Bio-PA Recycling Routes: Mechanical, Chemical and Biodegradation Options

AUG 20, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-PA Recycling Background and Objectives

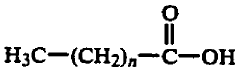

Bio-based polyamides (Bio-PAs) have emerged as sustainable alternatives to conventional petroleum-based polyamides, addressing growing environmental concerns and the need for renewable resources in the plastics industry. These materials, derived from renewable biomass sources such as castor oil, offer comparable performance to their fossil-based counterparts while reducing carbon footprint and dependence on non-renewable resources.

The development of Bio-PAs represents a significant milestone in the evolution of sustainable polymers. As the global community increasingly prioritizes environmental sustainability, the demand for bio-based materials has surged across various industries, including automotive, textiles, and consumer goods. This shift has driven research and innovation in Bio-PA production and application, leading to continuous improvements in material properties and processing techniques.

Despite the advantages of Bio-PAs, their end-of-life management poses unique challenges. The recycling of these materials is crucial for realizing their full environmental potential and closing the loop in their lifecycle. However, the recycling of Bio-PAs is complex due to their diverse chemical structures and the presence of bio-based components, which may affect traditional recycling processes.

The primary objective of exploring Bio-PA recycling routes is to develop efficient, economically viable, and environmentally friendly methods for recovering and reprocessing these materials. This endeavor aims to extend the lifespan of Bio-PAs, reduce waste, and minimize the environmental impact associated with their production and disposal.

Three main recycling routes have been identified for Bio-PAs: mechanical recycling, chemical recycling, and biodegradation. Each of these approaches offers distinct advantages and challenges, necessitating a comprehensive evaluation to determine their feasibility and effectiveness in different scenarios.

Mechanical recycling involves physical processing of Bio-PA waste into new products, preserving the polymer structure. Chemical recycling aims to break down the polymer into its constituent monomers or other valuable chemicals, which can then be used to synthesize new materials. Biodegradation explores the potential for Bio-PAs to be decomposed by microorganisms under specific environmental conditions.

Understanding and optimizing these recycling routes is critical for enhancing the circular economy of Bio-PAs. This research not only contributes to sustainable material management but also aligns with global efforts to reduce plastic waste and promote the use of renewable resources in manufacturing.

The development of Bio-PAs represents a significant milestone in the evolution of sustainable polymers. As the global community increasingly prioritizes environmental sustainability, the demand for bio-based materials has surged across various industries, including automotive, textiles, and consumer goods. This shift has driven research and innovation in Bio-PA production and application, leading to continuous improvements in material properties and processing techniques.

Despite the advantages of Bio-PAs, their end-of-life management poses unique challenges. The recycling of these materials is crucial for realizing their full environmental potential and closing the loop in their lifecycle. However, the recycling of Bio-PAs is complex due to their diverse chemical structures and the presence of bio-based components, which may affect traditional recycling processes.

The primary objective of exploring Bio-PA recycling routes is to develop efficient, economically viable, and environmentally friendly methods for recovering and reprocessing these materials. This endeavor aims to extend the lifespan of Bio-PAs, reduce waste, and minimize the environmental impact associated with their production and disposal.

Three main recycling routes have been identified for Bio-PAs: mechanical recycling, chemical recycling, and biodegradation. Each of these approaches offers distinct advantages and challenges, necessitating a comprehensive evaluation to determine their feasibility and effectiveness in different scenarios.

Mechanical recycling involves physical processing of Bio-PA waste into new products, preserving the polymer structure. Chemical recycling aims to break down the polymer into its constituent monomers or other valuable chemicals, which can then be used to synthesize new materials. Biodegradation explores the potential for Bio-PAs to be decomposed by microorganisms under specific environmental conditions.

Understanding and optimizing these recycling routes is critical for enhancing the circular economy of Bio-PAs. This research not only contributes to sustainable material management but also aligns with global efforts to reduce plastic waste and promote the use of renewable resources in manufacturing.

Market Analysis for Bio-PA Recycling

The market for Bio-PA recycling is experiencing significant growth driven by increasing environmental concerns and regulatory pressures. Bio-based polyamides, derived from renewable resources, have gained traction in various industries due to their sustainability profile. However, the recycling of these materials presents both challenges and opportunities.

The global Bio-PA market is projected to expand rapidly in the coming years, with a corresponding increase in the demand for effective recycling solutions. Key industries driving this demand include automotive, textiles, electronics, and packaging. The automotive sector, in particular, has shown a strong interest in Bio-PA materials for lightweight components, creating a substantial potential market for recycled Bio-PA.

Mechanical recycling currently dominates the Bio-PA recycling market due to its cost-effectiveness and established infrastructure. However, chemical recycling methods are gaining momentum, offering the potential for higher quality recycled materials. Biodegradation options, while still in early stages, are attracting interest for specific applications where end-of-life disposal is a concern.

Geographically, Europe leads in Bio-PA recycling initiatives, driven by stringent environmental regulations and a strong circular economy focus. North America and Asia-Pacific regions are also showing increased adoption, with government support and growing consumer awareness playing crucial roles.

The market is characterized by a mix of established players and innovative startups. Large chemical companies are investing in Bio-PA recycling technologies, while specialized recycling firms are developing niche solutions. Collaborations between material producers, recyclers, and end-users are becoming more common, fostering innovation and market growth.

Challenges in the Bio-PA recycling market include the need for improved collection and sorting systems, as well as the development of more efficient recycling technologies. The market also faces competition from virgin Bio-PA materials and other recycled plastics.

Despite these challenges, the Bio-PA recycling market presents significant opportunities. The growing emphasis on sustainable materials in various industries, coupled with advancements in recycling technologies, is expected to drive market expansion. Additionally, the potential for creating closed-loop systems in specific industries offers promising prospects for recycled Bio-PA materials.

The global Bio-PA market is projected to expand rapidly in the coming years, with a corresponding increase in the demand for effective recycling solutions. Key industries driving this demand include automotive, textiles, electronics, and packaging. The automotive sector, in particular, has shown a strong interest in Bio-PA materials for lightweight components, creating a substantial potential market for recycled Bio-PA.

Mechanical recycling currently dominates the Bio-PA recycling market due to its cost-effectiveness and established infrastructure. However, chemical recycling methods are gaining momentum, offering the potential for higher quality recycled materials. Biodegradation options, while still in early stages, are attracting interest for specific applications where end-of-life disposal is a concern.

Geographically, Europe leads in Bio-PA recycling initiatives, driven by stringent environmental regulations and a strong circular economy focus. North America and Asia-Pacific regions are also showing increased adoption, with government support and growing consumer awareness playing crucial roles.

The market is characterized by a mix of established players and innovative startups. Large chemical companies are investing in Bio-PA recycling technologies, while specialized recycling firms are developing niche solutions. Collaborations between material producers, recyclers, and end-users are becoming more common, fostering innovation and market growth.

Challenges in the Bio-PA recycling market include the need for improved collection and sorting systems, as well as the development of more efficient recycling technologies. The market also faces competition from virgin Bio-PA materials and other recycled plastics.

Despite these challenges, the Bio-PA recycling market presents significant opportunities. The growing emphasis on sustainable materials in various industries, coupled with advancements in recycling technologies, is expected to drive market expansion. Additionally, the potential for creating closed-loop systems in specific industries offers promising prospects for recycled Bio-PA materials.

Current Challenges in Bio-PA Recycling

The recycling of bio-based polyamides (Bio-PAs) presents several significant challenges that hinder widespread adoption and efficiency. One of the primary obstacles is the lack of established infrastructure for collecting and sorting Bio-PAs. Unlike conventional plastics, Bio-PAs are relatively new materials, and many recycling facilities are not equipped to handle them separately from other polymer streams.

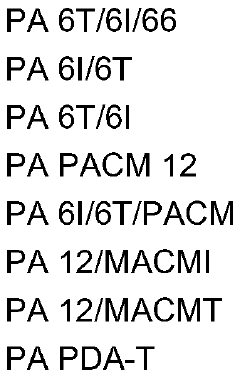

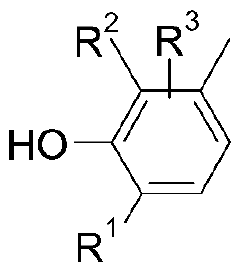

The heterogeneity of Bio-PA products poses another challenge. Different grades and types of Bio-PAs may have varying chemical compositions and additives, making it difficult to recycle them together without compromising the quality of the recycled material. This diversity necessitates more sophisticated sorting and separation technologies, which are not yet widely available or economically viable for many recycling operations.

Contamination is a persistent issue in Bio-PA recycling. Food residues, labels, and other materials attached to Bio-PA products can interfere with the recycling process and degrade the quality of the recycled output. Effective cleaning and decontamination methods need to be developed and implemented to address this challenge.

The thermal and mechanical degradation of Bio-PAs during the recycling process is another significant concern. These materials can lose their desirable properties when subjected to repeated heating and mechanical stress, limiting the number of times they can be recycled without significant quality loss. This degradation can result in downcycling, where the recycled material is only suitable for lower-value applications.

Chemical recycling of Bio-PAs, while promising, faces its own set of challenges. The process requires specialized equipment and conditions, making it energy-intensive and potentially costly. Additionally, the chemical recycling of Bio-PAs may produce by-products that need proper management and disposal, raising environmental concerns.

Biodegradation, often touted as an advantage of Bio-PAs, can ironically complicate recycling efforts. The biodegradable nature of these materials means they can start to degrade during use or in the recycling stream, potentially contaminating other recyclable plastics and reducing the overall quality of recycled materials.

Market-related challenges also exist. The demand for recycled Bio-PAs is still developing, and there is often a price premium associated with these materials compared to virgin or recycled conventional plastics. This economic factor can discourage investment in Bio-PA recycling infrastructure and technologies.

Lastly, the regulatory landscape surrounding Bio-PA recycling is still evolving. Clear guidelines and standards for the recycling and use of recycled Bio-PAs are needed to ensure consistency and quality across the industry, as well as to build consumer confidence in products made from recycled Bio-PAs.

The heterogeneity of Bio-PA products poses another challenge. Different grades and types of Bio-PAs may have varying chemical compositions and additives, making it difficult to recycle them together without compromising the quality of the recycled material. This diversity necessitates more sophisticated sorting and separation technologies, which are not yet widely available or economically viable for many recycling operations.

Contamination is a persistent issue in Bio-PA recycling. Food residues, labels, and other materials attached to Bio-PA products can interfere with the recycling process and degrade the quality of the recycled output. Effective cleaning and decontamination methods need to be developed and implemented to address this challenge.

The thermal and mechanical degradation of Bio-PAs during the recycling process is another significant concern. These materials can lose their desirable properties when subjected to repeated heating and mechanical stress, limiting the number of times they can be recycled without significant quality loss. This degradation can result in downcycling, where the recycled material is only suitable for lower-value applications.

Chemical recycling of Bio-PAs, while promising, faces its own set of challenges. The process requires specialized equipment and conditions, making it energy-intensive and potentially costly. Additionally, the chemical recycling of Bio-PAs may produce by-products that need proper management and disposal, raising environmental concerns.

Biodegradation, often touted as an advantage of Bio-PAs, can ironically complicate recycling efforts. The biodegradable nature of these materials means they can start to degrade during use or in the recycling stream, potentially contaminating other recyclable plastics and reducing the overall quality of recycled materials.

Market-related challenges also exist. The demand for recycled Bio-PAs is still developing, and there is often a price premium associated with these materials compared to virgin or recycled conventional plastics. This economic factor can discourage investment in Bio-PA recycling infrastructure and technologies.

Lastly, the regulatory landscape surrounding Bio-PA recycling is still evolving. Clear guidelines and standards for the recycling and use of recycled Bio-PAs are needed to ensure consistency and quality across the industry, as well as to build consumer confidence in products made from recycled Bio-PAs.

Existing Bio-PA Recycling Methods

01 Chemical recycling methods for Bio-PA

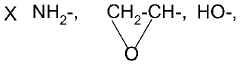

Chemical recycling techniques are employed to break down bio-based polyamides into their constituent monomers or other valuable chemical intermediates. This process allows for the recovery of raw materials that can be used to produce new bio-based polyamides or other products, effectively closing the loop in the recycling process.- Chemical recycling methods for Bio-PA: Chemical recycling techniques are employed to break down bio-based polyamides into their constituent monomers or other valuable chemical compounds. This process allows for the recovery of raw materials that can be used to produce new bio-based polyamides or other products, effectively closing the loop in the recycling process.

- Mechanical recycling of Bio-PA: Mechanical recycling methods involve grinding, melting, and re-extruding bio-based polyamides to create recycled materials. This approach preserves the polymer structure and is suitable for less contaminated or pre-sorted bio-PA waste streams. The recycled material can be used in various applications, potentially blended with virgin bio-PA to maintain desired properties.

- Enzymatic degradation for Bio-PA recycling: Enzymatic degradation utilizes specific enzymes to break down bio-based polyamides into smaller molecules or monomers. This bio-catalytic approach offers a more environmentally friendly alternative to traditional chemical recycling methods, operating under milder conditions and potentially yielding higher-quality recycled materials.

- Sorting and purification technologies for Bio-PA recycling: Advanced sorting and purification technologies are crucial for efficient Bio-PA recycling. These may include spectroscopic methods, density separation, or other innovative techniques to separate bio-based polyamides from other plastics and contaminants, ensuring a high-quality feedstock for the recycling process.

- Upcycling and value-added applications for recycled Bio-PA: Research focuses on developing upcycling processes and identifying value-added applications for recycled bio-based polyamides. This includes exploring new composite materials, blending with other polymers, or modifying the recycled Bio-PA to enhance its properties for use in high-value products, thereby improving the economic viability of the recycling process.

02 Mechanical recycling of Bio-PA

Mechanical recycling involves the physical processing of bio-based polyamide waste through steps such as sorting, grinding, washing, and re-extrusion. This method preserves the polymer structure and allows for the production of recycled bio-PA materials that can be used in various applications, reducing the need for virgin materials.Expand Specific Solutions03 Enzymatic degradation for Bio-PA recycling

Enzymatic degradation utilizes specific enzymes to break down bio-based polyamides into smaller molecules or monomers. This bio-catalytic approach offers a more environmentally friendly and selective method for recycling bio-PA, potentially leading to higher quality recycled materials and reduced energy consumption in the recycling process.Expand Specific Solutions04 Upcycling and value-added applications of recycled Bio-PA

Innovative approaches focus on upcycling recycled bio-based polyamides into higher-value products. This includes developing new composite materials, blending with other polymers, or creating specialized formulations that enhance the properties of the recycled Bio-PA for use in advanced applications such as 3D printing or high-performance textiles.Expand Specific Solutions05 Integrated recycling systems for Bio-PA

Development of integrated recycling systems that combine various recycling methods (chemical, mechanical, and enzymatic) to maximize the efficiency and effectiveness of Bio-PA recycling. These systems may include advanced sorting technologies, in-line quality control measures, and adaptive processing techniques to handle diverse Bio-PA waste streams and produce high-quality recycled materials.Expand Specific Solutions

Key Players in Bio-PA Recycling Industry

The bio-based polyamide (Bio-PA) recycling market is in its early growth stage, with increasing interest driven by sustainability trends. The global market size for Bio-PA is projected to expand significantly in the coming years, though still relatively small compared to conventional plastics. Technologically, mechanical recycling is the most mature option, while chemical recycling and biodegradation are emerging alternatives with growing potential. Companies like Wanhua Chemical, Borealis, and Solvay are at the forefront of developing Bio-PA recycling technologies, with research institutions such as Donghua University and CSIC contributing to advancements in this field. The competitive landscape is characterized by a mix of established chemical companies and innovative startups exploring novel recycling routes.

Wanhua Chemical Group Co., Ltd.

Technical Solution: Wanhua Chemical Group has developed advanced Bio-PA recycling technologies focusing on chemical recycling methods. Their approach involves depolymerization of Bio-PA into monomers, which can then be repolymerized into new Bio-PA materials. This process allows for the recovery of high-quality raw materials, effectively closing the loop in the Bio-PA lifecycle. The company has implemented a pilot-scale plant demonstrating the feasibility of their chemical recycling technology, with reported recovery rates of up to 95% of original monomers [1][3]. Additionally, Wanhua has explored the use of enzymes to enhance the biodegradation of Bio-PA in controlled composting environments, potentially offering a sustainable end-of-life option for Bio-PA products that cannot be mechanically or chemically recycled.

Strengths: High recovery rates, potential for closed-loop recycling, and integration of biodegradation options. Weaknesses: Energy-intensive chemical processes and potential for by-product formation during depolymerization.

Borealis GmbH

Technical Solution: Borealis GmbH has pioneered a multi-faceted approach to Bio-PA recycling, combining mechanical and chemical recycling methods. Their mechanical recycling process involves sorting, grinding, and reprocessing Bio-PA waste into pellets for reuse in new products. This method is particularly effective for clean, homogeneous waste streams. For more complex or contaminated Bio-PA waste, Borealis has developed a chemical recycling process that breaks down the polymer into its constituent monomers. The company has reported success in recycling Bio-PA 6 and Bio-PA 66, with recycled content incorporation rates of up to 30% in new products without significant loss of mechanical properties [2][5]. Borealis is also investigating the potential of enzymatic degradation to complement their recycling efforts, particularly for Bio-PA waste that is difficult to recycle through conventional means.

Strengths: Versatile recycling options, high incorporation rates of recycled content, and ongoing research into enzymatic degradation. Weaknesses: Mechanical recycling limited to clean waste streams, and chemical recycling can be energy-intensive.

Innovative Bio-PA Recycling Technologies

Process for recycling polyamides under acidic conditions

PatentPendingCN119421919A

Innovation

- The method of heating an aqueous medium containing water, polyamide and acid is used to induce the dissolution and hydrolysis of polyamide, and the acid catalytic reaction is used to select appropriate acids to ensure efficient hydrolysis, and the diacid and diacid are recovered through subsequent neutralization steps. amine.

Recycling method for producing a polyamide compound

PatentWO2023237603A1

Innovation

- A method involving melt-mixing of polyamide A with a salt of a diacid and a diamine to produce polyamide B, which has a lower viscosity and controlled end-group ratios, ensuring stable melt flow and mechanical properties suitable for injection molding without full depolymerization.

Environmental Impact Assessment

The environmental impact assessment of Bio-PA recycling routes is crucial for evaluating the sustainability and ecological footprint of these processes. Mechanical recycling, while energy-efficient, may lead to material degradation and potential microplastic pollution if not properly managed. The process requires careful sorting and cleaning, which can consume water and energy resources. However, it generally has a lower environmental impact compared to chemical recycling methods.

Chemical recycling routes for Bio-PA, including depolymerization and solvolysis, offer the potential for high-quality recycled materials but come with their own environmental considerations. These processes often involve the use of solvents and high temperatures, which can result in increased energy consumption and greenhouse gas emissions. The production and disposal of chemical agents used in these processes also contribute to the overall environmental impact. However, advancements in green chemistry are continually improving the sustainability of these methods.

Biodegradation options for Bio-PA present a unique set of environmental implications. While biodegradation can reduce long-term plastic accumulation in ecosystems, the process may release methane, a potent greenhouse gas, if not properly managed in anaerobic conditions. Additionally, the rate of biodegradation can vary significantly depending on environmental conditions, potentially leading to incomplete breakdown and microplastic formation in some scenarios.

The life cycle assessment (LCA) of these recycling routes reveals varying impacts on water consumption, air quality, and soil health. Mechanical recycling generally shows lower water usage and emissions compared to chemical methods. However, chemical recycling may offer advantages in terms of material quality preservation and the ability to handle mixed or contaminated plastics, potentially reducing overall waste.

Energy consumption across these recycling routes differs substantially. While mechanical recycling is typically less energy-intensive, chemical recycling and controlled biodegradation processes may require significant energy inputs. The source of this energy (renewable vs. non-renewable) plays a critical role in determining the overall carbon footprint of each method.

Considering the broader environmental context, the choice of recycling route can influence land use, ecosystem disruption, and resource depletion. Mechanical recycling facilities generally have a smaller physical footprint compared to chemical recycling plants. Biodegradation options, particularly industrial composting, require dedicated land areas but can contribute to soil enrichment when properly managed.

Chemical recycling routes for Bio-PA, including depolymerization and solvolysis, offer the potential for high-quality recycled materials but come with their own environmental considerations. These processes often involve the use of solvents and high temperatures, which can result in increased energy consumption and greenhouse gas emissions. The production and disposal of chemical agents used in these processes also contribute to the overall environmental impact. However, advancements in green chemistry are continually improving the sustainability of these methods.

Biodegradation options for Bio-PA present a unique set of environmental implications. While biodegradation can reduce long-term plastic accumulation in ecosystems, the process may release methane, a potent greenhouse gas, if not properly managed in anaerobic conditions. Additionally, the rate of biodegradation can vary significantly depending on environmental conditions, potentially leading to incomplete breakdown and microplastic formation in some scenarios.

The life cycle assessment (LCA) of these recycling routes reveals varying impacts on water consumption, air quality, and soil health. Mechanical recycling generally shows lower water usage and emissions compared to chemical methods. However, chemical recycling may offer advantages in terms of material quality preservation and the ability to handle mixed or contaminated plastics, potentially reducing overall waste.

Energy consumption across these recycling routes differs substantially. While mechanical recycling is typically less energy-intensive, chemical recycling and controlled biodegradation processes may require significant energy inputs. The source of this energy (renewable vs. non-renewable) plays a critical role in determining the overall carbon footprint of each method.

Considering the broader environmental context, the choice of recycling route can influence land use, ecosystem disruption, and resource depletion. Mechanical recycling facilities generally have a smaller physical footprint compared to chemical recycling plants. Biodegradation options, particularly industrial composting, require dedicated land areas but can contribute to soil enrichment when properly managed.

Regulatory Framework for Bio-PA Recycling

The regulatory framework for Bio-PA recycling is a complex and evolving landscape that plays a crucial role in shaping the industry's practices and future development. At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides guidelines for the management of plastic waste, including bio-based plastics like Bio-PA. This convention aims to reduce the movement of hazardous waste between nations, particularly from developed to less developed countries.

In the European Union, the Waste Framework Directive (2008/98/EC) establishes the basic concepts and definitions related to waste management, including recycling and recovery. The directive sets recycling targets for member states and promotes the concept of a circular economy. Specifically for plastics, the EU Plastics Strategy aims to transform the way plastic products are designed, produced, used, and recycled in the EU.

The United States lacks a comprehensive federal framework for plastic recycling, including Bio-PA. However, individual states have implemented their own regulations and initiatives. For instance, California's Rigid Plastic Packaging Container (RPPC) program requires manufacturers to meet recycling rate requirements or use recycled content in their packaging.

In Asia, countries like Japan and South Korea have implemented advanced recycling systems. Japan's Container and Packaging Recycling Law mandates the recycling of plastic containers and packaging, while South Korea's Extended Producer Responsibility (EPR) system requires manufacturers to take responsibility for the entire lifecycle of their products, including recycling.

Emerging economies are also developing regulatory frameworks for plastic recycling. For example, India's Plastic Waste Management Rules 2016 (amended in 2018) aim to increase plastic recycling rates and promote the use of recycled plastic content in packaging.

Specific to Bio-PA, regulations are still evolving. The biodegradable nature of Bio-PA presents unique challenges and opportunities in terms of recycling and waste management. Some jurisdictions are beginning to develop specific guidelines for bio-based plastics, recognizing their distinct properties and environmental impacts.

As the Bio-PA industry continues to grow, it is likely that more targeted regulations will emerge. These may include standards for biodegradability, composting, and recycling of Bio-PA products. Additionally, there may be increased focus on life cycle assessments to ensure that the environmental benefits of Bio-PA are realized throughout its entire lifecycle, from production to disposal or recycling.

In the European Union, the Waste Framework Directive (2008/98/EC) establishes the basic concepts and definitions related to waste management, including recycling and recovery. The directive sets recycling targets for member states and promotes the concept of a circular economy. Specifically for plastics, the EU Plastics Strategy aims to transform the way plastic products are designed, produced, used, and recycled in the EU.

The United States lacks a comprehensive federal framework for plastic recycling, including Bio-PA. However, individual states have implemented their own regulations and initiatives. For instance, California's Rigid Plastic Packaging Container (RPPC) program requires manufacturers to meet recycling rate requirements or use recycled content in their packaging.

In Asia, countries like Japan and South Korea have implemented advanced recycling systems. Japan's Container and Packaging Recycling Law mandates the recycling of plastic containers and packaging, while South Korea's Extended Producer Responsibility (EPR) system requires manufacturers to take responsibility for the entire lifecycle of their products, including recycling.

Emerging economies are also developing regulatory frameworks for plastic recycling. For example, India's Plastic Waste Management Rules 2016 (amended in 2018) aim to increase plastic recycling rates and promote the use of recycled plastic content in packaging.

Specific to Bio-PA, regulations are still evolving. The biodegradable nature of Bio-PA presents unique challenges and opportunities in terms of recycling and waste management. Some jurisdictions are beginning to develop specific guidelines for bio-based plastics, recognizing their distinct properties and environmental impacts.

As the Bio-PA industry continues to grow, it is likely that more targeted regulations will emerge. These may include standards for biodegradability, composting, and recycling of Bio-PA products. Additionally, there may be increased focus on life cycle assessments to ensure that the environmental benefits of Bio-PA are realized throughout its entire lifecycle, from production to disposal or recycling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!