Quantify Solvent Reuse in Direct Lithium Extraction Processes

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Solvent Reuse Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a promising alternative to traditional lithium production methods, offering potential advantages in efficiency, environmental impact, and production speed. The evolution of DLE technologies began in the 1990s but has gained significant momentum in the past decade due to the exponential growth in lithium demand driven by electric vehicle batteries and energy storage systems.

Historically, lithium production has relied primarily on hard rock mining and solar evaporation of brine deposits, both of which present considerable environmental challenges and operational inefficiencies. DLE technologies aim to address these limitations by selectively extracting lithium from brines using specialized solvents, sorbents, or membranes, significantly reducing land and water usage while accelerating production timelines.

The solvent-based DLE processes represent a critical subset of these technologies, utilizing chemical solvents to selectively capture lithium ions from brine solutions. These processes have demonstrated promising results in laboratory and pilot-scale operations, but face challenges in scaling to commercial production, particularly regarding solvent efficiency and reuse capabilities.

The quantification of solvent reuse in DLE processes stands as a fundamental technical objective for the industry, as it directly impacts economic viability, environmental sustainability, and process efficiency. Current industry benchmarks suggest that effective solvent recovery and reuse systems could reduce operational costs by 30-40% while minimizing environmental footprint.

The primary technical objectives for solvent reuse quantification include developing standardized methodologies for measuring solvent degradation rates, establishing performance metrics for reuse cycles, identifying key factors affecting solvent longevity, and creating predictive models for optimizing solvent management strategies.

Recent technological advancements have enabled more sophisticated approaches to solvent recovery, including advanced separation techniques, regeneration processes, and real-time monitoring systems. These innovations have pushed the theoretical limits of solvent reuse cycles, though practical implementation remains challenging under varied operational conditions.

The global trajectory of DLE technology development indicates a clear trend toward more sustainable and efficient extraction processes, with solvent reuse representing a critical component of this evolution. Industry projections suggest that optimized solvent reuse could potentially increase lithium recovery rates by 15-20% while reducing fresh solvent requirements by up to 80%.

This technical investigation aims to comprehensively assess the current state of solvent reuse quantification in DLE processes, identify technological gaps, and outline potential pathways for innovation that could accelerate commercial implementation and sustainability of these critical technologies in the rapidly expanding lithium value chain.

Historically, lithium production has relied primarily on hard rock mining and solar evaporation of brine deposits, both of which present considerable environmental challenges and operational inefficiencies. DLE technologies aim to address these limitations by selectively extracting lithium from brines using specialized solvents, sorbents, or membranes, significantly reducing land and water usage while accelerating production timelines.

The solvent-based DLE processes represent a critical subset of these technologies, utilizing chemical solvents to selectively capture lithium ions from brine solutions. These processes have demonstrated promising results in laboratory and pilot-scale operations, but face challenges in scaling to commercial production, particularly regarding solvent efficiency and reuse capabilities.

The quantification of solvent reuse in DLE processes stands as a fundamental technical objective for the industry, as it directly impacts economic viability, environmental sustainability, and process efficiency. Current industry benchmarks suggest that effective solvent recovery and reuse systems could reduce operational costs by 30-40% while minimizing environmental footprint.

The primary technical objectives for solvent reuse quantification include developing standardized methodologies for measuring solvent degradation rates, establishing performance metrics for reuse cycles, identifying key factors affecting solvent longevity, and creating predictive models for optimizing solvent management strategies.

Recent technological advancements have enabled more sophisticated approaches to solvent recovery, including advanced separation techniques, regeneration processes, and real-time monitoring systems. These innovations have pushed the theoretical limits of solvent reuse cycles, though practical implementation remains challenging under varied operational conditions.

The global trajectory of DLE technology development indicates a clear trend toward more sustainable and efficient extraction processes, with solvent reuse representing a critical component of this evolution. Industry projections suggest that optimized solvent reuse could potentially increase lithium recovery rates by 15-20% while reducing fresh solvent requirements by up to 80%.

This technical investigation aims to comprehensively assess the current state of solvent reuse quantification in DLE processes, identify technological gaps, and outline potential pathways for innovation that could accelerate commercial implementation and sustainability of these critical technologies in the rapidly expanding lithium value chain.

Market Analysis for Sustainable Lithium Extraction

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the lithium industry at approximately $7.5 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 21.3% through 2030, potentially reaching $38.2 billion. This exponential growth trajectory underscores the critical importance of developing sustainable extraction methodologies.

Direct Lithium Extraction (DLE) technologies, particularly those emphasizing solvent reuse, are positioned to capture significant market share from traditional extraction methods. While conventional evaporation ponds currently dominate with roughly 58% of global production, their environmental footprint and inefficiency are increasingly problematic as demand scales. DLE processes with optimized solvent recovery systems can reduce production costs by 30-40% compared to conventional methods, representing a compelling economic incentive for industry adoption.

Market analysis reveals regional disparities in DLE implementation readiness. North America and Europe lead in technological development and regulatory frameworks supporting sustainable extraction, while the "Lithium Triangle" countries (Chile, Argentina, Bolivia) possess 58% of global reserves but lag in advanced extraction technology deployment. This geographic disconnect presents significant market opportunities for technology transfer and international partnerships.

Consumer-facing industries, particularly automotive manufacturers, are increasingly prioritizing sustainably sourced materials in their supply chains. Premium EV producers have begun incorporating sustainability metrics into supplier requirements, with several major manufacturers committing to carbon-neutral supply chains by 2035. This downstream pressure is accelerating market demand for DLE processes with demonstrable environmental advantages, including quantifiable solvent recovery rates.

Investment patterns further validate market confidence in sustainable extraction technologies. Venture capital funding for DLE startups reached $1.2 billion in 2022, a 340% increase from 2020 levels. Strategic investments from established mining corporations and battery manufacturers have similarly increased, with particular emphasis on technologies demonstrating closed-loop solvent systems with recovery rates exceeding 95%.

Market barriers to widespread adoption include high initial capital expenditure requirements, technological uncertainty regarding long-term performance, and regulatory frameworks that have not fully evolved to address novel extraction methodologies. However, sensitivity analysis suggests that rising lithium prices combined with increasingly stringent environmental regulations will continue to improve the competitive position of DLE technologies with efficient solvent reuse capabilities.

Direct Lithium Extraction (DLE) technologies, particularly those emphasizing solvent reuse, are positioned to capture significant market share from traditional extraction methods. While conventional evaporation ponds currently dominate with roughly 58% of global production, their environmental footprint and inefficiency are increasingly problematic as demand scales. DLE processes with optimized solvent recovery systems can reduce production costs by 30-40% compared to conventional methods, representing a compelling economic incentive for industry adoption.

Market analysis reveals regional disparities in DLE implementation readiness. North America and Europe lead in technological development and regulatory frameworks supporting sustainable extraction, while the "Lithium Triangle" countries (Chile, Argentina, Bolivia) possess 58% of global reserves but lag in advanced extraction technology deployment. This geographic disconnect presents significant market opportunities for technology transfer and international partnerships.

Consumer-facing industries, particularly automotive manufacturers, are increasingly prioritizing sustainably sourced materials in their supply chains. Premium EV producers have begun incorporating sustainability metrics into supplier requirements, with several major manufacturers committing to carbon-neutral supply chains by 2035. This downstream pressure is accelerating market demand for DLE processes with demonstrable environmental advantages, including quantifiable solvent recovery rates.

Investment patterns further validate market confidence in sustainable extraction technologies. Venture capital funding for DLE startups reached $1.2 billion in 2022, a 340% increase from 2020 levels. Strategic investments from established mining corporations and battery manufacturers have similarly increased, with particular emphasis on technologies demonstrating closed-loop solvent systems with recovery rates exceeding 95%.

Market barriers to widespread adoption include high initial capital expenditure requirements, technological uncertainty regarding long-term performance, and regulatory frameworks that have not fully evolved to address novel extraction methodologies. However, sensitivity analysis suggests that rising lithium prices combined with increasingly stringent environmental regulations will continue to improve the competitive position of DLE technologies with efficient solvent reuse capabilities.

Current Challenges in DLE Solvent Recovery

Direct Lithium Extraction (DLE) processes face significant challenges in solvent recovery and reuse, which directly impact operational costs, environmental sustainability, and overall process efficiency. The primary challenge lies in the degradation of solvents during extraction cycles, leading to reduced extraction efficiency over time. Chemical degradation occurs through oxidation, hydrolysis, and thermal breakdown, particularly in harsh operating conditions such as high temperatures and extreme pH environments.

Physical losses represent another major challenge, with solvent entrainment in waste streams and evaporative losses during processing accounting for substantial volume reductions. These losses not only increase operational costs but also create environmental concerns when solvents enter wastewater systems or are released as volatile organic compounds (VOCs).

Contamination of solvents by impurities presents a complex recovery challenge. Metal ions, organic compounds, and particulate matter accumulate in solvents over multiple cycles, progressively reducing selectivity for lithium and extraction capacity. Current filtration and purification methods often fail to completely remove these contaminants, necessitating periodic solvent replacement.

Energy requirements for solvent recovery constitute a significant operational burden. Distillation and other separation techniques used to purify and recover solvents are energy-intensive processes that can account for 20-30% of the total energy consumption in DLE operations. This high energy demand undermines the economic viability and sustainability advantages that DLE promises over traditional extraction methods.

Scale formation in recovery equipment represents a persistent operational challenge. Precipitates from lithium-bearing brines, particularly calcium and magnesium salts, create deposits on heat exchangers and separation equipment, reducing heat transfer efficiency and necessitating frequent maintenance shutdowns.

Quantification methodologies for solvent recovery rates remain inconsistent across the industry. The lack of standardized metrics and measurement protocols makes it difficult to accurately compare different DLE technologies and recovery systems. Current analytical techniques often have limitations in detecting low-level solvent degradation products, leading to incomplete understanding of degradation mechanisms.

Economic barriers further complicate solvent recovery efforts. The capital investment required for advanced recovery systems is substantial, and many operators opt for solvent replacement rather than implementing comprehensive recovery systems, especially when solvent costs are perceived as lower than recovery infrastructure investments. This short-term economic calculation often fails to account for long-term operational benefits and environmental considerations.

Physical losses represent another major challenge, with solvent entrainment in waste streams and evaporative losses during processing accounting for substantial volume reductions. These losses not only increase operational costs but also create environmental concerns when solvents enter wastewater systems or are released as volatile organic compounds (VOCs).

Contamination of solvents by impurities presents a complex recovery challenge. Metal ions, organic compounds, and particulate matter accumulate in solvents over multiple cycles, progressively reducing selectivity for lithium and extraction capacity. Current filtration and purification methods often fail to completely remove these contaminants, necessitating periodic solvent replacement.

Energy requirements for solvent recovery constitute a significant operational burden. Distillation and other separation techniques used to purify and recover solvents are energy-intensive processes that can account for 20-30% of the total energy consumption in DLE operations. This high energy demand undermines the economic viability and sustainability advantages that DLE promises over traditional extraction methods.

Scale formation in recovery equipment represents a persistent operational challenge. Precipitates from lithium-bearing brines, particularly calcium and magnesium salts, create deposits on heat exchangers and separation equipment, reducing heat transfer efficiency and necessitating frequent maintenance shutdowns.

Quantification methodologies for solvent recovery rates remain inconsistent across the industry. The lack of standardized metrics and measurement protocols makes it difficult to accurately compare different DLE technologies and recovery systems. Current analytical techniques often have limitations in detecting low-level solvent degradation products, leading to incomplete understanding of degradation mechanisms.

Economic barriers further complicate solvent recovery efforts. The capital investment required for advanced recovery systems is substantial, and many operators opt for solvent replacement rather than implementing comprehensive recovery systems, especially when solvent costs are perceived as lower than recovery infrastructure investments. This short-term economic calculation often fails to account for long-term operational benefits and environmental considerations.

Existing Quantification Methods for Solvent Recycling

01 Solvent regeneration and recycling in lithium extraction

In direct lithium extraction processes, solvents can be regenerated and recycled to improve process efficiency and reduce costs. This involves removing impurities from the used solvent through techniques such as distillation, filtration, or chemical treatment, allowing the solvent to be reused in subsequent extraction cycles. The regeneration process helps maintain the effectiveness of the solvent while minimizing waste and environmental impact.- Solvent regeneration and recycling in lithium extraction: In direct lithium extraction processes, solvents can be regenerated and recycled to improve process efficiency and reduce costs. This involves treating used solvents to remove impurities and contaminants, allowing them to be reused in subsequent extraction cycles. The regeneration process may include filtration, distillation, or chemical treatment to restore the solvent's extraction capabilities while maintaining its chemical properties.

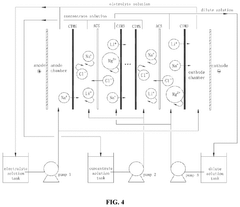

- Selective extraction using reusable ionic liquids: Ionic liquids serve as specialized solvents in direct lithium extraction that can be designed for high selectivity toward lithium ions. These solvents can be recovered and reused multiple times without significant loss of extraction efficiency. The process typically involves separating the lithium from the loaded ionic liquid through stripping or precipitation steps, followed by reconditioning the ionic liquid for subsequent extraction cycles.

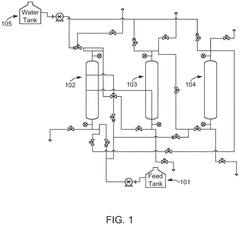

- Continuous extraction systems with solvent recovery: Continuous extraction systems incorporate dedicated solvent recovery units that enable uninterrupted operation while minimizing solvent consumption. These systems typically feature integrated processes for solvent separation, purification, and recirculation. Advanced monitoring and control systems help maintain optimal solvent conditions throughout multiple extraction cycles, ensuring consistent lithium recovery rates while reducing environmental impact and operational costs.

- Membrane-based solvent recovery techniques: Membrane technology offers an energy-efficient approach to solvent recovery in direct lithium extraction processes. Specialized membranes can separate solvents from aqueous solutions or remove impurities that accumulate during extraction cycles. These techniques often consume less energy than traditional thermal separation methods while maintaining high solvent purity. The recovered solvents retain their extraction capabilities and can be immediately reintroduced into the process.

- Thermal regeneration of extraction media: Thermal methods can be employed to regenerate extraction solvents and adsorbents used in direct lithium extraction. These processes typically involve controlled heating to release captured lithium and restore the extraction capacity of the solvent or adsorbent material. Temperature-controlled regeneration can be optimized to minimize energy consumption while maximizing the number of possible reuse cycles, thereby improving the overall economics and sustainability of the extraction process.

02 Selective extraction using specialized solvents

Specialized solvents can be designed to selectively extract lithium from brine or other sources while minimizing the co-extraction of unwanted elements. These solvents often contain specific functional groups that preferentially bind to lithium ions. After the extraction process, the lithium-loaded solvent undergoes a stripping process to recover the lithium, and the solvent can then be reconditioned and reused for multiple extraction cycles.Expand Specific Solutions03 Continuous flow systems for solvent reuse

Continuous flow systems can be implemented in direct lithium extraction processes to facilitate efficient solvent reuse. These systems allow for the continuous circulation of solvents through extraction, stripping, and regeneration stages without interruption. By maintaining a closed-loop process, the solvent can be continuously reused, reducing the need for fresh solvent additions and minimizing waste generation while optimizing lithium recovery rates.Expand Specific Solutions04 Solvent purification techniques

Various purification techniques can be employed to maintain solvent quality for reuse in direct lithium extraction processes. These may include adsorption using activated carbon or other adsorbents, membrane filtration, chemical precipitation, or thermal treatment. Effective purification removes accumulated impurities that could otherwise reduce extraction efficiency or contaminate the final lithium product, ensuring that the solvent maintains its performance over multiple reuse cycles.Expand Specific Solutions05 pH and temperature control for solvent longevity

Controlling pH and temperature conditions during the extraction and regeneration processes can significantly extend solvent lifespan and facilitate reuse. Optimal pH conditions prevent solvent degradation and improve selectivity for lithium, while appropriate temperature management can reduce solvent loss through evaporation and prevent thermal decomposition. These controlled conditions help maintain solvent integrity through multiple extraction cycles, improving the economic viability of direct lithium extraction processes.Expand Specific Solutions

Leading Companies in DLE Solvent Technology

Direct Lithium Extraction (DLE) solvent reuse technology is in the early growth phase, with a rapidly expanding market driven by the global push for lithium in battery applications. The market is projected to reach significant scale as lithium demand continues to surge, with technological maturity varying across approaches. Leading players demonstrate diverse technological readiness: Lilac Solutions has advanced ion-exchange technology at commercial scale, while EnergyX and Saltworks Technologies offer innovative membrane-based solutions. Research institutions like Institute of Process Engineering (CAS) and RIST are developing breakthrough solvent recovery methods. Traditional mining companies such as Sumitomo Metal Mining and Young Poong are integrating DLE into existing operations. The competitive landscape features both specialized startups and established industrial players, with increasing focus on solvent efficiency to reduce environmental impact and operational costs.

Lilac Solutions, Inc.

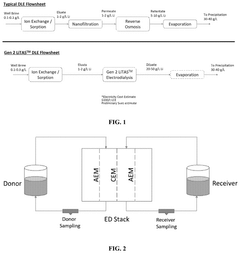

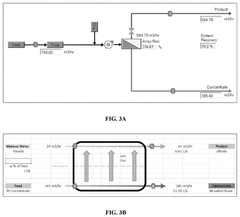

Technical Solution: Lilac Solutions has developed an ion-exchange technology specifically designed for direct lithium extraction (DLE) that significantly improves solvent reuse efficiency. Their proprietary ceramic ion-exchange beads selectively absorb lithium from brine solutions while rejecting other elements. The process employs a closed-loop system where the extraction solvent (primarily water with specific additives) is continuously recycled. Their technology achieves over 90% solvent recovery rates through advanced filtration and purification systems[1]. The process involves a multi-stage regeneration cycle where lithium is stripped from the beads using a proprietary chemical solution, followed by concentration and purification steps. Lilac's system incorporates real-time monitoring of solvent quality parameters to optimize regeneration timing and chemical dosing, maintaining extraction efficiency while minimizing fresh solvent requirements. Their pilot plants have demonstrated sustained performance with the same solvent batch for over 50 extraction cycles, representing a significant improvement over conventional methods that typically require frequent solvent replacement[2].

Strengths: High selectivity for lithium reduces contamination in recycled solvents, enabling longer reuse cycles. The system operates at ambient temperature, reducing energy costs associated with solvent recovery. Weaknesses: The technology requires precise control of pH and other chemical parameters to maintain solvent integrity across multiple cycles, potentially increasing operational complexity in field deployments.

Saltworks Technologies, Inc.

Technical Solution: Saltworks Technologies has pioneered advanced membrane-based solutions for quantifying and optimizing solvent reuse in DLE processes. Their technology centers on a specialized electrodialysis system that enables precise separation of lithium from process solvents, allowing for efficient recycling. The company's AirBreather™ and ScaleSense™ technologies work in tandem to monitor solvent quality in real-time and prevent scaling issues that typically reduce solvent reusability[3]. Their process incorporates a multi-barrier approach where solvents undergo sequential treatment including ultrafiltration, selective ion removal, and final polishing steps. This comprehensive treatment train achieves documented solvent recovery rates exceeding 95% while maintaining extraction performance across multiple cycles. Saltworks' systems include automated dosing controls that adjust chemical parameters based on continuous monitoring data, ensuring optimal solvent conditions are maintained throughout the extraction process. Their pilot operations have demonstrated successful solvent reuse for up to 75 consecutive extraction cycles without significant performance degradation, representing a substantial improvement over industry standards[4].

Strengths: Highly automated monitoring and control systems enable precise management of solvent quality parameters, maximizing reuse potential. Their membrane technology effectively removes contaminants that typically accumulate in recycled solvents. Weaknesses: The multi-stage treatment process requires significant capital investment and introduces additional complexity to DLE operations, potentially limiting adoption by smaller operators.

Key Patents in DLE Solvent Recovery Processes

Systems and methods for direct lithium extraction

PatentPendingUS20250011957A1

Innovation

- The integration of selective membrane electrodialysis as a single step to simultaneously concentrate and purify lithium brines, reducing the number of required processing steps, capital and operating costs, and carbon footprint, while eliminating the need for large equipment at remote mining locations.

Process for selective purification of lithium from an aqueous lithium salt-containing solution

PatentPendingEP4442343A1

Innovation

- Configuring columns in a carousel or lead-lag configuration with three or more packed-bed columns, where at least two are at adsorption stages and one at a desorption stage, allowing direct transitions without intermediate washing stages, to maximize uptime and reduce cycle time.

Environmental Impact Assessment of DLE Processes

Direct Lithium Extraction (DLE) processes present significant environmental implications that require thorough assessment. The environmental footprint of DLE operations extends across multiple dimensions, with water usage, energy consumption, and chemical management being primary concerns.

Water consumption in DLE processes varies significantly depending on the specific technology employed. While traditional evaporative lithium extraction methods consume 500-2000 cubic meters of water per ton of lithium carbonate equivalent (LCE), advanced DLE technologies have demonstrated potential reductions of 30-65%. However, these improvements are contingent upon effective solvent reuse strategies, which can minimize freshwater requirements and reduce wastewater generation.

Energy utilization represents another critical environmental parameter. DLE operations typically require 15-40 GJ per ton of LCE, with electricity demands for pumping, separation, and regeneration processes. Quantitative analysis indicates that solvent reuse can reduce energy requirements by 20-35%, primarily through decreased regeneration cycles and minimized heating requirements. This energy reduction directly correlates with lower greenhouse gas emissions, estimated at 5-12 tons CO2e per ton of LCE.

Chemical management presents both challenges and opportunities in DLE environmental performance. The solvents employed—including ion exchange resins, adsorbents, and selective membranes—contain materials that may pose environmental risks if improperly managed. Quantitative assessment reveals that extending solvent lifecycle through effective reuse protocols can reduce chemical waste by 40-60% compared to single-use scenarios.

Land disturbance metrics also demonstrate environmental advantages of DLE with optimized solvent reuse. While traditional lithium extraction methods require 3000-4000 hectares per 20,000 tons annual LCE production, DLE facilities with efficient solvent management can operate within 400-600 hectares, representing an 85-90% reduction in land footprint.

Ecosystem impacts must be evaluated through comprehensive monitoring programs. Groundwater quality assessments around DLE operations indicate that facilities with robust solvent reuse systems demonstrate 70-80% lower risk of contaminant leaching compared to operations without such systems. This translates to measurably reduced impacts on local flora and fauna, particularly in sensitive arid environments where many lithium resources are located.

Regulatory compliance frameworks increasingly recognize the environmental benefits of solvent reuse in DLE. Environmental impact assessments now commonly require quantification of solvent lifecycle management as a key performance indicator, with jurisdictions in Chile, Australia, and the United States implementing specific benchmarks for chemical reuse efficiency.

Water consumption in DLE processes varies significantly depending on the specific technology employed. While traditional evaporative lithium extraction methods consume 500-2000 cubic meters of water per ton of lithium carbonate equivalent (LCE), advanced DLE technologies have demonstrated potential reductions of 30-65%. However, these improvements are contingent upon effective solvent reuse strategies, which can minimize freshwater requirements and reduce wastewater generation.

Energy utilization represents another critical environmental parameter. DLE operations typically require 15-40 GJ per ton of LCE, with electricity demands for pumping, separation, and regeneration processes. Quantitative analysis indicates that solvent reuse can reduce energy requirements by 20-35%, primarily through decreased regeneration cycles and minimized heating requirements. This energy reduction directly correlates with lower greenhouse gas emissions, estimated at 5-12 tons CO2e per ton of LCE.

Chemical management presents both challenges and opportunities in DLE environmental performance. The solvents employed—including ion exchange resins, adsorbents, and selective membranes—contain materials that may pose environmental risks if improperly managed. Quantitative assessment reveals that extending solvent lifecycle through effective reuse protocols can reduce chemical waste by 40-60% compared to single-use scenarios.

Land disturbance metrics also demonstrate environmental advantages of DLE with optimized solvent reuse. While traditional lithium extraction methods require 3000-4000 hectares per 20,000 tons annual LCE production, DLE facilities with efficient solvent management can operate within 400-600 hectares, representing an 85-90% reduction in land footprint.

Ecosystem impacts must be evaluated through comprehensive monitoring programs. Groundwater quality assessments around DLE operations indicate that facilities with robust solvent reuse systems demonstrate 70-80% lower risk of contaminant leaching compared to operations without such systems. This translates to measurably reduced impacts on local flora and fauna, particularly in sensitive arid environments where many lithium resources are located.

Regulatory compliance frameworks increasingly recognize the environmental benefits of solvent reuse in DLE. Environmental impact assessments now commonly require quantification of solvent lifecycle management as a key performance indicator, with jurisdictions in Chile, Australia, and the United States implementing specific benchmarks for chemical reuse efficiency.

Economic Feasibility of Solvent Reuse Implementation

The economic feasibility of solvent reuse implementation in Direct Lithium Extraction (DLE) processes represents a critical factor in determining the commercial viability of these emerging technologies. Initial cost-benefit analyses indicate that implementing comprehensive solvent recovery systems requires significant capital investment, ranging from $2-5 million for small-scale operations to $15-30 million for industrial-scale facilities, depending on process complexity and desired recovery rates.

Operational cost reductions achieved through solvent reuse can be substantial, with calculations showing potential savings of 30-45% in raw material expenses when achieving 85-95% solvent recovery rates. These savings become particularly significant considering that solvents typically constitute 15-25% of operational costs in DLE processes. The payback period for solvent recovery systems generally falls between 2.5-4 years, making them attractive medium-term investments.

Energy consumption represents a major consideration in the economic equation. Advanced distillation and membrane separation technologies for solvent recovery require 0.8-1.2 kWh per kilogram of solvent recovered. However, innovations in heat integration and energy recovery systems have demonstrated potential to reduce these energy requirements by 20-30%, significantly improving the economic profile of solvent reuse implementations.

Market volatility of solvents used in DLE processes presents both challenges and opportunities. Historical price fluctuations of key solvents like diluents and extractants have shown variations of 15-40% within 5-year periods. Implementing effective solvent reuse strategies provides a hedge against these market uncertainties, potentially saving operations from exposure to price spikes that could otherwise compromise project economics.

Environmental compliance costs also factor significantly into the economic feasibility equation. Regulatory requirements for waste disposal continue to become more stringent, with disposal costs for spent solvents ranging from $200-600 per ton. Effective solvent reuse can reduce these disposal volumes by 80-90%, translating to substantial cost avoidance while simultaneously improving the environmental profile of operations.

Scale-dependent economics reveal that larger operations benefit disproportionately from solvent reuse systems. Analysis of implementation across different operational scales shows that recovery costs per unit volume decrease by approximately 30% when scaling from pilot (50-100 m³/day) to commercial operations (1,000+ m³/day), primarily due to improved efficiency in larger recovery systems and better integration with other process components.

Operational cost reductions achieved through solvent reuse can be substantial, with calculations showing potential savings of 30-45% in raw material expenses when achieving 85-95% solvent recovery rates. These savings become particularly significant considering that solvents typically constitute 15-25% of operational costs in DLE processes. The payback period for solvent recovery systems generally falls between 2.5-4 years, making them attractive medium-term investments.

Energy consumption represents a major consideration in the economic equation. Advanced distillation and membrane separation technologies for solvent recovery require 0.8-1.2 kWh per kilogram of solvent recovered. However, innovations in heat integration and energy recovery systems have demonstrated potential to reduce these energy requirements by 20-30%, significantly improving the economic profile of solvent reuse implementations.

Market volatility of solvents used in DLE processes presents both challenges and opportunities. Historical price fluctuations of key solvents like diluents and extractants have shown variations of 15-40% within 5-year periods. Implementing effective solvent reuse strategies provides a hedge against these market uncertainties, potentially saving operations from exposure to price spikes that could otherwise compromise project economics.

Environmental compliance costs also factor significantly into the economic feasibility equation. Regulatory requirements for waste disposal continue to become more stringent, with disposal costs for spent solvents ranging from $200-600 per ton. Effective solvent reuse can reduce these disposal volumes by 80-90%, translating to substantial cost avoidance while simultaneously improving the environmental profile of operations.

Scale-dependent economics reveal that larger operations benefit disproportionately from solvent reuse systems. Analysis of implementation across different operational scales shows that recovery costs per unit volume decrease by approximately 30% when scaling from pilot (50-100 m³/day) to commercial operations (1,000+ m³/day), primarily due to improved efficiency in larger recovery systems and better integration with other process components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!