Quantify Water Usage in Direct Lithium Extraction Methods

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Water Usage Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a promising alternative to traditional lithium extraction methods, particularly in response to the exponential growth in lithium demand driven by the electric vehicle revolution and renewable energy storage systems. Historically, lithium production has relied heavily on evaporative brine processing and hard rock mining, both of which present significant environmental challenges, particularly regarding water consumption.

The evolution of lithium extraction technologies has been marked by a continuous search for more sustainable and efficient methods. Traditional evaporation pond techniques, which have dominated the industry for decades, require approximately 500,000 gallons of water per metric ton of lithium produced. This intensive water usage has raised serious concerns, especially in water-stressed regions like the Lithium Triangle in South America, where approximately 65% of global lithium reserves are located.

DLE technologies represent a paradigm shift in lithium production, promising to reduce water consumption by 50-90% compared to conventional methods. These technologies utilize various mechanisms including adsorption, ion exchange, and membrane processes to selectively extract lithium from brine solutions without the need for extensive evaporation ponds.

The primary objective of this technical research is to quantify and compare water usage across different DLE methodologies, establishing a comprehensive framework for evaluating their environmental sustainability. This analysis aims to provide stakeholders with data-driven insights to inform strategic decisions regarding technology adoption and investment in the lithium production sector.

Additionally, this research seeks to identify the key factors influencing water consumption in DLE processes, including operational parameters, technological design considerations, and geographical contexts. By understanding these variables, we can develop optimization strategies to further reduce water footprint in lithium production.

The scope of this investigation encompasses both established DLE technologies currently deployed in commercial operations and emerging innovations at various stages of development. This comprehensive approach ensures that our findings remain relevant as the technological landscape continues to evolve.

Furthermore, this research aims to establish standardized metrics for water usage assessment in lithium extraction, facilitating meaningful comparisons between different technologies and production sites. Such standardization is crucial for transparent sustainability reporting and informed policy development in the rapidly growing lithium industry.

The evolution of lithium extraction technologies has been marked by a continuous search for more sustainable and efficient methods. Traditional evaporation pond techniques, which have dominated the industry for decades, require approximately 500,000 gallons of water per metric ton of lithium produced. This intensive water usage has raised serious concerns, especially in water-stressed regions like the Lithium Triangle in South America, where approximately 65% of global lithium reserves are located.

DLE technologies represent a paradigm shift in lithium production, promising to reduce water consumption by 50-90% compared to conventional methods. These technologies utilize various mechanisms including adsorption, ion exchange, and membrane processes to selectively extract lithium from brine solutions without the need for extensive evaporation ponds.

The primary objective of this technical research is to quantify and compare water usage across different DLE methodologies, establishing a comprehensive framework for evaluating their environmental sustainability. This analysis aims to provide stakeholders with data-driven insights to inform strategic decisions regarding technology adoption and investment in the lithium production sector.

Additionally, this research seeks to identify the key factors influencing water consumption in DLE processes, including operational parameters, technological design considerations, and geographical contexts. By understanding these variables, we can develop optimization strategies to further reduce water footprint in lithium production.

The scope of this investigation encompasses both established DLE technologies currently deployed in commercial operations and emerging innovations at various stages of development. This comprehensive approach ensures that our findings remain relevant as the technological landscape continues to evolve.

Furthermore, this research aims to establish standardized metrics for water usage assessment in lithium extraction, facilitating meaningful comparisons between different technologies and production sites. Such standardization is crucial for transparent sustainability reporting and informed policy development in the rapidly growing lithium industry.

Market Analysis of Water-Efficient Lithium Extraction

The global lithium market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Market projections indicate that lithium demand will increase from approximately 500,000 metric tons of lithium carbonate equivalent (LCE) in 2021 to over 3 million metric tons by 2030, representing a compound annual growth rate exceeding 20%. Within this expanding market, water-efficient lithium extraction methods are gaining significant attention due to increasing environmental concerns and regulatory pressures.

Traditional lithium extraction methods, particularly evaporative brine processing in the "Lithium Triangle" of South America, consume between 500,000 to 2 million gallons of water per ton of lithium produced. This intensive water usage has created substantial market pressure for more sustainable alternatives, especially in water-stressed regions where lithium resources are abundant.

Direct Lithium Extraction (DLE) technologies that minimize water consumption represent a high-growth segment within the broader lithium market. Current market analysis suggests that water-efficient DLE methods could capture 25-30% of new lithium production capacity by 2025, growing to potentially 40-50% by 2030. This transition is being accelerated by ESG (Environmental, Social, and Governance) investment criteria that increasingly favor water-conscious extraction technologies.

The market for water-efficient lithium extraction is segmented by technology type, with ion-exchange, adsorption-based, and membrane separation technologies showing the strongest commercial potential. Geographically, North America and Australia are emerging as key markets for these technologies, with significant investments in pilot plants and commercial facilities.

End-user industries are demonstrating strong willingness to pay premium prices for lithium produced through water-efficient methods. Major automotive manufacturers and battery producers have announced procurement policies that prioritize sustainably sourced materials, creating price differentials of 5-10% for lithium produced with reduced environmental impact.

Market barriers include high capital expenditure requirements for new DLE facilities and technological maturity concerns. However, the return on investment calculations increasingly favor water-efficient methods when factoring in regulatory compliance costs, community relations, and long-term operational sustainability in water-stressed regions.

Competitive dynamics in this market segment show a mix of established mining companies investing in technological transitions and specialized technology startups securing significant venture capital funding. Strategic partnerships between technology providers and resource owners are becoming the dominant market entry strategy, with several major deals announced in the past 24 months.

Traditional lithium extraction methods, particularly evaporative brine processing in the "Lithium Triangle" of South America, consume between 500,000 to 2 million gallons of water per ton of lithium produced. This intensive water usage has created substantial market pressure for more sustainable alternatives, especially in water-stressed regions where lithium resources are abundant.

Direct Lithium Extraction (DLE) technologies that minimize water consumption represent a high-growth segment within the broader lithium market. Current market analysis suggests that water-efficient DLE methods could capture 25-30% of new lithium production capacity by 2025, growing to potentially 40-50% by 2030. This transition is being accelerated by ESG (Environmental, Social, and Governance) investment criteria that increasingly favor water-conscious extraction technologies.

The market for water-efficient lithium extraction is segmented by technology type, with ion-exchange, adsorption-based, and membrane separation technologies showing the strongest commercial potential. Geographically, North America and Australia are emerging as key markets for these technologies, with significant investments in pilot plants and commercial facilities.

End-user industries are demonstrating strong willingness to pay premium prices for lithium produced through water-efficient methods. Major automotive manufacturers and battery producers have announced procurement policies that prioritize sustainably sourced materials, creating price differentials of 5-10% for lithium produced with reduced environmental impact.

Market barriers include high capital expenditure requirements for new DLE facilities and technological maturity concerns. However, the return on investment calculations increasingly favor water-efficient methods when factoring in regulatory compliance costs, community relations, and long-term operational sustainability in water-stressed regions.

Competitive dynamics in this market segment show a mix of established mining companies investing in technological transitions and specialized technology startups securing significant venture capital funding. Strategic partnerships between technology providers and resource owners are becoming the dominant market entry strategy, with several major deals announced in the past 24 months.

Current DLE Water Quantification Challenges

Despite significant advancements in Direct Lithium Extraction (DLE) technologies, quantifying water usage remains one of the most challenging aspects of implementation and optimization. Current methodologies for water usage measurement in DLE processes suffer from inconsistent reporting standards across the industry, making comparative analysis between different extraction methods nearly impossible. This lack of standardization extends to terminology, measurement protocols, and reporting frameworks.

The complexity of water accounting in DLE systems stems from the multifaceted nature of water involvement throughout the process chain. Water serves various functions including as a transport medium, reactant, cooling agent, and washing solution. Distinguishing between consumptive and non-consumptive water usage presents significant technical difficulties, as does accurately tracking water that is recycled within closed-loop systems.

Field measurements of water consumption in operational DLE facilities are hampered by inadequate metering infrastructure. Many pilot projects and even commercial operations lack comprehensive water monitoring systems capable of tracking water flows at each process stage. This creates substantial data gaps that impede accurate water footprint calculations and optimization efforts.

Environmental variables further complicate water quantification efforts. Seasonal variations in water availability, evaporation rates, and source water quality significantly impact overall water usage metrics. These fluctuations are rarely accounted for in current reporting methodologies, leading to potentially misleading efficiency claims.

The distinction between freshwater and brine usage represents another major quantification challenge. While some DLE methods utilize significant volumes of freshwater for processing, others primarily recirculate brine. Current measurement approaches often fail to differentiate between these water types or account for their different environmental impacts and associated costs.

Laboratory-scale water efficiency data frequently fails to translate accurately to commercial-scale operations. Scaling factors are poorly understood, and the relationship between bench-scale water requirements and industrial implementation remains largely theoretical rather than empirically validated.

Regulatory frameworks governing water reporting in lithium extraction vary dramatically across jurisdictions, creating a fragmented landscape of compliance requirements. This regulatory inconsistency further complicates the development of standardized quantification methodologies that could enable meaningful cross-technology comparisons.

The absence of life-cycle assessment (LCA) approaches to water quantification represents a significant gap in current practice. Most water usage reports focus exclusively on operational consumption without considering embedded water in equipment manufacturing, infrastructure development, or post-operational remediation activities.

The complexity of water accounting in DLE systems stems from the multifaceted nature of water involvement throughout the process chain. Water serves various functions including as a transport medium, reactant, cooling agent, and washing solution. Distinguishing between consumptive and non-consumptive water usage presents significant technical difficulties, as does accurately tracking water that is recycled within closed-loop systems.

Field measurements of water consumption in operational DLE facilities are hampered by inadequate metering infrastructure. Many pilot projects and even commercial operations lack comprehensive water monitoring systems capable of tracking water flows at each process stage. This creates substantial data gaps that impede accurate water footprint calculations and optimization efforts.

Environmental variables further complicate water quantification efforts. Seasonal variations in water availability, evaporation rates, and source water quality significantly impact overall water usage metrics. These fluctuations are rarely accounted for in current reporting methodologies, leading to potentially misleading efficiency claims.

The distinction between freshwater and brine usage represents another major quantification challenge. While some DLE methods utilize significant volumes of freshwater for processing, others primarily recirculate brine. Current measurement approaches often fail to differentiate between these water types or account for their different environmental impacts and associated costs.

Laboratory-scale water efficiency data frequently fails to translate accurately to commercial-scale operations. Scaling factors are poorly understood, and the relationship between bench-scale water requirements and industrial implementation remains largely theoretical rather than empirically validated.

Regulatory frameworks governing water reporting in lithium extraction vary dramatically across jurisdictions, creating a fragmented landscape of compliance requirements. This regulatory inconsistency further complicates the development of standardized quantification methodologies that could enable meaningful cross-technology comparisons.

The absence of life-cycle assessment (LCA) approaches to water quantification represents a significant gap in current practice. Most water usage reports focus exclusively on operational consumption without considering embedded water in equipment manufacturing, infrastructure development, or post-operational remediation activities.

Existing Water Quantification Methodologies

01 Water-efficient direct lithium extraction technologies

Advanced direct lithium extraction (DLE) technologies have been developed to minimize water consumption compared to traditional evaporation methods. These technologies utilize selective adsorption materials, ion exchange resins, or membranes that can extract lithium from brines while returning most of the water back to the source. This approach significantly reduces the water footprint of lithium production, making it more environmentally sustainable, especially in water-scarce regions.- Water-efficient direct lithium extraction technologies: Advanced direct lithium extraction (DLE) technologies focus on minimizing water consumption through closed-loop systems and water recycling processes. These methods significantly reduce freshwater requirements compared to traditional evaporation ponds by implementing water recovery systems that capture and reuse process water. The technologies include specialized membranes and filtration systems designed specifically to maximize water efficiency while maintaining effective lithium recovery rates.

- Membrane-based lithium extraction with reduced water footprint: Membrane-based extraction techniques utilize selective membranes to separate lithium ions from brine solutions while minimizing water usage. These systems employ ion-exchange membranes or nanofiltration technologies that allow for selective lithium passage while rejecting other ions. The process operates at ambient temperatures, eliminating water loss through evaporation and reducing overall water consumption. Some systems incorporate water recovery modules that can reclaim up to 90% of process water for reuse.

- Adsorption-based lithium extraction systems with water conservation: Adsorption-based lithium extraction utilizes specialized adsorbent materials that selectively capture lithium ions from brine solutions. These systems require significantly less water than conventional methods as they operate in concentrated solutions without the need for extensive dilution. The process includes water-efficient regeneration cycles where the lithium-loaded adsorbents are stripped using minimal volumes of regeneration solution. Some advanced systems incorporate precipitation techniques that further reduce water requirements during the lithium recovery phase.

- Electrochemical lithium extraction with integrated water management: Electrochemical extraction methods employ electrical potential to selectively extract lithium from brines while implementing sophisticated water management systems. These processes use specialized electrodes and cell designs that minimize water consumption through precise control of electrochemical reactions. The systems often incorporate water purification and recycling components that treat and reuse process water, significantly reducing freshwater intake. Some advanced designs include electrodialysis or capacitive deionization techniques that further enhance water efficiency.

- Hybrid lithium extraction systems with optimized water usage: Hybrid extraction systems combine multiple technologies to optimize both lithium recovery and water efficiency. These integrated approaches may combine adsorption, membrane filtration, and electrochemical methods in sequence to maximize resource efficiency. The systems often incorporate advanced water treatment stages that enable near-complete water recycling between process steps. Some hybrid technologies utilize solar energy for partial concentration of brines before extraction, reducing the overall water footprint while maintaining high lithium recovery rates.

02 Closed-loop water recycling systems in lithium extraction

Closed-loop water systems have been implemented in direct lithium extraction processes to maximize water conservation. These systems capture, treat, and reuse process water multiple times within the extraction circuit, dramatically reducing freshwater requirements. Advanced filtration, purification, and water treatment technologies enable the removal of impurities, allowing for continuous recycling of water throughout the lithium extraction process while maintaining extraction efficiency.Expand Specific Solutions03 Brine reinjection methods for sustainable lithium production

Brine reinjection methods involve returning processed brine back to the source aquifer after lithium extraction, helping to maintain hydrological balance. These methods extract lithium selectively while preserving the overall water volume in the source reservoir. By reinjecting the majority of the brine after lithium removal, these techniques help prevent groundwater depletion and minimize environmental impact on surrounding ecosystems, addressing concerns about water table reduction in lithium-rich regions.Expand Specific Solutions04 Membrane and filtration technologies for water-efficient lithium recovery

Specialized membrane and filtration technologies have been developed specifically for water-efficient lithium recovery. These include nanofiltration, reverse osmosis, and selective membranes that can separate lithium ions from other components in brine solutions while minimizing water loss. The technologies enable more precise separation of lithium from other elements, reducing the need for extensive water usage in subsequent purification steps and allowing for higher recovery rates of both lithium and process water.Expand Specific Solutions05 Alternative water sources for lithium extraction processes

Innovative approaches utilize alternative water sources for lithium extraction processes to reduce pressure on freshwater resources. These methods include using seawater, treated wastewater, or produced water from other industrial processes as input for lithium extraction operations. Some technologies have been specifically designed to extract lithium from unconventional water sources like geothermal brines or oil field produced water, creating dual benefits of lithium production and water treatment while minimizing the demand for fresh water.Expand Specific Solutions

Leading Companies in DLE Water Management

The direct lithium extraction (DLE) technology landscape is evolving rapidly, currently transitioning from early development to commercial implementation phase. The global market is projected to grow significantly as demand for lithium in battery applications surges, with estimates suggesting a multi-billion dollar opportunity by 2030. Technologically, the field shows varying maturity levels across different approaches. Leading players like Schlumberger, Lilac Solutions, and Pure Lithium are advancing membrane and electrochemical technologies, while POSCO Holdings and Saltworks Technologies focus on adsorption-based methods. Academic institutions including University of California and Chinese Academy of Sciences are contributing fundamental research. Water usage efficiency remains a critical differentiator among competitors, with newer entrants like Forager Station and Evove developing solutions specifically targeting water conservation in extraction processes.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed an integrated Direct Lithium Extraction platform called "NeoLith Energy" that incorporates advanced water management systems. Their approach uses selective adsorption technology combined with sophisticated water monitoring and recycling infrastructure. The NeoLith system quantifies water usage through a network of digital sensors and flow meters that track water inputs, outputs, and recycling rates throughout the extraction process. Schlumberger's technology reduces water consumption by up to 85% compared to traditional evaporation methods by implementing a closed-loop design where process water is continuously treated and reused. Their system includes real-time analytics that monitor water quality parameters and optimize treatment processes to maximize recycling efficiency. The company has also developed predictive modeling tools that can forecast water requirements based on brine chemistry, production targets, and environmental conditions, enabling proactive water management strategies.

Strengths: Leverages extensive oil and gas industry expertise in fluid management; comprehensive digital monitoring provides precise water usage data; integrated approach addresses the entire extraction process. Weaknesses: Technology is still being scaled up from pilot to commercial operations; requires significant technical expertise to operate; higher initial capital investment compared to conventional methods.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed advanced membrane-based separation technologies for Direct Lithium Extraction that focus on water conservation and reuse. Their system employs specialized nanofiltration and reverse osmosis membranes that enable selective lithium recovery while minimizing water consumption. The company has implemented comprehensive water accounting methodologies that track water usage across the entire extraction process, from initial brine processing to lithium concentration and purification. Their technology incorporates a multi-stage water recovery system that captures and treats process water for reuse, achieving water recycling rates exceeding 85%. Koch's approach includes sophisticated sensors and flow meters that provide continuous data on water volumes and quality at each process stage, enabling precise quantification of net water consumption. The company has also developed predictive modeling tools that optimize water usage based on brine chemistry and desired lithium output specifications.

Strengths: Extensive experience in industrial-scale membrane technologies; comprehensive water accounting systems provide accurate usage metrics; high water recycling capabilities reduce environmental impact. Weaknesses: Membrane fouling can occur in certain brine compositions requiring additional maintenance; higher energy requirements for membrane-based systems compared to some alternatives; initial capital costs are significant.

Key Technologies for Water Usage Monitoring

Method of extracting lithium from lithium-containing solution

PatentPendingUS20230038391A1

Innovation

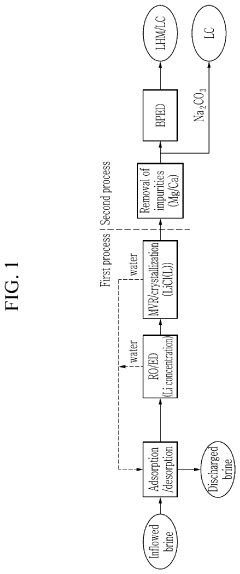

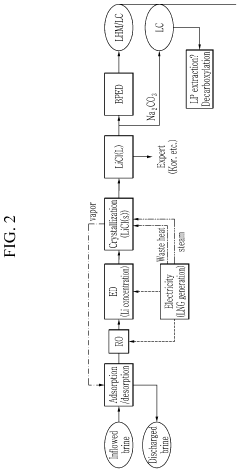

- A method involving the crystallization and removal of sodium chloride from a lithium chloride solution using vacuum evaporation, followed by lithium chloride concentration through adsorption, reverse osmosis, electrodialysis, and bipolar electrodialysis to produce lithium hydroxide or carbonate, minimizing chemical use and reusing water, thereby reducing environmental impact and costs.

Lithium ion adsorbents

PatentPendingEP4223409A1

Innovation

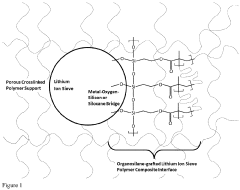

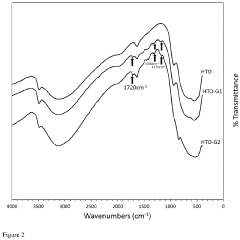

- Development of an organosilane-grafted lithium ion sieve covalently incorporated into a porous crosslinked polymeric support scaffold, enhancing selectivity and durability through improved porosity and resistance to degradation under turbulent and high-temperature conditions.

Environmental Impact Assessment Framework

The Environmental Impact Assessment Framework for Direct Lithium Extraction (DLE) methods requires a comprehensive approach to quantify water usage across the entire extraction process. This framework must establish standardized metrics and methodologies to accurately measure water consumption, enabling meaningful comparisons between different DLE technologies and conventional lithium extraction methods.

The framework should incorporate a life-cycle assessment perspective, tracking water usage from initial extraction through processing and waste management. Key water-related metrics must include total water withdrawal, consumptive use, water quality impacts, and water recycling efficiency. These metrics should be normalized per unit of lithium produced to facilitate technology comparison and benchmarking against industry standards.

Water footprint analysis must distinguish between different water sources (freshwater, brackish water, seawater) and account for regional water stress conditions where extraction occurs. This contextual analysis is crucial as the environmental significance of water usage varies dramatically between water-abundant and water-scarce regions. The framework should incorporate regional water availability indices to weight the impact of water consumption based on local hydrological conditions.

Temporal considerations are equally important within the assessment framework. Seasonal variations in water availability and usage patterns should be documented, particularly in regions with pronounced wet and dry seasons. The framework must also account for long-term changes in water availability due to climate change projections, ensuring that water usage assessments remain relevant over the operational lifetime of extraction facilities.

Uncertainty analysis should be integrated into the framework, acknowledging limitations in measurement techniques and data availability. This includes establishing confidence intervals for water usage estimates and identifying key variables that contribute most significantly to uncertainty. Sensitivity analysis can help determine how changes in process parameters affect overall water consumption, guiding optimization efforts.

The framework should establish clear reporting protocols and verification mechanisms to ensure transparency and accountability. This includes third-party verification procedures, regular auditing requirements, and standardized reporting formats that facilitate comparison across the industry. Public disclosure of water usage data should be encouraged to promote industry-wide improvements and stakeholder trust.

Finally, the framework must provide guidance for continuous improvement, establishing water efficiency targets and best practices for water management in DLE operations. This includes recommendations for water recycling systems, process optimization strategies, and alternative water sourcing options to minimize environmental impact while maintaining economic viability.

The framework should incorporate a life-cycle assessment perspective, tracking water usage from initial extraction through processing and waste management. Key water-related metrics must include total water withdrawal, consumptive use, water quality impacts, and water recycling efficiency. These metrics should be normalized per unit of lithium produced to facilitate technology comparison and benchmarking against industry standards.

Water footprint analysis must distinguish between different water sources (freshwater, brackish water, seawater) and account for regional water stress conditions where extraction occurs. This contextual analysis is crucial as the environmental significance of water usage varies dramatically between water-abundant and water-scarce regions. The framework should incorporate regional water availability indices to weight the impact of water consumption based on local hydrological conditions.

Temporal considerations are equally important within the assessment framework. Seasonal variations in water availability and usage patterns should be documented, particularly in regions with pronounced wet and dry seasons. The framework must also account for long-term changes in water availability due to climate change projections, ensuring that water usage assessments remain relevant over the operational lifetime of extraction facilities.

Uncertainty analysis should be integrated into the framework, acknowledging limitations in measurement techniques and data availability. This includes establishing confidence intervals for water usage estimates and identifying key variables that contribute most significantly to uncertainty. Sensitivity analysis can help determine how changes in process parameters affect overall water consumption, guiding optimization efforts.

The framework should establish clear reporting protocols and verification mechanisms to ensure transparency and accountability. This includes third-party verification procedures, regular auditing requirements, and standardized reporting formats that facilitate comparison across the industry. Public disclosure of water usage data should be encouraged to promote industry-wide improvements and stakeholder trust.

Finally, the framework must provide guidance for continuous improvement, establishing water efficiency targets and best practices for water management in DLE operations. This includes recommendations for water recycling systems, process optimization strategies, and alternative water sourcing options to minimize environmental impact while maintaining economic viability.

Regulatory Compliance for Water Usage in Mining

The regulatory landscape for water usage in mining operations, particularly for lithium extraction, has become increasingly stringent worldwide as water scarcity concerns intensify. Companies engaged in Direct Lithium Extraction (DLE) must navigate complex compliance frameworks that vary significantly across jurisdictions, with some regions implementing volumetric limits on water withdrawal while others focus on quality parameters for discharge.

In the United States, the Environmental Protection Agency (EPA) regulates water usage in mining through the Clean Water Act and Safe Drinking Water Act, requiring permits for water withdrawal and discharge. The Bureau of Land Management imposes additional requirements for operations on federal lands. California, a key lithium production region, has implemented the Sustainable Groundwater Management Act, which directly impacts DLE operations in the Salton Sea area by requiring detailed water accounting and sustainability plans.

Chile and Argentina, major players in the "Lithium Triangle," have established water-specific regulations for mining operations in their arid regions. Chile's water code requires companies to obtain water rights and demonstrate sustainable usage patterns, with recent amendments prioritizing human consumption over industrial use. Argentina's federal system creates a patchwork of provincial regulations, though most require environmental impact assessments with specific water usage components.

Compliance monitoring has evolved significantly, with regulatory bodies increasingly requiring real-time water metering and reporting. Advanced monitoring technologies including flow meters, automated sampling systems, and satellite-based monitoring are becoming standard requirements in many jurisdictions. Companies must implement comprehensive water accounting systems that track withdrawal, consumption, recycling, and discharge volumes with high precision.

Non-compliance penalties have increased substantially, ranging from significant financial penalties to operational restrictions and license revocations. In Chile, water rights can be revoked for excessive usage, while in Australia, non-compliance can trigger comprehensive environmental audits and mandatory operational changes. These enforcement mechanisms reflect the growing recognition of water as a critical resource requiring stringent protection.

Forward-looking companies are adopting proactive compliance strategies, implementing water stewardship programs that exceed regulatory requirements. These programs typically include water recycling initiatives, community engagement on water issues, and transparent reporting frameworks. Such approaches not only ensure regulatory compliance but also address growing investor and consumer concerns regarding environmental sustainability in the mining sector.

In the United States, the Environmental Protection Agency (EPA) regulates water usage in mining through the Clean Water Act and Safe Drinking Water Act, requiring permits for water withdrawal and discharge. The Bureau of Land Management imposes additional requirements for operations on federal lands. California, a key lithium production region, has implemented the Sustainable Groundwater Management Act, which directly impacts DLE operations in the Salton Sea area by requiring detailed water accounting and sustainability plans.

Chile and Argentina, major players in the "Lithium Triangle," have established water-specific regulations for mining operations in their arid regions. Chile's water code requires companies to obtain water rights and demonstrate sustainable usage patterns, with recent amendments prioritizing human consumption over industrial use. Argentina's federal system creates a patchwork of provincial regulations, though most require environmental impact assessments with specific water usage components.

Compliance monitoring has evolved significantly, with regulatory bodies increasingly requiring real-time water metering and reporting. Advanced monitoring technologies including flow meters, automated sampling systems, and satellite-based monitoring are becoming standard requirements in many jurisdictions. Companies must implement comprehensive water accounting systems that track withdrawal, consumption, recycling, and discharge volumes with high precision.

Non-compliance penalties have increased substantially, ranging from significant financial penalties to operational restrictions and license revocations. In Chile, water rights can be revoked for excessive usage, while in Australia, non-compliance can trigger comprehensive environmental audits and mandatory operational changes. These enforcement mechanisms reflect the growing recognition of water as a critical resource requiring stringent protection.

Forward-looking companies are adopting proactive compliance strategies, implementing water stewardship programs that exceed regulatory requirements. These programs typically include water recycling initiatives, community engagement on water issues, and transparent reporting frameworks. Such approaches not only ensure regulatory compliance but also address growing investor and consumer concerns regarding environmental sustainability in the mining sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!