How to Achieve FDA-Grade Bio-PA for Food Contact Applications (regulatory steps)

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FDA-Grade Bio-PA Background and Objectives

Bio-based polyamides (Bio-PAs) have emerged as a sustainable alternative to traditional petroleum-based polyamides in food contact applications. The development of FDA-grade Bio-PAs represents a significant advancement in the field of bioplastics, addressing both environmental concerns and regulatory requirements for food safety.

The evolution of Bio-PAs can be traced back to the early 2000s when researchers began exploring renewable resources for polymer production. Initial efforts focused on utilizing plant-based feedstocks such as castor oil and sebacic acid to create bio-based monomers. As the technology progressed, more diverse biomass sources were incorporated, including corn, sugarcane, and even agricultural waste products.

The primary objective in developing FDA-grade Bio-PAs is to create materials that meet or exceed the performance characteristics of conventional polyamides while ensuring compliance with stringent food safety regulations. This involves optimizing the chemical composition, processing techniques, and additive formulations to achieve desired mechanical properties, thermal stability, and barrier performance.

A key challenge in this pursuit is maintaining consistent quality and purity of bio-based raw materials, which can vary depending on agricultural conditions and processing methods. Researchers and manufacturers are working to develop standardized protocols for sourcing and refining bio-based monomers to ensure reproducible results in polymer production.

Another critical aspect of FDA-grade Bio-PA development is the need for comprehensive toxicological assessments and migration studies. These evaluations are essential to demonstrate the safety of the material when in contact with food and to obtain regulatory approval. Researchers are focusing on developing analytical methods to accurately detect and quantify potential migrants from Bio-PAs, as well as studying the long-term stability of these materials under various food contact conditions.

The regulatory landscape for Bio-PAs in food contact applications is complex and evolving. In the United States, the FDA's Food Contact Notification (FCN) program provides a pathway for manufacturers to obtain clearance for new food contact substances. Achieving FDA approval for Bio-PAs requires extensive documentation, including detailed information on the manufacturing process, chemical composition, and safety data.

Looking ahead, the development of FDA-grade Bio-PAs is expected to accelerate as sustainability becomes an increasingly important factor in material selection for food packaging. Researchers are exploring novel bio-based monomers and innovative polymerization techniques to further enhance the properties and reduce the environmental footprint of these materials. Additionally, efforts are underway to improve the end-of-life options for Bio-PAs, including biodegradability and recyclability, to create a more circular economy for food packaging materials.

The evolution of Bio-PAs can be traced back to the early 2000s when researchers began exploring renewable resources for polymer production. Initial efforts focused on utilizing plant-based feedstocks such as castor oil and sebacic acid to create bio-based monomers. As the technology progressed, more diverse biomass sources were incorporated, including corn, sugarcane, and even agricultural waste products.

The primary objective in developing FDA-grade Bio-PAs is to create materials that meet or exceed the performance characteristics of conventional polyamides while ensuring compliance with stringent food safety regulations. This involves optimizing the chemical composition, processing techniques, and additive formulations to achieve desired mechanical properties, thermal stability, and barrier performance.

A key challenge in this pursuit is maintaining consistent quality and purity of bio-based raw materials, which can vary depending on agricultural conditions and processing methods. Researchers and manufacturers are working to develop standardized protocols for sourcing and refining bio-based monomers to ensure reproducible results in polymer production.

Another critical aspect of FDA-grade Bio-PA development is the need for comprehensive toxicological assessments and migration studies. These evaluations are essential to demonstrate the safety of the material when in contact with food and to obtain regulatory approval. Researchers are focusing on developing analytical methods to accurately detect and quantify potential migrants from Bio-PAs, as well as studying the long-term stability of these materials under various food contact conditions.

The regulatory landscape for Bio-PAs in food contact applications is complex and evolving. In the United States, the FDA's Food Contact Notification (FCN) program provides a pathway for manufacturers to obtain clearance for new food contact substances. Achieving FDA approval for Bio-PAs requires extensive documentation, including detailed information on the manufacturing process, chemical composition, and safety data.

Looking ahead, the development of FDA-grade Bio-PAs is expected to accelerate as sustainability becomes an increasingly important factor in material selection for food packaging. Researchers are exploring novel bio-based monomers and innovative polymerization techniques to further enhance the properties and reduce the environmental footprint of these materials. Additionally, efforts are underway to improve the end-of-life options for Bio-PAs, including biodegradability and recyclability, to create a more circular economy for food packaging materials.

Market Analysis for Food Contact Bio-PA

The market for food contact Bio-PA (bio-based polyamides) is experiencing significant growth driven by increasing consumer demand for sustainable and eco-friendly packaging solutions. This trend is particularly pronounced in developed regions such as North America and Europe, where stringent regulations on food safety and environmental protection are in place. The global market for bio-based polymers in food packaging is projected to expand at a compound annual growth rate (CAGR) of over 15% in the next five years.

Bio-PA offers several advantages over traditional petroleum-based polyamides, including reduced carbon footprint, improved recyclability, and enhanced barrier properties. These characteristics make Bio-PA an attractive option for food packaging manufacturers seeking to meet sustainability goals while maintaining product performance. The market demand is particularly strong in applications such as flexible packaging films, rigid containers, and beverage bottles.

Key market drivers include the growing awareness of environmental issues among consumers, government regulations promoting the use of bio-based materials, and the food industry's commitment to reducing plastic waste. Major food and beverage companies have set ambitious targets to increase the use of sustainable packaging materials, creating a favorable market environment for Bio-PA producers.

However, the market faces challenges such as higher production costs compared to conventional polyamides and limited production capacity. The price premium for Bio-PA remains a significant barrier to widespread adoption, especially in price-sensitive market segments. Additionally, the availability of raw materials for Bio-PA production, primarily derived from renewable sources like castor oil or corn, can be subject to supply chain disruptions and price fluctuations.

The competitive landscape is characterized by a mix of established chemical companies and innovative start-ups. Major players are investing heavily in research and development to improve the performance and cost-effectiveness of Bio-PA materials. Collaborations between material suppliers, packaging manufacturers, and food companies are becoming increasingly common to accelerate the development and commercialization of Bio-PA solutions.

Geographically, Europe leads the market for food contact Bio-PA, followed by North America and Asia-Pacific. The European market benefits from supportive regulatory frameworks and consumer preferences for sustainable products. In North America, the market is driven by the adoption of Bio-PA by large food and beverage brands. The Asia-Pacific region is expected to show the highest growth rate in the coming years, fueled by rapid industrialization and increasing environmental awareness.

Looking ahead, the market for food contact Bio-PA is poised for continued expansion. Technological advancements in production processes and the development of new Bio-PA grades with enhanced properties are expected to drive market growth. The increasing focus on circular economy principles and the potential for Bio-PA in recycling streams will likely create new opportunities in the market.

Bio-PA offers several advantages over traditional petroleum-based polyamides, including reduced carbon footprint, improved recyclability, and enhanced barrier properties. These characteristics make Bio-PA an attractive option for food packaging manufacturers seeking to meet sustainability goals while maintaining product performance. The market demand is particularly strong in applications such as flexible packaging films, rigid containers, and beverage bottles.

Key market drivers include the growing awareness of environmental issues among consumers, government regulations promoting the use of bio-based materials, and the food industry's commitment to reducing plastic waste. Major food and beverage companies have set ambitious targets to increase the use of sustainable packaging materials, creating a favorable market environment for Bio-PA producers.

However, the market faces challenges such as higher production costs compared to conventional polyamides and limited production capacity. The price premium for Bio-PA remains a significant barrier to widespread adoption, especially in price-sensitive market segments. Additionally, the availability of raw materials for Bio-PA production, primarily derived from renewable sources like castor oil or corn, can be subject to supply chain disruptions and price fluctuations.

The competitive landscape is characterized by a mix of established chemical companies and innovative start-ups. Major players are investing heavily in research and development to improve the performance and cost-effectiveness of Bio-PA materials. Collaborations between material suppliers, packaging manufacturers, and food companies are becoming increasingly common to accelerate the development and commercialization of Bio-PA solutions.

Geographically, Europe leads the market for food contact Bio-PA, followed by North America and Asia-Pacific. The European market benefits from supportive regulatory frameworks and consumer preferences for sustainable products. In North America, the market is driven by the adoption of Bio-PA by large food and beverage brands. The Asia-Pacific region is expected to show the highest growth rate in the coming years, fueled by rapid industrialization and increasing environmental awareness.

Looking ahead, the market for food contact Bio-PA is poised for continued expansion. Technological advancements in production processes and the development of new Bio-PA grades with enhanced properties are expected to drive market growth. The increasing focus on circular economy principles and the potential for Bio-PA in recycling streams will likely create new opportunities in the market.

Current Challenges in Bio-PA for Food Contact

The development of bio-based polyamides (Bio-PA) for food contact applications faces several significant challenges that hinder their widespread adoption and regulatory approval. One of the primary obstacles is achieving consistent quality and performance comparable to traditional petroleum-based polyamides. Bio-PAs often exhibit variations in mechanical properties, thermal stability, and barrier characteristics due to the inherent variability of their bio-based raw materials.

Another major challenge lies in the sourcing and supply chain management of bio-based feedstocks. Ensuring a stable and sustainable supply of high-quality bio-based monomers can be difficult, as agricultural yields and quality can fluctuate due to environmental factors. This inconsistency can lead to variations in the final product's properties and performance, making it challenging to meet the stringent requirements for food contact materials.

The migration of substances from Bio-PAs into food is a critical concern for regulatory bodies like the FDA. Demonstrating that these materials do not release harmful substances or alter the organoleptic properties of food under various conditions is complex and requires extensive testing. The potential presence of residual monomers, oligomers, or processing aids specific to bio-based production methods adds another layer of complexity to migration studies and safety assessments.

Biodegradability and compostability, while often seen as advantages of bio-based materials, can pose challenges in food contact applications. Ensuring that Bio-PAs maintain their integrity and barrier properties throughout the intended shelf life of the packaged food product, while still offering environmental benefits, requires careful material design and extensive stability testing.

Cost-effectiveness remains a significant hurdle for Bio-PAs in food contact applications. The production processes for these materials are often more expensive than those for conventional polyamides, making it difficult to compete in price-sensitive markets. Scaling up production to achieve economies of scale while maintaining consistent quality is a challenge that manufacturers must overcome to make Bio-PAs commercially viable for food packaging.

Lastly, navigating the complex regulatory landscape for novel food contact materials presents a formidable challenge. The FDA's approval process for new food contact substances is rigorous and time-consuming, requiring extensive documentation, toxicological studies, and migration data. For Bio-PAs, demonstrating equivalence to existing approved materials or establishing a new safety profile can be particularly challenging due to their unique composition and production methods.

Another major challenge lies in the sourcing and supply chain management of bio-based feedstocks. Ensuring a stable and sustainable supply of high-quality bio-based monomers can be difficult, as agricultural yields and quality can fluctuate due to environmental factors. This inconsistency can lead to variations in the final product's properties and performance, making it challenging to meet the stringent requirements for food contact materials.

The migration of substances from Bio-PAs into food is a critical concern for regulatory bodies like the FDA. Demonstrating that these materials do not release harmful substances or alter the organoleptic properties of food under various conditions is complex and requires extensive testing. The potential presence of residual monomers, oligomers, or processing aids specific to bio-based production methods adds another layer of complexity to migration studies and safety assessments.

Biodegradability and compostability, while often seen as advantages of bio-based materials, can pose challenges in food contact applications. Ensuring that Bio-PAs maintain their integrity and barrier properties throughout the intended shelf life of the packaged food product, while still offering environmental benefits, requires careful material design and extensive stability testing.

Cost-effectiveness remains a significant hurdle for Bio-PAs in food contact applications. The production processes for these materials are often more expensive than those for conventional polyamides, making it difficult to compete in price-sensitive markets. Scaling up production to achieve economies of scale while maintaining consistent quality is a challenge that manufacturers must overcome to make Bio-PAs commercially viable for food packaging.

Lastly, navigating the complex regulatory landscape for novel food contact materials presents a formidable challenge. The FDA's approval process for new food contact substances is rigorous and time-consuming, requiring extensive documentation, toxicological studies, and migration data. For Bio-PAs, demonstrating equivalence to existing approved materials or establishing a new safety profile can be particularly challenging due to their unique composition and production methods.

Existing FDA-Grade Bio-PA Solutions

01 Synthesis of bio-based polyamides

Bio-based polyamides are synthesized using renewable resources such as plant-derived monomers. This process involves the polymerization of bio-based diamines and diacids to create environmentally friendly alternatives to traditional petroleum-based polyamides. The resulting materials often exhibit comparable or superior properties to their conventional counterparts.- Synthesis of bio-based polyamides: Bio-based polyamides are synthesized using renewable resources such as plant-derived monomers. These processes often involve the polymerization of bio-based diamines and diacids to create sustainable alternatives to traditional petroleum-based polyamides. The resulting materials offer improved environmental profiles while maintaining desirable mechanical properties.

- Blending bio-PA with other polymers: Bio-based polyamides are often blended with other polymers to enhance their properties or create composite materials. These blends can improve characteristics such as strength, flexibility, or heat resistance. The resulting materials find applications in various industries, including automotive, packaging, and textiles.

- Bio-PA in 3D printing applications: Bio-based polyamides are increasingly used in 3D printing applications due to their sustainability and performance characteristics. These materials offer advantages such as good layer adhesion, dimensional stability, and resistance to warping. They are particularly suitable for producing functional prototypes and end-use parts in various industries.

- Modification of bio-PA properties: Various techniques are employed to modify the properties of bio-based polyamides, including chemical modification, addition of nanofillers, and surface treatments. These modifications can enhance characteristics such as thermal stability, flame retardancy, or barrier properties, expanding the range of applications for bio-PAs in demanding environments.

- Bio-PA in packaging and textile applications: Bio-based polyamides are increasingly used in packaging and textile applications due to their renewable nature and performance characteristics. In packaging, they offer good barrier properties and durability. In textiles, bio-PAs provide moisture management, comfort, and durability, making them suitable for sportswear and technical textiles.

02 Blending bio-PA with other polymers

Bio-based polyamides can be blended with other polymers to enhance their properties or create new materials with unique characteristics. These blends may improve mechanical strength, thermal stability, or processability. The resulting composites often find applications in various industries, including automotive, packaging, and textiles.Expand Specific Solutions03 Modification of bio-PA for specific applications

Bio-based polyamides can be chemically or physically modified to tailor their properties for specific applications. This may involve the incorporation of additives, surface treatments, or the creation of copolymers. Such modifications can enhance properties like flame retardancy, impact resistance, or barrier properties.Expand Specific Solutions04 Processing techniques for bio-PA

Various processing techniques are employed to manufacture products from bio-based polyamides. These may include injection molding, extrusion, or 3D printing. The processing parameters are often optimized to account for the unique characteristics of bio-PAs, ensuring high-quality end products with desired properties.Expand Specific Solutions05 Recycling and end-of-life considerations for bio-PA

Research is conducted on the recyclability and biodegradability of bio-based polyamides to address end-of-life concerns. This includes developing efficient recycling processes, studying the environmental impact of bio-PA products, and exploring potential biodegradation pathways. These efforts aim to create a more sustainable lifecycle for bio-PA materials.Expand Specific Solutions

Key Players in Bio-PA and Food Packaging Industry

The regulatory landscape for FDA-grade Bio-PA in food contact applications is evolving, with the market in its early growth stage. The global bio-based plastics market, including Bio-PA, is projected to reach $19.93 billion by 2026, growing at a CAGR of 16.2%. Technological maturity varies among key players, with companies like DSM IP Assets BV, Cathay Biotech, and Wanhua Chemical Group Co., Ltd. leading in innovation and commercialization. These firms are investing heavily in R&D to improve Bio-PA properties and production efficiency. Regulatory compliance remains a critical challenge, with companies navigating complex FDA approval processes to ensure food safety standards are met.

DSM IP Assets BV

Technical Solution: DSM has developed a bio-based polyamide (Bio-PA) for food contact applications that meets FDA requirements. Their approach involves using renewable resources to produce monomers for PA synthesis. The company has implemented a rigorous quality control system to ensure consistent production of FDA-compliant Bio-PA. DSM's process includes thorough documentation of raw materials, manufacturing processes, and final product testing to meet regulatory standards[1]. They have also invested in advanced analytical techniques to detect and quantify potential migrants from the Bio-PA material, ensuring compliance with FDA limits[2].

Strengths: Established expertise in bio-based materials, strong R&D capabilities, and existing relationships with regulatory bodies. Weaknesses: Potentially higher production costs compared to traditional petroleum-based PA, and limited scalability of bio-based raw materials.

Cathay Biotech, Inc.

Technical Solution: Cathay Biotech has developed a proprietary fermentation process to produce bio-based monomers for PA synthesis. Their technology focuses on using renewable feedstocks to create high-performance Bio-PA that meets FDA standards for food contact applications. The company has implemented a comprehensive traceability system to track the entire production process, from raw material sourcing to final product testing[3]. Cathay Biotech's regulatory approach includes extensive migration studies and toxicological assessments to ensure compliance with FDA guidelines. They have also developed specialized additives to enhance the performance and stability of their Bio-PA in food contact scenarios[4].

Strengths: Innovative fermentation technology, vertically integrated production process, and focus on high-performance materials. Weaknesses: Relatively new player in the market, potentially limited production capacity compared to established petrochemical companies.

Core Innovations in Bio-PA Food Contact Materials

A kind of food contact grade phenolic molding compound and its preparation method and application

PatentActiveCN102276956A

Innovation

- Using raw materials such as oxalic acid-catalyzed thermoplastic phenolic resin, citric acid-purified wood powder, toothpaste-grade aluminum hydroxide, and methenamine, a food-contact grade phenolic molding compound is prepared with the specified ratio and process flow. , control the content of free phenol and formaldehyde, use carbon black produced by Cabot Company of the United States as colorant, and can add lubricants and curing accelerators.

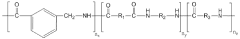

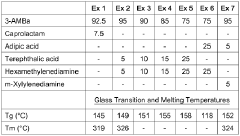

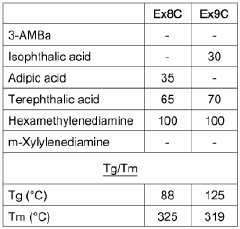

Copolyamides obtainable from 3-(aminomethyl)benzoic acid

PatentWO2018229127A1

Innovation

- Development of copolyamides comprising at least 5 mol% of 3-(aminomethyl)benzoic acid, derived from biomass, which are copolymerized with dicarboxylic acids, diamines, and/or lactams to achieve high glass transition temperatures suitable for demanding applications.

Regulatory Framework for FDA-Grade Bio-PA

The regulatory framework for FDA-grade Bio-PA in food contact applications is a complex and multifaceted system designed to ensure the safety and compliance of biobased polyamides. This framework is primarily governed by the U.S. Food and Drug Administration (FDA) under the Federal Food, Drug, and Cosmetic Act (FD&C Act) and its subsequent amendments.

At the core of this regulatory structure is the FDA's Food Contact Substance Notification (FCN) program. This program requires manufacturers to submit detailed information about the chemical composition, manufacturing process, and intended use of their Bio-PA materials. The FCN must demonstrate that the substance is safe for its intended use and will not migrate to food in quantities that could pose a health risk.

The FDA's guidance for food contact substances includes specific requirements for toxicological testing and exposure assessment. Manufacturers must provide data on the potential migration of Bio-PA components into food, as well as comprehensive toxicological studies to evaluate any potential health risks. These studies typically include genotoxicity tests, subchronic toxicity studies, and, in some cases, chronic toxicity or carcinogenicity studies.

In addition to the FCN program, Bio-PA manufacturers must comply with Good Manufacturing Practices (GMPs) as outlined in 21 CFR Part 174. These practices ensure that food contact materials are produced under conditions that prevent contamination and maintain consistent quality. The FDA also requires ongoing compliance monitoring and reporting of any new information that may affect the safety assessment of the Bio-PA.

The regulatory framework also addresses the sourcing of raw materials for Bio-PA production. Manufacturers must provide detailed information on the biobased feedstocks used, including their origin, processing methods, and potential contaminants. This is particularly important for ensuring the sustainability and safety of Bio-PA materials derived from renewable resources.

Furthermore, the FDA's regulatory approach considers the entire lifecycle of Bio-PA materials in food contact applications. This includes evaluating the potential for chemical changes during use, such as degradation products that may form under various conditions of temperature, pH, and food composition. Manufacturers must demonstrate that their Bio-PA materials maintain their integrity and safety throughout their intended use.

Internationally, the regulatory framework for FDA-grade Bio-PA must also align with global standards to facilitate trade and ensure consistent safety measures. This often involves harmonization efforts with regulatory bodies such as the European Food Safety Authority (EFSA) and consideration of international guidelines like those set by the World Health Organization (WHO).

At the core of this regulatory structure is the FDA's Food Contact Substance Notification (FCN) program. This program requires manufacturers to submit detailed information about the chemical composition, manufacturing process, and intended use of their Bio-PA materials. The FCN must demonstrate that the substance is safe for its intended use and will not migrate to food in quantities that could pose a health risk.

The FDA's guidance for food contact substances includes specific requirements for toxicological testing and exposure assessment. Manufacturers must provide data on the potential migration of Bio-PA components into food, as well as comprehensive toxicological studies to evaluate any potential health risks. These studies typically include genotoxicity tests, subchronic toxicity studies, and, in some cases, chronic toxicity or carcinogenicity studies.

In addition to the FCN program, Bio-PA manufacturers must comply with Good Manufacturing Practices (GMPs) as outlined in 21 CFR Part 174. These practices ensure that food contact materials are produced under conditions that prevent contamination and maintain consistent quality. The FDA also requires ongoing compliance monitoring and reporting of any new information that may affect the safety assessment of the Bio-PA.

The regulatory framework also addresses the sourcing of raw materials for Bio-PA production. Manufacturers must provide detailed information on the biobased feedstocks used, including their origin, processing methods, and potential contaminants. This is particularly important for ensuring the sustainability and safety of Bio-PA materials derived from renewable resources.

Furthermore, the FDA's regulatory approach considers the entire lifecycle of Bio-PA materials in food contact applications. This includes evaluating the potential for chemical changes during use, such as degradation products that may form under various conditions of temperature, pH, and food composition. Manufacturers must demonstrate that their Bio-PA materials maintain their integrity and safety throughout their intended use.

Internationally, the regulatory framework for FDA-grade Bio-PA must also align with global standards to facilitate trade and ensure consistent safety measures. This often involves harmonization efforts with regulatory bodies such as the European Food Safety Authority (EFSA) and consideration of international guidelines like those set by the World Health Organization (WHO).

Environmental Impact of Bio-PA in Food Packaging

The environmental impact of Bio-PA in food packaging is a crucial consideration as the industry moves towards more sustainable solutions. Bio-PA, or bio-based polyamide, offers a promising alternative to traditional petroleum-based plastics, potentially reducing the carbon footprint of food packaging materials.

One of the primary environmental benefits of Bio-PA is its renewable source material. Derived from plant-based resources such as castor oil or corn, Bio-PA reduces dependency on fossil fuels and contributes to a more circular economy. This shift towards renewable resources aligns with global efforts to mitigate climate change and reduce greenhouse gas emissions associated with plastic production.

In terms of biodegradability, Bio-PA presents a mixed picture. While it is not inherently biodegradable, some Bio-PA formulations can be designed to be compostable under specific conditions. This characteristic could potentially reduce the accumulation of plastic waste in landfills and oceans, a significant environmental concern associated with conventional plastics.

The production process of Bio-PA also tends to have a lower environmental impact compared to traditional polyamides. Studies have shown reduced energy consumption and lower emissions of harmful substances during manufacturing. However, the overall environmental benefit depends on factors such as farming practices for raw materials and the efficiency of the production chain.

When considering the entire lifecycle of Bio-PA food packaging, it's important to note its potential for recyclability. Many Bio-PA materials can be recycled through existing plastic recycling streams, which can further reduce their environmental footprint. However, the effectiveness of recycling depends on the availability and efficiency of local recycling infrastructure.

The durability and barrier properties of Bio-PA can contribute to extended shelf life for food products, potentially reducing food waste. This indirect environmental benefit is significant, as food waste is a major contributor to greenhouse gas emissions and resource depletion.

However, challenges remain in fully assessing the environmental impact of Bio-PA. The diversity of Bio-PA formulations and the complexity of food packaging systems make it difficult to draw universal conclusions. Additionally, the end-of-life management of Bio-PA products requires careful consideration to ensure that potential benefits are not offset by improper disposal or recycling practices.

As the food packaging industry continues to evolve, ongoing research and life cycle assessments will be crucial in fully understanding and optimizing the environmental performance of Bio-PA. Collaboration between material scientists, packaging designers, and environmental experts will be key to developing Bio-PA solutions that maximize environmental benefits while meeting the stringent requirements of food contact applications.

One of the primary environmental benefits of Bio-PA is its renewable source material. Derived from plant-based resources such as castor oil or corn, Bio-PA reduces dependency on fossil fuels and contributes to a more circular economy. This shift towards renewable resources aligns with global efforts to mitigate climate change and reduce greenhouse gas emissions associated with plastic production.

In terms of biodegradability, Bio-PA presents a mixed picture. While it is not inherently biodegradable, some Bio-PA formulations can be designed to be compostable under specific conditions. This characteristic could potentially reduce the accumulation of plastic waste in landfills and oceans, a significant environmental concern associated with conventional plastics.

The production process of Bio-PA also tends to have a lower environmental impact compared to traditional polyamides. Studies have shown reduced energy consumption and lower emissions of harmful substances during manufacturing. However, the overall environmental benefit depends on factors such as farming practices for raw materials and the efficiency of the production chain.

When considering the entire lifecycle of Bio-PA food packaging, it's important to note its potential for recyclability. Many Bio-PA materials can be recycled through existing plastic recycling streams, which can further reduce their environmental footprint. However, the effectiveness of recycling depends on the availability and efficiency of local recycling infrastructure.

The durability and barrier properties of Bio-PA can contribute to extended shelf life for food products, potentially reducing food waste. This indirect environmental benefit is significant, as food waste is a major contributor to greenhouse gas emissions and resource depletion.

However, challenges remain in fully assessing the environmental impact of Bio-PA. The diversity of Bio-PA formulations and the complexity of food packaging systems make it difficult to draw universal conclusions. Additionally, the end-of-life management of Bio-PA products requires careful consideration to ensure that potential benefits are not offset by improper disposal or recycling practices.

As the food packaging industry continues to evolve, ongoing research and life cycle assessments will be crucial in fully understanding and optimizing the environmental performance of Bio-PA. Collaboration between material scientists, packaging designers, and environmental experts will be key to developing Bio-PA solutions that maximize environmental benefits while meeting the stringent requirements of food contact applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!