Direct Lithium Extraction: Guidelines for Process Optimization

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a revolutionary approach to lithium production, representing a significant departure from traditional extraction methods that have dominated the industry for decades. The evolution of lithium extraction technology began with conventional methods such as solar evaporation from salt flats (salars) and hard rock mining, which have been employed since the 1950s. These traditional approaches, while effective, are characterized by lengthy production timelines, substantial land and water requirements, and considerable environmental impacts.

The technological trajectory shifted significantly in the early 2000s with the initial development of DLE technologies, driven by increasing global demand for lithium in battery applications and growing environmental concerns. DLE encompasses a diverse range of innovative processes including adsorption, ion exchange, solvent extraction, and membrane filtration techniques, all designed to selectively extract lithium from brine resources with greater efficiency and reduced environmental footprint.

The primary objective of DLE technology development is to establish more sustainable, economically viable, and environmentally responsible methods for lithium production. Specifically, DLE aims to significantly reduce water consumption, minimize land disturbance, accelerate production timelines from years to days, and increase lithium recovery rates from the typical 30-50% achieved in evaporation ponds to potentially over 90%.

Current technological trends in the DLE space focus on enhancing selectivity for lithium over competing ions, improving sorbent durability and regeneration capabilities, reducing energy requirements, and developing processes adaptable to diverse brine chemistries. The field is witnessing rapid innovation in materials science, particularly in the development of novel sorbents and membranes with superior lithium selectivity and longevity.

The global transition toward electrification and renewable energy storage has created unprecedented demand for lithium, with projections indicating a potential supply gap by 2025. This market pressure has accelerated DLE technology development, with significant investments flowing into research and commercialization efforts. The technology is approaching a critical inflection point, transitioning from laboratory and pilot demonstrations to commercial-scale implementations.

Looking forward, DLE technology evolution is expected to focus on process optimization to enhance economic viability across diverse brine resources, integration with renewable energy sources to minimize carbon footprint, and development of closed-loop systems that maximize resource efficiency while minimizing waste generation. The ultimate goal remains establishing DLE as the predominant lithium production method, capable of meeting growing global demand while adhering to increasingly stringent environmental and social governance standards.

The technological trajectory shifted significantly in the early 2000s with the initial development of DLE technologies, driven by increasing global demand for lithium in battery applications and growing environmental concerns. DLE encompasses a diverse range of innovative processes including adsorption, ion exchange, solvent extraction, and membrane filtration techniques, all designed to selectively extract lithium from brine resources with greater efficiency and reduced environmental footprint.

The primary objective of DLE technology development is to establish more sustainable, economically viable, and environmentally responsible methods for lithium production. Specifically, DLE aims to significantly reduce water consumption, minimize land disturbance, accelerate production timelines from years to days, and increase lithium recovery rates from the typical 30-50% achieved in evaporation ponds to potentially over 90%.

Current technological trends in the DLE space focus on enhancing selectivity for lithium over competing ions, improving sorbent durability and regeneration capabilities, reducing energy requirements, and developing processes adaptable to diverse brine chemistries. The field is witnessing rapid innovation in materials science, particularly in the development of novel sorbents and membranes with superior lithium selectivity and longevity.

The global transition toward electrification and renewable energy storage has created unprecedented demand for lithium, with projections indicating a potential supply gap by 2025. This market pressure has accelerated DLE technology development, with significant investments flowing into research and commercialization efforts. The technology is approaching a critical inflection point, transitioning from laboratory and pilot demonstrations to commercial-scale implementations.

Looking forward, DLE technology evolution is expected to focus on process optimization to enhance economic viability across diverse brine resources, integration with renewable energy sources to minimize carbon footprint, and development of closed-loop systems that maximize resource efficiency while minimizing waste generation. The ultimate goal remains establishing DLE as the predominant lithium production method, capable of meeting growing global demand while adhering to increasingly stringent environmental and social governance standards.

Market Analysis for Lithium Extraction Solutions

The global lithium market is experiencing unprecedented growth driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the lithium extraction industry at approximately $6.8 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 12.3% through 2030, potentially reaching $18.2 billion. This accelerated growth trajectory is primarily fueled by government initiatives promoting clean energy adoption and automotive manufacturers' commitments to electrification.

Direct Lithium Extraction (DLE) technologies are positioned to capture significant market share from traditional extraction methods. While conventional evaporation ponds currently account for 58% of global lithium production, their market dominance is expected to decline as DLE solutions demonstrate superior efficiency and environmental performance. Industry analysts predict DLE market penetration to increase from current levels of 10% to potentially 35-40% by 2030.

Regional market dynamics reveal interesting patterns, with North America emerging as a critical growth center for DLE implementation. The United States Geological Survey estimates that domestic lithium resources could support substantial production expansion, with DLE technologies enabling access to previously uneconomical deposits. The European market similarly shows strong potential, driven by the European Battery Alliance's strategic initiatives to secure regional lithium supply chains.

Customer segmentation within the lithium extraction market reveals three primary buyer categories: established mining corporations seeking technological upgrades, battery manufacturers pursuing vertical integration, and specialized lithium producers. Each segment demonstrates distinct requirements regarding process efficiency, environmental impact, and capital expenditure constraints that influence DLE technology adoption decisions.

Competitive analysis indicates intensifying market competition with over 40 companies actively developing proprietary DLE solutions. Market concentration remains relatively low with a Herfindahl-Hirschman Index below 1000, suggesting a fragmented competitive landscape with significant opportunities for technological differentiation and market entry.

Price sensitivity analysis reveals that DLE solutions must achieve production costs below $5,000 per ton of lithium carbonate equivalent to maintain competitive advantage against traditional methods in current market conditions. However, as battery manufacturers increasingly prioritize sustainability metrics and supply chain reliability, premium pricing for environmentally superior extraction methods is becoming more viable.

Market barriers include high capital requirements, technical complexity of implementation, and regulatory uncertainties regarding water usage and waste management. These factors currently limit market penetration but are expected to diminish as technology matures and regulatory frameworks evolve to accommodate innovative extraction methodologies.

Direct Lithium Extraction (DLE) technologies are positioned to capture significant market share from traditional extraction methods. While conventional evaporation ponds currently account for 58% of global lithium production, their market dominance is expected to decline as DLE solutions demonstrate superior efficiency and environmental performance. Industry analysts predict DLE market penetration to increase from current levels of 10% to potentially 35-40% by 2030.

Regional market dynamics reveal interesting patterns, with North America emerging as a critical growth center for DLE implementation. The United States Geological Survey estimates that domestic lithium resources could support substantial production expansion, with DLE technologies enabling access to previously uneconomical deposits. The European market similarly shows strong potential, driven by the European Battery Alliance's strategic initiatives to secure regional lithium supply chains.

Customer segmentation within the lithium extraction market reveals three primary buyer categories: established mining corporations seeking technological upgrades, battery manufacturers pursuing vertical integration, and specialized lithium producers. Each segment demonstrates distinct requirements regarding process efficiency, environmental impact, and capital expenditure constraints that influence DLE technology adoption decisions.

Competitive analysis indicates intensifying market competition with over 40 companies actively developing proprietary DLE solutions. Market concentration remains relatively low with a Herfindahl-Hirschman Index below 1000, suggesting a fragmented competitive landscape with significant opportunities for technological differentiation and market entry.

Price sensitivity analysis reveals that DLE solutions must achieve production costs below $5,000 per ton of lithium carbonate equivalent to maintain competitive advantage against traditional methods in current market conditions. However, as battery manufacturers increasingly prioritize sustainability metrics and supply chain reliability, premium pricing for environmentally superior extraction methods is becoming more viable.

Market barriers include high capital requirements, technical complexity of implementation, and regulatory uncertainties regarding water usage and waste management. These factors currently limit market penetration but are expected to diminish as technology matures and regulatory frameworks evolve to accommodate innovative extraction methodologies.

Current DLE Challenges and Technical Limitations

Despite significant advancements in Direct Lithium Extraction (DLE) technologies, several critical challenges and technical limitations continue to impede widespread commercial adoption. The primary obstacle remains the selective extraction of lithium from complex brines containing numerous competing ions such as sodium, potassium, magnesium, and calcium. Current sorbents and extraction media demonstrate insufficient selectivity coefficients, particularly in high-salinity environments where lithium concentrations are relatively low compared to other constituents.

Energy consumption represents another significant barrier, with most DLE processes requiring substantial thermal or electrical inputs for regeneration cycles. This energy intensity directly impacts operational costs and carbon footprints, undermining the sustainability credentials of lithium production for clean energy applications. Preliminary assessments indicate that energy requirements can range from 5 to 15 kWh per kilogram of lithium carbonate equivalent (LCE) depending on the specific technology employed.

Water management presents a multifaceted challenge across DLE operations. Many current technologies require substantial freshwater inputs for regeneration and washing cycles, creating a paradoxical situation where water-intensive processes are deployed in water-scarce regions. The water footprint of DLE operations can exceed 50-100 cubic meters per ton of LCE, raising serious sustainability concerns in arid lithium-rich regions.

Sorbent durability and lifecycle performance remain problematic, with most advanced materials showing significant degradation after repeated adsorption-desorption cycles. Field tests reveal that many promising laboratory-developed sorbents experience 15-30% capacity reduction after just 100-200 cycles, necessitating frequent and costly replacements. This degradation is often accelerated by impurities in the brine, creating a complex relationship between pre-treatment requirements and sorbent longevity.

Scaling issues present formidable engineering challenges, particularly in high-recovery systems where mineral precipitation can foul equipment and reduce operational efficiency. Calcium and magnesium scaling is especially problematic, requiring sophisticated anti-scaling strategies that add complexity and cost to DLE implementations.

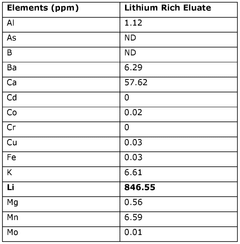

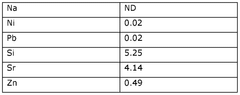

Process integration with downstream conversion steps remains suboptimal, creating inefficiencies in the transition from lithium-enriched eluate to battery-grade compounds. The variable composition of DLE outputs often necessitates additional purification steps, reducing the overall process economics compared to conventional evaporation pond methods.

Regulatory frameworks and environmental permitting processes are still evolving for these novel technologies, creating uncertainty and delays in project development timelines. The absence of standardized environmental impact assessment methodologies specifically tailored to DLE operations further complicates deployment efforts.

Energy consumption represents another significant barrier, with most DLE processes requiring substantial thermal or electrical inputs for regeneration cycles. This energy intensity directly impacts operational costs and carbon footprints, undermining the sustainability credentials of lithium production for clean energy applications. Preliminary assessments indicate that energy requirements can range from 5 to 15 kWh per kilogram of lithium carbonate equivalent (LCE) depending on the specific technology employed.

Water management presents a multifaceted challenge across DLE operations. Many current technologies require substantial freshwater inputs for regeneration and washing cycles, creating a paradoxical situation where water-intensive processes are deployed in water-scarce regions. The water footprint of DLE operations can exceed 50-100 cubic meters per ton of LCE, raising serious sustainability concerns in arid lithium-rich regions.

Sorbent durability and lifecycle performance remain problematic, with most advanced materials showing significant degradation after repeated adsorption-desorption cycles. Field tests reveal that many promising laboratory-developed sorbents experience 15-30% capacity reduction after just 100-200 cycles, necessitating frequent and costly replacements. This degradation is often accelerated by impurities in the brine, creating a complex relationship between pre-treatment requirements and sorbent longevity.

Scaling issues present formidable engineering challenges, particularly in high-recovery systems where mineral precipitation can foul equipment and reduce operational efficiency. Calcium and magnesium scaling is especially problematic, requiring sophisticated anti-scaling strategies that add complexity and cost to DLE implementations.

Process integration with downstream conversion steps remains suboptimal, creating inefficiencies in the transition from lithium-enriched eluate to battery-grade compounds. The variable composition of DLE outputs often necessitates additional purification steps, reducing the overall process economics compared to conventional evaporation pond methods.

Regulatory frameworks and environmental permitting processes are still evolving for these novel technologies, creating uncertainty and delays in project development timelines. The absence of standardized environmental impact assessment methodologies specifically tailored to DLE operations further complicates deployment efforts.

Current DLE Process Optimization Approaches

01 Adsorption-based lithium extraction methods

Adsorption-based methods utilize specialized materials to selectively capture lithium ions from brine solutions. These processes typically involve ion exchange materials or lithium-selective adsorbents that can be regenerated for continuous operation. Optimization of these methods focuses on improving selectivity for lithium over competing ions like sodium and magnesium, enhancing adsorption capacity, and developing efficient regeneration protocols to maximize lithium recovery while minimizing reagent consumption.- Selective ion exchange materials for lithium extraction: Advanced ion exchange materials can be used to selectively capture lithium ions from brine solutions while minimizing the co-extraction of other ions. These materials include specialized sorbents, membranes, and resins that have high selectivity for lithium over competing ions such as sodium, potassium, and magnesium. The optimization of these materials involves tailoring their physical and chemical properties to enhance lithium adsorption capacity, selectivity, and regeneration efficiency.

- Electrochemical processes for lithium recovery: Electrochemical methods offer promising approaches for direct lithium extraction by using electrical potential differences to selectively separate lithium ions from brine solutions. These processes include electrochemical intercalation, electrodialysis, and capacitive deionization techniques. Process optimization focuses on electrode material development, cell design, and operating parameters such as current density and voltage to maximize lithium recovery while minimizing energy consumption and operational costs.

- Membrane-based separation technologies: Membrane technologies play a crucial role in direct lithium extraction processes by providing selective barriers that allow lithium ions to pass while blocking other components. Advanced membrane systems include nanofiltration, forward osmosis, and supported liquid membranes. Optimization efforts focus on improving membrane selectivity, permeability, and durability under various operating conditions, as well as reducing fouling and scaling issues that can decrease efficiency over time.

- Process integration and system optimization: Comprehensive system integration approaches combine multiple extraction technologies and process steps to create more efficient lithium recovery systems. This includes optimizing pre-treatment methods, extraction sequences, and post-processing steps. Advanced process control systems, real-time monitoring, and automation are implemented to maintain optimal operating conditions. Energy and water recovery systems are also integrated to improve overall sustainability and reduce operational costs.

- Brine pre-treatment and impurity management: Effective pre-treatment of lithium-rich brines is essential for optimizing direct lithium extraction processes. This includes methods for removing impurities such as magnesium, calcium, boron, and organic compounds that can interfere with lithium recovery. Advanced techniques include selective precipitation, adsorption, and oxidation processes. Optimization focuses on developing tailored pre-treatment protocols based on specific brine compositions to maximize subsequent lithium extraction efficiency and product purity.

02 Membrane and electrochemical separation technologies

Electrochemical and membrane-based separation technologies offer promising approaches for direct lithium extraction. These methods utilize electrical potential differences or selective membranes to separate lithium from other components in brine solutions. Process optimization involves developing more selective membranes, reducing energy consumption, improving system durability under harsh brine conditions, and enhancing overall lithium recovery rates while maintaining high purity of the extracted lithium.Expand Specific Solutions03 Brine pre-treatment and impurity removal

Effective pre-treatment of lithium-rich brines is crucial for optimizing direct lithium extraction processes. This includes removing impurities such as magnesium, calcium, and boron that can interfere with extraction efficiency. Optimization strategies focus on developing selective precipitation methods, filtration techniques, and chemical treatments that can be tailored to specific brine compositions, thereby improving downstream extraction efficiency and reducing operational costs while minimizing environmental impact.Expand Specific Solutions04 Process integration and continuous operation systems

Integrated systems that combine multiple extraction steps into continuous operation processes represent a significant advancement in direct lithium extraction. These systems optimize the entire extraction workflow from brine intake to lithium product formation. Key optimization areas include developing automated control systems, improving heat and energy recovery between process steps, minimizing reagent consumption through recycling loops, and designing modular systems that can be scaled according to resource characteristics and production requirements.Expand Specific Solutions05 Lithium product refinement and conversion technologies

After initial extraction, lithium-containing solutions require further processing to produce commercial-grade lithium products such as lithium carbonate or hydroxide. Optimization of these refinement processes focuses on improving precipitation efficiency, reducing chemical consumption, enhancing product purity, and developing methods that can operate effectively with varying feed compositions. Advanced crystallization techniques and direct conversion methods are being developed to streamline the production of battery-grade lithium compounds.Expand Specific Solutions

Key Industry Players in DLE Technology

Direct Lithium Extraction (DLE) technology is currently in the early growth phase, with a rapidly expanding market projected to reach $1.45 billion by 2030. The competitive landscape features established players like Albemarle Corp. and Schlumberger alongside innovative startups such as Lilac Solutions and Energy Exploration Technologies. Technical maturity varies significantly across approaches, with companies like Koch Technology Solutions and Lilac Solutions demonstrating advanced ion-exchange technologies, while academic institutions including the Institute of Process Engineering (CAS) and North Carolina State University contribute fundamental research. BYD and Taiheiyo Cement represent industrial adopters exploring integration opportunities. The field is characterized by intense competition between membrane-based, adsorption, and electrochemical extraction methods, with optimization efforts focused on improving selectivity, recovery rates, and environmental sustainability.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering at the Chinese Academy of Sciences has developed several innovative Direct Lithium Extraction technologies focusing on electrochemical and adsorption-based approaches. Their primary technology utilizes novel lithium-selective adsorbents based on lithium manganese oxide (LMO) and lithium titanium oxide (LTO) materials that demonstrate exceptional selectivity for lithium ions even in brines with high Mg/Li ratios. The institute has pioneered a continuous-flow electrochemical lithium extraction system that combines selective adsorption with electrochemical regeneration, reducing chemical reagent consumption. Their process incorporates a multi-stage configuration that maximizes lithium recovery while minimizing energy consumption through careful optimization of current density and flow rates. The technology features advanced materials with high lithium capacity (>40 mg/g) and excellent cycling stability, maintaining performance over hundreds of adsorption-desorption cycles. Their research has demonstrated lithium recovery rates exceeding 90% from various brine sources, including geothermal fluids and salt lake brines with complex compositions.

Strengths: Cutting-edge materials science expertise; highly selective adsorbents for challenging brine compositions; reduced chemical reagent requirements; excellent cycling stability of materials; comprehensive understanding of lithium extraction mechanisms. Weaknesses: Some approaches may have high energy consumption; potential scaling challenges when moving from laboratory to industrial scale; may require specialized manufacturing capabilities for advanced materials; limited commercial implementation experience compared to industry players.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed an advanced Direct Lithium Extraction technology based on their expertise in separation processes across multiple industries. Their approach utilizes a proprietary selective adsorption system that employs engineered materials designed to capture lithium ions with high selectivity from various brine sources. The process operates in a multi-stage configuration where brine flows through a series of adsorption columns, allowing for continuous operation as some columns adsorb lithium while others undergo regeneration. Koch's technology incorporates sophisticated fluid dynamics modeling to optimize flow patterns and contact time between brine and adsorbent materials. Their system features automated process controls that adjust operating parameters based on real-time monitoring of brine composition and system performance. The technology is designed to be modular and scalable, allowing for phased implementation and capacity expansion. Koch claims their process can achieve lithium recovery rates exceeding 85% while reducing water consumption by 70-90% compared to traditional evaporation methods.

Strengths: Extensive engineering expertise in separation technologies; robust system design with high operational reliability; advanced process control systems; modular approach allowing for scalability; reduced environmental footprint with minimal water usage. Weaknesses: Relatively new entrant to lithium extraction specifically; potentially high capital costs for initial implementation; may require specific pre-treatment depending on brine chemistry; technology still being proven at commercial scale for lithium applications.

Critical Patents and Innovations in DLE

Process and product

PatentPendingUS20250161879A1

Innovation

- The process involves contacting an aqueous lithium solution with a lithium sorbent to absorb lithium, followed by separation of the loaded sorbent and depleted solution, and subsequent treatment to regenerate the sorbent. This process utilizes pH control to maintain the lithium depleted solution at a pH of about 3 to 7 and employs ultrafiltration or nanofiltration membranes for separation.

Process and product

PatentWO2025105970A1

Innovation

- A DLE process using a lithium sorbent with a high specific surface area, combined with ultrafiltration or nanofiltration membranes for separation, and a pH-controlled upload step to optimize lithium absorption and reduce impurity carryover.

Environmental Impact Assessment of DLE Methods

The environmental impact of Direct Lithium Extraction (DLE) methods represents a critical consideration in the broader adoption of these technologies. Traditional lithium extraction methods, particularly evaporative ponds, have faced significant criticism for their substantial water consumption, land use requirements, and potential for chemical contamination. DLE technologies offer promising alternatives with potentially reduced environmental footprints, though comprehensive assessment is necessary.

Water usage metrics across various DLE methods demonstrate significant variability. Adsorption-based technologies typically consume 10-50 gallons per kilogram of lithium carbonate equivalent (LCE), while ion exchange systems may require 15-70 gallons per kilogram LCE. These figures represent substantial improvements compared to evaporative methods, which can demand 500-2,000 gallons per kilogram LCE. The water quality impact also differs substantially, with closed-loop DLE systems demonstrating reduced risk of groundwater contamination.

Land disturbance patterns reveal another environmental advantage of DLE methods. While traditional evaporation ponds require approximately 2-3 square kilometers per 20,000 tons of annual LCE production, most DLE facilities can operate within compact industrial footprints of less than 0.1 square kilometers for equivalent output. This dramatic reduction in land use minimizes habitat disruption and preserves natural landscapes in lithium-rich regions.

Carbon emissions associated with DLE operations present a more complex picture. The energy-intensive nature of certain DLE processes, particularly those requiring significant heating or electrochemical systems, can generate 5-15 tons of CO2 per ton of LCE produced. However, when renewable energy sources power these operations, emissions can decrease by 60-80%, creating pathways toward carbon-neutral lithium production.

Chemical usage and waste generation constitute additional environmental considerations. Most DLE methods utilize specialized sorbents, resins, or membranes that require periodic replacement and proper disposal. The regeneration processes often involve acids, bases, or other chemicals that must be carefully managed. Advanced DLE systems incorporating chemical recovery loops have demonstrated 80-95% reagent recycling rates, substantially reducing waste streams.

Ecosystem impact assessments of DLE implementations reveal varying degrees of disruption to local hydrology. Groundwater-sourced DLE operations must carefully monitor and mitigate potential impacts on aquifer levels and freshwater availability for local communities and ecosystems. Recent field studies in Argentina and Chile suggest that properly managed DLE operations can maintain groundwater equilibrium when extraction rates are scientifically determined and continuously monitored.

Water usage metrics across various DLE methods demonstrate significant variability. Adsorption-based technologies typically consume 10-50 gallons per kilogram of lithium carbonate equivalent (LCE), while ion exchange systems may require 15-70 gallons per kilogram LCE. These figures represent substantial improvements compared to evaporative methods, which can demand 500-2,000 gallons per kilogram LCE. The water quality impact also differs substantially, with closed-loop DLE systems demonstrating reduced risk of groundwater contamination.

Land disturbance patterns reveal another environmental advantage of DLE methods. While traditional evaporation ponds require approximately 2-3 square kilometers per 20,000 tons of annual LCE production, most DLE facilities can operate within compact industrial footprints of less than 0.1 square kilometers for equivalent output. This dramatic reduction in land use minimizes habitat disruption and preserves natural landscapes in lithium-rich regions.

Carbon emissions associated with DLE operations present a more complex picture. The energy-intensive nature of certain DLE processes, particularly those requiring significant heating or electrochemical systems, can generate 5-15 tons of CO2 per ton of LCE produced. However, when renewable energy sources power these operations, emissions can decrease by 60-80%, creating pathways toward carbon-neutral lithium production.

Chemical usage and waste generation constitute additional environmental considerations. Most DLE methods utilize specialized sorbents, resins, or membranes that require periodic replacement and proper disposal. The regeneration processes often involve acids, bases, or other chemicals that must be carefully managed. Advanced DLE systems incorporating chemical recovery loops have demonstrated 80-95% reagent recycling rates, substantially reducing waste streams.

Ecosystem impact assessments of DLE implementations reveal varying degrees of disruption to local hydrology. Groundwater-sourced DLE operations must carefully monitor and mitigate potential impacts on aquifer levels and freshwater availability for local communities and ecosystems. Recent field studies in Argentina and Chile suggest that properly managed DLE operations can maintain groundwater equilibrium when extraction rates are scientifically determined and continuously monitored.

Economic Feasibility and Scalability Analysis

The economic viability of Direct Lithium Extraction (DLE) technologies represents a critical factor in determining their adoption across the lithium production landscape. Current economic analyses indicate that DLE processes can potentially reduce production costs by 30-50% compared to traditional evaporation pond methods, primarily through shortened production timelines and higher recovery rates. Capital expenditure requirements for DLE facilities range from $15,000-$30,000 per annual tonne of lithium carbonate equivalent (LCE), varying significantly based on brine chemistry, target capacity, and selected technology platform.

Operational expenditures demonstrate considerable variability, with estimates between $2,500-$7,000 per tonne of LCE, heavily influenced by energy consumption, chemical reagent costs, and water treatment requirements. Energy consumption emerges as a particularly significant cost driver, with advanced DLE systems requiring 5-15 kWh per kilogram of lithium recovered. This energy intensity necessitates strategic facility placement near affordable and preferably renewable energy sources to maintain economic competitiveness.

Scalability considerations reveal that most current DLE technologies have been validated at pilot or small commercial scales (100-5,000 tonnes LCE/year), with limited demonstration at the scales necessary for meeting projected global demand (20,000+ tonnes LCE/year per facility). Technical challenges in scaling include maintaining consistent performance across larger membrane or adsorbent arrays, managing increased volumes of spent regeneration solutions, and ensuring uniform flow distribution in larger adsorption columns.

Return on investment calculations suggest payback periods of 3-7 years for optimized DLE operations, contingent upon lithium market prices remaining above $15,000/tonne. Sensitivity analyses indicate that a 20% reduction in recovery efficiency can extend payback periods by 1.5-2.5 years, underscoring the economic importance of process optimization.

The economic competitiveness of DLE varies significantly by geographic region and brine characteristics. Projects targeting high-concentration brines (>500 mg/L Li) demonstrate more favorable economics, while those processing lower-grade resources (<200 mg/L Li) require exceptional efficiency in other operational parameters to achieve profitability. Continental brines in South America currently present the most economically attractive targets, though geothermal brines are gaining attention due to potential energy integration synergies.

Market analysis projects that DLE technologies capable of achieving >90% recovery rates with operational costs below $4,000/tonne LCE will capture significant market share by 2030, potentially accounting for 25-35% of global lithium production. This transition depends on continued process optimization and successful demonstration of commercial-scale operations across diverse brine chemistries.

Operational expenditures demonstrate considerable variability, with estimates between $2,500-$7,000 per tonne of LCE, heavily influenced by energy consumption, chemical reagent costs, and water treatment requirements. Energy consumption emerges as a particularly significant cost driver, with advanced DLE systems requiring 5-15 kWh per kilogram of lithium recovered. This energy intensity necessitates strategic facility placement near affordable and preferably renewable energy sources to maintain economic competitiveness.

Scalability considerations reveal that most current DLE technologies have been validated at pilot or small commercial scales (100-5,000 tonnes LCE/year), with limited demonstration at the scales necessary for meeting projected global demand (20,000+ tonnes LCE/year per facility). Technical challenges in scaling include maintaining consistent performance across larger membrane or adsorbent arrays, managing increased volumes of spent regeneration solutions, and ensuring uniform flow distribution in larger adsorption columns.

Return on investment calculations suggest payback periods of 3-7 years for optimized DLE operations, contingent upon lithium market prices remaining above $15,000/tonne. Sensitivity analyses indicate that a 20% reduction in recovery efficiency can extend payback periods by 1.5-2.5 years, underscoring the economic importance of process optimization.

The economic competitiveness of DLE varies significantly by geographic region and brine characteristics. Projects targeting high-concentration brines (>500 mg/L Li) demonstrate more favorable economics, while those processing lower-grade resources (<200 mg/L Li) require exceptional efficiency in other operational parameters to achieve profitability. Continental brines in South America currently present the most economically attractive targets, though geothermal brines are gaining attention due to potential energy integration synergies.

Market analysis projects that DLE technologies capable of achieving >90% recovery rates with operational costs below $4,000/tonne LCE will capture significant market share by 2030, potentially accounting for 25-35% of global lithium production. This transition depends on continued process optimization and successful demonstration of commercial-scale operations across diverse brine chemistries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!