Benchmarking Direct Lithium Extraction in Pilot vs Full Scale

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a revolutionary technology in the lithium production landscape over the past decade. Traditional lithium extraction methods, primarily evaporative brine processing and hard rock mining, have dominated the industry for decades but present significant environmental and efficiency challenges. DLE technologies aim to address these limitations by offering more sustainable, faster, and potentially more cost-effective approaches to lithium recovery.

The evolution of DLE technologies can be traced back to the early 2000s, with significant acceleration in research and development occurring after 2010 when the demand for lithium began to surge due to the electric vehicle revolution. The technology has progressed through various iterations, from laboratory-scale proof-of-concept to today's pilot plants and emerging commercial implementations.

DLE encompasses a diverse range of technological approaches, including adsorption, ion exchange, solvent extraction, and membrane processes. Each method offers distinct advantages and challenges in terms of selectivity, recovery rates, water usage, and energy consumption. The technological trajectory indicates a continuous refinement of these methods, with increasing focus on minimizing environmental footprint while maximizing lithium recovery efficiency.

The primary objective of benchmarking DLE in pilot versus full-scale operations is to establish reliable performance metrics that can accurately predict commercial viability. This includes evaluating how key performance indicators such as recovery rates, purity levels, operational costs, and environmental impacts translate from controlled pilot environments to full-scale industrial operations.

Another critical goal is to identify scaling challenges that may not be apparent in smaller pilot operations. These could include issues related to material durability under continuous operation, flow dynamics in larger systems, waste management at scale, and energy optimization across the entire process chain.

Furthermore, this benchmarking aims to establish standardized evaluation frameworks that can facilitate meaningful comparisons between different DLE technologies and implementation approaches. The lithium industry currently lacks consistent benchmarking methodologies, making it difficult for stakeholders to make informed decisions about technology adoption and investment.

The ultimate technical objective is to accelerate the commercial deployment of DLE technologies by reducing investment risks through improved predictability of full-scale performance. This would contribute significantly to meeting the rapidly growing global demand for lithium, which is projected to increase by 400-800% by 2030, primarily driven by battery applications in electric vehicles and grid storage systems.

The evolution of DLE technologies can be traced back to the early 2000s, with significant acceleration in research and development occurring after 2010 when the demand for lithium began to surge due to the electric vehicle revolution. The technology has progressed through various iterations, from laboratory-scale proof-of-concept to today's pilot plants and emerging commercial implementations.

DLE encompasses a diverse range of technological approaches, including adsorption, ion exchange, solvent extraction, and membrane processes. Each method offers distinct advantages and challenges in terms of selectivity, recovery rates, water usage, and energy consumption. The technological trajectory indicates a continuous refinement of these methods, with increasing focus on minimizing environmental footprint while maximizing lithium recovery efficiency.

The primary objective of benchmarking DLE in pilot versus full-scale operations is to establish reliable performance metrics that can accurately predict commercial viability. This includes evaluating how key performance indicators such as recovery rates, purity levels, operational costs, and environmental impacts translate from controlled pilot environments to full-scale industrial operations.

Another critical goal is to identify scaling challenges that may not be apparent in smaller pilot operations. These could include issues related to material durability under continuous operation, flow dynamics in larger systems, waste management at scale, and energy optimization across the entire process chain.

Furthermore, this benchmarking aims to establish standardized evaluation frameworks that can facilitate meaningful comparisons between different DLE technologies and implementation approaches. The lithium industry currently lacks consistent benchmarking methodologies, making it difficult for stakeholders to make informed decisions about technology adoption and investment.

The ultimate technical objective is to accelerate the commercial deployment of DLE technologies by reducing investment risks through improved predictability of full-scale performance. This would contribute significantly to meeting the rapidly growing global demand for lithium, which is projected to increase by 400-800% by 2030, primarily driven by battery applications in electric vehicles and grid storage systems.

Market Analysis for Lithium Extraction Solutions

The global lithium extraction market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the direct lithium extraction (DLE) sector at approximately $1.2 billion in 2023, with projections indicating a compound annual growth rate of 25-30% through 2030, potentially reaching $6.5 billion by the end of the decade.

Traditional lithium extraction methods—evaporation ponds and hard-rock mining—currently dominate the market with over 80% market share. However, DLE technologies are gaining significant traction due to their reduced environmental footprint, higher recovery rates, and faster production timelines. The market share for DLE solutions is expected to grow from current levels of 15-20% to potentially 35-40% by 2028.

Regional analysis reveals that North America and Australia are leading the charge in DLE technology development, while actual lithium production remains concentrated in the "Lithium Triangle" of South America (Chile, Argentina, and Bolivia) and Australia. China dominates the downstream processing market, controlling approximately 60% of global lithium refining capacity.

Market segmentation shows distinct customer profiles: major mining corporations seeking to optimize existing operations, technology startups focused exclusively on DLE innovations, and battery manufacturers looking to secure supply chains through vertical integration. Each segment presents different requirements for scaling from pilot to commercial operations.

The economic drivers for DLE adoption are compelling. While traditional extraction methods cost between $5,000-$6,000 per ton of lithium carbonate equivalent (LCE), advanced DLE technologies are demonstrating potential costs of $3,500-$4,500 per ton at scale. This cost advantage becomes particularly significant when factoring in the reduced time-to-market (months versus years for evaporation ponds) and higher purity levels that command premium pricing.

Market barriers include high initial capital expenditure requirements for full-scale implementation, technical challenges in scaling pilot technologies, and regulatory uncertainties regarding water usage and environmental impacts. These factors create a notable "valley of death" between successful pilot demonstrations and commercially viable full-scale operations.

Customer demand increasingly emphasizes sustainability metrics alongside traditional cost and quality considerations. Buyers are willing to pay premiums of 10-15% for lithium extracted using methods that demonstrate significantly reduced water consumption, minimal land disturbance, and lower carbon footprints—all potential advantages of optimized DLE systems when successfully scaled from pilot to commercial operations.

Traditional lithium extraction methods—evaporation ponds and hard-rock mining—currently dominate the market with over 80% market share. However, DLE technologies are gaining significant traction due to their reduced environmental footprint, higher recovery rates, and faster production timelines. The market share for DLE solutions is expected to grow from current levels of 15-20% to potentially 35-40% by 2028.

Regional analysis reveals that North America and Australia are leading the charge in DLE technology development, while actual lithium production remains concentrated in the "Lithium Triangle" of South America (Chile, Argentina, and Bolivia) and Australia. China dominates the downstream processing market, controlling approximately 60% of global lithium refining capacity.

Market segmentation shows distinct customer profiles: major mining corporations seeking to optimize existing operations, technology startups focused exclusively on DLE innovations, and battery manufacturers looking to secure supply chains through vertical integration. Each segment presents different requirements for scaling from pilot to commercial operations.

The economic drivers for DLE adoption are compelling. While traditional extraction methods cost between $5,000-$6,000 per ton of lithium carbonate equivalent (LCE), advanced DLE technologies are demonstrating potential costs of $3,500-$4,500 per ton at scale. This cost advantage becomes particularly significant when factoring in the reduced time-to-market (months versus years for evaporation ponds) and higher purity levels that command premium pricing.

Market barriers include high initial capital expenditure requirements for full-scale implementation, technical challenges in scaling pilot technologies, and regulatory uncertainties regarding water usage and environmental impacts. These factors create a notable "valley of death" between successful pilot demonstrations and commercially viable full-scale operations.

Customer demand increasingly emphasizes sustainability metrics alongside traditional cost and quality considerations. Buyers are willing to pay premiums of 10-15% for lithium extracted using methods that demonstrate significantly reduced water consumption, minimal land disturbance, and lower carbon footprints—all potential advantages of optimized DLE systems when successfully scaled from pilot to commercial operations.

Current DLE Technical Challenges and Limitations

Direct Lithium Extraction (DLE) technologies face significant challenges when scaling from pilot to full-scale operations. The primary technical limitation is the inconsistent performance across different brine compositions. Pilot studies often utilize idealized or simplified brine solutions, whereas full-scale operations must contend with complex, variable brines containing numerous interfering ions such as magnesium, calcium, and boron that can reduce selectivity and efficiency.

Scaling issues present another major challenge. The hydrodynamics of adsorption columns, ion exchange beds, or membrane systems behave differently at industrial scales compared to laboratory or pilot demonstrations. This scaling discrepancy often results in decreased lithium recovery rates and increased processing times in full-scale implementations, creating a significant gap between theoretical and actual performance metrics.

Energy consumption represents a critical limitation for commercial viability. Many DLE technologies require substantial energy inputs for processes such as brine pre-treatment, adsorption/desorption cycles, or membrane operations. While pilot projects can optimize energy usage in controlled environments, full-scale operations frequently encounter higher energy demands per unit of lithium recovered, impacting operational costs and sustainability profiles.

Sorbent or membrane durability constitutes another significant challenge. Materials that perform adequately during short-term pilot testing often experience accelerated degradation under continuous industrial operation. This degradation manifests as reduced lithium selectivity, diminished capacity, and shortened operational lifespans, necessitating more frequent and costly material replacements in full-scale facilities.

Water management presents complex challenges at scale. DLE processes typically require substantial water volumes for regeneration and washing cycles. Pilot projects rarely account for the full complexity of water balance and management required in water-scarce regions where many lithium resources are located, creating sustainability concerns for full-scale implementation.

Equipment fouling and scaling occur more prominently in full-scale operations. Continuous exposure to mineral-rich brines leads to precipitation and deposition on equipment surfaces, reducing efficiency and increasing maintenance requirements. These issues are often underrepresented in pilot studies due to their shorter operational timeframes and more frequent maintenance intervals.

Waste management capabilities also differ significantly between scales. Full-scale operations generate substantial volumes of spent regenerants, brine tailings, and other process wastes that require environmentally responsible disposal solutions. The economic and environmental impacts of these waste streams are frequently underestimated during pilot-scale evaluations, creating unexpected challenges during commercial implementation.

Scaling issues present another major challenge. The hydrodynamics of adsorption columns, ion exchange beds, or membrane systems behave differently at industrial scales compared to laboratory or pilot demonstrations. This scaling discrepancy often results in decreased lithium recovery rates and increased processing times in full-scale implementations, creating a significant gap between theoretical and actual performance metrics.

Energy consumption represents a critical limitation for commercial viability. Many DLE technologies require substantial energy inputs for processes such as brine pre-treatment, adsorption/desorption cycles, or membrane operations. While pilot projects can optimize energy usage in controlled environments, full-scale operations frequently encounter higher energy demands per unit of lithium recovered, impacting operational costs and sustainability profiles.

Sorbent or membrane durability constitutes another significant challenge. Materials that perform adequately during short-term pilot testing often experience accelerated degradation under continuous industrial operation. This degradation manifests as reduced lithium selectivity, diminished capacity, and shortened operational lifespans, necessitating more frequent and costly material replacements in full-scale facilities.

Water management presents complex challenges at scale. DLE processes typically require substantial water volumes for regeneration and washing cycles. Pilot projects rarely account for the full complexity of water balance and management required in water-scarce regions where many lithium resources are located, creating sustainability concerns for full-scale implementation.

Equipment fouling and scaling occur more prominently in full-scale operations. Continuous exposure to mineral-rich brines leads to precipitation and deposition on equipment surfaces, reducing efficiency and increasing maintenance requirements. These issues are often underrepresented in pilot studies due to their shorter operational timeframes and more frequent maintenance intervals.

Waste management capabilities also differ significantly between scales. Full-scale operations generate substantial volumes of spent regenerants, brine tailings, and other process wastes that require environmentally responsible disposal solutions. The economic and environmental impacts of these waste streams are frequently underestimated during pilot-scale evaluations, creating unexpected challenges during commercial implementation.

Pilot-to-Commercial Scale DLE Implementation Methods

01 Scale-up challenges in DLE technology

The transition from pilot to full-scale Direct Lithium Extraction (DLE) operations presents significant engineering challenges. These include maintaining extraction efficiency at larger volumes, managing increased energy requirements, and ensuring consistent performance of sorbents or ion exchange materials. Full-scale operations often require redesigned equipment and process modifications to handle the higher throughput while maintaining the same recovery rates and purity levels achieved in pilot plants.- Scale-up challenges in DLE technology: The transition from pilot to full-scale Direct Lithium Extraction (DLE) operations presents significant engineering challenges. These include maintaining extraction efficiency at larger volumes, managing increased energy requirements, and addressing the complexities of handling larger quantities of brine. The scale-up process requires careful consideration of factors such as flow rates, contact time between extraction media and brine, and the design of larger adsorption columns or extraction units while maintaining performance parameters established at pilot scale.

- Equipment design differences between pilot and commercial DLE systems: Pilot and full-scale DLE systems differ significantly in equipment design and configuration. Pilot systems typically use smaller, modular components that allow for rapid testing and modification, while commercial-scale systems require robust, industrial-grade equipment designed for continuous operation. Full-scale systems incorporate more sophisticated monitoring systems, automated controls, and redundancy features. The materials of construction may also differ, with commercial systems using more durable materials to withstand long-term operation in harsh brine environments.

- Performance metrics comparison between pilot and full-scale DLE: Key performance metrics often show variations between pilot and full-scale DLE operations. These metrics include lithium recovery rates, selectivity over competing ions, cycle times, and overall process efficiency. Pilot systems typically demonstrate higher theoretical recovery rates under controlled conditions, while full-scale operations must balance recovery with throughput and operational stability. Energy consumption per unit of lithium produced tends to be higher in pilot systems, while water usage efficiency often improves at commercial scale due to better integration of recycling systems.

- Economic considerations in DLE scale-up: The economic viability of DLE technology changes significantly during scale-up from pilot to commercial operations. Capital expenditure requirements increase substantially, but unit production costs typically decrease due to economies of scale. Full-scale operations benefit from optimized reagent usage, energy efficiency improvements, and better integration with downstream processing. The economic assessment must consider factors such as operational lifetime, maintenance requirements, and the ability to adapt to varying brine compositions, which may not be fully apparent during pilot testing.

- Environmental impact differences between pilot and commercial DLE: Environmental footprints differ significantly between pilot and full-scale DLE operations. Commercial-scale facilities generate larger volumes of spent brine and require more comprehensive water management systems. However, they also typically implement more advanced waste treatment processes and energy recovery systems that improve overall sustainability. Full-scale operations must address concerns related to land use, water consumption, and potential impacts on local ecosystems that may not be fully evaluated during pilot testing. The implementation of closed-loop systems and resource recovery from waste streams becomes more economically viable at commercial scale.

02 Equipment design differences between pilot and commercial DLE systems

Pilot and full-scale DLE systems differ significantly in equipment design and configuration. While pilot systems often use laboratory or small industrial equipment with manual controls, commercial-scale operations require automated systems, larger extraction columns, and industrial-grade pumping and filtration systems. The materials of construction may also change to accommodate continuous operation and higher pressure requirements, with specialized designs to minimize maintenance downtime and optimize flow dynamics.Expand Specific Solutions03 Economic viability comparison between pilot and full-scale DLE

Economic assessments reveal significant differences between pilot and full-scale DLE operations. Pilot plants typically have higher per-unit production costs but lower capital expenditure, while full-scale operations benefit from economies of scale despite requiring substantial initial investment. The economic viability of scaling up depends on factors such as lithium concentration in the brine, energy costs, reagent consumption rates, and recovery efficiency. Full-scale operations must optimize these parameters to achieve competitive production costs compared to conventional extraction methods.Expand Specific Solutions04 Environmental impact differences between pilot and commercial DLE operations

Environmental footprints differ significantly between pilot and full-scale DLE operations. While pilot plants generate minimal waste and use relatively small amounts of water and energy, commercial-scale facilities must implement comprehensive waste management systems and optimize resource consumption. Full-scale operations typically incorporate water recycling systems, energy recovery technologies, and waste treatment processes that may not be economically feasible at the pilot scale. The environmental sustainability of scaled-up DLE depends on these mitigation strategies and local environmental regulations.Expand Specific Solutions05 Performance metrics and optimization between pilot and full-scale DLE

Key performance indicators often change when scaling from pilot to commercial DLE operations. While pilot plants focus on proving technical feasibility and optimizing extraction parameters, full-scale operations prioritize throughput, operational stability, and long-term sorbent performance. Data shows that lithium recovery rates may decrease initially during scale-up but can be optimized through process refinements. Continuous monitoring systems and advanced control algorithms become essential at full scale to maintain consistent performance across larger and more complex extraction circuits.Expand Specific Solutions

Key Industry Players in Direct Lithium Extraction

The Direct Lithium Extraction (DLE) technology landscape is currently in a transitional phase from pilot to commercial scale, with the market expected to grow significantly as global lithium demand increases for battery applications. The competitive landscape features established energy companies like Koch Technology Solutions and Schlumberger alongside specialized technology providers such as Evove, Energy Exploration Technologies, and GEO40. Major battery manufacturers including CATL, LG Energy Solution, BYD, and Svolt are increasingly investing in securing lithium supply chains through DLE technologies. Academic institutions like Tsinghua University, University of Manchester, and Tianjin University are contributing fundamental research, while automotive players like Geely are vertically integrating to secure battery materials. Current technical challenges center on scaling pilot technologies to full commercial operations while maintaining extraction efficiency, selectivity, and economic viability across diverse brine sources.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed a comprehensive Direct Lithium Extraction (DLE) benchmarking framework that bridges the gap between pilot and commercial-scale operations. Their approach utilizes a modular ion-exchange technology platform called Li-Pro™, which employs proprietary adsorbent materials specifically designed for selective lithium extraction from various brine sources. The system incorporates real-time monitoring with advanced analytics to optimize performance parameters across different scales. Koch's methodology includes standardized testing protocols that account for scaling factors such as flow dynamics, mass transfer limitations, and system hydrodynamics that typically differ between pilot and full-scale implementations. Their benchmarking process incorporates multi-parameter analysis including recovery rates, selectivity ratios, adsorbent lifecycle performance, and energy consumption metrics that are normalized across different operational scales to provide accurate predictive models for commercial deployment.

Strengths: Koch's extensive experience in separation technologies provides robust scaling methodologies that accurately predict commercial performance from pilot data. Their modular approach allows for rapid iteration and optimization across different brine chemistries. Weaknesses: The technology may require significant customization for each specific brine source, potentially increasing implementation costs and timeframes for new projects.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has pioneered an advanced Direct Lithium Extraction benchmarking system called LithiScale™ that systematically evaluates performance metrics between pilot and commercial implementations. Their technology integrates sophisticated reservoir modeling with extraction process simulation to create digital twins of both pilot and full-scale operations. This approach incorporates geological characteristics of brine sources with process engineering parameters to develop accurate scaling relationships. Schlumberger's benchmarking methodology employs a suite of proprietary analytical tools that monitor key performance indicators including lithium recovery efficiency, selectivity over competing ions (particularly sodium, magnesium, and calcium), adsorbent capacity degradation rates, and process economics across different operational scales. Their system utilizes machine learning algorithms trained on extensive field data to identify potential scaling challenges and optimize process parameters for commercial deployment. The company has successfully demonstrated correlation coefficients exceeding 0.92 between predicted and actual performance metrics when scaling from pilot to commercial operations.

Strengths: Schlumberger leverages its extensive experience in oilfield technologies and subsurface characterization to provide highly accurate scaling predictions. Their digital twin approach enables virtual testing of multiple operational scenarios before physical implementation. Weaknesses: The sophisticated modeling approach requires substantial input data and expertise to implement effectively, potentially limiting accessibility for smaller lithium development projects.

Critical Patents and Technical Innovations in DLE

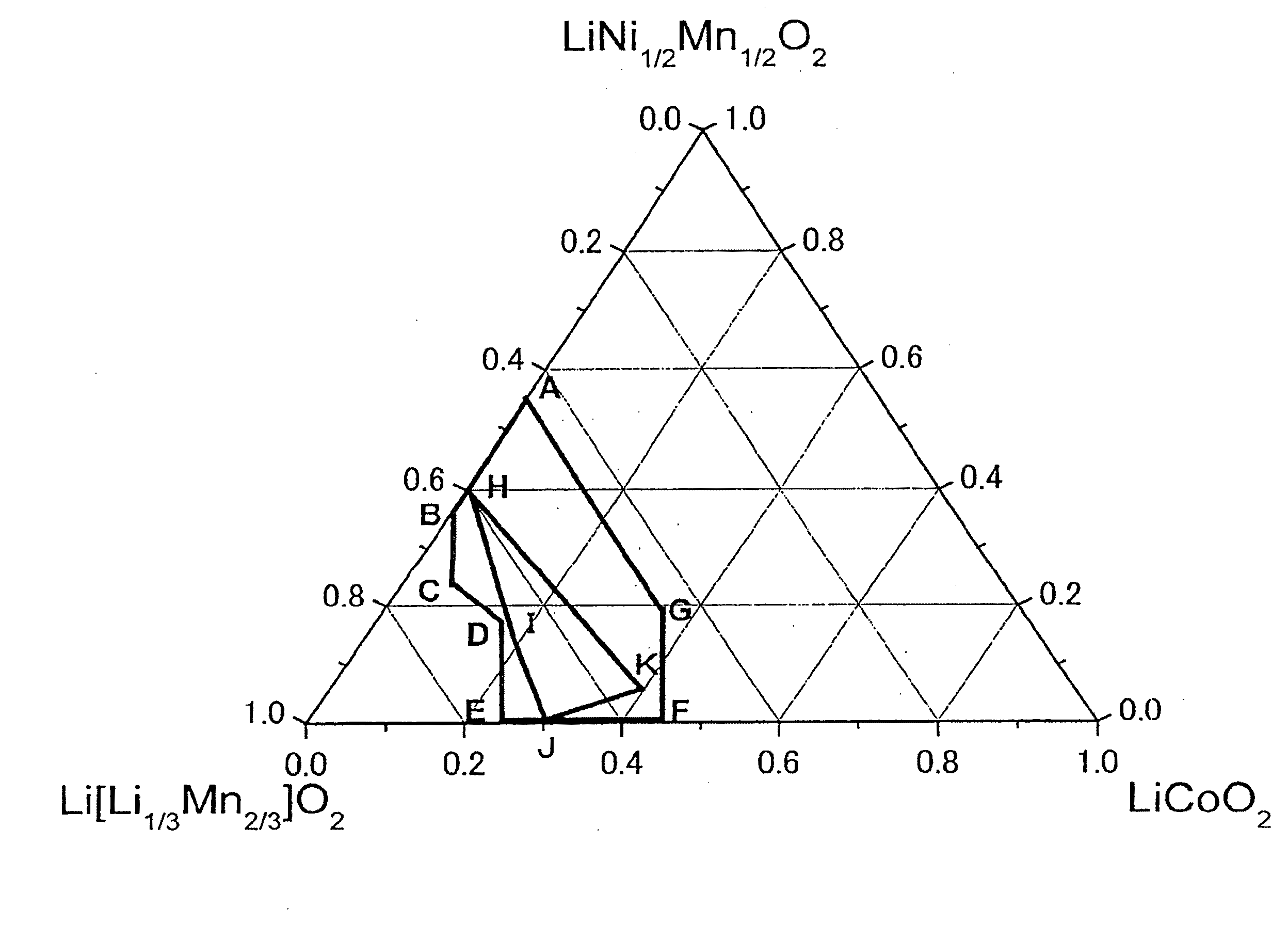

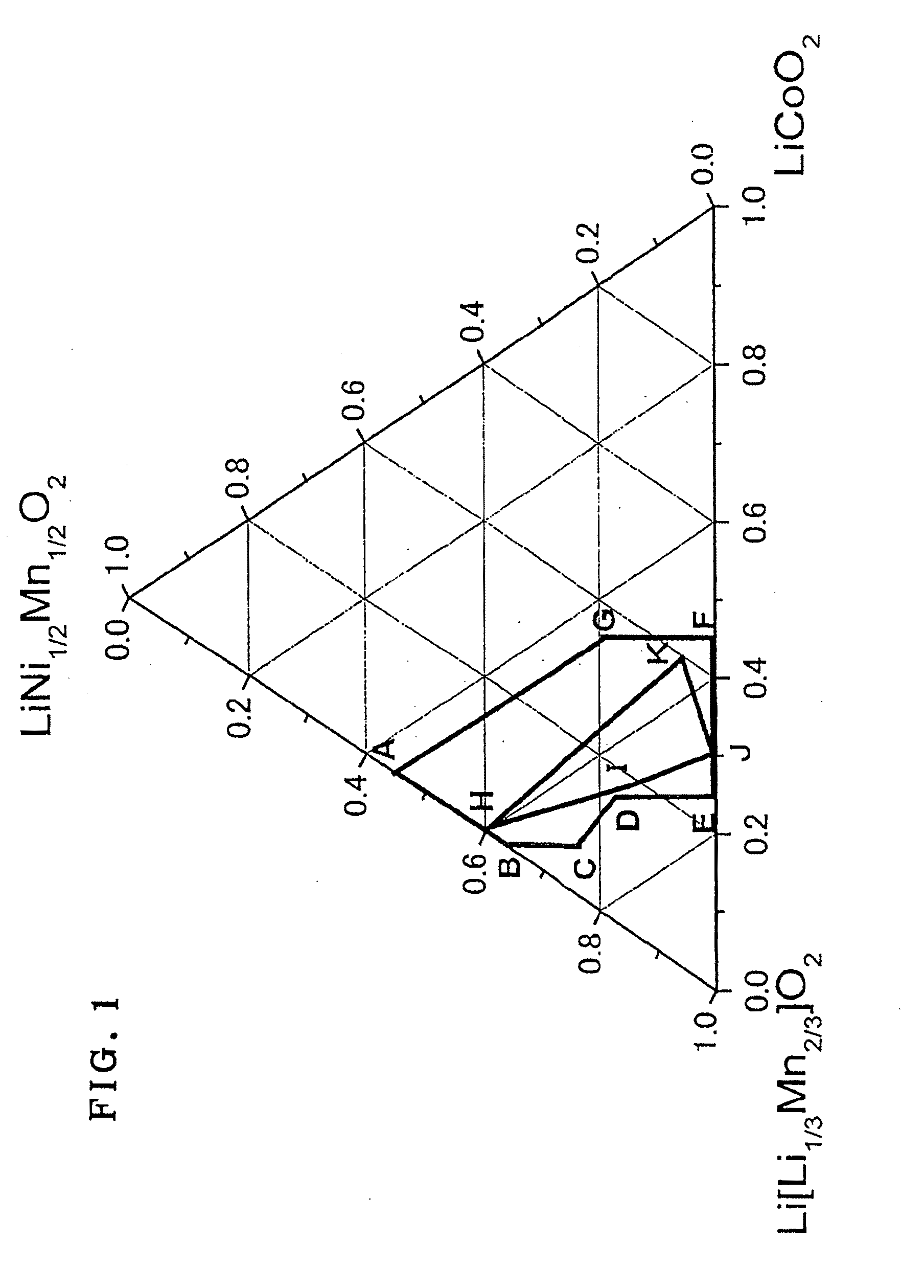

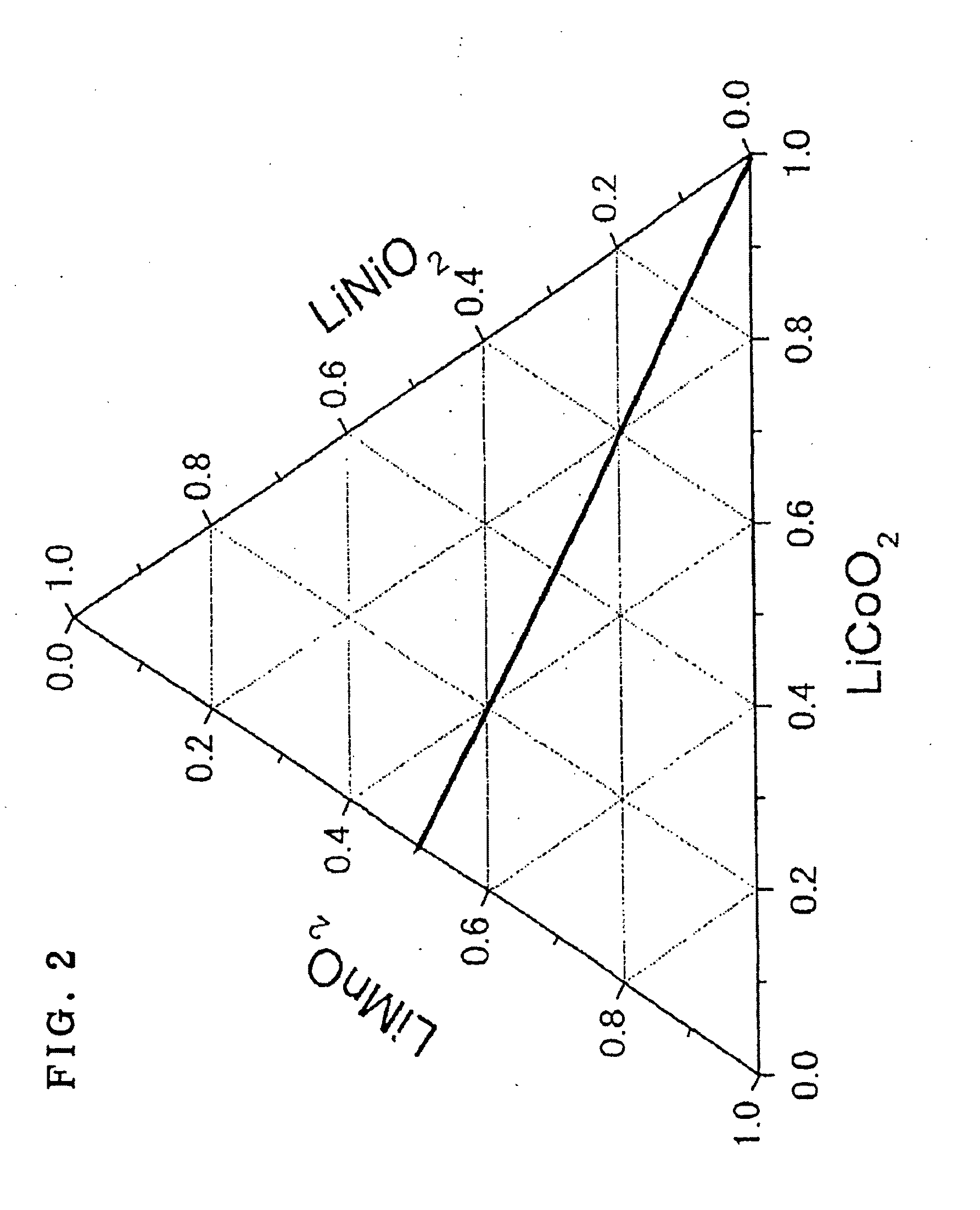

Process for producing lithium secondary battery

PatentActiveUS20110037440A1

Innovation

- A ternary solid solution of Li[Li1/3Mn2/3]O2, LiNi1/2Mn1/2O2, and LiCoO2 with a specific composition ratio, where the valences of Co, Ni, and Mn are optimized to Co3+, Ni2+, and Mn4+, forming a stable discharge capacity and cycle performance by adjusting the Li content and calcining conditions.

Environmental Impact Assessment of DLE Technologies

The environmental impact assessment of Direct Lithium Extraction (DLE) technologies reveals significant advantages over traditional extraction methods, particularly regarding water usage and land disturbance. Conventional lithium extraction from salt flats typically consumes 500,000 to 2 million gallons of water per ton of lithium produced, while advanced DLE technologies can reduce this by 50-90%. This water conservation aspect becomes increasingly critical as many lithium-rich regions face severe water scarcity issues.

Land footprint analysis demonstrates that DLE facilities require substantially less surface area compared to evaporation ponds, which can span thousands of hectares. The reduced spatial requirements of DLE technologies minimize habitat disruption and preserve biodiversity in sensitive ecosystems where lithium resources are abundant.

Carbon emissions profiles vary significantly between pilot and full-scale implementations. Pilot DLE operations typically show promising emissions reductions compared to traditional methods, but scaling considerations often reveal increased energy demands that may partially offset these benefits. Full-scale DLE operations require comprehensive life cycle assessments to accurately quantify their carbon footprint, with current data suggesting a 30-40% reduction in greenhouse gas emissions compared to conventional extraction methods.

Chemical usage presents another environmental consideration, as most DLE technologies employ sorbents, solvents, or membranes that require periodic replacement and proper disposal. The environmental impact of these materials varies widely between different DLE approaches, with ion-exchange resins generally showing lower toxicity profiles than solvent-based systems.

Waste management strategies differ substantially between pilot and commercial implementations. While pilot projects can often manage residual brines and spent materials through specialized handling, full-scale operations require integrated waste management systems. The composition of waste streams from DLE processes typically contains fewer harmful elements than traditional extraction methods, though concentrated salt solutions require careful management to prevent soil and groundwater contamination.

Ecosystem impact monitoring reveals that DLE technologies generally cause less disruption to local hydrology and associated ecosystems than evaporation ponds. However, the extraction and reinjection of subsurface brines may still alter groundwater dynamics, requiring careful monitoring and management, particularly when scaling from pilot to commercial operations.

Land footprint analysis demonstrates that DLE facilities require substantially less surface area compared to evaporation ponds, which can span thousands of hectares. The reduced spatial requirements of DLE technologies minimize habitat disruption and preserve biodiversity in sensitive ecosystems where lithium resources are abundant.

Carbon emissions profiles vary significantly between pilot and full-scale implementations. Pilot DLE operations typically show promising emissions reductions compared to traditional methods, but scaling considerations often reveal increased energy demands that may partially offset these benefits. Full-scale DLE operations require comprehensive life cycle assessments to accurately quantify their carbon footprint, with current data suggesting a 30-40% reduction in greenhouse gas emissions compared to conventional extraction methods.

Chemical usage presents another environmental consideration, as most DLE technologies employ sorbents, solvents, or membranes that require periodic replacement and proper disposal. The environmental impact of these materials varies widely between different DLE approaches, with ion-exchange resins generally showing lower toxicity profiles than solvent-based systems.

Waste management strategies differ substantially between pilot and commercial implementations. While pilot projects can often manage residual brines and spent materials through specialized handling, full-scale operations require integrated waste management systems. The composition of waste streams from DLE processes typically contains fewer harmful elements than traditional extraction methods, though concentrated salt solutions require careful management to prevent soil and groundwater contamination.

Ecosystem impact monitoring reveals that DLE technologies generally cause less disruption to local hydrology and associated ecosystems than evaporation ponds. However, the extraction and reinjection of subsurface brines may still alter groundwater dynamics, requiring careful monitoring and management, particularly when scaling from pilot to commercial operations.

Economic Feasibility Analysis of Scale-up Operations

The economic feasibility of scaling up Direct Lithium Extraction (DLE) operations from pilot to full scale requires comprehensive analysis of capital expenditures, operational costs, and potential returns on investment. Initial assessments indicate that capital costs for full-scale DLE facilities range from $15,000 to $30,000 per ton of annual lithium carbonate equivalent (LCE) production capacity, significantly higher than traditional evaporation pond methods at early implementation stages.

Operational expenditures demonstrate interesting economies of scale, with pilot operations typically costing $5,000-7,000 per ton of LCE, while optimized full-scale operations can potentially reduce costs to $3,500-5,000 per ton. This cost reduction primarily stems from energy efficiency improvements, reagent recycling capabilities, and labor optimization that become viable at larger scales.

The economic viability threshold appears to be approximately 5,000 tons of annual LCE production, below which the unit economics become challenging. Analysis of existing commercial implementations shows payback periods ranging from 4-7 years for full-scale operations, compared to rarely achieving positive returns for pilot-scale projects that remain in extended testing phases.

Resource quality significantly impacts economic feasibility during scale-up. Lithium brine concentrations above 200 mg/L demonstrate substantially better economics, with each 50 mg/L decrease in concentration approximately doubling energy requirements and increasing operational costs by 30-40%. This relationship becomes even more pronounced at full scale where energy consumption represents 25-35% of operational expenses.

Market dynamics create additional complexity for scale-up economics. Current lithium carbonate prices of $15,000-25,000 per ton support investment in full-scale DLE operations, but historical price volatility suggests incorporating sensitivity analyses for prices as low as $8,000 per ton to ensure long-term viability. Projects demonstrating resilience at these lower price points represent lower investment risk.

Infrastructure requirements present significant hidden costs in scale-up economics. Full-scale operations require substantial investments in water treatment facilities, power supply infrastructure, and transportation logistics that may represent 20-30% of total capital expenditure but are often underestimated in preliminary feasibility studies. Pilot operations typically leverage existing infrastructure, masking these costs during early assessment phases.

Regulatory compliance costs increase non-linearly with scale, particularly regarding environmental monitoring, water rights management, and waste disposal. These expenses typically account for 5-8% of operational costs at full scale but less than 2% at pilot scale, creating an often overlooked economic burden during scale-up planning.

Operational expenditures demonstrate interesting economies of scale, with pilot operations typically costing $5,000-7,000 per ton of LCE, while optimized full-scale operations can potentially reduce costs to $3,500-5,000 per ton. This cost reduction primarily stems from energy efficiency improvements, reagent recycling capabilities, and labor optimization that become viable at larger scales.

The economic viability threshold appears to be approximately 5,000 tons of annual LCE production, below which the unit economics become challenging. Analysis of existing commercial implementations shows payback periods ranging from 4-7 years for full-scale operations, compared to rarely achieving positive returns for pilot-scale projects that remain in extended testing phases.

Resource quality significantly impacts economic feasibility during scale-up. Lithium brine concentrations above 200 mg/L demonstrate substantially better economics, with each 50 mg/L decrease in concentration approximately doubling energy requirements and increasing operational costs by 30-40%. This relationship becomes even more pronounced at full scale where energy consumption represents 25-35% of operational expenses.

Market dynamics create additional complexity for scale-up economics. Current lithium carbonate prices of $15,000-25,000 per ton support investment in full-scale DLE operations, but historical price volatility suggests incorporating sensitivity analyses for prices as low as $8,000 per ton to ensure long-term viability. Projects demonstrating resilience at these lower price points represent lower investment risk.

Infrastructure requirements present significant hidden costs in scale-up economics. Full-scale operations require substantial investments in water treatment facilities, power supply infrastructure, and transportation logistics that may represent 20-30% of total capital expenditure but are often underestimated in preliminary feasibility studies. Pilot operations typically leverage existing infrastructure, masking these costs during early assessment phases.

Regulatory compliance costs increase non-linearly with scale, particularly regarding environmental monitoring, water rights management, and waste disposal. These expenses typically account for 5-8% of operational costs at full scale but less than 2% at pilot scale, creating an often overlooked economic burden during scale-up planning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!