What Is Bio-Based Polyamide: PA11 vs PA12 Properties and Typical Uses

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-Based Polyamide Overview and Objectives

Bio-based polyamides, particularly PA11 and PA12, represent a significant advancement in sustainable polymer technology. These materials have emerged as eco-friendly alternatives to traditional petroleum-based polyamides, addressing the growing demand for environmentally responsible engineering plastics. The development of bio-based polyamides aligns with the global shift towards renewable resources and reduced carbon footprint in industrial applications.

The primary objective of bio-based polyamide research and development is to create high-performance materials that match or exceed the properties of their fossil-based counterparts while offering improved sustainability. PA11 and PA12, derived from renewable sources such as castor oil, have gained prominence due to their unique combination of mechanical, thermal, and chemical properties.

As the polymer industry evolves, there is an increasing focus on understanding the nuanced differences between PA11 and PA12. Both materials offer distinct advantages in various applications, ranging from automotive components to industrial machinery and consumer goods. The comparison between PA11 and PA12 is crucial for engineers and product designers seeking to optimize material selection for specific end-use requirements.

The technological evolution of bio-based polyamides has been driven by advancements in polymer chemistry, process engineering, and material science. Researchers have made significant strides in improving the synthesis methods, enhancing the molecular structure, and fine-tuning the properties of these materials to meet diverse industrial needs.

A key aspect of the ongoing research is the exploration of structure-property relationships in bio-based polyamides. This involves investigating how variations in molecular weight, crystallinity, and chemical composition influence the mechanical strength, thermal stability, and chemical resistance of PA11 and PA12. Such insights are essential for tailoring these materials to specific applications and expanding their potential use cases.

The development of bio-based polyamides also addresses broader sustainability goals, including reducing dependence on fossil fuels, minimizing greenhouse gas emissions, and promoting circular economy principles. As such, the research objectives extend beyond mere material properties to encompass life cycle assessments, recyclability studies, and the optimization of production processes to further reduce environmental impact.

The primary objective of bio-based polyamide research and development is to create high-performance materials that match or exceed the properties of their fossil-based counterparts while offering improved sustainability. PA11 and PA12, derived from renewable sources such as castor oil, have gained prominence due to their unique combination of mechanical, thermal, and chemical properties.

As the polymer industry evolves, there is an increasing focus on understanding the nuanced differences between PA11 and PA12. Both materials offer distinct advantages in various applications, ranging from automotive components to industrial machinery and consumer goods. The comparison between PA11 and PA12 is crucial for engineers and product designers seeking to optimize material selection for specific end-use requirements.

The technological evolution of bio-based polyamides has been driven by advancements in polymer chemistry, process engineering, and material science. Researchers have made significant strides in improving the synthesis methods, enhancing the molecular structure, and fine-tuning the properties of these materials to meet diverse industrial needs.

A key aspect of the ongoing research is the exploration of structure-property relationships in bio-based polyamides. This involves investigating how variations in molecular weight, crystallinity, and chemical composition influence the mechanical strength, thermal stability, and chemical resistance of PA11 and PA12. Such insights are essential for tailoring these materials to specific applications and expanding their potential use cases.

The development of bio-based polyamides also addresses broader sustainability goals, including reducing dependence on fossil fuels, minimizing greenhouse gas emissions, and promoting circular economy principles. As such, the research objectives extend beyond mere material properties to encompass life cycle assessments, recyclability studies, and the optimization of production processes to further reduce environmental impact.

Market Demand Analysis for Sustainable Polymers

The market demand for sustainable polymers, including bio-based polyamides such as PA11 and PA12, has been steadily increasing in recent years. This growth is driven by several factors, including environmental concerns, regulatory pressures, and consumer preferences for eco-friendly products. The automotive industry, in particular, has shown significant interest in these materials as they seek to reduce vehicle weight and improve fuel efficiency while meeting stringent environmental regulations.

In the automotive sector, bio-based polyamides are increasingly being used in fuel lines, air brake tubing, and other under-the-hood applications due to their excellent chemical resistance and thermal stability. The demand for these materials in this sector is expected to continue growing as manufacturers strive to meet emissions targets and improve overall vehicle sustainability.

The electronics industry has also emerged as a key market for sustainable polymers. Bio-based polyamides are being utilized in various electronic components, including connectors, cable ties, and housings. The demand in this sector is driven by the need for materials that can withstand high temperatures and offer good electrical insulation properties while meeting sustainability goals.

The packaging industry represents another significant market for bio-based polyamides. As consumers become more environmentally conscious, there is a growing demand for sustainable packaging solutions. PA11 and PA12, with their bio-based origins and recyclability, are well-positioned to meet this demand, particularly in food packaging and flexible film applications.

The medical and healthcare sectors are also showing increased interest in sustainable polymers. Bio-based polyamides are being used in various medical devices and equipment due to their biocompatibility and sterilization resistance. The ongoing trend towards more sustainable healthcare practices is expected to further drive demand in this sector.

In terms of regional demand, Europe and North America currently lead the market for sustainable polymers, including bio-based polyamides. This is largely due to stringent environmental regulations and high consumer awareness in these regions. However, the Asia-Pacific region is expected to show the fastest growth in demand, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable materials.

The overall market for bio-based polyamides is projected to grow significantly in the coming years. This growth is supported by ongoing research and development efforts to improve the performance and cost-effectiveness of these materials, as well as the expansion of production capacities by key manufacturers. As industries continue to prioritize sustainability and seek alternatives to traditional petroleum-based polymers, the demand for bio-based polyamides like PA11 and PA12 is expected to remain strong across various sectors.

In the automotive sector, bio-based polyamides are increasingly being used in fuel lines, air brake tubing, and other under-the-hood applications due to their excellent chemical resistance and thermal stability. The demand for these materials in this sector is expected to continue growing as manufacturers strive to meet emissions targets and improve overall vehicle sustainability.

The electronics industry has also emerged as a key market for sustainable polymers. Bio-based polyamides are being utilized in various electronic components, including connectors, cable ties, and housings. The demand in this sector is driven by the need for materials that can withstand high temperatures and offer good electrical insulation properties while meeting sustainability goals.

The packaging industry represents another significant market for bio-based polyamides. As consumers become more environmentally conscious, there is a growing demand for sustainable packaging solutions. PA11 and PA12, with their bio-based origins and recyclability, are well-positioned to meet this demand, particularly in food packaging and flexible film applications.

The medical and healthcare sectors are also showing increased interest in sustainable polymers. Bio-based polyamides are being used in various medical devices and equipment due to their biocompatibility and sterilization resistance. The ongoing trend towards more sustainable healthcare practices is expected to further drive demand in this sector.

In terms of regional demand, Europe and North America currently lead the market for sustainable polymers, including bio-based polyamides. This is largely due to stringent environmental regulations and high consumer awareness in these regions. However, the Asia-Pacific region is expected to show the fastest growth in demand, driven by rapid industrialization, increasing environmental concerns, and government initiatives promoting sustainable materials.

The overall market for bio-based polyamides is projected to grow significantly in the coming years. This growth is supported by ongoing research and development efforts to improve the performance and cost-effectiveness of these materials, as well as the expansion of production capacities by key manufacturers. As industries continue to prioritize sustainability and seek alternatives to traditional petroleum-based polymers, the demand for bio-based polyamides like PA11 and PA12 is expected to remain strong across various sectors.

Current State of Bio-Based PA11 and PA12 Technologies

Bio-based polyamides PA11 and PA12 have gained significant traction in recent years as sustainable alternatives to their petroleum-based counterparts. The current state of these technologies reflects a growing maturity in production processes and an expanding range of applications across various industries.

PA11, derived from castor oil, has seen substantial advancements in its production technology. Manufacturers have optimized the extraction and polymerization processes, leading to improved yield and quality consistency. The current production capacity for PA11 has increased globally, with major players like Arkema expanding their facilities to meet the rising demand.

PA12, while traditionally petroleum-based, has also seen developments in bio-based versions. These are typically produced from renewable resources such as castor oil or other plant-based feedstocks. The technology for bio-based PA12 production is still evolving, with ongoing research focused on enhancing efficiency and reducing costs.

Both bio-based PA11 and PA12 exhibit excellent mechanical properties, chemical resistance, and thermal stability. Recent technological advancements have further improved these characteristics, making them suitable for more demanding applications. For instance, innovations in polymer chain modification have led to enhanced impact resistance and flexibility in PA11, while maintaining its inherent low moisture absorption properties.

The processing technologies for these materials have also progressed significantly. Injection molding, extrusion, and 3D printing techniques have been refined to accommodate the specific characteristics of bio-based PA11 and PA12. This has expanded their use in complex part designs and opened up new application areas.

In terms of market penetration, bio-based PA11 has established a strong presence in automotive, oil and gas, and consumer goods sectors. Its use in fuel lines, pneumatic systems, and sports equipment demonstrates its versatility. PA12, including its bio-based variants, continues to dominate in high-performance applications such as automotive fuel lines and air brake systems.

Recent developments in surface treatment and coating technologies have further enhanced the performance of both materials, particularly in areas requiring improved wear resistance or reduced friction. This has led to their increased adoption in moving parts and tribological applications.

The current state of bio-based PA11 and PA12 technologies also reflects a growing focus on sustainability and circular economy principles. Manufacturers are investing in recycling technologies specific to these materials, aiming to create closed-loop systems that further reduce their environmental impact.

PA11, derived from castor oil, has seen substantial advancements in its production technology. Manufacturers have optimized the extraction and polymerization processes, leading to improved yield and quality consistency. The current production capacity for PA11 has increased globally, with major players like Arkema expanding their facilities to meet the rising demand.

PA12, while traditionally petroleum-based, has also seen developments in bio-based versions. These are typically produced from renewable resources such as castor oil or other plant-based feedstocks. The technology for bio-based PA12 production is still evolving, with ongoing research focused on enhancing efficiency and reducing costs.

Both bio-based PA11 and PA12 exhibit excellent mechanical properties, chemical resistance, and thermal stability. Recent technological advancements have further improved these characteristics, making them suitable for more demanding applications. For instance, innovations in polymer chain modification have led to enhanced impact resistance and flexibility in PA11, while maintaining its inherent low moisture absorption properties.

The processing technologies for these materials have also progressed significantly. Injection molding, extrusion, and 3D printing techniques have been refined to accommodate the specific characteristics of bio-based PA11 and PA12. This has expanded their use in complex part designs and opened up new application areas.

In terms of market penetration, bio-based PA11 has established a strong presence in automotive, oil and gas, and consumer goods sectors. Its use in fuel lines, pneumatic systems, and sports equipment demonstrates its versatility. PA12, including its bio-based variants, continues to dominate in high-performance applications such as automotive fuel lines and air brake systems.

Recent developments in surface treatment and coating technologies have further enhanced the performance of both materials, particularly in areas requiring improved wear resistance or reduced friction. This has led to their increased adoption in moving parts and tribological applications.

The current state of bio-based PA11 and PA12 technologies also reflects a growing focus on sustainability and circular economy principles. Manufacturers are investing in recycling technologies specific to these materials, aiming to create closed-loop systems that further reduce their environmental impact.

Comparative Analysis of PA11 and PA12 Properties

01 Mechanical properties of bio-based PA11 and PA12

Bio-based polyamides PA11 and PA12 exhibit excellent mechanical properties, including high tensile strength, flexibility, and impact resistance. These materials offer a good balance of stiffness and toughness, making them suitable for various applications in automotive, electronics, and consumer goods industries.- Mechanical properties of bio-based PA11 and PA12: Bio-based polyamides PA11 and PA12 exhibit excellent mechanical properties, including high tensile strength, impact resistance, and flexibility. These materials offer a good balance of stiffness and toughness, making them suitable for various applications in automotive, electronics, and consumer goods industries.

- Thermal characteristics of bio-based PA11 and PA12: Bio-based PA11 and PA12 demonstrate good thermal properties, including high melting points and heat resistance. These materials maintain their structural integrity and performance at elevated temperatures, making them suitable for applications requiring thermal stability and resistance to heat aging.

- Chemical resistance of bio-based PA11 and PA12: Bio-based polyamides PA11 and PA12 exhibit excellent chemical resistance to a wide range of substances, including oils, fuels, and solvents. This property makes them suitable for use in harsh chemical environments and applications requiring resistance to degradation from exposure to various chemicals.

- Environmental benefits of bio-based PA11 and PA12: Bio-based PA11 and PA12 offer significant environmental advantages compared to their petroleum-based counterparts. These materials are derived from renewable resources, have a lower carbon footprint, and contribute to reduced dependency on fossil fuels. They also maintain the ability to be recycled, supporting circular economy initiatives.

- Processing characteristics of bio-based PA11 and PA12: Bio-based PA11 and PA12 demonstrate excellent processability, allowing for various manufacturing methods such as injection molding, extrusion, and 3D printing. These materials exhibit good flow properties, dimensional stability, and surface finish, enabling the production of complex parts with high precision and quality.

02 Thermal characteristics of bio-based PA11 and PA12

Bio-based PA11 and PA12 demonstrate good thermal properties, including high melting points and thermal stability. These polyamides maintain their mechanical properties over a wide temperature range, making them suitable for applications requiring heat resistance and dimensional stability.Expand Specific Solutions03 Chemical resistance of bio-based PA11 and PA12

Bio-based PA11 and PA12 exhibit excellent chemical resistance to a wide range of substances, including oils, fuels, and many organic solvents. This property makes them suitable for applications in harsh chemical environments, such as automotive fuel systems and industrial components.Expand Specific Solutions04 Processing characteristics of bio-based PA11 and PA12

Bio-based PA11 and PA12 offer good processability, allowing for various manufacturing techniques such as injection molding, extrusion, and 3D printing. These materials exhibit low moisture absorption and good dimensional stability during processing, resulting in high-quality finished products.Expand Specific Solutions05 Environmental benefits of bio-based PA11 and PA12

Bio-based PA11 and PA12 offer significant environmental advantages compared to their petroleum-based counterparts. These materials are derived from renewable resources, have a lower carbon footprint, and can be recycled or biodegraded under certain conditions, contributing to sustainability efforts in various industries.Expand Specific Solutions

Key Players in Bio-Based Polyamide Industry

The bio-based polyamide market is in a growth phase, driven by increasing demand for sustainable materials. The global market size for bio-based polyamides is projected to expand significantly in the coming years. Technologically, PA11 and PA12 are relatively mature, with ongoing research to improve properties and production efficiency. Key players like Arkema, Evonik, and Cathay Biotech are leading innovation in this space. Arkema is particularly strong in PA11 production, while Evonik focuses on PA12. Cathay Biotech has made strides in bio-based monomer production. Other companies like Solvay and EMS-CHEMIE are also actively developing bio-based polyamide technologies, indicating a competitive and dynamic market landscape.

Arkema France SA

Technical Solution: Arkema is a pioneer in bio-based polyamides, particularly PA11. Their Rilsan® PA11 is derived from castor oil, offering 100% bio-based content[1]. The company has developed a range of PA11 grades for various applications, including automotive, electronics, and consumer goods. Arkema's PA11 production process involves the extraction of undecanoic acid from castor oil, which is then polymerized to form the final product[2]. This method ensures a renewable source material while maintaining high performance characteristics comparable to traditional petroleum-based polyamides[3].

Strengths: Fully bio-based, excellent chemical resistance, low moisture absorption, and good dimensional stability. Weaknesses: Higher cost compared to conventional polyamides, limited availability of raw materials (castor oil).

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed a range of high-performance polyamides, including PA6.10, which is partially bio-based. Their Technyl® eXten product line utilizes sebacic acid derived from castor oil, resulting in a 60% bio-based content[4]. Solvay's approach focuses on balancing sustainability with performance, offering materials that can replace traditional PA6 and PA66 in various applications. The company has invested in optimizing the polymerization process to enhance the mechanical and thermal properties of their bio-based polyamides, making them suitable for demanding applications in automotive and industrial sectors[5].

Strengths: Improved environmental footprint, good balance of properties, drop-in replacement for conventional polyamides. Weaknesses: Not fully bio-based, performance may not match 100% petroleum-based polyamides in some applications.

Core Innovations in Bio-Based Polyamide Synthesis

Additive manufacturing method with biobased polyamide composition having high thermal stability

PatentWO2023203213A1

Innovation

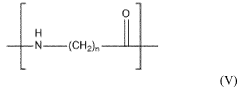

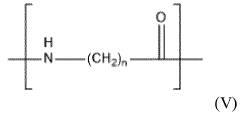

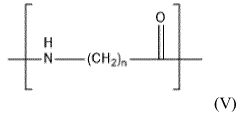

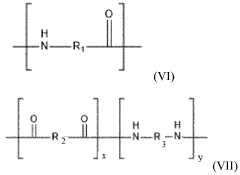

- An additive manufacturing method utilizing a polyamide composition with at least 50% by weight of polyamide comprising 90% recurring units of formula -NH-(CH2)s-C(O)- and/or -NH-(CH2)9-C(O)-, combined with reinforcing agents and additives, which is processed using Fused Filament Fabrication (FFF) to produce 3D objects with enhanced thermal stability and hydrophobic properties.

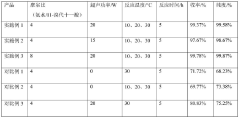

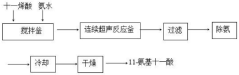

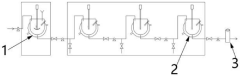

Process and equipment for preparing 11-aminoundecanoic acid by ultrasonic ammonification method

PatentPendingCN118005522A

Innovation

- Using the ultrasonic ammoniation method, 11-bromoundecanoic acid and ammonia water are stirred and ultrasonic-strengthened in an ultrasonic continuous reactor, and the reaction process is controlled by gradient temperature rise to generate 11-aminoundecanoic acid suspension, which is filtered , hydrothermal ammonia removal, cooling and drying to obtain the product.

Environmental Impact Assessment

The environmental impact assessment of bio-based polyamides, specifically PA11 and PA12, reveals significant advantages over their petroleum-based counterparts. These materials, derived from renewable resources such as castor oil, contribute to reduced carbon footprints and decreased dependence on fossil fuels.

PA11 and PA12 production processes generally require less energy compared to traditional polyamides, resulting in lower greenhouse gas emissions. The renewable nature of their raw materials also promotes carbon sequestration during plant growth, further offsetting environmental impacts. Additionally, these bio-based polyamides often exhibit improved end-of-life scenarios, with enhanced biodegradability in certain conditions.

However, the environmental benefits of PA11 and PA12 are not without challenges. The cultivation of castor plants, the primary source for these materials, raises concerns about land use and potential competition with food crops. Sustainable agricultural practices and responsible land management are crucial to mitigate these issues and ensure the long-term viability of bio-based polyamide production.

Water consumption and potential pesticide use in castor plant cultivation also warrant consideration. While generally less water-intensive than some other crops, optimizing irrigation methods and promoting organic farming practices can further enhance the environmental profile of PA11 and PA12.

Life cycle assessments (LCAs) comparing bio-based PA11 and PA12 to conventional polyamides demonstrate overall environmental advantages. These assessments typically show reduced global warming potential, lower fossil resource depletion, and decreased ecotoxicity. However, results can vary depending on specific production methods, transportation distances, and end-of-life scenarios.

The durability and performance characteristics of PA11 and PA12 contribute to their positive environmental impact. Their resistance to wear, chemicals, and temperature fluctuations often leads to longer product lifespans, reducing the need for frequent replacements and associated resource consumption.

Recycling and circular economy initiatives for bio-based polyamides are emerging, though still in early stages. Developing efficient recycling processes for PA11 and PA12 will be crucial to maximizing their environmental benefits and closing the loop on material use. Research into chemical recycling methods shows promise for recovering high-quality monomers from these materials.

In conclusion, while bio-based PA11 and PA12 offer significant environmental advantages, ongoing efforts to optimize production processes, improve agricultural practices, and develop effective recycling methods are essential to fully realize their potential as sustainable alternatives to conventional polyamides.

PA11 and PA12 production processes generally require less energy compared to traditional polyamides, resulting in lower greenhouse gas emissions. The renewable nature of their raw materials also promotes carbon sequestration during plant growth, further offsetting environmental impacts. Additionally, these bio-based polyamides often exhibit improved end-of-life scenarios, with enhanced biodegradability in certain conditions.

However, the environmental benefits of PA11 and PA12 are not without challenges. The cultivation of castor plants, the primary source for these materials, raises concerns about land use and potential competition with food crops. Sustainable agricultural practices and responsible land management are crucial to mitigate these issues and ensure the long-term viability of bio-based polyamide production.

Water consumption and potential pesticide use in castor plant cultivation also warrant consideration. While generally less water-intensive than some other crops, optimizing irrigation methods and promoting organic farming practices can further enhance the environmental profile of PA11 and PA12.

Life cycle assessments (LCAs) comparing bio-based PA11 and PA12 to conventional polyamides demonstrate overall environmental advantages. These assessments typically show reduced global warming potential, lower fossil resource depletion, and decreased ecotoxicity. However, results can vary depending on specific production methods, transportation distances, and end-of-life scenarios.

The durability and performance characteristics of PA11 and PA12 contribute to their positive environmental impact. Their resistance to wear, chemicals, and temperature fluctuations often leads to longer product lifespans, reducing the need for frequent replacements and associated resource consumption.

Recycling and circular economy initiatives for bio-based polyamides are emerging, though still in early stages. Developing efficient recycling processes for PA11 and PA12 will be crucial to maximizing their environmental benefits and closing the loop on material use. Research into chemical recycling methods shows promise for recovering high-quality monomers from these materials.

In conclusion, while bio-based PA11 and PA12 offer significant environmental advantages, ongoing efforts to optimize production processes, improve agricultural practices, and develop effective recycling methods are essential to fully realize their potential as sustainable alternatives to conventional polyamides.

Regulatory Framework for Bio-Based Materials

The regulatory framework for bio-based materials, including bio-based polyamides such as PA11 and PA12, is evolving to support the transition towards a more sustainable and circular economy. In the European Union, the Renewable Energy Directive (RED II) provides a framework for promoting the use of renewable energy sources, including bio-based materials. This directive sets targets for renewable energy consumption and establishes sustainability criteria for biofuels and bio-based products.

The EU's Circular Economy Action Plan also plays a crucial role in promoting bio-based materials. It aims to reduce waste, increase recycling, and encourage the use of sustainable materials. The plan includes measures to support the development and adoption of bio-based alternatives to fossil-based products, which directly impacts the market for bio-based polyamides like PA11 and PA12.

In the United States, the USDA BioPreferred Program promotes the purchase and use of bio-based products. This program includes a voluntary labeling initiative for bio-based products and a mandatory purchasing requirement for federal agencies. While not specifically targeting polyamides, this program creates a favorable environment for bio-based materials in general.

The ISO 14855 standard provides a method for determining the ultimate aerobic biodegradability of plastic materials under controlled composting conditions. This standard is relevant for assessing the environmental impact of bio-based polyamides and other bio-based materials. Additionally, the EN 16785 series of standards focuses on bio-based content determination, which is crucial for verifying claims about the renewable content of materials like PA11 and PA12.

Regulatory bodies are also addressing the need for clear definitions and standards for bio-based materials. The CEN Technical Committee 411 on Bio-based Products is developing standards for terminology, sampling, bio-based content, sustainability criteria, and life cycle assessment specifically for bio-based products. These standards will provide a common language and framework for the industry, facilitating the adoption and comparison of bio-based polyamides and other materials.

As environmental concerns continue to drive policy decisions, it is likely that regulations will increasingly favor bio-based materials. This trend may lead to more stringent requirements for the use of renewable resources in product manufacturing, potentially benefiting producers of bio-based polyamides like PA11 and PA12. However, it is important to note that regulations may also impose stricter sustainability criteria, requiring manufacturers to demonstrate the full life cycle benefits of their bio-based products.

The EU's Circular Economy Action Plan also plays a crucial role in promoting bio-based materials. It aims to reduce waste, increase recycling, and encourage the use of sustainable materials. The plan includes measures to support the development and adoption of bio-based alternatives to fossil-based products, which directly impacts the market for bio-based polyamides like PA11 and PA12.

In the United States, the USDA BioPreferred Program promotes the purchase and use of bio-based products. This program includes a voluntary labeling initiative for bio-based products and a mandatory purchasing requirement for federal agencies. While not specifically targeting polyamides, this program creates a favorable environment for bio-based materials in general.

The ISO 14855 standard provides a method for determining the ultimate aerobic biodegradability of plastic materials under controlled composting conditions. This standard is relevant for assessing the environmental impact of bio-based polyamides and other bio-based materials. Additionally, the EN 16785 series of standards focuses on bio-based content determination, which is crucial for verifying claims about the renewable content of materials like PA11 and PA12.

Regulatory bodies are also addressing the need for clear definitions and standards for bio-based materials. The CEN Technical Committee 411 on Bio-based Products is developing standards for terminology, sampling, bio-based content, sustainability criteria, and life cycle assessment specifically for bio-based products. These standards will provide a common language and framework for the industry, facilitating the adoption and comparison of bio-based polyamides and other materials.

As environmental concerns continue to drive policy decisions, it is likely that regulations will increasingly favor bio-based materials. This trend may lead to more stringent requirements for the use of renewable resources in product manufacturing, potentially benefiting producers of bio-based polyamides like PA11 and PA12. However, it is important to note that regulations may also impose stricter sustainability criteria, requiring manufacturers to demonstrate the full life cycle benefits of their bio-based products.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!