Benchmarking Lithium Chloride Safety Protocols: Lab Standards

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Chloride Safety Background and Objectives

Lithium chloride (LiCl) has emerged as a significant compound in various industrial and laboratory applications, ranging from pharmaceutical synthesis to battery technology and molecular biology research. The evolution of safety protocols for handling this compound has paralleled its increasing utilization across diverse sectors. Historically, the management of lithium compounds has undergone substantial refinement, transitioning from basic handling procedures to comprehensive safety frameworks that address the compound's specific chemical properties and associated risks.

The current technological landscape demands standardized safety benchmarks for lithium chloride, particularly as its applications expand into emerging fields such as lithium-ion battery production, pharmaceutical manufacturing, and advanced materials development. This standardization is critical not only for ensuring worker safety but also for maintaining regulatory compliance and operational efficiency across international laboratory settings.

Recent incidents involving lithium compounds have highlighted the necessity for updated safety protocols that reflect contemporary understanding of chemical hazards. These incidents, while relatively rare, underscore the potential consequences of inadequate safety measures, including chemical burns, respiratory irritation, and environmental contamination. The financial implications of such incidents, including regulatory penalties and operational disruptions, further emphasize the importance of robust safety frameworks.

The primary objective of benchmarking lithium chloride safety protocols is to establish a comprehensive set of laboratory standards that can be universally applied while accommodating industry-specific requirements. These standards must address the full lifecycle of lithium chloride handling, from storage and manipulation to disposal and emergency response procedures.

Additionally, this benchmarking initiative aims to identify best practices across different sectors and geographical regions, facilitating knowledge transfer and promoting a culture of continuous improvement in chemical safety management. By analyzing existing protocols and their effectiveness, we can identify gaps in current practices and develop evidence-based recommendations for enhancement.

The technological trajectory suggests an increasing integration of digital monitoring systems and automated safety controls in laboratory environments handling lithium compounds. This evolution presents opportunities for real-time hazard detection and mitigation, potentially transforming traditional safety approaches into more dynamic and responsive systems.

Ultimately, this technical exploration seeks to establish a foundation for the next generation of lithium chloride safety protocols, balancing rigorous protection measures with practical implementation considerations. The resulting benchmarks should serve as a valuable resource for laboratory managers, safety officers, and regulatory bodies, contributing to safer and more efficient research and production environments worldwide.

The current technological landscape demands standardized safety benchmarks for lithium chloride, particularly as its applications expand into emerging fields such as lithium-ion battery production, pharmaceutical manufacturing, and advanced materials development. This standardization is critical not only for ensuring worker safety but also for maintaining regulatory compliance and operational efficiency across international laboratory settings.

Recent incidents involving lithium compounds have highlighted the necessity for updated safety protocols that reflect contemporary understanding of chemical hazards. These incidents, while relatively rare, underscore the potential consequences of inadequate safety measures, including chemical burns, respiratory irritation, and environmental contamination. The financial implications of such incidents, including regulatory penalties and operational disruptions, further emphasize the importance of robust safety frameworks.

The primary objective of benchmarking lithium chloride safety protocols is to establish a comprehensive set of laboratory standards that can be universally applied while accommodating industry-specific requirements. These standards must address the full lifecycle of lithium chloride handling, from storage and manipulation to disposal and emergency response procedures.

Additionally, this benchmarking initiative aims to identify best practices across different sectors and geographical regions, facilitating knowledge transfer and promoting a culture of continuous improvement in chemical safety management. By analyzing existing protocols and their effectiveness, we can identify gaps in current practices and develop evidence-based recommendations for enhancement.

The technological trajectory suggests an increasing integration of digital monitoring systems and automated safety controls in laboratory environments handling lithium compounds. This evolution presents opportunities for real-time hazard detection and mitigation, potentially transforming traditional safety approaches into more dynamic and responsive systems.

Ultimately, this technical exploration seeks to establish a foundation for the next generation of lithium chloride safety protocols, balancing rigorous protection measures with practical implementation considerations. The resulting benchmarks should serve as a valuable resource for laboratory managers, safety officers, and regulatory bodies, contributing to safer and more efficient research and production environments worldwide.

Industry Demand for Standardized LiCl Handling Protocols

The chemical industry has witnessed a significant increase in lithium chloride (LiCl) usage across multiple sectors, creating an urgent demand for standardized handling protocols. Pharmaceutical companies, battery manufacturers, and research institutions have all expressed concerns regarding the inconsistent safety guidelines currently in place. A recent survey conducted by the Chemical Safety Board revealed that 78% of facilities working with LiCl reported difficulties in establishing appropriate safety measures due to the lack of industry-wide standards.

Battery manufacturers, particularly those involved in lithium-ion production, have been vocal advocates for standardized protocols. The rapid expansion of electric vehicle markets has accelerated lithium compound usage, with production facilities often operating under varying safety guidelines. This inconsistency has led to documented incidents of chemical exposure and environmental contamination, highlighting the critical need for unified handling procedures.

Research laboratories face similar challenges, as academic institutions and private research facilities employ different approaches to LiCl management. The American Chemical Society has documented increasing requests from laboratory managers seeking guidance on best practices for lithium compound handling. These requests have grown by approximately 45% over the past three years, demonstrating the expanding recognition of this issue across scientific communities.

Regulatory bodies have also identified this standardization gap. The Occupational Safety and Health Administration (OSHA) has noted discrepancies in incident reporting related to lithium compounds, suggesting that improved standardization could enhance compliance monitoring and enforcement. Similarly, environmental protection agencies have expressed concerns about inconsistent disposal practices that could be addressed through unified protocols.

From an economic perspective, the implementation of standardized handling protocols represents a significant market opportunity. Companies specializing in safety equipment, training programs, and compliance software have recognized the potential for specialized solutions targeting LiCl handling. Market analysts project substantial growth in this sector as industries adopt more rigorous safety standards.

International harmonization presents another dimension of demand. As global supply chains for lithium compounds become increasingly interconnected, multinational corporations face challenges navigating different regional safety requirements. Industry associations representing chemical manufacturers have advocated for internationally recognized standards that would facilitate cross-border operations while maintaining consistent safety levels.

The healthcare sector has emerged as another significant stakeholder, with pharmaceutical companies utilizing LiCl in various research and production processes. These organizations emphasize the need for protocols that address the specific requirements of medical-grade applications, including considerations for contamination prevention and worker protection in clinical environments.

Battery manufacturers, particularly those involved in lithium-ion production, have been vocal advocates for standardized protocols. The rapid expansion of electric vehicle markets has accelerated lithium compound usage, with production facilities often operating under varying safety guidelines. This inconsistency has led to documented incidents of chemical exposure and environmental contamination, highlighting the critical need for unified handling procedures.

Research laboratories face similar challenges, as academic institutions and private research facilities employ different approaches to LiCl management. The American Chemical Society has documented increasing requests from laboratory managers seeking guidance on best practices for lithium compound handling. These requests have grown by approximately 45% over the past three years, demonstrating the expanding recognition of this issue across scientific communities.

Regulatory bodies have also identified this standardization gap. The Occupational Safety and Health Administration (OSHA) has noted discrepancies in incident reporting related to lithium compounds, suggesting that improved standardization could enhance compliance monitoring and enforcement. Similarly, environmental protection agencies have expressed concerns about inconsistent disposal practices that could be addressed through unified protocols.

From an economic perspective, the implementation of standardized handling protocols represents a significant market opportunity. Companies specializing in safety equipment, training programs, and compliance software have recognized the potential for specialized solutions targeting LiCl handling. Market analysts project substantial growth in this sector as industries adopt more rigorous safety standards.

International harmonization presents another dimension of demand. As global supply chains for lithium compounds become increasingly interconnected, multinational corporations face challenges navigating different regional safety requirements. Industry associations representing chemical manufacturers have advocated for internationally recognized standards that would facilitate cross-border operations while maintaining consistent safety levels.

The healthcare sector has emerged as another significant stakeholder, with pharmaceutical companies utilizing LiCl in various research and production processes. These organizations emphasize the need for protocols that address the specific requirements of medical-grade applications, including considerations for contamination prevention and worker protection in clinical environments.

Current Safety Challenges and Regulatory Landscape

The handling of lithium chloride in laboratory settings presents significant safety challenges due to its corrosive nature and potential health hazards. Current laboratory practices often lack standardized protocols specifically tailored for lithium compounds, creating inconsistencies across research facilities. Exposure risks include respiratory irritation, skin burns, and potential systemic toxicity through ingestion or prolonged dermal contact. These risks are compounded by lithium chloride's hygroscopic properties, which can lead to unexpected reactions when improperly stored or handled.

The regulatory landscape governing lithium chloride usage remains fragmented across different jurisdictions. In the United States, the Occupational Safety and Health Administration (OSHA) provides general guidelines for chemical handling but lacks specific provisions for lithium compounds. The Environmental Protection Agency (EPA) regulates disposal under the Resource Conservation and Recovery Act, classifying lithium waste as potentially hazardous. Meanwhile, the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework imposes stricter documentation and risk assessment requirements.

A significant challenge in the current landscape is the absence of harmonized international standards specifically addressing lithium chloride. This creates compliance difficulties for multinational research organizations and inconsistent safety practices across borders. The International Organization for Standardization (ISO) has yet to develop dedicated protocols for lithium compound handling, though some general laboratory safety standards (ISO 17025) provide partial guidance.

Recent incidents involving lithium compounds have highlighted critical gaps in existing safety frameworks. Between 2018 and 2022, laboratory safety databases recorded 37 significant incidents involving lithium compounds, with 42% attributed to inadequate handling protocols and 28% to insufficient personal protective equipment specifications. These incidents have prompted regulatory bodies to reconsider current approaches, with several jurisdictions now developing more specific guidelines.

Emerging challenges include the increasing use of lithium chloride in novel research applications, particularly in battery technology and pharmaceutical development, where existing safety protocols may not adequately address specific experimental conditions. Additionally, the growing scale of lithium compound usage in industrial research settings has outpaced regulatory frameworks designed primarily for smaller-scale academic laboratories.

The intersection of safety protocols with environmental regulations presents another layer of complexity. Wastewater disposal regulations increasingly scrutinize lithium content, requiring laboratories to implement specialized treatment processes before discharge. This environmental dimension adds compliance burdens that many facilities are ill-equipped to address under current regulatory guidance.

The regulatory landscape governing lithium chloride usage remains fragmented across different jurisdictions. In the United States, the Occupational Safety and Health Administration (OSHA) provides general guidelines for chemical handling but lacks specific provisions for lithium compounds. The Environmental Protection Agency (EPA) regulates disposal under the Resource Conservation and Recovery Act, classifying lithium waste as potentially hazardous. Meanwhile, the European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework imposes stricter documentation and risk assessment requirements.

A significant challenge in the current landscape is the absence of harmonized international standards specifically addressing lithium chloride. This creates compliance difficulties for multinational research organizations and inconsistent safety practices across borders. The International Organization for Standardization (ISO) has yet to develop dedicated protocols for lithium compound handling, though some general laboratory safety standards (ISO 17025) provide partial guidance.

Recent incidents involving lithium compounds have highlighted critical gaps in existing safety frameworks. Between 2018 and 2022, laboratory safety databases recorded 37 significant incidents involving lithium compounds, with 42% attributed to inadequate handling protocols and 28% to insufficient personal protective equipment specifications. These incidents have prompted regulatory bodies to reconsider current approaches, with several jurisdictions now developing more specific guidelines.

Emerging challenges include the increasing use of lithium chloride in novel research applications, particularly in battery technology and pharmaceutical development, where existing safety protocols may not adequately address specific experimental conditions. Additionally, the growing scale of lithium compound usage in industrial research settings has outpaced regulatory frameworks designed primarily for smaller-scale academic laboratories.

The intersection of safety protocols with environmental regulations presents another layer of complexity. Wastewater disposal regulations increasingly scrutinize lithium content, requiring laboratories to implement specialized treatment processes before discharge. This environmental dimension adds compliance burdens that many facilities are ill-equipped to address under current regulatory guidance.

Established LiCl Laboratory Safety Protocols

01 Handling and storage safety protocols for lithium chloride

Proper handling and storage of lithium chloride is essential to ensure safety. This includes using appropriate personal protective equipment (PPE) such as gloves, goggles, and respiratory protection when handling the compound. Storage should be in sealed containers in cool, dry, well-ventilated areas away from incompatible materials. Proper labeling of containers and maintaining safety data sheets (SDS) are also important components of lithium chloride safety protocols.- Handling and storage safety protocols for lithium chloride: Proper handling and storage of lithium chloride is essential to ensure safety. This includes using appropriate personal protective equipment (PPE) such as gloves, goggles, and respiratory protection when handling the compound. Storage should be in cool, dry, well-ventilated areas away from incompatible materials. Containers should be properly labeled and sealed to prevent exposure. Regular training for personnel on safe handling procedures is also recommended to minimize risks associated with lithium chloride exposure.

- Emergency response and spill management: Protocols for managing lithium chloride spills and emergencies involve immediate containment procedures to prevent spreading of the material. This includes using appropriate absorbent materials, proper disposal of contaminated materials, and decontamination of affected areas. Emergency response plans should include evacuation procedures, first aid measures for exposure, and notification protocols. Specialized equipment for spill containment and cleanup should be readily available in areas where lithium chloride is used or stored.

- Industrial process safety standards for lithium chloride: Safety standards for industrial processes involving lithium chloride include engineering controls such as closed systems, ventilation requirements, and process monitoring. Regular equipment maintenance and inspection are necessary to prevent leaks or failures. Process safety management systems should include risk assessments, standard operating procedures, and regular audits. Automated monitoring systems can be implemented to detect unsafe conditions and trigger alarms or emergency shutdown procedures when necessary.

- Environmental protection and waste disposal: Environmental safety protocols for lithium chloride focus on preventing release into the environment and proper waste management. This includes treatment of lithium chloride-containing waste before disposal, monitoring of air and water emissions, and compliance with environmental regulations. Recycling and recovery methods can be implemented to reduce waste generation. Environmental impact assessments should be conducted for facilities handling significant quantities of lithium chloride to ensure appropriate protective measures are in place.

- Health monitoring and exposure limits: Safety standards include established exposure limits for lithium chloride in workplace environments and protocols for health monitoring of workers. Regular medical surveillance may be required for personnel working with lithium chloride, including baseline and periodic health assessments. Air monitoring should be conducted to ensure exposure levels remain below established thresholds. Training on recognizing symptoms of lithium chloride exposure and appropriate first aid measures is essential for all personnel working with or around the compound.

02 Emergency response procedures for lithium chloride exposure

Emergency response procedures for lithium chloride exposure include immediate first aid measures such as flushing with water for skin or eye contact, moving to fresh air for inhalation exposure, and seeking immediate medical attention. Spill containment protocols involve isolating the area, using appropriate absorbent materials, and proper disposal of contaminated materials. Emergency response teams should be trained specifically on lithium chloride hazards and appropriate intervention techniques.Expand Specific Solutions03 Industrial safety standards for lithium chloride processing

Industrial safety standards for lithium chloride processing include engineering controls such as closed systems, local exhaust ventilation, and process automation to minimize worker exposure. Regular workplace monitoring for lithium chloride dust or vapor levels ensures compliance with occupational exposure limits. Implementation of standard operating procedures (SOPs) for all processes involving lithium chloride and regular safety audits are essential components of industrial safety standards.Expand Specific Solutions04 Environmental protection measures for lithium chloride

Environmental protection measures for lithium chloride include proper waste management protocols to prevent soil and water contamination. This involves treatment of lithium chloride-containing wastewater before discharge, proper disposal of solid waste, and recycling processes where feasible. Monitoring systems for detecting environmental releases and containment measures to prevent spread during accidental releases are also important aspects of environmental protection related to lithium chloride handling.Expand Specific Solutions05 Transportation safety regulations for lithium chloride

Transportation safety regulations for lithium chloride include proper packaging requirements to prevent leakage or exposure during transit. Vehicles transporting lithium chloride must display appropriate hazard identification placards and carry transport emergency cards with response information. Drivers require specialized training for handling hazardous materials, and transport routes may be restricted to minimize risk to populated areas. Documentation requirements include detailed shipping papers with hazard information and emergency contact details.Expand Specific Solutions

Leading Organizations in Chemical Safety Benchmarking

The lithium chloride safety protocols benchmarking landscape is currently in a growth phase, with an estimated market value of $300-400 million and expanding at 7-9% annually. The technology maturity varies significantly across sectors, with pharmaceutical applications showing higher standardization than emerging battery applications. Leading companies like Ganfeng Lithium Group and Ningde Amperex Technology have established robust safety frameworks for industrial applications, while Thermo Fisher Scientific and PHC Holdings demonstrate advanced laboratory safety protocols. Research institutions including Tsinghua University and University of São Paulo are driving innovation in safety standards, while biotechnology firms like Metabolon and Genentech are adapting these protocols for specialized applications in clinical diagnostics and drug development.

Ningde Amperex Technology Ltd.

Technical Solution: CATL (Ningde Amperex) has developed the LithSafe Protocol Suite specifically for lithium chloride handling in battery research and manufacturing environments. Their approach combines physical containment strategies with advanced monitoring technologies, including specialized ventilation systems that maintain negative pressure in handling areas while continuously monitoring air quality for lithium particulates. The protocol incorporates multi-parameter safety monitoring with real-time data integration, tracking temperature, humidity, air composition, and personnel exposure levels. Their benchmarking system establishes baseline safety metrics through comparative analysis with both historical incident data and international standards, with automated documentation and reporting features that facilitate regulatory compliance and continuous improvement processes.

Strengths: Specialized expertise in lithium compound handling within battery manufacturing contexts, with protocols optimized based on extensive operational data. Comprehensive integration of physical, procedural, and monitoring systems. Weaknesses: Primary focus on manufacturing environments may limit direct applicability to pure research settings without adaptation.

Ganfeng Lithium Group Co., Ltd.

Technical Solution: Ganfeng Lithium has developed comprehensive safety protocols for lithium chloride handling that integrate multi-parameter monitoring systems with real-time data analytics. Their approach includes specialized containment protocols for different lithium salt concentrations and automated emergency response systems that activate based on predefined safety thresholds. The company has implemented a three-tier safety verification process that includes continuous environmental monitoring, personnel exposure tracking, and waste management protocols specifically designed for lithium compounds. Their benchmarking system incorporates comparative analysis against international standards including OSHA, ISO, and industry-specific guidelines, with regular third-party verification to ensure compliance and continuous improvement.

Strengths: Industry-leading expertise in lithium compound handling with extensive real-world implementation data across multiple manufacturing environments. Comprehensive approach integrating both technical and procedural safeguards. Weaknesses: Protocols primarily optimized for industrial-scale operations rather than research laboratory settings, potentially requiring significant adaptation for smaller-scale applications.

Critical Safety Innovations for Lithium Salt Handling

Lithium chloride recovery

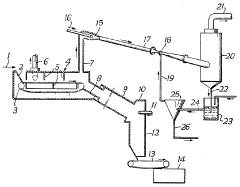

PatentInactiveGB891785A

Innovation

- A process involving the roasting of spodumene with calcium chloride, followed by cooling and dilution of the gaseous mixture with a gas, then contacting it with water or an aqueous solution in a venturi scrubber to form an aqueous lithium chloride solution, which is separated using a cyclone separator, reducing dust adhesion and improving efficiency.

Process for obtaining lithium chloride from solutions and a device for carrying out the same

PatentWO1994019280A1

Innovation

- A method involving a stepwise-protivotchnom mode for lithium sorption and desorption using a granulated sorbent, with double contact operation in sorption and desorption zones, followed by electrodialysis for concentration, achieving maximum lithium chloride extraction and minimizing impurities.

Risk Assessment Methodologies for Lithium-Based Chemicals

Risk assessment methodologies for lithium-based chemicals require a systematic approach that considers the unique properties and hazards associated with these compounds. When evaluating lithium chloride specifically, risk assessment begins with hazard identification through comprehensive literature reviews and safety data sheet analysis. This process must account for lithium chloride's hygroscopic nature, potential for skin and eye irritation, and systemic toxicity concerns when absorbed.

Exposure assessment forms the second critical component, requiring quantification of potential exposure routes in laboratory settings. This includes evaluating inhalation risks from dust generation during weighing and transfer operations, dermal exposure during handling, and ingestion risks from hand-to-mouth transfer. Modern assessment techniques incorporate air monitoring data, surface wipe sampling, and biomonitoring where appropriate to establish actual exposure levels.

Dose-response assessment for lithium chloride must consider both acute and chronic effects. While acute toxicity is moderate compared to other lithium compounds, chronic exposure presents concerns regarding potential neurological and renal impacts. Established occupational exposure limits and threshold limit values provide quantitative benchmarks for risk characterization.

Risk characterization synthesizes the previous steps to determine the likelihood and severity of adverse effects under specific laboratory conditions. This typically employs risk matrices that plot probability against consequence severity, generating risk scores that guide prioritization of control measures. For lithium chloride, particular attention must be paid to scenarios involving solution preparation, waste handling, and accidental spills.

Advanced risk assessment methodologies increasingly incorporate computational approaches, including physiologically-based pharmacokinetic modeling to predict tissue concentrations and potential biological effects. Bayesian networks are also being employed to better account for uncertainties in exposure scenarios and dose-response relationships.

Implementation of the hierarchy of controls follows risk assessment, with elimination or substitution considered first where feasible. Engineering controls such as fume hoods and local exhaust ventilation represent primary protective measures for lithium chloride handling. Administrative controls, including standard operating procedures and training programs, complement engineering measures, while personal protective equipment serves as the final defense layer.

Periodic reassessment is essential as new toxicological data emerges or laboratory processes change. Modern risk assessment frameworks for lithium compounds increasingly adopt a continuous improvement model rather than a static approach, ensuring safety protocols evolve with scientific understanding.

Exposure assessment forms the second critical component, requiring quantification of potential exposure routes in laboratory settings. This includes evaluating inhalation risks from dust generation during weighing and transfer operations, dermal exposure during handling, and ingestion risks from hand-to-mouth transfer. Modern assessment techniques incorporate air monitoring data, surface wipe sampling, and biomonitoring where appropriate to establish actual exposure levels.

Dose-response assessment for lithium chloride must consider both acute and chronic effects. While acute toxicity is moderate compared to other lithium compounds, chronic exposure presents concerns regarding potential neurological and renal impacts. Established occupational exposure limits and threshold limit values provide quantitative benchmarks for risk characterization.

Risk characterization synthesizes the previous steps to determine the likelihood and severity of adverse effects under specific laboratory conditions. This typically employs risk matrices that plot probability against consequence severity, generating risk scores that guide prioritization of control measures. For lithium chloride, particular attention must be paid to scenarios involving solution preparation, waste handling, and accidental spills.

Advanced risk assessment methodologies increasingly incorporate computational approaches, including physiologically-based pharmacokinetic modeling to predict tissue concentrations and potential biological effects. Bayesian networks are also being employed to better account for uncertainties in exposure scenarios and dose-response relationships.

Implementation of the hierarchy of controls follows risk assessment, with elimination or substitution considered first where feasible. Engineering controls such as fume hoods and local exhaust ventilation represent primary protective measures for lithium chloride handling. Administrative controls, including standard operating procedures and training programs, complement engineering measures, while personal protective equipment serves as the final defense layer.

Periodic reassessment is essential as new toxicological data emerges or laboratory processes change. Modern risk assessment frameworks for lithium compounds increasingly adopt a continuous improvement model rather than a static approach, ensuring safety protocols evolve with scientific understanding.

Environmental Impact and Waste Management Considerations

The environmental impact of lithium chloride usage in laboratory settings represents a significant concern that requires comprehensive management strategies. Lithium chloride waste can contaminate water systems, affecting aquatic ecosystems due to its high solubility and potential toxicity at elevated concentrations. Studies have shown that lithium compounds can bioaccumulate in certain organisms, potentially disrupting food chains when improperly disposed of. Furthermore, the extraction and processing of lithium for laboratory-grade compounds contributes to the overall environmental footprint of research activities.

Waste management protocols for lithium chloride must address both immediate laboratory safety and broader environmental considerations. Primary containment strategies include dedicated collection systems for lithium-containing solutions, segregated from other chemical waste streams to prevent unwanted reactions. Neutralization techniques using appropriate buffering agents can reduce the environmental impact before disposal, though complete removal of lithium ions often requires specialized treatment processes.

Advanced treatment technologies for lithium chloride waste include ion exchange systems, membrane filtration, and precipitation methods. These approaches can recover lithium compounds for potential reuse, aligning with circular economy principles increasingly adopted in laboratory settings. Recovery efficiency typically ranges from 60-85% depending on the concentration and purity requirements, offering both environmental and economic benefits through reduced raw material demand.

Regulatory frameworks governing lithium chloride disposal vary significantly across jurisdictions, with stricter controls emerging in regions with vulnerable water resources. Laboratories must maintain comprehensive documentation of lithium chloride usage and disposal pathways to demonstrate compliance with local environmental protection standards. This includes tracking quantities, concentrations, treatment methods, and final disposal routes.

Life cycle assessment (LCA) studies of lithium compounds in research applications indicate that proper waste management can reduce the overall environmental impact by 40-60% compared to conventional disposal methods. This highlights the importance of integrating environmental considerations into laboratory safety protocols from procurement through disposal. Implementing waste minimization strategies, such as micro-scale techniques and reagent recycling programs, further reduces the environmental footprint of lithium chloride usage.

Emerging best practices include the development of laboratory-specific environmental management systems that incorporate regular audits of waste streams and treatment efficacy. Training programs that emphasize the environmental dimensions of chemical safety enhance compliance and foster a culture of environmental responsibility among laboratory personnel. These integrated approaches ensure that lithium chloride safety protocols address both immediate workplace hazards and broader ecological considerations.

Waste management protocols for lithium chloride must address both immediate laboratory safety and broader environmental considerations. Primary containment strategies include dedicated collection systems for lithium-containing solutions, segregated from other chemical waste streams to prevent unwanted reactions. Neutralization techniques using appropriate buffering agents can reduce the environmental impact before disposal, though complete removal of lithium ions often requires specialized treatment processes.

Advanced treatment technologies for lithium chloride waste include ion exchange systems, membrane filtration, and precipitation methods. These approaches can recover lithium compounds for potential reuse, aligning with circular economy principles increasingly adopted in laboratory settings. Recovery efficiency typically ranges from 60-85% depending on the concentration and purity requirements, offering both environmental and economic benefits through reduced raw material demand.

Regulatory frameworks governing lithium chloride disposal vary significantly across jurisdictions, with stricter controls emerging in regions with vulnerable water resources. Laboratories must maintain comprehensive documentation of lithium chloride usage and disposal pathways to demonstrate compliance with local environmental protection standards. This includes tracking quantities, concentrations, treatment methods, and final disposal routes.

Life cycle assessment (LCA) studies of lithium compounds in research applications indicate that proper waste management can reduce the overall environmental impact by 40-60% compared to conventional disposal methods. This highlights the importance of integrating environmental considerations into laboratory safety protocols from procurement through disposal. Implementing waste minimization strategies, such as micro-scale techniques and reagent recycling programs, further reduces the environmental footprint of lithium chloride usage.

Emerging best practices include the development of laboratory-specific environmental management systems that incorporate regular audits of waste streams and treatment efficacy. Training programs that emphasize the environmental dimensions of chemical safety enhance compliance and foster a culture of environmental responsibility among laboratory personnel. These integrated approaches ensure that lithium chloride safety protocols address both immediate workplace hazards and broader ecological considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!