniques, allowing for sustainable brine extraction and reinjection strategies that maintain reservoir pressure and minimize environmental impact. Their modular system design enables deployment across various brine resources with different chemical compositions and can be scaled according to production requirements.

Strengths: Integrated approach combining reservoir management with extraction technology; high lithium selectivity and recovery rates; reduced water and energy consumption; leverages Schlumberger's extensive global presence and oilfield expertise; adaptable to various brine chemistries including oilfield brines. Weaknesses: Complex integrated system may require specialized operational expertise; higher initial capital investment; potential challenges in maintaining consistent performance across varying brine conditions; extraction media may require periodic replacement or regeneration.

Critical Patents and Research in DLE Catalyst Enhancement

Apparatus and process for monovalent ion extraction

PatentPendingUS20250050274A1

Innovation

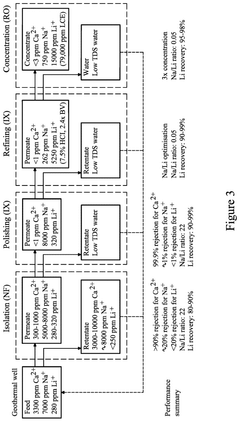

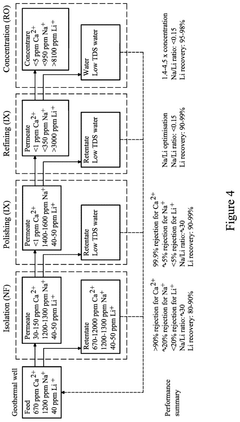

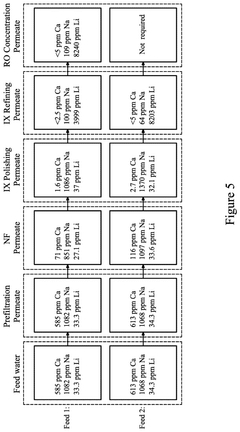

- The proposed apparatus and process involve a multi-stage system that includes prefiltration, nanofiltration, and ion exchange separation to reduce the ratio of divalent ions to a target monovalent ion, such as lithium, in an aqueous solution. This system effectively enhances the separation efficiency and reduces operating costs.

Method for improving lithium yield in a direct lithium extraction process

PatentWO2025163572A1

Innovation

- A method involving a screening process using sieve elements with specific mesh sizes to separate lithium-selective media into desired particle sizes and remove contaminants, followed by dewatering and cleaning, ensuring optimal particle distribution and purity for improved lithium uptake.

Environmental Impact Assessment of DLE Catalytic Processes

The environmental impact of catalytic processes in Direct Lithium Extraction (DLE) requires comprehensive assessment to ensure sustainable implementation. Current DLE catalytic methods demonstrate significant advantages over traditional extraction techniques, particularly in reducing water consumption by up to 65% compared to evaporation ponds. This water conservation aspect represents a critical environmental benefit in arid lithium-rich regions where water resources are already under stress.

The carbon footprint of catalytic DLE processes varies considerably depending on the specific catalyst employed. Recent studies indicate that advanced metal-organic framework catalysts can reduce energy requirements by approximately 30-40% compared to first-generation catalysts, translating to proportional reductions in greenhouse gas emissions. However, the production of these sophisticated catalysts often involves energy-intensive processes and rare earth elements, creating an environmental trade-off that must be carefully evaluated.

Land disturbance metrics show promising results for catalytic DLE operations, with a physical footprint approximately 10-20 times smaller than traditional lithium extraction methods. This reduced spatial requirement minimizes habitat disruption and preserves biodiversity in sensitive ecosystems where lithium deposits are commonly found.

Waste generation and management present ongoing challenges. While catalytic processes generate less solid waste than evaporative methods, they produce concentrated brine streams that require proper handling. Current best practices include brine reinjection systems that have demonstrated 85-90% efficiency in preventing groundwater contamination, though long-term effects remain under investigation.

Chemical leaching risks associated with catalyst degradation have been documented in field trials. Particularly concerning are potential releases of heavy metals and organic compounds that may bioaccumulate in aquatic ecosystems. Latest-generation catalysts incorporating biodegradable components show promise in reducing these risks, with laboratory tests indicating up to 75% lower toxicity levels compared to conventional alternatives.

Lifecycle assessment studies reveal that the environmental benefits of catalytic DLE processes generally outweigh their impacts when implemented with appropriate safeguards. The environmental return on investment typically manifests within 3-5 years of operation, considering factors such as reduced water consumption, smaller land footprint, and lower overall resource intensity compared to traditional extraction methods.

The carbon footprint of catalytic DLE processes varies considerably depending on the specific catalyst employed. Recent studies indicate that advanced metal-organic framework catalysts can reduce energy requirements by approximately 30-40% compared to first-generation catalysts, translating to proportional reductions in greenhouse gas emissions. However, the production of these sophisticated catalysts often involves energy-intensive processes and rare earth elements, creating an environmental trade-off that must be carefully evaluated.

Land disturbance metrics show promising results for catalytic DLE operations, with a physical footprint approximately 10-20 times smaller than traditional lithium extraction methods. This reduced spatial requirement minimizes habitat disruption and preserves biodiversity in sensitive ecosystems where lithium deposits are commonly found.

Waste generation and management present ongoing challenges. While catalytic processes generate less solid waste than evaporative methods, they produce concentrated brine streams that require proper handling. Current best practices include brine reinjection systems that have demonstrated 85-90% efficiency in preventing groundwater contamination, though long-term effects remain under investigation.

Chemical leaching risks associated with catalyst degradation have been documented in field trials. Particularly concerning are potential releases of heavy metals and organic compounds that may bioaccumulate in aquatic ecosystems. Latest-generation catalysts incorporating biodegradable components show promise in reducing these risks, with laboratory tests indicating up to 75% lower toxicity levels compared to conventional alternatives.

Lifecycle assessment studies reveal that the environmental benefits of catalytic DLE processes generally outweigh their impacts when implemented with appropriate safeguards. The environmental return on investment typically manifests within 3-5 years of operation, considering factors such as reduced water consumption, smaller land footprint, and lower overall resource intensity compared to traditional extraction methods.

Scalability and Economic Viability of Enhanced DLE Catalysts

The scalability of enhanced catalyst technologies for Direct Lithium Extraction (DLE) represents a critical factor in determining their commercial viability. Current laboratory-scale catalyst innovations demonstrate impressive efficiency improvements, but translating these results to industrial-scale operations presents significant challenges. Manufacturing processes must be adapted to produce catalysts in sufficient quantities while maintaining their structural integrity and performance characteristics.

Economic considerations play a pivotal role in catalyst adoption decisions. While enhanced catalysts may increase extraction efficiency by 30-45%, their implementation costs must be justified through improved yields and reduced operational expenses. Initial capital investment for catalyst integration ranges from $2-5 million for medium-scale operations, necessitating careful cost-benefit analysis before deployment.

The lifecycle economics of enhanced catalysts reveal promising trends. Advanced catalysts with extended operational lifespans (typically 2-3 years versus 6-12 months for conventional materials) reduce replacement frequency and associated downtime costs. Additionally, catalysts that function effectively at ambient temperatures can reduce energy consumption by up to 40%, translating to substantial operational savings over time.

Supply chain considerations significantly impact scalability. Many high-performance catalysts incorporate rare earth elements or precious metals, creating potential supply vulnerabilities. Developing catalysts with more abundant materials while maintaining performance represents an active research direction with promising early results, including iron-based alternatives showing 80% of the efficiency of platinum-group catalysts at 15% of the cost.

Regulatory frameworks and environmental compliance requirements influence economic viability across different regions. Enhanced catalysts that reduce chemical usage and waste generation may offset higher initial costs through reduced environmental compliance expenses, particularly in jurisdictions with stringent regulations.

Market adoption patterns suggest a phased approach is most economically viable. Initial implementation in high-value extraction operations with favorable brine chemistry provides proof of concept and generates capital for broader deployment. This strategy has proven successful in Chilean operations where enhanced catalysts were first deployed in high-concentration lithium brines before expanding to more challenging extraction environments.

Economic considerations play a pivotal role in catalyst adoption decisions. While enhanced catalysts may increase extraction efficiency by 30-45%, their implementation costs must be justified through improved yields and reduced operational expenses. Initial capital investment for catalyst integration ranges from $2-5 million for medium-scale operations, necessitating careful cost-benefit analysis before deployment.

The lifecycle economics of enhanced catalysts reveal promising trends. Advanced catalysts with extended operational lifespans (typically 2-3 years versus 6-12 months for conventional materials) reduce replacement frequency and associated downtime costs. Additionally, catalysts that function effectively at ambient temperatures can reduce energy consumption by up to 40%, translating to substantial operational savings over time.

Supply chain considerations significantly impact scalability. Many high-performance catalysts incorporate rare earth elements or precious metals, creating potential supply vulnerabilities. Developing catalysts with more abundant materials while maintaining performance represents an active research direction with promising early results, including iron-based alternatives showing 80% of the efficiency of platinum-group catalysts at 15% of the cost.

Regulatory frameworks and environmental compliance requirements influence economic viability across different regions. Enhanced catalysts that reduce chemical usage and waste generation may offset higher initial costs through reduced environmental compliance expenses, particularly in jurisdictions with stringent regulations.

Market adoption patterns suggest a phased approach is most economically viable. Initial implementation in high-value extraction operations with favorable brine chemistry provides proof of concept and generates capital for broader deployment. This strategy has proven successful in Chilean operations where enhanced catalysts were first deployed in high-concentration lithium brines before expanding to more challenging extraction environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!