Case Study: Direct Lithium Extraction in Geothermal Brines

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geothermal Lithium Extraction Background and Objectives

Direct Lithium Extraction (DLE) from geothermal brines represents a convergence of renewable energy production and critical mineral extraction, offering a potentially sustainable pathway to meet the surging global demand for lithium. The evolution of this technology can be traced back to the 1970s when initial research explored the possibility of extracting minerals from geothermal fluids. However, significant technological advancements only emerged in the early 2000s, coinciding with the growing recognition of lithium's strategic importance for energy storage applications.

The technological trajectory has accelerated markedly over the past decade, driven by the exponential growth in electric vehicle production and grid-scale battery storage systems. Traditional lithium extraction methods—primarily evaporative ponds in salt flats and hard-rock mining—face increasing scrutiny due to their substantial environmental footprint, water consumption, and lengthy production timelines. These limitations have catalyzed interest in alternative extraction methodologies, with geothermal brine extraction emerging as a promising frontier.

Geothermal brines, particularly those found in locations such as California's Salton Sea, Germany's Upper Rhine Valley, and Cornwall in the United Kingdom, contain significant lithium concentrations ranging from 100 to 400 mg/L. These resources represent a substantial untapped lithium reserve that could be extracted as a valuable by-product of geothermal energy production, creating a dual-revenue stream model for operators.

The primary technical objective of DLE from geothermal brines is to develop economically viable and environmentally sustainable processes that can selectively extract lithium from high-temperature, mineral-rich brines while maintaining the operational integrity of geothermal power plants. This involves addressing challenges related to brine chemistry complexity, scaling and corrosion issues, and the development of materials capable of withstanding harsh operating conditions.

Secondary objectives include minimizing water consumption, reducing carbon footprint compared to conventional extraction methods, accelerating production timelines, and achieving higher lithium recovery rates. The ideal technological solution would integrate seamlessly with existing geothermal operations, requiring minimal additional infrastructure while maximizing resource utilization efficiency.

The ultimate goal extends beyond mere technical feasibility to establishing a new paradigm in critical mineral extraction—one that aligns with circular economy principles and contributes to energy transition objectives. Success in this domain could potentially transform geothermal resources from being solely energy producers to becoming integrated energy-mineral hubs, significantly altering the global lithium supply chain dynamics and reducing dependency on geographically concentrated conventional resources.

The technological trajectory has accelerated markedly over the past decade, driven by the exponential growth in electric vehicle production and grid-scale battery storage systems. Traditional lithium extraction methods—primarily evaporative ponds in salt flats and hard-rock mining—face increasing scrutiny due to their substantial environmental footprint, water consumption, and lengthy production timelines. These limitations have catalyzed interest in alternative extraction methodologies, with geothermal brine extraction emerging as a promising frontier.

Geothermal brines, particularly those found in locations such as California's Salton Sea, Germany's Upper Rhine Valley, and Cornwall in the United Kingdom, contain significant lithium concentrations ranging from 100 to 400 mg/L. These resources represent a substantial untapped lithium reserve that could be extracted as a valuable by-product of geothermal energy production, creating a dual-revenue stream model for operators.

The primary technical objective of DLE from geothermal brines is to develop economically viable and environmentally sustainable processes that can selectively extract lithium from high-temperature, mineral-rich brines while maintaining the operational integrity of geothermal power plants. This involves addressing challenges related to brine chemistry complexity, scaling and corrosion issues, and the development of materials capable of withstanding harsh operating conditions.

Secondary objectives include minimizing water consumption, reducing carbon footprint compared to conventional extraction methods, accelerating production timelines, and achieving higher lithium recovery rates. The ideal technological solution would integrate seamlessly with existing geothermal operations, requiring minimal additional infrastructure while maximizing resource utilization efficiency.

The ultimate goal extends beyond mere technical feasibility to establishing a new paradigm in critical mineral extraction—one that aligns with circular economy principles and contributes to energy transition objectives. Success in this domain could potentially transform geothermal resources from being solely energy producers to becoming integrated energy-mineral hubs, significantly altering the global lithium supply chain dynamics and reducing dependency on geographically concentrated conventional resources.

Market Analysis for Geothermal Lithium Resources

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the lithium industry at approximately $7.5 billion, with projections indicating potential growth to $20 billion by 2030, representing a compound annual growth rate (CAGR) of over 12%. Within this expanding market, geothermal brine-sourced lithium represents an emerging segment with significant potential to disrupt traditional supply chains.

Geothermal lithium extraction offers a compelling value proposition compared to conventional methods. Traditional lithium sources—hard rock mining and solar evaporation of salt flats—face increasing scrutiny due to their substantial environmental footprint, high water consumption, and lengthy production timelines. In contrast, geothermal brine extraction can potentially reduce water usage by up to 90%, decrease land disturbance by 85%, and accelerate production timelines from 18 months to mere hours.

The demand-supply dynamics for lithium are increasingly favorable for new extraction technologies. Current global lithium demand stands at approximately 500,000 metric tons of lithium carbonate equivalent (LCE) annually, with forecasts suggesting this could reach 1.5-2 million metric tons by 2030. Traditional supply sources are struggling to keep pace, creating a strategic opportunity for geothermal lithium extraction to fill the emerging supply gap.

Geographically, the most promising markets for geothermal lithium extraction include the Salton Sea region in California (estimated 18 million metric tons of lithium reserves), the Upper Rhine Valley in Germany, the Cesme-Seferihisar region in Turkey, and various sites across New Zealand and Japan. These regions combine abundant geothermal resources with proximity to manufacturing hubs, creating ideal conditions for integrated supply chains.

From a pricing perspective, lithium carbonate has experienced significant volatility, with prices ranging from $6,000 to $78,000 per metric ton over the past five years. While recent market corrections have moderated prices, long-term forecasts remain bullish due to structural supply constraints and accelerating demand from battery manufacturers.

The economic viability of geothermal lithium projects is increasingly attractive, with production cost estimates ranging from $3,500 to $5,500 per metric ton—potentially 30-40% lower than traditional extraction methods. This cost advantage, combined with environmental benefits and co-generation of renewable energy, positions geothermal lithium extraction as a particularly compelling investment opportunity in regions with suitable geological conditions.

Geothermal lithium extraction offers a compelling value proposition compared to conventional methods. Traditional lithium sources—hard rock mining and solar evaporation of salt flats—face increasing scrutiny due to their substantial environmental footprint, high water consumption, and lengthy production timelines. In contrast, geothermal brine extraction can potentially reduce water usage by up to 90%, decrease land disturbance by 85%, and accelerate production timelines from 18 months to mere hours.

The demand-supply dynamics for lithium are increasingly favorable for new extraction technologies. Current global lithium demand stands at approximately 500,000 metric tons of lithium carbonate equivalent (LCE) annually, with forecasts suggesting this could reach 1.5-2 million metric tons by 2030. Traditional supply sources are struggling to keep pace, creating a strategic opportunity for geothermal lithium extraction to fill the emerging supply gap.

Geographically, the most promising markets for geothermal lithium extraction include the Salton Sea region in California (estimated 18 million metric tons of lithium reserves), the Upper Rhine Valley in Germany, the Cesme-Seferihisar region in Turkey, and various sites across New Zealand and Japan. These regions combine abundant geothermal resources with proximity to manufacturing hubs, creating ideal conditions for integrated supply chains.

From a pricing perspective, lithium carbonate has experienced significant volatility, with prices ranging from $6,000 to $78,000 per metric ton over the past five years. While recent market corrections have moderated prices, long-term forecasts remain bullish due to structural supply constraints and accelerating demand from battery manufacturers.

The economic viability of geothermal lithium projects is increasingly attractive, with production cost estimates ranging from $3,500 to $5,500 per metric ton—potentially 30-40% lower than traditional extraction methods. This cost advantage, combined with environmental benefits and co-generation of renewable energy, positions geothermal lithium extraction as a particularly compelling investment opportunity in regions with suitable geological conditions.

Technical Challenges in Direct Lithium Extraction

Direct Lithium Extraction (DLE) from geothermal brines faces several significant technical challenges that currently limit its widespread commercial implementation. The primary obstacle is the complex chemical composition of geothermal brines, which contain numerous dissolved minerals and elements besides lithium. These brines typically have lithium concentrations ranging from 10 to 200 mg/L, while containing much higher concentrations of interfering ions such as sodium, potassium, calcium, and magnesium, often in concentrations 1,000 to 10,000 times higher than lithium.

The selective extraction of lithium from this complex solution presents a formidable challenge. Current ion exchange and adsorption technologies struggle with selectivity issues, often capturing unwanted elements alongside lithium, which reduces efficiency and increases purification costs. The development of highly selective lithium sorbents remains an active area of research but has not yet yielded materials with ideal performance characteristics at commercial scale.

Temperature management represents another significant technical hurdle. Geothermal brines typically emerge at temperatures between 70°C and 250°C, while many extraction technologies operate optimally at lower temperatures. Cooling the brine for processing and then reheating it for reinjection results in substantial energy losses and operational inefficiencies, undermining the sustainability advantages of geothermal lithium extraction.

Scaling and corrosion issues present persistent operational challenges. The high mineral content of geothermal brines leads to scale formation in pipes, heat exchangers, and extraction equipment. Additionally, the brines' high salinity, combined with elevated temperatures and often acidic conditions, creates a highly corrosive environment that damages equipment and increases maintenance costs and downtime.

Water management poses another critical challenge. While DLE is more water-efficient than traditional evaporation pond methods, it still requires significant water volumes for processing and washing cycles. In many geothermal regions, which are often located in water-scarce areas, this creates additional resource constraints and potential environmental concerns.

Process integration with existing geothermal power operations presents both technical and logistical challenges. Retrofitting DLE systems into operational geothermal plants requires careful engineering to avoid disrupting power generation while maximizing lithium recovery. The balance between power production and lithium extraction objectives can create competing operational priorities.

Finally, the development of cost-effective and environmentally sound methods for processing the lithium concentrate into battery-grade lithium compounds (typically lithium carbonate or lithium hydroxide) remains challenging. Current processes often involve additional chemical treatments that generate waste streams requiring proper management and disposal.

The selective extraction of lithium from this complex solution presents a formidable challenge. Current ion exchange and adsorption technologies struggle with selectivity issues, often capturing unwanted elements alongside lithium, which reduces efficiency and increases purification costs. The development of highly selective lithium sorbents remains an active area of research but has not yet yielded materials with ideal performance characteristics at commercial scale.

Temperature management represents another significant technical hurdle. Geothermal brines typically emerge at temperatures between 70°C and 250°C, while many extraction technologies operate optimally at lower temperatures. Cooling the brine for processing and then reheating it for reinjection results in substantial energy losses and operational inefficiencies, undermining the sustainability advantages of geothermal lithium extraction.

Scaling and corrosion issues present persistent operational challenges. The high mineral content of geothermal brines leads to scale formation in pipes, heat exchangers, and extraction equipment. Additionally, the brines' high salinity, combined with elevated temperatures and often acidic conditions, creates a highly corrosive environment that damages equipment and increases maintenance costs and downtime.

Water management poses another critical challenge. While DLE is more water-efficient than traditional evaporation pond methods, it still requires significant water volumes for processing and washing cycles. In many geothermal regions, which are often located in water-scarce areas, this creates additional resource constraints and potential environmental concerns.

Process integration with existing geothermal power operations presents both technical and logistical challenges. Retrofitting DLE systems into operational geothermal plants requires careful engineering to avoid disrupting power generation while maximizing lithium recovery. The balance between power production and lithium extraction objectives can create competing operational priorities.

Finally, the development of cost-effective and environmentally sound methods for processing the lithium concentrate into battery-grade lithium compounds (typically lithium carbonate or lithium hydroxide) remains challenging. Current processes often involve additional chemical treatments that generate waste streams requiring proper management and disposal.

Current DLE Methods for Geothermal Brines

01 Adsorption-based extraction methods

Adsorption-based methods for direct lithium extraction utilize specialized materials that selectively bind to lithium ions from brine solutions. These methods typically employ ion-exchange resins, inorganic adsorbents, or functionalized polymers that can capture lithium while rejecting competing ions like sodium, potassium, and magnesium. The efficiency of these processes depends on the selectivity of the adsorbent material, contact time, and regeneration protocols. Advanced adsorbents can achieve high lithium recovery rates while minimizing water and chemical consumption compared to traditional evaporation methods.- Adsorption-based extraction methods: Adsorption-based methods utilize specialized materials that selectively bind to lithium ions from brine solutions. These methods typically employ ion exchange resins, inorganic adsorbents, or metal-organic frameworks that can capture lithium ions while rejecting competing ions like sodium, magnesium, and calcium. The efficiency of these methods depends on the selectivity of the adsorbent material, contact time, and regeneration processes. Advanced adsorbents can achieve high lithium recovery rates while minimizing water and chemical consumption compared to traditional evaporation methods.

- Membrane and electrochemical separation techniques: Membrane and electrochemical techniques employ selective barriers or electrical potential differences to separate lithium from other elements in brine solutions. These methods include electrodialysis, nanofiltration, and electrochemical cells with lithium-selective membranes. The efficiency of these techniques is influenced by membrane selectivity, applied voltage, solution composition, and flow rates. These approaches can significantly reduce processing time compared to traditional evaporation methods and often achieve higher lithium concentration factors with lower energy consumption.

- Solvent extraction and chemical precipitation: Solvent extraction and chemical precipitation methods involve the use of specific chemicals that react preferentially with lithium to form extractable complexes or precipitates. These methods typically use organic solvents, complexing agents, or precipitating reagents that selectively interact with lithium ions. The efficiency depends on reagent selectivity, pH control, temperature, and phase separation parameters. These approaches can achieve high purity lithium products and are often used in combination with other extraction methods to enhance overall process efficiency.

- Process optimization and efficiency enhancement: Various techniques for optimizing direct lithium extraction processes focus on improving operational parameters to enhance efficiency. These include multi-stage extraction processes, recycling of reagents, heat integration, and advanced process control systems. Optimization strategies may involve adjusting pH, temperature, pressure, contact time, and flow rates to maximize lithium recovery while minimizing energy and reagent consumption. Advanced modeling and simulation tools are also employed to predict and improve extraction efficiency under various operating conditions.

- Novel materials and composite systems: Innovative materials and composite systems are being developed to enhance lithium extraction efficiency. These include nanostructured adsorbents, composite membranes, functionalized polymers, and hybrid extraction systems that combine multiple separation mechanisms. These advanced materials often feature improved selectivity, capacity, stability, and regeneration characteristics. Some novel approaches incorporate stimuli-responsive materials that can change their lithium affinity in response to external triggers, allowing for more efficient extraction and regeneration cycles.

02 Membrane and electrochemical separation techniques

Membrane and electrochemical techniques for lithium extraction utilize selective membranes, electrodialysis, or electrochemical cells to separate lithium from other ions in solution. These methods apply electrical potential across specialized membranes that allow preferential transport of lithium ions. The extraction efficiency is influenced by membrane selectivity, applied voltage, solution composition, and system design. These techniques can achieve continuous operation with reduced environmental footprint compared to conventional methods, though energy consumption remains a critical factor affecting overall efficiency.Expand Specific Solutions03 Solvent extraction and chemical precipitation

Solvent extraction and chemical precipitation methods involve the use of specific chemicals or solvents that selectively react with or extract lithium from brine solutions. These processes typically include steps for mixing the brine with extraction agents, phase separation, and lithium recovery from the loaded solvent or precipitate. The efficiency depends on the selectivity of the extraction agent, pH conditions, temperature, and contact time. These methods can achieve high purity lithium products but may require multiple stages to reach desired extraction efficiencies.Expand Specific Solutions04 Process optimization and system integration

Optimization approaches for direct lithium extraction focus on integrating multiple technologies and improving system design to enhance overall efficiency. These include hybrid processes combining adsorption with membrane separation, multi-stage extraction systems, continuous flow designs, and heat/energy recovery systems. Process optimization considers factors such as pre-treatment of feed solutions, recycling of process streams, and minimizing reagent consumption. Advanced control systems and real-time monitoring help maintain optimal operating conditions to maximize lithium recovery while reducing operational costs.Expand Specific Solutions05 Novel materials and extraction media

Development of novel materials specifically designed for lithium extraction has significantly improved extraction efficiency. These include engineered inorganic sorbents, metal-organic frameworks, functionalized polymers, and composite materials with enhanced lithium selectivity. The materials feature optimized pore structures, functional groups, and surface properties that maximize lithium uptake while minimizing interference from competing ions. Advances in material science have led to extraction media with faster kinetics, higher capacity, improved stability, and better regeneration characteristics, directly translating to higher extraction efficiencies.Expand Specific Solutions

Key Industry Players in Geothermal Lithium Extraction

Direct Lithium Extraction (DLE) from geothermal brines represents an emerging market in the early growth phase, with projected global market size reaching $1.5-2 billion by 2030. The technology is transitioning from pilot to commercial scale, with varying maturity levels across key players. Companies like Vulcan Energy and Energy Exploration Technologies are pioneering commercial DLE operations in geothermal fields, while established players such as International Battery Metals and Sunresin New Materials are advancing membrane and adsorption technologies. Academic institutions including Qinghai Institute of Salt Lakes and The University of Manchester are contributing fundamental research. The competitive landscape is diversifying with oil service companies like Baker Hughes and Schlumberger entering the space, indicating growing industry recognition of DLE's strategic importance in sustainable lithium production.

Vulcan Energie Ressourcen GmbH

Technical Solution: Vulcan has developed a proprietary Direct Lithium Extraction (DLE) technology called "Zero Carbon Lithium™" that specifically targets geothermal brines in the Upper Rhine Valley of Germany. Their process combines geothermal energy production with lithium extraction, creating a unique dual-revenue business model. The technology uses sorption-based extraction with proprietary adsorbents that selectively capture lithium ions from geothermal brines. After adsorption, lithium is stripped using water-based solutions rather than harsh chemicals, and the depleted brine is reinjected into the reservoir. This closed-loop system maintains reservoir pressure and prevents subsidence issues. Vulcan's process is powered by the geothermal energy extracted from the same brine, making it a carbon-neutral or potentially carbon-negative operation. Their pilot plant has demonstrated successful extraction of lithium chloride from geothermal brines, which is then processed into battery-grade lithium hydroxide through electrolysis.

Strengths: Zero carbon footprint due to geothermal power integration; dual revenue streams from energy and lithium production; minimal environmental footprint with closed-loop system; no evaporation ponds required. Weaknesses: Technology still scaling from pilot to commercial scale; specific to certain geothermal brine compositions; capital-intensive initial development; dependent on geothermal resource quality.

Terralithium LLC

Technical Solution: Terralithium has developed an advanced ion-exchange technology specifically designed for lithium extraction from geothermal brines. Their proprietary process utilizes selective ceramic adsorbents that can operate at the high temperatures typical of geothermal fluids (up to 200°C), eliminating the need for cooling steps that reduce energy efficiency. The technology employs a continuous countercurrent extraction system where the brine flows through multiple adsorption columns in sequence, maximizing lithium recovery rates to over 90%. After adsorption, lithium is eluted using a mild acid solution, producing a concentrated lithium chloride stream that undergoes further purification. Terralithium's system is modular and scalable, allowing for deployment at various geothermal sites with different brine chemistries. The company has demonstrated their technology at pilot scale in the Salton Sea geothermal field, processing brines with complex chemistry containing high levels of silica, manganese, and other potentially interfering elements.

Strengths: High-temperature operation capability reduces energy costs; modular design allows for scalable implementation; demonstrated effectiveness with complex brine chemistries; high recovery rates. Weaknesses: Requires specialized ceramic materials that may be costly to manufacture; acid regeneration creates waste streams requiring management; technology relatively new to commercial-scale implementation.

Critical Patents and Innovations in DLE Technology

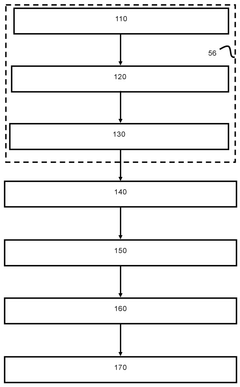

LITHIUM EXTRACTION PROCESS FROM GEOTHERMAL BRINE USING THE ION SIEVED ADSORBTION METHOD WITH TiO2

PatentPendingID202405200A

Innovation

- A lithium extraction process using the ion sieved adsorption method with TiO2, involving the synthesis of titanium dioxide-based adsorbent material, calcination, acid treatment, and controlled adsorption conditions to enhance lithium recovery from geothermal brine.

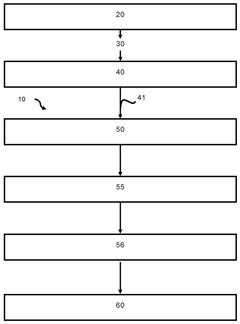

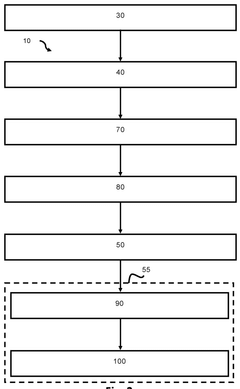

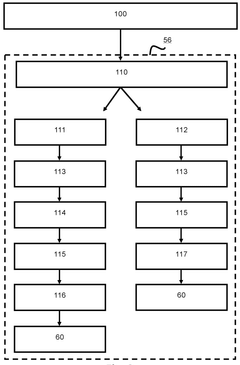

Post processing in a system and process for extracting lithium enriched eluates from an untreated brine

PatentWO2025036579A1

Innovation

- A system and process that directly injects untreated geothermal brine into a direct lithium extraction unit, followed by a membrane purification unit and a foreign ion removal unit, allowing for the extraction of lithium enriched eluates without pre-treatment.

Environmental Impact Assessment

The environmental impact assessment of Direct Lithium Extraction (DLE) from geothermal brines reveals a complex interplay of benefits and challenges. Compared to traditional lithium extraction methods such as evaporation ponds and hard rock mining, DLE in geothermal operations demonstrates significant environmental advantages. The process utilizes existing geothermal infrastructure, thereby minimizing additional land disturbance and habitat fragmentation that typically accompany new mining operations.

Water consumption represents a critical environmental consideration in lithium production. Traditional evaporation pond methods consume approximately 500,000 gallons of water per ton of lithium carbonate produced. In contrast, DLE from geothermal brines can reduce water consumption by up to 90%, presenting a substantial improvement in water resource management, particularly in water-stressed regions where lithium resources are often concentrated.

Carbon footprint analysis indicates that DLE integrated with geothermal energy production creates a synergistic environmental benefit. The geothermal power generation provides carbon-free electricity for the extraction process, resulting in lithium production with significantly lower greenhouse gas emissions compared to conventional methods. Studies suggest that the carbon footprint could be reduced by 30-60% through this integrated approach.

However, several environmental challenges require careful management. The handling and disposal of spent sorbents and chemicals used in the extraction process present potential contamination risks if not properly managed. Additionally, the extraction process may alter brine chemistry, potentially affecting subsurface microbial communities and geochemical equilibria in the geothermal reservoir.

Groundwater protection remains a priority concern, as improper reinjection of processed brines could potentially impact aquifer quality. Comprehensive monitoring systems are essential to detect any changes in groundwater chemistry and prevent contamination events. The long-term effects of continuous brine extraction and reinjection on subsurface geological structures also warrant ongoing assessment.

Regulatory frameworks for DLE environmental management are still evolving in many jurisdictions. Current operations typically fall under existing geothermal and mining regulations, which may not adequately address the unique environmental aspects of DLE processes. Industry stakeholders and regulatory bodies are working to develop specific guidelines that balance environmental protection with the strategic importance of domestic lithium production.

Water consumption represents a critical environmental consideration in lithium production. Traditional evaporation pond methods consume approximately 500,000 gallons of water per ton of lithium carbonate produced. In contrast, DLE from geothermal brines can reduce water consumption by up to 90%, presenting a substantial improvement in water resource management, particularly in water-stressed regions where lithium resources are often concentrated.

Carbon footprint analysis indicates that DLE integrated with geothermal energy production creates a synergistic environmental benefit. The geothermal power generation provides carbon-free electricity for the extraction process, resulting in lithium production with significantly lower greenhouse gas emissions compared to conventional methods. Studies suggest that the carbon footprint could be reduced by 30-60% through this integrated approach.

However, several environmental challenges require careful management. The handling and disposal of spent sorbents and chemicals used in the extraction process present potential contamination risks if not properly managed. Additionally, the extraction process may alter brine chemistry, potentially affecting subsurface microbial communities and geochemical equilibria in the geothermal reservoir.

Groundwater protection remains a priority concern, as improper reinjection of processed brines could potentially impact aquifer quality. Comprehensive monitoring systems are essential to detect any changes in groundwater chemistry and prevent contamination events. The long-term effects of continuous brine extraction and reinjection on subsurface geological structures also warrant ongoing assessment.

Regulatory frameworks for DLE environmental management are still evolving in many jurisdictions. Current operations typically fall under existing geothermal and mining regulations, which may not adequately address the unique environmental aspects of DLE processes. Industry stakeholders and regulatory bodies are working to develop specific guidelines that balance environmental protection with the strategic importance of domestic lithium production.

Economic Feasibility Analysis

The economic feasibility of Direct Lithium Extraction (DLE) from geothermal brines represents a critical factor in determining the commercial viability of this emerging technology. Current cost analyses indicate that DLE methods can achieve production costs between $3,000 and $7,000 per ton of lithium carbonate equivalent (LCE), comparing favorably against traditional evaporation pond methods which average $5,000 to $8,000 per ton. This cost advantage becomes particularly significant when factoring in the reduced environmental footprint and accelerated production timelines.

Capital expenditure requirements for DLE facilities integrated with existing geothermal power plants range from $20-50 million for small-scale operations (500-1,000 tons LCE/year) to $100-300 million for commercial-scale facilities (5,000-20,000 tons LCE/year). These investments typically yield payback periods of 3-7 years at current lithium market prices, with internal rates of return (IRR) between 15-30% depending on brine concentration and operational efficiency.

Revenue projections remain highly favorable given the sustained growth in lithium demand, primarily driven by electric vehicle battery production. Market analysts forecast lithium prices to maintain a range of $15,000-$25,000 per ton through 2030, providing substantial profit margins for efficient DLE operations. The co-generation aspect of geothermal energy production creates additional revenue streams, improving the overall project economics.

Sensitivity analysis reveals that economic viability is most heavily influenced by three factors: lithium concentration in brine (with 100+ ppm generally considered economically viable), extraction efficiency (with current technologies achieving 70-90%), and energy costs. The integration with geothermal power generation provides a significant advantage by utilizing already-pumped brine and potentially self-supplying energy requirements.

Government incentives further enhance the economic outlook, with several jurisdictions offering tax credits, grants, and expedited permitting for critical mineral projects. In the United States, the Inflation Reduction Act provides tax credits up to 10% for domestic critical mineral production, while the European Union's Critical Raw Materials Act offers similar financial incentives for sustainable lithium extraction projects.

Risk factors affecting economic feasibility include technological reliability at scale, potential lithium price volatility, and uncertainty regarding long-term brine reservoir performance. Pilot projects in the Salton Sea (California), Rhine Valley (Germany), and Cornish geothermal fields (UK) are currently generating crucial operational data to refine economic models and reduce investment uncertainty.

Capital expenditure requirements for DLE facilities integrated with existing geothermal power plants range from $20-50 million for small-scale operations (500-1,000 tons LCE/year) to $100-300 million for commercial-scale facilities (5,000-20,000 tons LCE/year). These investments typically yield payback periods of 3-7 years at current lithium market prices, with internal rates of return (IRR) between 15-30% depending on brine concentration and operational efficiency.

Revenue projections remain highly favorable given the sustained growth in lithium demand, primarily driven by electric vehicle battery production. Market analysts forecast lithium prices to maintain a range of $15,000-$25,000 per ton through 2030, providing substantial profit margins for efficient DLE operations. The co-generation aspect of geothermal energy production creates additional revenue streams, improving the overall project economics.

Sensitivity analysis reveals that economic viability is most heavily influenced by three factors: lithium concentration in brine (with 100+ ppm generally considered economically viable), extraction efficiency (with current technologies achieving 70-90%), and energy costs. The integration with geothermal power generation provides a significant advantage by utilizing already-pumped brine and potentially self-supplying energy requirements.

Government incentives further enhance the economic outlook, with several jurisdictions offering tax credits, grants, and expedited permitting for critical mineral projects. In the United States, the Inflation Reduction Act provides tax credits up to 10% for domestic critical mineral production, while the European Union's Critical Raw Materials Act offers similar financial incentives for sustainable lithium extraction projects.

Risk factors affecting economic feasibility include technological reliability at scale, potential lithium price volatility, and uncertainty regarding long-term brine reservoir performance. Pilot projects in the Salton Sea (California), Rhine Valley (Germany), and Cornish geothermal fields (UK) are currently generating crucial operational data to refine economic models and reduce investment uncertainty.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!