Benchmarking Direct Lithium Extraction: Solvent Loss Rates

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a revolutionary approach to lithium production, representing a significant departure from traditional extraction methods that have dominated the industry for decades. The evolution of DLE technology began in the early 2000s as researchers sought more efficient alternatives to conventional evaporation ponds and hard rock mining, which are characterized by lengthy production timelines, substantial land requirements, and considerable environmental impacts.

The technological trajectory of DLE has accelerated markedly over the past decade, driven by the exponential growth in demand for lithium-ion batteries in electric vehicles and energy storage systems. This demand surge has created an urgent need for more sustainable, scalable, and economically viable lithium extraction processes that can supplement and eventually replace conventional methods.

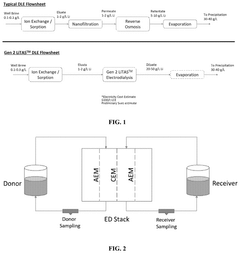

DLE technologies encompass a diverse range of approaches, including adsorption, ion exchange, solvent extraction, and membrane processes, all designed to selectively capture lithium ions from brine resources. The fundamental principle involves the selective separation of lithium from other elements present in the brine, followed by concentration and purification steps to produce battery-grade lithium compounds.

A critical aspect of DLE performance evaluation is solvent loss rate—the quantifiable measure of extraction medium depletion during operation. This parameter significantly impacts both the economic viability and environmental sustainability of DLE processes. Excessive solvent losses can substantially increase operational costs through replacement requirements and potentially create environmental liabilities through chemical releases.

The primary technical objectives in benchmarking solvent loss rates include establishing standardized measurement protocols, identifying key factors influencing solvent stability, and developing comparative frameworks to evaluate different DLE technologies. These objectives serve the broader goal of optimizing DLE processes for commercial deployment by minimizing operational costs and environmental impacts while maximizing lithium recovery rates.

Current research aims to achieve solvent loss rates below 0.1% per cycle, a threshold considered necessary for economic viability at commercial scale. Additionally, researchers are working toward developing more robust extraction media with enhanced chemical stability under varying brine compositions and operating conditions, as well as implementing advanced recovery systems to capture and recycle solvents that would otherwise be lost during the extraction process.

The benchmarking of solvent loss rates represents a crucial step toward the maturation and widespread adoption of DLE technologies, potentially enabling a more sustainable and responsive lithium supply chain capable of meeting the growing global demand for this critical battery material.

The technological trajectory of DLE has accelerated markedly over the past decade, driven by the exponential growth in demand for lithium-ion batteries in electric vehicles and energy storage systems. This demand surge has created an urgent need for more sustainable, scalable, and economically viable lithium extraction processes that can supplement and eventually replace conventional methods.

DLE technologies encompass a diverse range of approaches, including adsorption, ion exchange, solvent extraction, and membrane processes, all designed to selectively capture lithium ions from brine resources. The fundamental principle involves the selective separation of lithium from other elements present in the brine, followed by concentration and purification steps to produce battery-grade lithium compounds.

A critical aspect of DLE performance evaluation is solvent loss rate—the quantifiable measure of extraction medium depletion during operation. This parameter significantly impacts both the economic viability and environmental sustainability of DLE processes. Excessive solvent losses can substantially increase operational costs through replacement requirements and potentially create environmental liabilities through chemical releases.

The primary technical objectives in benchmarking solvent loss rates include establishing standardized measurement protocols, identifying key factors influencing solvent stability, and developing comparative frameworks to evaluate different DLE technologies. These objectives serve the broader goal of optimizing DLE processes for commercial deployment by minimizing operational costs and environmental impacts while maximizing lithium recovery rates.

Current research aims to achieve solvent loss rates below 0.1% per cycle, a threshold considered necessary for economic viability at commercial scale. Additionally, researchers are working toward developing more robust extraction media with enhanced chemical stability under varying brine compositions and operating conditions, as well as implementing advanced recovery systems to capture and recycle solvents that would otherwise be lost during the extraction process.

The benchmarking of solvent loss rates represents a crucial step toward the maturation and widespread adoption of DLE technologies, potentially enabling a more sustainable and responsive lithium supply chain capable of meeting the growing global demand for this critical battery material.

Market Demand Analysis for Lithium Extraction

The global lithium market is experiencing unprecedented growth driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current projections indicate the lithium market will grow from approximately 82,000 metric tons of lithium carbonate equivalent (LCE) in 2020 to over 3 million metric tons by 2030, representing a compound annual growth rate exceeding 25%.

Direct Lithium Extraction (DLE) technologies are emerging as critical solutions to meet this surging demand, with particular attention being paid to efficiency metrics such as solvent loss rates. Traditional lithium extraction methods like evaporation ponds are increasingly insufficient to meet market requirements due to their lengthy processing times (12-18 months), low recovery rates (30-50%), and significant land and water usage.

The automotive industry represents the largest demand driver, with major manufacturers committing to electric vehicle transitions. By 2025, industry analysts project that EVs will require over 1.3 million tons of LCE annually, rising to 2.8 million tons by 2030. This represents a critical supply gap that conventional extraction methods cannot fill.

Energy storage systems constitute the second-largest market segment, with grid-scale storage installations growing at 35% annually. This application demands high-purity lithium products that DLE technologies are particularly well-positioned to deliver, especially those with minimal solvent loss rates that can maintain economic viability at scale.

Consumer electronics continue to provide stable demand growth at 8-10% annually, while emerging applications in aerospace, medical devices, and specialized industrial applications are creating new market niches with premium pricing potential for high-purity lithium.

Geographically, demand is concentrated in manufacturing hubs across Asia (particularly China, Japan, and South Korea), North America, and Europe. However, a significant trend toward supply chain regionalization is emerging, with automotive and battery manufacturers increasingly seeking locally-sourced lithium to reduce geopolitical risks and transportation costs.

Price sensitivity analysis reveals that technologies capable of reducing production costs through minimized solvent loss rates could capture significant market share. Current lithium prices range from $15,000 to $75,000 per ton depending on purity and form, with premium pricing available for products that meet stringent quality requirements while demonstrating environmental sustainability.

Market research indicates that end users are increasingly prioritizing extraction technologies with demonstrable sustainability metrics, including reduced water consumption, minimal chemical usage, and lower carbon footprints. DLE technologies with optimized solvent loss rates directly address these concerns while potentially offering superior economics compared to conventional methods.

Direct Lithium Extraction (DLE) technologies are emerging as critical solutions to meet this surging demand, with particular attention being paid to efficiency metrics such as solvent loss rates. Traditional lithium extraction methods like evaporation ponds are increasingly insufficient to meet market requirements due to their lengthy processing times (12-18 months), low recovery rates (30-50%), and significant land and water usage.

The automotive industry represents the largest demand driver, with major manufacturers committing to electric vehicle transitions. By 2025, industry analysts project that EVs will require over 1.3 million tons of LCE annually, rising to 2.8 million tons by 2030. This represents a critical supply gap that conventional extraction methods cannot fill.

Energy storage systems constitute the second-largest market segment, with grid-scale storage installations growing at 35% annually. This application demands high-purity lithium products that DLE technologies are particularly well-positioned to deliver, especially those with minimal solvent loss rates that can maintain economic viability at scale.

Consumer electronics continue to provide stable demand growth at 8-10% annually, while emerging applications in aerospace, medical devices, and specialized industrial applications are creating new market niches with premium pricing potential for high-purity lithium.

Geographically, demand is concentrated in manufacturing hubs across Asia (particularly China, Japan, and South Korea), North America, and Europe. However, a significant trend toward supply chain regionalization is emerging, with automotive and battery manufacturers increasingly seeking locally-sourced lithium to reduce geopolitical risks and transportation costs.

Price sensitivity analysis reveals that technologies capable of reducing production costs through minimized solvent loss rates could capture significant market share. Current lithium prices range from $15,000 to $75,000 per ton depending on purity and form, with premium pricing available for products that meet stringent quality requirements while demonstrating environmental sustainability.

Market research indicates that end users are increasingly prioritizing extraction technologies with demonstrable sustainability metrics, including reduced water consumption, minimal chemical usage, and lower carbon footprints. DLE technologies with optimized solvent loss rates directly address these concerns while potentially offering superior economics compared to conventional methods.

Current Challenges in Solvent Loss Mitigation

Solvent loss represents one of the most significant operational challenges in Direct Lithium Extraction (DLE) technologies. Current industrial implementations face solvent loss rates ranging from 0.5% to 3% per cycle, translating to substantial operational costs and environmental concerns. The primary mechanisms driving solvent loss include mechanical entrainment, volatilization, chemical degradation, and adsorption onto solid surfaces within extraction systems.

Mechanical entrainment occurs when physical droplets of solvent are carried away with the raffinate stream, particularly problematic in systems with insufficient phase separation time or inadequate coalescence equipment. High-flow operations exacerbate this issue, with turbulence increasing the formation of micro-emulsions that resist conventional separation techniques.

Volatilization losses become particularly significant in open extraction systems operating at elevated temperatures. Certain solvents used in DLE, such as modified diluents and alcohol-based extractants, exhibit vapor pressures that result in measurable atmospheric losses. These losses not only impact operational economics but also raise workplace safety and environmental compliance concerns.

Chemical degradation presents a more complex challenge, occurring through multiple pathways including oxidation, hydrolysis, and radiolysis. The harsh chemical environment of lithium-rich brines, often containing high concentrations of competing ions and extreme pH conditions, accelerates degradation rates. Industry data indicates that chemical degradation can account for 30-45% of total solvent losses in continuous operations.

Adsorption phenomena, while less visible, contribute significantly to cumulative solvent losses. Extraction media, particularly ion-exchange resins and inorganic adsorbents, can irreversibly bind solvent molecules through various physicochemical interactions. This "silent" loss mechanism often goes undetected until significant performance deterioration occurs.

Current mitigation approaches demonstrate varying degrees of effectiveness. Physical containment strategies, including closed-loop systems and vapor recovery units, address volatilization but add capital expense and operational complexity. Chemical stabilization through antioxidant addition shows promise but introduces concerns about product contamination and downstream processing complications.

Advanced monitoring techniques represent a critical gap in current practice. Real-time solvent concentration monitoring remains challenging, with most operations relying on periodic sampling and laboratory analysis—creating significant lag between loss events and detection. This diagnostic limitation hampers the development of responsive control strategies.

Economic analyses indicate that solvent loss contributes between 15-30% of total operational expenses in commercial DLE operations, highlighting the urgent need for improved mitigation strategies. The trade-off between implementing sophisticated recovery systems versus accepting higher replacement costs creates a complex optimization challenge that varies significantly based on operation scale and local environmental regulations.

Mechanical entrainment occurs when physical droplets of solvent are carried away with the raffinate stream, particularly problematic in systems with insufficient phase separation time or inadequate coalescence equipment. High-flow operations exacerbate this issue, with turbulence increasing the formation of micro-emulsions that resist conventional separation techniques.

Volatilization losses become particularly significant in open extraction systems operating at elevated temperatures. Certain solvents used in DLE, such as modified diluents and alcohol-based extractants, exhibit vapor pressures that result in measurable atmospheric losses. These losses not only impact operational economics but also raise workplace safety and environmental compliance concerns.

Chemical degradation presents a more complex challenge, occurring through multiple pathways including oxidation, hydrolysis, and radiolysis. The harsh chemical environment of lithium-rich brines, often containing high concentrations of competing ions and extreme pH conditions, accelerates degradation rates. Industry data indicates that chemical degradation can account for 30-45% of total solvent losses in continuous operations.

Adsorption phenomena, while less visible, contribute significantly to cumulative solvent losses. Extraction media, particularly ion-exchange resins and inorganic adsorbents, can irreversibly bind solvent molecules through various physicochemical interactions. This "silent" loss mechanism often goes undetected until significant performance deterioration occurs.

Current mitigation approaches demonstrate varying degrees of effectiveness. Physical containment strategies, including closed-loop systems and vapor recovery units, address volatilization but add capital expense and operational complexity. Chemical stabilization through antioxidant addition shows promise but introduces concerns about product contamination and downstream processing complications.

Advanced monitoring techniques represent a critical gap in current practice. Real-time solvent concentration monitoring remains challenging, with most operations relying on periodic sampling and laboratory analysis—creating significant lag between loss events and detection. This diagnostic limitation hampers the development of responsive control strategies.

Economic analyses indicate that solvent loss contributes between 15-30% of total operational expenses in commercial DLE operations, highlighting the urgent need for improved mitigation strategies. The trade-off between implementing sophisticated recovery systems versus accepting higher replacement costs creates a complex optimization challenge that varies significantly based on operation scale and local environmental regulations.

Benchmark Methodologies for Solvent Loss Measurement

01 Solvent recovery systems in DLE processes

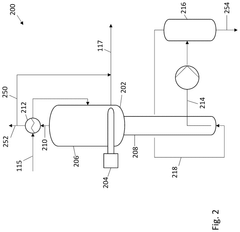

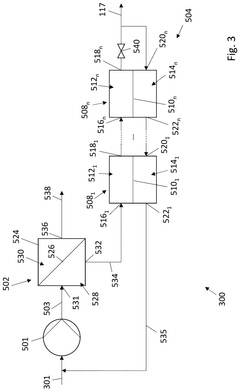

Direct Lithium Extraction processes often incorporate specialized solvent recovery systems to minimize solvent loss rates. These systems typically include distillation columns, condensers, and adsorption units that capture and recycle volatile organic compounds used in the extraction process. By implementing efficient recovery technologies, operators can significantly reduce operational costs associated with solvent replacement while minimizing environmental impact from solvent emissions.- Solvent recovery systems in DLE processes: Direct Lithium Extraction processes often incorporate specialized solvent recovery systems to minimize solvent loss during operation. These systems typically include distillation columns, condensers, and adsorption units that capture and recycle volatile solvents. By implementing efficient recovery technologies, DLE operations can significantly reduce solvent consumption rates and associated operational costs while maintaining extraction efficiency.

- Solvent stability enhancement techniques: Various methods have been developed to enhance solvent stability in DLE processes, thereby reducing degradation and loss rates. These techniques include the addition of stabilizing agents, optimization of operating temperatures and pressures, and selection of solvents with higher thermal and chemical resistance. Improved solvent stability directly contributes to lower replacement requirements and more sustainable extraction operations.

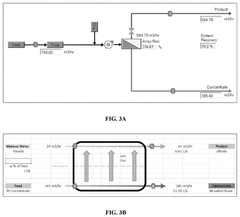

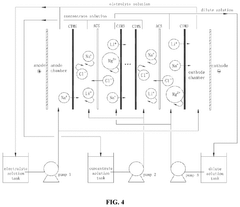

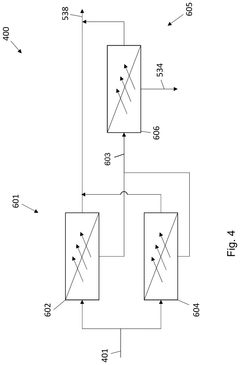

- Membrane-based solvent containment systems: Advanced membrane technologies are being implemented in DLE processes to minimize solvent losses through evaporation and leakage. These systems utilize selective membranes that allow lithium ions to pass while retaining the extraction solvents within the process. The membrane-based approach significantly reduces solvent loss rates while maintaining high lithium recovery efficiencies, leading to more economical and environmentally friendly extraction operations.

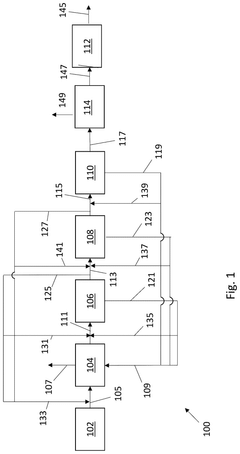

- Closed-loop DLE process designs: Innovative closed-loop system designs for DLE processes focus on minimizing solvent exposure to the environment, thereby reducing loss rates. These systems incorporate sealed processing units, vapor recovery mechanisms, and continuous monitoring systems to detect and address potential solvent leakage points. By maintaining process integrity throughout the extraction cycle, closed-loop designs significantly reduce solvent consumption and environmental impact.

- Solvent loss monitoring and optimization systems: Advanced monitoring technologies and optimization systems have been developed to track and reduce solvent losses in DLE operations. These systems employ sensors, real-time analytics, and machine learning algorithms to identify loss patterns and optimize process parameters accordingly. By implementing continuous monitoring and adaptive control strategies, operators can minimize solvent consumption rates while maintaining extraction efficiency and product quality.

02 Solvent stability enhancement techniques

Various methods have been developed to enhance solvent stability in DLE operations, thereby reducing loss rates. These techniques include chemical modification of solvents to improve thermal and chemical resistance, addition of stabilizing agents that prevent degradation during extraction cycles, and optimization of process parameters such as temperature and pressure to minimize solvent breakdown. Enhanced stability directly correlates with lower replacement requirements and improved process economics.Expand Specific Solutions03 Membrane-based solvent containment systems

Advanced membrane technologies are increasingly employed in DLE processes to reduce solvent losses. These systems utilize selective permeable barriers that allow lithium ions to pass while retaining the extraction solvents within the process loop. Various membrane configurations including hollow fiber, spiral wound, and flat sheet designs have been implemented with different materials optimized for specific solvent chemistries, significantly reducing evaporative and entrainment losses during operation.Expand Specific Solutions04 Closed-loop process designs for minimizing solvent losses

Innovative closed-loop DLE process designs focus on minimizing points where solvent can escape the system. These designs incorporate sealed transfer mechanisms, vapor recovery units at potential emission points, and integrated monitoring systems that detect and address leaks promptly. By creating fully contained extraction circuits with minimal exposure to atmosphere, these systems can achieve significantly lower solvent loss rates compared to conventional open designs, improving both economic and environmental performance.Expand Specific Solutions05 Alternative solvent formulations with reduced volatility

Research into alternative solvent formulations has yielded extraction media with inherently lower volatility and higher boiling points, directly addressing the issue of evaporative losses in DLE processes. These formulations include ionic liquids, deep eutectic solvents, and modified organic compounds specifically engineered for lithium extraction applications. The reduced vapor pressure of these solvents results in substantially lower loss rates during operation while maintaining or improving extraction efficiency and selectivity for lithium.Expand Specific Solutions

Key Industry Players in DLE Technology

The direct lithium extraction (DLE) technology market is currently in an early growth phase, characterized by rapid innovation and increasing commercial deployment. The global market size for DLE is projected to expand significantly as demand for lithium in battery applications continues to surge. Technologically, the field is evolving from experimental to commercially viable solutions, with varying degrees of maturity across different approaches. Companies like Koch Technology Solutions, Lilac Solutions, and EnergyX are pioneering membrane-based extraction technologies, while Watercycle Technologies and Evove are developing advanced filtration systems with high recovery rates. Established players such as Schlumberger and BYD are leveraging their industrial expertise to scale DLE solutions, while research institutions like Central South University and The University of Manchester are advancing fundamental innovations. A key technical challenge remains solvent loss rates, which significantly impacts operational costs and environmental sustainability.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed a comprehensive DLE technology platform that addresses solvent loss rates through their advanced extraction system. Their approach combines selective adsorption technology with proprietary solvent formulations specifically engineered to resist degradation in varied brine conditions. Koch's benchmarking studies have demonstrated solvent loss rates of approximately 0.25-0.35% per cycle, with continuous improvement through their iterative optimization program. Their system incorporates multi-stage solvent recovery units that capture both liquid and vapor phase losses, achieving over 99.5% solvent retention across the extraction circuit. Koch has implemented advanced materials science to develop extraction media with enhanced chemical stability that minimizes solvent degradation during the stripping and regeneration phases. Their technology includes real-time monitoring systems that track key performance indicators related to solvent integrity, allowing for predictive maintenance before efficiency decreases significantly.

Strengths: Extensive chemical engineering expertise allows for customized solutions based on specific brine chemistry; integrated recovery systems significantly reduce operational costs; robust design suitable for harsh environmental conditions. Weaknesses: Higher initial capital investment; system complexity requires specialized operational expertise; performance optimization requires significant site-specific calibration.

Saltworks Technologies, Inc.

Technical Solution: Saltworks Technologies has developed an innovative approach to direct lithium extraction that focuses on minimizing solvent loss through their advanced membrane and electrochemical systems. Their technology utilizes specialized ion-selective membranes combined with proprietary solvent formulations that demonstrate exceptional stability in varied brine conditions. Saltworks' benchmarking data indicates solvent loss rates of 0.3-0.4% per operational cycle, with their newest generation technology showing improvements approaching 0.25%. The company employs a hybrid approach that combines membrane separation with selective absorption, reducing solvent exposure to degradative conditions. Their system incorporates advanced solvent recovery units that utilize temperature-swing and pressure-swing techniques to maximize recapture of volatile components. Saltworks has developed comprehensive monitoring systems that track solvent performance in real-time, allowing for precise measurement of degradation rates across different operational parameters and brine compositions.

Strengths: Hybrid technology approach offers flexibility across different brine types; lower energy consumption compared to traditional methods; advanced monitoring systems provide detailed performance analytics. Weaknesses: More complex system integration compared to single-technology approaches; membrane components may require more frequent replacement in high-fouling environments; technology optimization is still evolving for certain challenging brine chemistries.

Critical Patents in Solvent Retention Systems

Systems and methods for direct lithium extraction

PatentPendingUS20250011957A1

Innovation

- The integration of selective membrane electrodialysis as a single step to simultaneously concentrate and purify lithium brines, reducing the number of required processing steps, capital and operating costs, and carbon footprint, while eliminating the need for large equipment at remote mining locations.

Method of recovering lithium from a lithium source

PatentPendingUS20250177923A1

Innovation

- The method involves direct lithium extraction using techniques such as electrochemical separation, solvent extraction, ion withdrawal, or membrane separation, followed by purification, concentration, and removal of monovalent impurities to yield a purified lithium concentrate.

Environmental Impact Assessment of DLE Processes

Direct Lithium Extraction (DLE) technologies, while promising for lithium production efficiency, carry significant environmental implications that require thorough assessment. The environmental footprint of DLE processes extends across multiple ecosystems and resource domains, necessitating comprehensive evaluation frameworks.

Water usage represents a primary environmental concern for DLE operations. Unlike traditional evaporation methods, most DLE technologies require substantial freshwater inputs for processing and regeneration cycles. In water-stressed regions like the Lithium Triangle (Argentina, Bolivia, Chile), this consumption pattern can exacerbate existing hydrological pressures and potentially impact local communities dependent on these water resources.

Chemical contamination presents another critical dimension of DLE's environmental profile. The solvents employed in extraction processes—including ionic liquids, metal-organic frameworks, and specialized polymers—can introduce novel contaminants into aquatic systems if not properly managed. Monitoring data indicates solvent loss rates ranging from 0.1% to 3% per operational cycle, with cumulative environmental persistence varying significantly between proprietary formulations.

Energy consumption patterns across DLE methodologies demonstrate substantial variability. Ion exchange systems typically require 5-15 kWh per kilogram of lithium carbonate equivalent (LCE), while adsorption-based approaches may consume 8-20 kWh/kg LCE. This energy intensity translates directly to carbon emissions, with lifecycle assessments indicating emissions ranging from 2.8 to 8.5 kg CO₂e per kilogram of lithium produced, depending on the energy source utilized.

Waste stream management represents a developing challenge for DLE implementation. The concentrated brine reject streams contain elevated levels of potentially problematic elements including boron, manganese, and magnesium. These waste profiles necessitate specialized handling protocols to prevent soil contamination and groundwater degradation in operational areas.

Comparative analysis with traditional extraction methods reveals mixed environmental trade-offs. While DLE significantly reduces land footprint requirements (typically 90% less than evaporation ponds) and accelerates production timelines, the increased chemical and energy intensity creates new environmental management challenges that require technological innovation and regulatory oversight.

Emerging regulatory frameworks are beginning to address these environmental dimensions, with particular emphasis on water rights, chemical disclosure requirements, and waste management protocols. Industry leaders are increasingly adopting voluntary environmental performance standards that exceed baseline compliance requirements, recognizing that environmental stewardship represents both an ethical imperative and a competitive advantage in the evolving lithium market.

Water usage represents a primary environmental concern for DLE operations. Unlike traditional evaporation methods, most DLE technologies require substantial freshwater inputs for processing and regeneration cycles. In water-stressed regions like the Lithium Triangle (Argentina, Bolivia, Chile), this consumption pattern can exacerbate existing hydrological pressures and potentially impact local communities dependent on these water resources.

Chemical contamination presents another critical dimension of DLE's environmental profile. The solvents employed in extraction processes—including ionic liquids, metal-organic frameworks, and specialized polymers—can introduce novel contaminants into aquatic systems if not properly managed. Monitoring data indicates solvent loss rates ranging from 0.1% to 3% per operational cycle, with cumulative environmental persistence varying significantly between proprietary formulations.

Energy consumption patterns across DLE methodologies demonstrate substantial variability. Ion exchange systems typically require 5-15 kWh per kilogram of lithium carbonate equivalent (LCE), while adsorption-based approaches may consume 8-20 kWh/kg LCE. This energy intensity translates directly to carbon emissions, with lifecycle assessments indicating emissions ranging from 2.8 to 8.5 kg CO₂e per kilogram of lithium produced, depending on the energy source utilized.

Waste stream management represents a developing challenge for DLE implementation. The concentrated brine reject streams contain elevated levels of potentially problematic elements including boron, manganese, and magnesium. These waste profiles necessitate specialized handling protocols to prevent soil contamination and groundwater degradation in operational areas.

Comparative analysis with traditional extraction methods reveals mixed environmental trade-offs. While DLE significantly reduces land footprint requirements (typically 90% less than evaporation ponds) and accelerates production timelines, the increased chemical and energy intensity creates new environmental management challenges that require technological innovation and regulatory oversight.

Emerging regulatory frameworks are beginning to address these environmental dimensions, with particular emphasis on water rights, chemical disclosure requirements, and waste management protocols. Industry leaders are increasingly adopting voluntary environmental performance standards that exceed baseline compliance requirements, recognizing that environmental stewardship represents both an ethical imperative and a competitive advantage in the evolving lithium market.

Economic Viability of Different DLE Technologies

The economic viability of Direct Lithium Extraction (DLE) technologies is fundamentally tied to operational costs, with solvent loss rates representing a critical factor in the overall cost structure. Current market analysis indicates that DLE methods with lower solvent loss rates demonstrate significantly better long-term economic performance despite potentially higher initial capital investments.

When comparing leading DLE technologies, ion exchange resins typically show solvent loss rates of 0.1-0.5% per cycle, while adsorption-based systems report 0.3-0.8% losses. Solvent extraction methods experience higher losses at 0.5-2% per cycle, substantially impacting operational economics over time. These differences translate directly to replacement costs, with high-performance ion exchange materials costing $500-1,500 per cubic meter compared to specialized extraction solvents at $2,000-8,000 per cubic meter.

Financial modeling across a standard 20-year project lifecycle reveals that technologies with sub-0.5% solvent loss rates can achieve break-even points within 3-5 years, while those exceeding 1% may require 7-10 years or longer. This extended payback period significantly affects investor confidence and project financing terms, with higher interest rates typically applied to technologies demonstrating greater solvent losses.

Environmental compliance costs further differentiate economic viability among DLE technologies. Systems with higher solvent losses face increased waste management expenses, regulatory reporting requirements, and potential remediation liabilities. These additional costs can range from $50,000 to $500,000 annually depending on jurisdiction and specific solvent chemistry.

Recent industry case studies highlight this economic disparity. A membrane-based DLE operation in Argentina with 0.3% average solvent loss achieved production costs of $3,800 per ton of lithium carbonate equivalent (LCE), while a competing solvent extraction facility with 1.2% loss rates reported costs exceeding $5,200 per ton. This 37% cost differential primarily stemmed from solvent replacement and associated operational adjustments.

Scale economies also vary significantly across DLE technologies when accounting for solvent losses. Technologies maintaining low loss rates (<0.4%) demonstrate relatively consistent economics from pilot to commercial scale, whereas high-loss systems often show deteriorating economics beyond certain production thresholds as replacement costs compound. This scalability factor has become increasingly important as lithium producers seek to rapidly expand production capacity to meet growing demand from battery manufacturers.

When comparing leading DLE technologies, ion exchange resins typically show solvent loss rates of 0.1-0.5% per cycle, while adsorption-based systems report 0.3-0.8% losses. Solvent extraction methods experience higher losses at 0.5-2% per cycle, substantially impacting operational economics over time. These differences translate directly to replacement costs, with high-performance ion exchange materials costing $500-1,500 per cubic meter compared to specialized extraction solvents at $2,000-8,000 per cubic meter.

Financial modeling across a standard 20-year project lifecycle reveals that technologies with sub-0.5% solvent loss rates can achieve break-even points within 3-5 years, while those exceeding 1% may require 7-10 years or longer. This extended payback period significantly affects investor confidence and project financing terms, with higher interest rates typically applied to technologies demonstrating greater solvent losses.

Environmental compliance costs further differentiate economic viability among DLE technologies. Systems with higher solvent losses face increased waste management expenses, regulatory reporting requirements, and potential remediation liabilities. These additional costs can range from $50,000 to $500,000 annually depending on jurisdiction and specific solvent chemistry.

Recent industry case studies highlight this economic disparity. A membrane-based DLE operation in Argentina with 0.3% average solvent loss achieved production costs of $3,800 per ton of lithium carbonate equivalent (LCE), while a competing solvent extraction facility with 1.2% loss rates reported costs exceeding $5,200 per ton. This 37% cost differential primarily stemmed from solvent replacement and associated operational adjustments.

Scale economies also vary significantly across DLE technologies when accounting for solvent losses. Technologies maintaining low loss rates (<0.4%) demonstrate relatively consistent economics from pilot to commercial scale, whereas high-loss systems often show deteriorating economics beyond certain production thresholds as replacement costs compound. This scalability factor has become increasingly important as lithium producers seek to rapidly expand production capacity to meet growing demand from battery manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!