Bio-PA Surface Treatments for Adhesion and Coating Applications

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-PA Surface Treatment Background and Objectives

Bio-based polyamides (Bio-PAs) have emerged as a promising class of sustainable materials in recent years, offering a viable alternative to traditional petroleum-based polyamides. The development of Bio-PAs has been driven by the growing demand for environmentally friendly and renewable materials across various industries. These bio-based polymers are derived from renewable resources such as castor oil, sebacic acid, and other plant-based feedstocks, making them an attractive option for reducing carbon footprint and dependence on fossil fuels.

The field of Bio-PA surface treatments has gained significant attention due to the increasing need for improved adhesion and coating properties in diverse applications. As Bio-PAs continue to replace conventional polyamides in automotive, electronics, and consumer goods industries, the demand for effective surface modification techniques has grown exponentially. The primary objective of Bio-PA surface treatments is to enhance the material's surface properties, including wettability, adhesion strength, and compatibility with various coatings and adhesives.

The evolution of Bio-PA surface treatments can be traced back to the early 2000s when researchers began exploring methods to improve the interfacial properties of these materials. Initial efforts focused on adapting existing surface modification techniques used for traditional polyamides to Bio-PAs. However, it soon became apparent that the unique chemical structure and properties of Bio-PAs necessitated the development of tailored surface treatment approaches.

Over the past decade, significant progress has been made in understanding the surface characteristics of Bio-PAs and developing innovative treatment methods. Researchers have explored a wide range of techniques, including plasma treatments, chemical etching, grafting, and the application of functional coatings. These advancements have led to improved adhesion properties, enhanced durability, and expanded the potential applications of Bio-PAs in various industries.

The current technological landscape for Bio-PA surface treatments is characterized by a diverse array of approaches, each offering specific advantages and limitations. Plasma treatments have gained popularity due to their ability to modify surface chemistry without altering bulk properties. Chemical etching methods have shown promise in creating micro-roughness and improving mechanical interlocking. Additionally, the development of bio-based coupling agents and compatibilizers has opened new avenues for enhancing the interfacial adhesion between Bio-PAs and other materials.

Looking ahead, the primary objectives of Bio-PA surface treatment research are focused on developing more efficient, cost-effective, and environmentally friendly methods. There is a growing emphasis on creating multifunctional surface treatments that can simultaneously improve adhesion, hydrophobicity, and other desired properties. Furthermore, researchers are exploring the integration of nanotechnology and smart materials to create responsive surfaces that can adapt to different environmental conditions.

The field of Bio-PA surface treatments has gained significant attention due to the increasing need for improved adhesion and coating properties in diverse applications. As Bio-PAs continue to replace conventional polyamides in automotive, electronics, and consumer goods industries, the demand for effective surface modification techniques has grown exponentially. The primary objective of Bio-PA surface treatments is to enhance the material's surface properties, including wettability, adhesion strength, and compatibility with various coatings and adhesives.

The evolution of Bio-PA surface treatments can be traced back to the early 2000s when researchers began exploring methods to improve the interfacial properties of these materials. Initial efforts focused on adapting existing surface modification techniques used for traditional polyamides to Bio-PAs. However, it soon became apparent that the unique chemical structure and properties of Bio-PAs necessitated the development of tailored surface treatment approaches.

Over the past decade, significant progress has been made in understanding the surface characteristics of Bio-PAs and developing innovative treatment methods. Researchers have explored a wide range of techniques, including plasma treatments, chemical etching, grafting, and the application of functional coatings. These advancements have led to improved adhesion properties, enhanced durability, and expanded the potential applications of Bio-PAs in various industries.

The current technological landscape for Bio-PA surface treatments is characterized by a diverse array of approaches, each offering specific advantages and limitations. Plasma treatments have gained popularity due to their ability to modify surface chemistry without altering bulk properties. Chemical etching methods have shown promise in creating micro-roughness and improving mechanical interlocking. Additionally, the development of bio-based coupling agents and compatibilizers has opened new avenues for enhancing the interfacial adhesion between Bio-PAs and other materials.

Looking ahead, the primary objectives of Bio-PA surface treatment research are focused on developing more efficient, cost-effective, and environmentally friendly methods. There is a growing emphasis on creating multifunctional surface treatments that can simultaneously improve adhesion, hydrophobicity, and other desired properties. Furthermore, researchers are exploring the integration of nanotechnology and smart materials to create responsive surfaces that can adapt to different environmental conditions.

Market Analysis for Bio-PA Adhesion Solutions

The market for Bio-PA adhesion solutions is experiencing significant growth, driven by increasing demand for sustainable and eco-friendly materials across various industries. Bio-based polyamides (Bio-PAs) are gaining traction as alternatives to traditional petroleum-based polyamides due to their renewable sourcing and reduced environmental impact. The global Bio-PA market is expected to expand at a compound annual growth rate (CAGR) of over 10% in the coming years, with adhesion and coating applications representing a substantial portion of this growth.

The automotive sector is emerging as a key driver for Bio-PA adhesion solutions. As automakers strive to meet stringent environmental regulations and consumer demands for greener vehicles, the adoption of bio-based materials in vehicle components is accelerating. Bio-PA adhesives offer excellent bonding properties for various automotive parts, including interior trims, exterior panels, and under-the-hood applications. The lightweight nature of Bio-PAs also contributes to improved fuel efficiency, further enhancing their appeal in the automotive industry.

In the packaging industry, Bio-PA adhesion solutions are gaining momentum as companies seek sustainable alternatives to traditional packaging materials. The food and beverage sector, in particular, is showing increased interest in Bio-PA coatings for flexible packaging applications. These coatings provide excellent barrier properties against oxygen and moisture, extending the shelf life of products while maintaining recyclability. The growing consumer awareness of environmental issues is driving the demand for eco-friendly packaging solutions, creating a favorable market environment for Bio-PA adhesives and coatings.

The construction industry represents another significant market opportunity for Bio-PA adhesion solutions. As green building practices become more prevalent, there is a rising demand for sustainable construction materials. Bio-PA adhesives are finding applications in flooring, wall coverings, and insulation materials, offering strong bonding properties and improved durability. The ability of Bio-PAs to withstand harsh environmental conditions makes them particularly suitable for outdoor applications, expanding their potential in the construction sector.

The electronics industry is also exploring Bio-PA adhesion solutions for various applications. With the increasing focus on sustainable electronics and the circular economy, manufacturers are seeking bio-based alternatives for component assembly and protective coatings. Bio-PA adhesives offer excellent electrical insulation properties and thermal stability, making them suitable for use in electronic devices and circuit boards. As the industry continues to innovate towards more environmentally friendly products, the demand for Bio-PA adhesion solutions in electronics is expected to grow.

The automotive sector is emerging as a key driver for Bio-PA adhesion solutions. As automakers strive to meet stringent environmental regulations and consumer demands for greener vehicles, the adoption of bio-based materials in vehicle components is accelerating. Bio-PA adhesives offer excellent bonding properties for various automotive parts, including interior trims, exterior panels, and under-the-hood applications. The lightweight nature of Bio-PAs also contributes to improved fuel efficiency, further enhancing their appeal in the automotive industry.

In the packaging industry, Bio-PA adhesion solutions are gaining momentum as companies seek sustainable alternatives to traditional packaging materials. The food and beverage sector, in particular, is showing increased interest in Bio-PA coatings for flexible packaging applications. These coatings provide excellent barrier properties against oxygen and moisture, extending the shelf life of products while maintaining recyclability. The growing consumer awareness of environmental issues is driving the demand for eco-friendly packaging solutions, creating a favorable market environment for Bio-PA adhesives and coatings.

The construction industry represents another significant market opportunity for Bio-PA adhesion solutions. As green building practices become more prevalent, there is a rising demand for sustainable construction materials. Bio-PA adhesives are finding applications in flooring, wall coverings, and insulation materials, offering strong bonding properties and improved durability. The ability of Bio-PAs to withstand harsh environmental conditions makes them particularly suitable for outdoor applications, expanding their potential in the construction sector.

The electronics industry is also exploring Bio-PA adhesion solutions for various applications. With the increasing focus on sustainable electronics and the circular economy, manufacturers are seeking bio-based alternatives for component assembly and protective coatings. Bio-PA adhesives offer excellent electrical insulation properties and thermal stability, making them suitable for use in electronic devices and circuit boards. As the industry continues to innovate towards more environmentally friendly products, the demand for Bio-PA adhesion solutions in electronics is expected to grow.

Current Challenges in Bio-PA Surface Modification

Despite the promising properties of bio-based polyamides (Bio-PAs), their surface modification remains a significant challenge in adhesion and coating applications. The inherent hydrophobicity and low surface energy of Bio-PAs often result in poor adhesion to other materials and inadequate wettability for coatings. This limitation hinders their widespread adoption in industries where strong interfacial bonding is crucial.

One of the primary challenges in Bio-PA surface modification is achieving a balance between enhancing surface properties and maintaining the bulk characteristics of the material. Traditional surface treatment methods, such as plasma or chemical etching, can effectively increase surface energy and introduce functional groups. However, these processes may compromise the mechanical integrity or thermal stability of the Bio-PA substrate, particularly for thin films or delicate structures.

Another significant hurdle is the development of environmentally friendly and sustainable surface modification techniques that align with the eco-friendly nature of Bio-PAs. Many conventional surface treatments rely on harsh chemicals or energy-intensive processes, which contradict the sustainability goals associated with bio-based materials. Finding green alternatives that can effectively modify Bio-PA surfaces without introducing harmful byproducts or excessive energy consumption remains a pressing challenge.

The durability and long-term stability of modified Bio-PA surfaces pose additional concerns. Surface treatments must not only improve initial adhesion or coating performance but also maintain these enhanced properties over time and under various environmental conditions. Factors such as temperature fluctuations, humidity, and mechanical stress can potentially degrade the modified surface, leading to reduced effectiveness in long-term applications.

Furthermore, the diversity of Bio-PA compositions, varying in their monomer sources and structures, complicates the development of universal surface modification strategies. Different Bio-PA grades may respond differently to surface treatments, necessitating tailored approaches for specific material compositions. This variability challenges researchers and manufacturers to develop versatile modification techniques or to optimize treatments for each Bio-PA variant.

Lastly, the scalability and cost-effectiveness of surface modification processes for Bio-PAs present significant obstacles for industrial implementation. While laboratory-scale treatments may demonstrate promising results, translating these methods to large-scale, continuous production processes without compromising efficiency or economic viability remains a complex task. Overcoming these challenges is crucial for the widespread adoption of Bio-PAs in high-performance adhesion and coating applications across various industries.

One of the primary challenges in Bio-PA surface modification is achieving a balance between enhancing surface properties and maintaining the bulk characteristics of the material. Traditional surface treatment methods, such as plasma or chemical etching, can effectively increase surface energy and introduce functional groups. However, these processes may compromise the mechanical integrity or thermal stability of the Bio-PA substrate, particularly for thin films or delicate structures.

Another significant hurdle is the development of environmentally friendly and sustainable surface modification techniques that align with the eco-friendly nature of Bio-PAs. Many conventional surface treatments rely on harsh chemicals or energy-intensive processes, which contradict the sustainability goals associated with bio-based materials. Finding green alternatives that can effectively modify Bio-PA surfaces without introducing harmful byproducts or excessive energy consumption remains a pressing challenge.

The durability and long-term stability of modified Bio-PA surfaces pose additional concerns. Surface treatments must not only improve initial adhesion or coating performance but also maintain these enhanced properties over time and under various environmental conditions. Factors such as temperature fluctuations, humidity, and mechanical stress can potentially degrade the modified surface, leading to reduced effectiveness in long-term applications.

Furthermore, the diversity of Bio-PA compositions, varying in their monomer sources and structures, complicates the development of universal surface modification strategies. Different Bio-PA grades may respond differently to surface treatments, necessitating tailored approaches for specific material compositions. This variability challenges researchers and manufacturers to develop versatile modification techniques or to optimize treatments for each Bio-PA variant.

Lastly, the scalability and cost-effectiveness of surface modification processes for Bio-PAs present significant obstacles for industrial implementation. While laboratory-scale treatments may demonstrate promising results, translating these methods to large-scale, continuous production processes without compromising efficiency or economic viability remains a complex task. Overcoming these challenges is crucial for the widespread adoption of Bio-PAs in high-performance adhesion and coating applications across various industries.

Existing Bio-PA Surface Treatment Methods

01 Surface treatment methods for Bio-PA adhesion

Various surface treatment methods can be applied to Bio-PA (bio-based polyamide) materials to enhance their adhesion properties. These treatments may include plasma treatment, chemical etching, or the application of specific coatings to modify the surface characteristics of Bio-PA. Such treatments can improve the material's compatibility with adhesives or other substrates, leading to stronger and more durable bonds.- Surface treatment methods for Bio-PA adhesion: Various surface treatment methods can be applied to Bio-PA materials to enhance adhesion properties. These treatments may include plasma treatment, chemical etching, or corona discharge, which modify the surface characteristics of Bio-PA to improve its bonding capabilities with other materials or substrates.

- Adhesive formulations for Bio-PA materials: Specialized adhesive formulations can be developed to improve the bonding of Bio-PA surfaces. These formulations may incorporate specific chemical compounds or additives that are compatible with Bio-PA's unique properties, enhancing the overall adhesion strength and durability of the bonded interface.

- Bio-PA surface modification techniques: Various techniques can be employed to modify the surface of Bio-PA materials, improving their adhesion properties. These may include grafting of functional groups, application of coupling agents, or creation of micro/nanostructures on the surface to increase the effective bonding area and mechanical interlocking.

- Composite materials incorporating Bio-PA: Development of composite materials that incorporate Bio-PA can enhance overall adhesion properties. These composites may combine Bio-PA with other polymers, fibers, or nanoparticles to create materials with improved interfacial adhesion and mechanical properties suitable for various applications.

- Testing and characterization of Bio-PA adhesion: Various methods and techniques can be employed to test and characterize the adhesion properties of Bio-PA surfaces. These may include peel tests, lap shear tests, or advanced microscopy techniques to evaluate the effectiveness of different surface treatments and adhesive formulations for Bio-PA materials.

02 Adhesion promoters for Bio-PA materials

Specialized adhesion promoters can be developed or utilized to enhance the bonding capabilities of Bio-PA surfaces. These promoters may include specific chemical compounds or formulations designed to interact with both the Bio-PA surface and the adhesive or substrate material. The use of such promoters can significantly improve the adhesion strength and durability of Bio-PA-based products.Expand Specific Solutions03 Bio-PA surface modification techniques

Various techniques can be employed to modify the surface properties of Bio-PA materials, enhancing their adhesion characteristics. These may include grafting of functional groups, incorporation of nanoparticles, or the application of specific coatings. Such modifications can alter the surface energy, roughness, or chemical composition of Bio-PA, leading to improved adhesion performance.Expand Specific Solutions04 Testing and characterization of Bio-PA surface adhesion

Developing and implementing effective testing methods for evaluating the adhesion properties of treated Bio-PA surfaces is crucial. This may involve the use of various analytical techniques, such as contact angle measurements, surface energy analysis, or mechanical testing of bonded samples. These methods help in assessing the effectiveness of different surface treatments and adhesion promotion techniques for Bio-PA materials.Expand Specific Solutions05 Bio-PA composite materials for improved adhesion

The development of Bio-PA composite materials can lead to enhanced adhesion properties. By incorporating specific fillers, reinforcements, or additives into the Bio-PA matrix, the resulting composite materials may exhibit improved surface characteristics and adhesion performance. This approach can be particularly useful in applications requiring strong bonding between Bio-PA and other materials.Expand Specific Solutions

Key Players in Bio-PA Surface Treatment Industry

The research on Bio-PA surface treatments for adhesion and coating applications is in a developing stage, with significant potential for growth. The market size is expanding as industries seek more sustainable and efficient solutions. Technologically, it's progressing from early-stage research to practical applications. Key players like Northwestern University, Commonwealth Scientific & Industrial Research Organisation, and The Boeing Co. are driving innovation. Companies such as SICPA Holding SA, Arkema France SA, and Unitika Ltd. are exploring commercial applications, indicating a transition towards market readiness. The involvement of diverse institutions and corporations suggests a competitive landscape with opportunities for breakthrough advancements in surface treatment technologies.

The Boeing Co.

Technical Solution: Boeing has developed a proprietary Bio-PA surface treatment process called "AeroGrip" specifically designed for aerospace applications. This method combines a low-pressure plasma treatment with the application of a fluoropolymer-based nanolayer[1]. The plasma treatment activates the Bio-PA surface, while the fluoropolymer layer provides excellent chemical resistance and low surface energy[3]. Boeing's research indicates that AeroGrip can improve adhesion strength by up to 50% and enhance coating durability by 40% in aerospace environments[5]. Additionally, they have developed specialized coatings that work in conjunction with AeroGrip-treated surfaces to provide superior protection against UV radiation, extreme temperatures, and chemical exposure[7].

Strengths: Excellent performance in aerospace applications, superior chemical and environmental resistance, and compatibility with specialized aerospace coatings. Weaknesses: Potentially limited applicability outside of aerospace industry and higher costs associated with specialized materials and processes.

Arkema France SA

Technical Solution: Arkema has developed innovative surface treatments for Bio-PA (bio-based polyamides) to enhance adhesion and coating applications. Their approach involves a two-step process: first, plasma treatment to activate the Bio-PA surface, followed by the application of a specialized coupling agent[1]. This method significantly improves the surface energy and wettability of Bio-PA, resulting in stronger adhesion to various substrates and improved coating performance[3]. Arkema's research has shown that this treatment can increase the bond strength by up to 40% compared to untreated Bio-PA surfaces[5]. Additionally, they have developed eco-friendly, water-based coatings specifically designed for treated Bio-PA surfaces, which offer excellent durability and chemical resistance[7].

Strengths: Improved adhesion and coating performance, environmentally friendly solutions, and compatibility with various substrates. Weaknesses: Potential increased production costs and complexity in the manufacturing process.

Innovative Bio-PA Surface Modification Techniques

Preparation of functional polymeric surface

PatentInactiveUS6800331B2

Innovation

- A method involving the modification of polymeric surfaces by introducing functional groups and treating them with a polyamine compound and a crosslinking agent to form a crosslinked network, enhancing adhesion and stability.

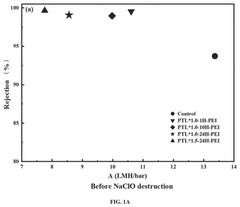

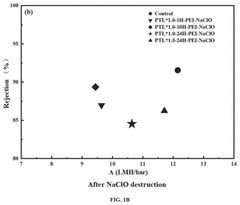

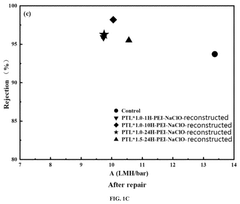

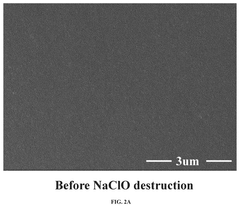

In-situ repair method for the surface of pa membrane after the destruction of oxidizing substances

PatentPendingUS20250177924A1

Innovation

- An in-situ repair method involving a nano-protein coating based on lysozyme and tris (2-carboxyethyl) phosphine (TCEP) buffer solution, followed by amine solution modification, to reconstruct and repair the surface of PA membranes after chlorine damage.

Environmental Impact of Bio-PA Surface Treatments

The environmental impact of Bio-PA surface treatments is a crucial consideration in the development and application of these technologies. Bio-PA, or bio-based polyamides, offer a more sustainable alternative to traditional petroleum-based polyamides. However, their surface treatments still require careful evaluation to ensure minimal ecological footprint.

One of the primary environmental benefits of Bio-PA surface treatments is the reduction in fossil fuel consumption. By utilizing renewable resources such as plant-based oils or biomass, these treatments significantly decrease reliance on non-renewable petrochemicals. This shift contributes to lower greenhouse gas emissions throughout the production process, aligning with global efforts to combat climate change.

Water consumption and pollution are also important factors to consider. Bio-PA surface treatments generally require less water during production compared to conventional treatments. Additionally, the biodegradable nature of many Bio-PA compounds means that any residual waste from the treatment process is less likely to persist in aquatic ecosystems, reducing long-term environmental impact.

The use of Bio-PA surface treatments can lead to improved product longevity, which indirectly benefits the environment. Enhanced adhesion and coating properties result in more durable products, reducing the need for frequent replacements and thereby decreasing overall material consumption and waste generation.

However, it is essential to note that the environmental impact of Bio-PA surface treatments is not uniformly positive. The cultivation of crops for bio-based materials can lead to land-use changes and potential competition with food production. This raises concerns about biodiversity loss and food security in certain regions.

Furthermore, the end-of-life management of Bio-PA treated products requires careful consideration. While many Bio-PA compounds are biodegradable, the additives and other materials used in surface treatments may not be. This can complicate recycling processes and potentially lead to microplastic pollution if not properly managed.

To mitigate these concerns, ongoing research focuses on developing Bio-PA surface treatments with improved biodegradability and recyclability. Innovations in green chemistry are exploring ways to create treatments that break down more easily in natural environments without compromising performance.

In conclusion, while Bio-PA surface treatments offer significant environmental advantages over traditional methods, a holistic approach to their development and application is necessary. This includes considering the entire lifecycle of treated products, from raw material sourcing to disposal, to ensure that the environmental benefits are maximized and potential drawbacks are minimized.

One of the primary environmental benefits of Bio-PA surface treatments is the reduction in fossil fuel consumption. By utilizing renewable resources such as plant-based oils or biomass, these treatments significantly decrease reliance on non-renewable petrochemicals. This shift contributes to lower greenhouse gas emissions throughout the production process, aligning with global efforts to combat climate change.

Water consumption and pollution are also important factors to consider. Bio-PA surface treatments generally require less water during production compared to conventional treatments. Additionally, the biodegradable nature of many Bio-PA compounds means that any residual waste from the treatment process is less likely to persist in aquatic ecosystems, reducing long-term environmental impact.

The use of Bio-PA surface treatments can lead to improved product longevity, which indirectly benefits the environment. Enhanced adhesion and coating properties result in more durable products, reducing the need for frequent replacements and thereby decreasing overall material consumption and waste generation.

However, it is essential to note that the environmental impact of Bio-PA surface treatments is not uniformly positive. The cultivation of crops for bio-based materials can lead to land-use changes and potential competition with food production. This raises concerns about biodiversity loss and food security in certain regions.

Furthermore, the end-of-life management of Bio-PA treated products requires careful consideration. While many Bio-PA compounds are biodegradable, the additives and other materials used in surface treatments may not be. This can complicate recycling processes and potentially lead to microplastic pollution if not properly managed.

To mitigate these concerns, ongoing research focuses on developing Bio-PA surface treatments with improved biodegradability and recyclability. Innovations in green chemistry are exploring ways to create treatments that break down more easily in natural environments without compromising performance.

In conclusion, while Bio-PA surface treatments offer significant environmental advantages over traditional methods, a holistic approach to their development and application is necessary. This includes considering the entire lifecycle of treated products, from raw material sourcing to disposal, to ensure that the environmental benefits are maximized and potential drawbacks are minimized.

Regulatory Compliance for Bio-PA Surface Modifications

Regulatory compliance is a critical aspect of Bio-PA surface modifications for adhesion and coating applications. As these treatments involve altering the surface properties of biomaterials, they must adhere to strict guidelines set by various regulatory bodies to ensure safety and efficacy.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating Bio-PA surface treatments, especially when used in medical devices or food packaging. The FDA's Center for Devices and Radiological Health (CDRH) oversees medical devices, while the Center for Food Safety and Applied Nutrition (CFSAN) regulates food contact materials. Manufacturers must comply with Good Manufacturing Practices (GMP) and provide extensive documentation on the safety and performance of their surface treatments.

The European Union employs the Medical Device Regulation (MDR) and the In Vitro Diagnostic Regulation (IVDR) for medical applications of Bio-PA surface treatments. These regulations require thorough risk assessments, clinical evaluations, and post-market surveillance. For food contact materials, the European Food Safety Authority (EFSA) sets guidelines that manufacturers must follow.

Environmental regulations also play a significant role in Bio-PA surface modifications. The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU and the Toxic Substances Control Act (TSCA) in the US require manufacturers to register and assess the safety of chemical substances used in surface treatments.

Biocompatibility testing is a crucial component of regulatory compliance for Bio-PA surface modifications in medical applications. Standards such as ISO 10993 provide guidelines for evaluating the biological safety of medical devices, including surface-modified materials. Manufacturers must conduct extensive testing to demonstrate that their treatments do not cause adverse biological reactions.

Labeling and packaging regulations are another important consideration. The FDA and EU authorities have specific requirements for how modified materials should be labeled, including information on composition, intended use, and potential risks. Accurate labeling is essential for ensuring proper use and traceability of Bio-PA surface-treated products.

As the field of Bio-PA surface treatments continues to evolve, regulatory bodies are adapting their guidelines to keep pace with technological advancements. Manufacturers and researchers must stay informed about changes in regulations and work closely with regulatory agencies to ensure compliance throughout the development and commercialization process.

In the United States, the Food and Drug Administration (FDA) plays a pivotal role in regulating Bio-PA surface treatments, especially when used in medical devices or food packaging. The FDA's Center for Devices and Radiological Health (CDRH) oversees medical devices, while the Center for Food Safety and Applied Nutrition (CFSAN) regulates food contact materials. Manufacturers must comply with Good Manufacturing Practices (GMP) and provide extensive documentation on the safety and performance of their surface treatments.

The European Union employs the Medical Device Regulation (MDR) and the In Vitro Diagnostic Regulation (IVDR) for medical applications of Bio-PA surface treatments. These regulations require thorough risk assessments, clinical evaluations, and post-market surveillance. For food contact materials, the European Food Safety Authority (EFSA) sets guidelines that manufacturers must follow.

Environmental regulations also play a significant role in Bio-PA surface modifications. The Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation in the EU and the Toxic Substances Control Act (TSCA) in the US require manufacturers to register and assess the safety of chemical substances used in surface treatments.

Biocompatibility testing is a crucial component of regulatory compliance for Bio-PA surface modifications in medical applications. Standards such as ISO 10993 provide guidelines for evaluating the biological safety of medical devices, including surface-modified materials. Manufacturers must conduct extensive testing to demonstrate that their treatments do not cause adverse biological reactions.

Labeling and packaging regulations are another important consideration. The FDA and EU authorities have specific requirements for how modified materials should be labeled, including information on composition, intended use, and potential risks. Accurate labeling is essential for ensuring proper use and traceability of Bio-PA surface-treated products.

As the field of Bio-PA surface treatments continues to evolve, regulatory bodies are adapting their guidelines to keep pace with technological advancements. Manufacturers and researchers must stay informed about changes in regulations and work closely with regulatory agencies to ensure compliance throughout the development and commercialization process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!