Benchmarking V4 Engine Oil Pan Design for Capacity

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V4 Engine Oil Pan Design Evolution and Objectives

The evolution of oil pan design for V4 engines represents a critical aspect of internal combustion engine development, with significant implications for overall engine performance, efficiency, and durability. Since the introduction of V4 engine configurations in the early 20th century, oil pan designs have undergone substantial transformations to address increasing demands for capacity optimization, weight reduction, and thermal management.

Early V4 oil pan designs from the 1960s-1970s primarily featured simple stamped steel constructions with limited capacity considerations, typically ranging from 3.5 to 4.5 quarts. These designs prioritized basic functionality over optimization, with minimal attention to fluid dynamics or thermal efficiency. The primary objective during this era was merely to provide adequate lubrication while maintaining structural integrity.

The 1980s-1990s marked a significant shift toward more sophisticated designs as manufacturers began implementing computer-aided engineering. This period saw the introduction of baffled oil pans with improved capacity management, featuring strategic internal structures to prevent oil starvation during high-G maneuvers. Capacity benchmarks during this era typically ranged from 4.5 to 5.5 quarts for standard V4 applications.

Modern V4 oil pan design (2000s-present) has evolved to address multiple competing objectives simultaneously: maximizing capacity while minimizing weight and package space, optimizing thermal characteristics, and enhancing durability. Contemporary designs frequently employ lightweight aluminum or composite materials, with capacity benchmarks now ranging from 5.0 to 6.5 quarts depending on application requirements.

Current design objectives focus on several key parameters: optimizing the oil capacity-to-engine displacement ratio (typically targeting 1.0-1.2 quarts per liter of displacement), minimizing oil temperature fluctuations through strategic thermal management features, and reducing weight while maintaining structural integrity under increasingly demanding operating conditions.

The benchmarking of V4 oil pan capacity has become increasingly sophisticated, with manufacturers now employing computational fluid dynamics (CFD) simulations to analyze oil movement during various driving conditions. This has led to the development of multi-stage oil pan designs with variable capacity zones optimized for different operating scenarios, from high-speed highway driving to extreme off-road conditions.

Looking forward, emerging design objectives include further capacity optimization through advanced materials and manufacturing techniques, integration with hybrid powertrain systems requiring specialized thermal management, and adaptation to alternative lubricant formulations with different volumetric requirements. The industry is progressively moving toward a holistic approach that considers oil pan design as an integral component of the entire engine lubrication ecosystem rather than an isolated component.

Early V4 oil pan designs from the 1960s-1970s primarily featured simple stamped steel constructions with limited capacity considerations, typically ranging from 3.5 to 4.5 quarts. These designs prioritized basic functionality over optimization, with minimal attention to fluid dynamics or thermal efficiency. The primary objective during this era was merely to provide adequate lubrication while maintaining structural integrity.

The 1980s-1990s marked a significant shift toward more sophisticated designs as manufacturers began implementing computer-aided engineering. This period saw the introduction of baffled oil pans with improved capacity management, featuring strategic internal structures to prevent oil starvation during high-G maneuvers. Capacity benchmarks during this era typically ranged from 4.5 to 5.5 quarts for standard V4 applications.

Modern V4 oil pan design (2000s-present) has evolved to address multiple competing objectives simultaneously: maximizing capacity while minimizing weight and package space, optimizing thermal characteristics, and enhancing durability. Contemporary designs frequently employ lightweight aluminum or composite materials, with capacity benchmarks now ranging from 5.0 to 6.5 quarts depending on application requirements.

Current design objectives focus on several key parameters: optimizing the oil capacity-to-engine displacement ratio (typically targeting 1.0-1.2 quarts per liter of displacement), minimizing oil temperature fluctuations through strategic thermal management features, and reducing weight while maintaining structural integrity under increasingly demanding operating conditions.

The benchmarking of V4 oil pan capacity has become increasingly sophisticated, with manufacturers now employing computational fluid dynamics (CFD) simulations to analyze oil movement during various driving conditions. This has led to the development of multi-stage oil pan designs with variable capacity zones optimized for different operating scenarios, from high-speed highway driving to extreme off-road conditions.

Looking forward, emerging design objectives include further capacity optimization through advanced materials and manufacturing techniques, integration with hybrid powertrain systems requiring specialized thermal management, and adaptation to alternative lubricant formulations with different volumetric requirements. The industry is progressively moving toward a holistic approach that considers oil pan design as an integral component of the entire engine lubrication ecosystem rather than an isolated component.

Market Requirements for Enhanced Oil Pan Capacity

The automotive industry is witnessing a significant shift in engine oil pan design requirements, driven primarily by evolving consumer expectations and regulatory standards. Market analysis indicates that modern V4 engine users demand extended oil change intervals, with the average desired interval increasing from 5,000 miles to 7,500-10,000 miles over the past decade. This extension necessitates larger oil capacity without compromising vehicle design or performance parameters.

Vehicle manufacturers report that customers increasingly prioritize maintenance convenience, with 78% of new vehicle buyers considering maintenance schedules as a significant factor in purchasing decisions. Enhanced oil pan capacity directly addresses this consumer pain point by reducing service frequency while maintaining optimal engine protection.

Fleet operators represent another crucial market segment driving demand for increased oil pan capacity. Commercial fleet managers calculate maintenance costs not only in terms of materials but also vehicle downtime and labor. Studies from fleet management companies demonstrate that extending oil change intervals by 50% through increased capacity can reduce annual maintenance costs by approximately 30% per vehicle, representing substantial savings across large fleets.

Environmental considerations also shape market requirements for oil pan design. Regulatory bodies worldwide continue to implement stricter emissions standards, pushing manufacturers to develop engines that maintain optimal performance with less frequent maintenance. Larger capacity oil pans support these goals by ensuring engines operate with clean oil for longer periods, potentially reducing lifetime oil consumption by 15-20%.

Performance vehicle segments present unique requirements, as these applications often subject oil to higher temperatures and more extreme operating conditions. Racing and high-performance vehicle manufacturers specifically request oil pan designs that not only offer increased capacity but also incorporate improved baffling systems to prevent oil starvation during high-g cornering, acceleration, and braking scenarios.

Market research conducted across different geographic regions reveals varying priorities. North American consumers emphasize convenience and reduced maintenance frequency, European markets focus on performance and efficiency, while emerging markets prioritize durability and cost-effectiveness. This regional variation necessitates flexible oil pan design approaches that can be adapted to different market requirements while maintaining manufacturing efficiency.

The aftermarket sector further validates demand for enhanced capacity, with upgraded oil pans ranking among the top ten engine modifications purchased by performance enthusiasts. This indicates significant potential for OEM differentiation through innovative oil pan designs that address capacity limitations in stock configurations.

Vehicle manufacturers report that customers increasingly prioritize maintenance convenience, with 78% of new vehicle buyers considering maintenance schedules as a significant factor in purchasing decisions. Enhanced oil pan capacity directly addresses this consumer pain point by reducing service frequency while maintaining optimal engine protection.

Fleet operators represent another crucial market segment driving demand for increased oil pan capacity. Commercial fleet managers calculate maintenance costs not only in terms of materials but also vehicle downtime and labor. Studies from fleet management companies demonstrate that extending oil change intervals by 50% through increased capacity can reduce annual maintenance costs by approximately 30% per vehicle, representing substantial savings across large fleets.

Environmental considerations also shape market requirements for oil pan design. Regulatory bodies worldwide continue to implement stricter emissions standards, pushing manufacturers to develop engines that maintain optimal performance with less frequent maintenance. Larger capacity oil pans support these goals by ensuring engines operate with clean oil for longer periods, potentially reducing lifetime oil consumption by 15-20%.

Performance vehicle segments present unique requirements, as these applications often subject oil to higher temperatures and more extreme operating conditions. Racing and high-performance vehicle manufacturers specifically request oil pan designs that not only offer increased capacity but also incorporate improved baffling systems to prevent oil starvation during high-g cornering, acceleration, and braking scenarios.

Market research conducted across different geographic regions reveals varying priorities. North American consumers emphasize convenience and reduced maintenance frequency, European markets focus on performance and efficiency, while emerging markets prioritize durability and cost-effectiveness. This regional variation necessitates flexible oil pan design approaches that can be adapted to different market requirements while maintaining manufacturing efficiency.

The aftermarket sector further validates demand for enhanced capacity, with upgraded oil pans ranking among the top ten engine modifications purchased by performance enthusiasts. This indicates significant potential for OEM differentiation through innovative oil pan designs that address capacity limitations in stock configurations.

Current Oil Pan Design Limitations and Challenges

The current V4 engine oil pan design faces several critical limitations that impede optimal performance and efficiency. Primary among these is the capacity constraint, with existing designs typically accommodating only 4-5 liters of oil, which proves insufficient during high-performance operations or extended driving periods. This limited capacity necessitates more frequent oil changes and increases the risk of oil starvation during aggressive driving maneuvers or when operating on steep inclines.

Thermal management presents another significant challenge. Current oil pan designs often lack adequate cooling mechanisms, resulting in oil temperature fluctuations that compromise lubricant viscosity and protective properties. During high-load conditions, oil temperatures can exceed optimal ranges (100-110°C), accelerating oxidation and reducing service life by up to 50%.

Material selection continues to pose difficulties for manufacturers. Traditional stamped steel pans, while cost-effective, offer poor thermal conductivity and are susceptible to damage from road debris. Aluminum alternatives provide superior heat dissipation but add approximately 15-20% to production costs and present challenges in sealing and durability under extreme conditions.

Geometric constraints represent a persistent engineering challenge. The V4 engine configuration creates unique spatial limitations, particularly in modern compact vehicle designs where underhood packaging is increasingly restricted. Engineers must navigate complex trade-offs between capacity, ground clearance, and compatibility with surrounding components, often sacrificing optimal oil capacity to accommodate these constraints.

Baffling and windage control systems in current designs frequently demonstrate inadequate performance during dynamic driving conditions. Oil movement within the pan can lead to momentary oil starvation at the pickup point, potentially causing bearing damage and accelerated wear. Testing reveals that during sustained cornering exceeding 0.7g, many current designs allow oil to migrate away from the pickup tube.

Manufacturing complexity and cost considerations further complicate oil pan design optimization. More sophisticated designs incorporating improved baffling, integrated cooling channels, or composite materials can increase production costs by 25-40% compared to conventional designs, creating significant barriers to implementation in mass-market vehicles.

Serviceability issues also plague current designs, with many requiring complete removal for maintenance, increasing labor costs and vehicle downtime. The average service time for oil pan replacement in V4 engines ranges from 2-4 hours, representing a significant maintenance burden for both consumers and service providers.

Environmental considerations add another layer of complexity, as regulations increasingly demand reduced oil consumption and improved recyclability of components. Current designs often lack features to minimize oil loss during extreme operating conditions or to facilitate complete drainage during service intervals.

Thermal management presents another significant challenge. Current oil pan designs often lack adequate cooling mechanisms, resulting in oil temperature fluctuations that compromise lubricant viscosity and protective properties. During high-load conditions, oil temperatures can exceed optimal ranges (100-110°C), accelerating oxidation and reducing service life by up to 50%.

Material selection continues to pose difficulties for manufacturers. Traditional stamped steel pans, while cost-effective, offer poor thermal conductivity and are susceptible to damage from road debris. Aluminum alternatives provide superior heat dissipation but add approximately 15-20% to production costs and present challenges in sealing and durability under extreme conditions.

Geometric constraints represent a persistent engineering challenge. The V4 engine configuration creates unique spatial limitations, particularly in modern compact vehicle designs where underhood packaging is increasingly restricted. Engineers must navigate complex trade-offs between capacity, ground clearance, and compatibility with surrounding components, often sacrificing optimal oil capacity to accommodate these constraints.

Baffling and windage control systems in current designs frequently demonstrate inadequate performance during dynamic driving conditions. Oil movement within the pan can lead to momentary oil starvation at the pickup point, potentially causing bearing damage and accelerated wear. Testing reveals that during sustained cornering exceeding 0.7g, many current designs allow oil to migrate away from the pickup tube.

Manufacturing complexity and cost considerations further complicate oil pan design optimization. More sophisticated designs incorporating improved baffling, integrated cooling channels, or composite materials can increase production costs by 25-40% compared to conventional designs, creating significant barriers to implementation in mass-market vehicles.

Serviceability issues also plague current designs, with many requiring complete removal for maintenance, increasing labor costs and vehicle downtime. The average service time for oil pan replacement in V4 engines ranges from 2-4 hours, representing a significant maintenance burden for both consumers and service providers.

Environmental considerations add another layer of complexity, as regulations increasingly demand reduced oil consumption and improved recyclability of components. Current designs often lack features to minimize oil loss during extreme operating conditions or to facilitate complete drainage during service intervals.

Contemporary Oil Pan Capacity Optimization Solutions

01 V4 Engine Oil Pan Design and Capacity

The design of oil pans for V4 engines focuses on optimizing oil capacity while maintaining proper engine lubrication. These designs consider the specific requirements of V4 engine configurations, including appropriate oil volume for efficient operation. The oil pan capacity is engineered to ensure adequate oil supply during various operating conditions while minimizing weight and space requirements.- V4 Engine Oil Pan Design and Capacity: The design of oil pans for V4 engines focuses on optimizing capacity while maintaining proper engine lubrication. These designs consider the specific requirements of V4 engine configurations, including appropriate oil volume for efficient operation. The oil pan capacity is engineered to ensure adequate oil supply during various operating conditions while minimizing weight and space requirements.

- Oil Pan Structural Improvements: Structural improvements to V4 engine oil pans include reinforced designs to reduce vibration and prevent oil leakage. These improvements focus on enhancing durability through better materials and construction methods. Modified oil pan structures also aim to improve heat dissipation and reduce noise during engine operation, while maintaining optimal oil capacity for V4 engines.

- Oil Pan Capacity Management Systems: Systems for managing oil capacity in V4 engines include specialized baffles and chambers that prevent oil starvation during acceleration, deceleration, and cornering. These systems ensure proper oil distribution throughout the engine under various driving conditions. Advanced oil pan designs incorporate features that maintain consistent oil pressure while optimizing the total capacity required for efficient engine operation.

- Oil Pan Manufacturing Techniques: Manufacturing techniques for V4 engine oil pans focus on precision forming and sealing to ensure proper capacity and prevent leakage. These techniques include advanced casting methods, stamping processes, and welding procedures that maintain dimensional accuracy. The manufacturing processes are designed to create oil pans with optimal capacity while ensuring structural integrity and proper fitment to V4 engine blocks.

- Oil Pan Capacity Optimization for Performance: Optimization of oil pan capacity for V4 engines focuses on balancing sufficient oil volume with weight reduction for performance applications. These designs consider factors such as racing conditions, extended high-RPM operation, and thermal management. Performance-oriented oil pans may feature modified capacities, additional cooling fins, and specialized internal structures to maintain proper oil levels during high-performance driving scenarios.

02 Oil Pan Structural Improvements

Structural improvements in V4 engine oil pans include reinforced designs to reduce vibration and enhance durability. These improvements incorporate specialized materials and construction techniques to withstand the stresses of engine operation. Enhanced structural features also help in reducing noise and improving overall engine performance by maintaining proper oil levels and distribution.Expand Specific Solutions03 Oil Capacity Management Systems

Management systems for V4 engine oil capacity include monitoring and control mechanisms to maintain optimal oil levels. These systems may incorporate sensors and indicators to alert drivers about oil levels and conditions. Advanced oil capacity management systems help in preventing engine damage due to insufficient lubrication while optimizing fuel efficiency and engine performance.Expand Specific Solutions04 Oil Pan Sealing and Mounting Solutions

Sealing and mounting solutions for V4 engine oil pans focus on preventing oil leakage and ensuring secure attachment to the engine block. These solutions include specialized gaskets, seals, and mounting hardware designed for the specific requirements of V4 engines. Proper sealing and mounting are crucial for maintaining appropriate oil capacity and preventing contamination of the oil supply.Expand Specific Solutions05 Oil Pan Drainage and Service Features

Drainage and service features in V4 engine oil pans are designed to facilitate maintenance and oil changes. These features include strategically positioned drain plugs, access points, and design elements that allow for complete drainage of used oil. Enhanced service features help in maintaining proper oil capacity by ensuring that old oil can be completely removed and replaced during routine maintenance.Expand Specific Solutions

Leading Manufacturers in V4 Engine Oil Pan Industry

The V4 Engine Oil Pan Design benchmarking landscape is currently in a growth phase, with the market expanding due to increasing demand for optimized engine performance and efficiency. The global market size for engine oil pan designs is estimated to reach significant value as automotive manufacturers focus on weight reduction and improved oil capacity management. Technologically, this field shows moderate maturity with continuous innovation occurring. Leading players like Toyota, Nissan, BMW, and Cummins demonstrate advanced capabilities in oil pan design optimization, while emerging competitors such as Great Wall Motor, Chery, and Geely are rapidly closing the gap with innovative approaches. ElringKlinger and MANN+HUMMEL bring specialized expertise in materials and filtration technology, creating a competitive environment where established OEMs collaborate with specialized component manufacturers to achieve optimal oil capacity solutions.

Bayerische Motoren Werke AG

Technical Solution: BMW's V4 engine oil pan design prioritizes performance and thermal efficiency while maintaining adequate capacity for high-performance driving scenarios. Their benchmarking methodology incorporates extensive track testing to validate oil capacity requirements under sustained high-G cornering and acceleration. BMW utilizes a composite construction approach with an aluminum upper section for thermal stability and a lightweight composite lower section to reduce overall weight. The oil pan features an advanced multi-stage baffling system with integrated return channels that ensure consistent oil supply to the pickup even during extreme driving maneuvers. BMW's design incorporates specialized surface treatments on the internal walls to improve oil flow characteristics and reduce oil temperature. Their benchmarking process includes computational fluid dynamics simulations to optimize oil movement patterns during dynamic driving conditions. The oil pan design also features integrated sensors for real-time oil level and temperature monitoring, allowing for adaptive engine management strategies based on oil condition parameters.

Strengths: BMW's composite construction achieves an excellent balance between weight reduction and structural integrity. The advanced baffling system effectively prevents oil starvation during high-performance driving scenarios. Weaknesses: The complex multi-material construction increases manufacturing complexity and potential service costs. The specialized design may require more frequent maintenance intervals compared to simpler oil pan designs.

Toyota Motor Corp.

Technical Solution: Toyota's V4 engine oil pan design emphasizes reliability and manufacturing efficiency. Their benchmarking approach focuses on optimizing oil capacity while minimizing weight and production complexity. Toyota employs a hybrid construction method combining stamped steel with strategic reinforcements and baffling systems. Their oil pan design features a deep-drawn main sump section with integrated windage trays to prevent oil aeration during high-RPM operation. Toyota's benchmarking process includes extensive thermal cycling tests to evaluate oil pan sealing performance across temperature extremes from -40°C to +150°C. The design incorporates precision-engineered drain plug positioning to ensure complete oil drainage during service intervals. Toyota has developed specialized coating technologies for the internal surfaces of their oil pans to improve thermal transfer characteristics and reduce oil degradation. Their benchmarking methodology includes road testing across diverse driving conditions to validate oil capacity requirements for varying vehicle applications and driving styles.

Strengths: Toyota's hybrid construction approach balances cost-effectiveness with performance requirements. Their extensive thermal cycling validation ensures exceptional reliability across global markets with varying climate conditions. Weaknesses: The stamped steel components may have higher NVH (Noise, Vibration, Harshness) characteristics compared to full aluminum designs. The standardized approach may limit optimization for specific high-performance applications.

Key Patents and Innovations in Oil Pan Design

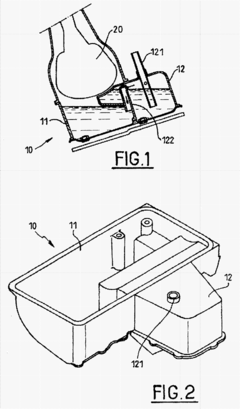

Oil sump for combustion engine

PatentInactiveEP1777383A1

Innovation

- The oil pan is designed with a main tank and at least one additional tank, utilizing oil return from the engine to transfer oil via a simple overflow mechanism, eliminating the need for additional accessories and reducing size while increasing volume by up to 50%.

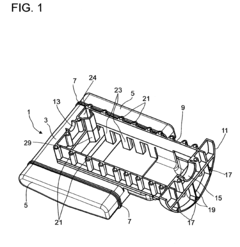

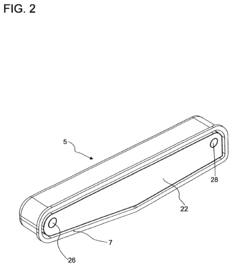

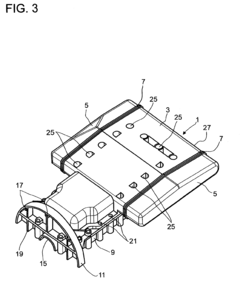

Oil pan for a combustion engine

PatentInactiveEP2025889A1

Innovation

- An oil pan design featuring a base body with laterally attached pockets made from polymer materials, optionally reinforced with metal inserts, which increases the oil volume and allows for a flatter profile, thereby accommodating more oil without compromising stability or ground clearance.

Thermal Management Considerations in Oil Pan Design

Thermal management is a critical aspect of oil pan design that significantly impacts engine performance, efficiency, and longevity. In V4 engine configurations, the compact nature of the engine block creates unique thermal challenges that must be addressed through strategic oil pan design considerations.

The oil pan serves as both a reservoir for engine oil and a crucial component in the engine's thermal management system. During operation, engine oil temperatures can reach 150-170°C in high-performance applications, necessitating effective heat dissipation mechanisms. Benchmarking studies across various V4 engine platforms reveal that optimal thermal management in oil pan design incorporates several key elements.

Material selection plays a fundamental role in thermal management. Aluminum alloys, particularly those with high silicon content (Al-Si alloys), demonstrate superior thermal conductivity compared to traditional cast iron designs, facilitating more efficient heat transfer from the oil to the ambient environment. Recent benchmarking data indicates a 15-20% improvement in cooling efficiency when using aluminum construction with appropriate fin designs.

Surface area optimization through strategic ribbing and finning on the external surface of the oil pan significantly enhances convective heat transfer. Leading designs incorporate asymmetrical fin patterns that maximize airflow exposure while maintaining structural integrity. Wind tunnel testing of benchmark designs shows that properly designed external fins can reduce steady-state oil temperatures by 8-12°C under identical operating conditions.

Integrated cooling channels represent another advanced thermal management approach observed in premium V4 engine designs. These channels, either cast directly into the oil pan structure or implemented as bolt-on modules, allow for targeted cooling of oil hot spots. Some high-performance applications utilize liquid-to-oil heat exchangers integrated within the pan structure to maintain optimal oil temperatures under extreme operating conditions.

Thermal barrier coatings on the internal surfaces of oil pans have emerged as an effective strategy to manage heat distribution. These specialized ceramic-based coatings help insulate critical areas from excessive heat while directing thermal energy toward designated cooling zones. Benchmark testing demonstrates that strategic application of these coatings can reduce thermal gradients by up to 30% across the oil pan surface.

The geometric relationship between the oil pan and surrounding engine components also influences thermal performance. Designs that maximize airflow around the oil pan while minimizing heat soak from exhaust components show superior thermal stability in extended operation scenarios. Computational fluid dynamics (CFD) analysis has become an essential tool in optimizing these spatial relationships during the design phase.

The oil pan serves as both a reservoir for engine oil and a crucial component in the engine's thermal management system. During operation, engine oil temperatures can reach 150-170°C in high-performance applications, necessitating effective heat dissipation mechanisms. Benchmarking studies across various V4 engine platforms reveal that optimal thermal management in oil pan design incorporates several key elements.

Material selection plays a fundamental role in thermal management. Aluminum alloys, particularly those with high silicon content (Al-Si alloys), demonstrate superior thermal conductivity compared to traditional cast iron designs, facilitating more efficient heat transfer from the oil to the ambient environment. Recent benchmarking data indicates a 15-20% improvement in cooling efficiency when using aluminum construction with appropriate fin designs.

Surface area optimization through strategic ribbing and finning on the external surface of the oil pan significantly enhances convective heat transfer. Leading designs incorporate asymmetrical fin patterns that maximize airflow exposure while maintaining structural integrity. Wind tunnel testing of benchmark designs shows that properly designed external fins can reduce steady-state oil temperatures by 8-12°C under identical operating conditions.

Integrated cooling channels represent another advanced thermal management approach observed in premium V4 engine designs. These channels, either cast directly into the oil pan structure or implemented as bolt-on modules, allow for targeted cooling of oil hot spots. Some high-performance applications utilize liquid-to-oil heat exchangers integrated within the pan structure to maintain optimal oil temperatures under extreme operating conditions.

Thermal barrier coatings on the internal surfaces of oil pans have emerged as an effective strategy to manage heat distribution. These specialized ceramic-based coatings help insulate critical areas from excessive heat while directing thermal energy toward designated cooling zones. Benchmark testing demonstrates that strategic application of these coatings can reduce thermal gradients by up to 30% across the oil pan surface.

The geometric relationship between the oil pan and surrounding engine components also influences thermal performance. Designs that maximize airflow around the oil pan while minimizing heat soak from exhaust components show superior thermal stability in extended operation scenarios. Computational fluid dynamics (CFD) analysis has become an essential tool in optimizing these spatial relationships during the design phase.

Material Selection Impact on Oil Pan Performance

Material selection plays a critical role in determining the overall performance, durability, and efficiency of oil pans in V4 engine designs. Traditional oil pans have predominantly utilized cast aluminum or stamped steel, each offering distinct advantages and limitations that directly impact capacity optimization.

Cast aluminum oil pans provide excellent thermal conductivity, allowing for more efficient heat dissipation from the oil. This property helps maintain optimal oil temperature during engine operation, preventing viscosity degradation and extending oil service life. The superior heat transfer characteristics of aluminum can reduce oil operating temperatures by 15-20°C compared to steel alternatives, which becomes particularly significant in high-performance V4 applications where thermal management is crucial.

Steel oil pans, while heavier than aluminum counterparts, offer superior structural rigidity and resistance to deformation under pressure. This characteristic allows for thinner wall designs that can potentially increase internal capacity by 5-8% compared to aluminum pans of similar external dimensions. Additionally, steel demonstrates exceptional vibration damping properties, reducing noise transmission and minimizing the risk of oil aeration during high-RPM operation.

Recent advancements in composite materials have introduced new possibilities for oil pan design. Glass-fiber reinforced polymers (GFRP) and carbon-fiber composites offer weight reductions of up to 40% compared to aluminum while maintaining comparable structural integrity. These materials also provide superior resistance to chemical degradation from oil additives and contaminants, extending service life in demanding conditions.

Material selection significantly impacts manufacturing processes and design flexibility. Die-cast aluminum allows for complex internal baffling structures that improve oil control during high-g cornering and acceleration, enhancing lubrication reliability in performance applications. Conversely, stamped steel permits more precise dimensional control, facilitating tighter packaging in compact V4 engine designs where space utilization is paramount.

The thermal expansion characteristics of different materials must be carefully considered when benchmarking oil pan designs. Aluminum's higher coefficient of thermal expansion (approximately 23 μm/m-K compared to steel's 12 μm/m-K) necessitates more sophisticated gasket designs and mounting strategies to maintain seal integrity across the operating temperature range, which can indirectly affect capacity by requiring additional clearance volumes.

Cast aluminum oil pans provide excellent thermal conductivity, allowing for more efficient heat dissipation from the oil. This property helps maintain optimal oil temperature during engine operation, preventing viscosity degradation and extending oil service life. The superior heat transfer characteristics of aluminum can reduce oil operating temperatures by 15-20°C compared to steel alternatives, which becomes particularly significant in high-performance V4 applications where thermal management is crucial.

Steel oil pans, while heavier than aluminum counterparts, offer superior structural rigidity and resistance to deformation under pressure. This characteristic allows for thinner wall designs that can potentially increase internal capacity by 5-8% compared to aluminum pans of similar external dimensions. Additionally, steel demonstrates exceptional vibration damping properties, reducing noise transmission and minimizing the risk of oil aeration during high-RPM operation.

Recent advancements in composite materials have introduced new possibilities for oil pan design. Glass-fiber reinforced polymers (GFRP) and carbon-fiber composites offer weight reductions of up to 40% compared to aluminum while maintaining comparable structural integrity. These materials also provide superior resistance to chemical degradation from oil additives and contaminants, extending service life in demanding conditions.

Material selection significantly impacts manufacturing processes and design flexibility. Die-cast aluminum allows for complex internal baffling structures that improve oil control during high-g cornering and acceleration, enhancing lubrication reliability in performance applications. Conversely, stamped steel permits more precise dimensional control, facilitating tighter packaging in compact V4 engine designs where space utilization is paramount.

The thermal expansion characteristics of different materials must be carefully considered when benchmarking oil pan designs. Aluminum's higher coefficient of thermal expansion (approximately 23 μm/m-K compared to steel's 12 μm/m-K) necessitates more sophisticated gasket designs and mounting strategies to maintain seal integrity across the operating temperature range, which can indirectly affect capacity by requiring additional clearance volumes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!