How to Evaluate Long-Term Creep and Fatigue in Bio-Based Polyamides

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-PA Creep and Fatigue Evaluation Background

Bio-based polyamides (Bio-PAs) have emerged as sustainable alternatives to conventional petroleum-based polyamides, offering comparable mechanical properties with reduced environmental impact. As these materials gain traction in various industries, understanding their long-term performance under stress becomes crucial. The evaluation of creep and fatigue behavior in Bio-PAs is essential for predicting their durability and reliability in applications ranging from automotive components to consumer goods.

Creep, the tendency of a material to deform permanently under constant stress over time, is a critical factor in the long-term performance of polymers. For Bio-PAs, creep behavior can significantly impact the dimensional stability and structural integrity of parts, especially in load-bearing applications. Fatigue, on the other hand, refers to the weakening of a material caused by repeatedly applied loads, which can lead to failure at stress levels below the material's yield strength.

The evaluation of these phenomena in Bio-PAs presents unique challenges due to their bio-based nature. The variability in raw material sources and processing conditions can influence the molecular structure and, consequently, the long-term mechanical properties of these materials. Traditional testing methods developed for conventional polyamides may not fully capture the nuanced behavior of Bio-PAs, necessitating the development of specialized evaluation techniques.

Long-term creep and fatigue testing for Bio-PAs typically involves subjecting material samples to controlled stress conditions over extended periods, often accelerated through elevated temperatures or cyclic loading. These tests aim to simulate real-world conditions and extrapolate the material's behavior over its intended service life. Advanced imaging techniques, such as X-ray tomography and atomic force microscopy, are increasingly employed to observe microstructural changes during creep and fatigue processes.

The development of predictive models for creep and fatigue in Bio-PAs is an active area of research. These models seek to correlate material composition, processing parameters, and environmental conditions with long-term performance metrics. Machine learning algorithms and finite element analysis are being leveraged to enhance the accuracy and efficiency of these predictive tools, enabling more informed material selection and design decisions.

As the adoption of Bio-PAs continues to grow, standardization efforts are underway to establish consistent testing protocols and performance criteria. These standards will facilitate fair comparisons between different Bio-PA formulations and conventional materials, providing engineers and designers with reliable data for material selection and product development.

Creep, the tendency of a material to deform permanently under constant stress over time, is a critical factor in the long-term performance of polymers. For Bio-PAs, creep behavior can significantly impact the dimensional stability and structural integrity of parts, especially in load-bearing applications. Fatigue, on the other hand, refers to the weakening of a material caused by repeatedly applied loads, which can lead to failure at stress levels below the material's yield strength.

The evaluation of these phenomena in Bio-PAs presents unique challenges due to their bio-based nature. The variability in raw material sources and processing conditions can influence the molecular structure and, consequently, the long-term mechanical properties of these materials. Traditional testing methods developed for conventional polyamides may not fully capture the nuanced behavior of Bio-PAs, necessitating the development of specialized evaluation techniques.

Long-term creep and fatigue testing for Bio-PAs typically involves subjecting material samples to controlled stress conditions over extended periods, often accelerated through elevated temperatures or cyclic loading. These tests aim to simulate real-world conditions and extrapolate the material's behavior over its intended service life. Advanced imaging techniques, such as X-ray tomography and atomic force microscopy, are increasingly employed to observe microstructural changes during creep and fatigue processes.

The development of predictive models for creep and fatigue in Bio-PAs is an active area of research. These models seek to correlate material composition, processing parameters, and environmental conditions with long-term performance metrics. Machine learning algorithms and finite element analysis are being leveraged to enhance the accuracy and efficiency of these predictive tools, enabling more informed material selection and design decisions.

As the adoption of Bio-PAs continues to grow, standardization efforts are underway to establish consistent testing protocols and performance criteria. These standards will facilitate fair comparisons between different Bio-PA formulations and conventional materials, providing engineers and designers with reliable data for material selection and product development.

Market Demand Analysis

The market demand for bio-based polyamides has been steadily increasing due to growing environmental concerns and the push for sustainable materials in various industries. These materials, derived from renewable resources, offer a promising alternative to traditional petroleum-based polyamides. The automotive sector, in particular, has shown significant interest in bio-based polyamides for their potential to reduce vehicle weight and improve fuel efficiency while meeting stringent environmental regulations.

The packaging industry is another key driver of market demand for bio-based polyamides. With consumers becoming more environmentally conscious, there is a growing preference for sustainable packaging solutions. Bio-based polyamides offer excellent barrier properties and durability, making them suitable for food packaging and other applications where long-term performance is crucial.

In the textile and apparel industry, bio-based polyamides are gaining traction as sustainable alternatives to conventional synthetic fibers. The demand for eco-friendly clothing and accessories has led to increased adoption of these materials in high-performance sportswear, outdoor gear, and fashion items.

The construction sector is also exploring the use of bio-based polyamides in various applications, such as insulation materials and structural components. The materials' durability and resistance to environmental factors make them attractive for long-term use in buildings and infrastructure projects.

However, the widespread adoption of bio-based polyamides faces challenges related to their long-term performance, particularly in terms of creep and fatigue behavior. Industries that require materials to withstand prolonged stress and cyclic loading, such as automotive and aerospace, are particularly concerned about these properties. The ability to accurately evaluate and predict long-term creep and fatigue in bio-based polyamides is crucial for their successful integration into these demanding applications.

As a result, there is a growing demand for advanced testing methodologies and predictive models that can assess the long-term performance of bio-based polyamides under various environmental conditions and stress scenarios. This need is driving research and development efforts in materials science and engineering, with a focus on developing standardized evaluation techniques and accelerated testing protocols.

The market for bio-based polyamides is expected to continue expanding as industries seek sustainable alternatives to traditional materials. However, the rate of adoption and market growth will largely depend on the ability to address concerns regarding long-term performance, including creep and fatigue resistance. As such, the development of reliable evaluation methods for these properties is not only a technical challenge but also a key factor in shaping the future market demand for bio-based polyamides across various industries.

The packaging industry is another key driver of market demand for bio-based polyamides. With consumers becoming more environmentally conscious, there is a growing preference for sustainable packaging solutions. Bio-based polyamides offer excellent barrier properties and durability, making them suitable for food packaging and other applications where long-term performance is crucial.

In the textile and apparel industry, bio-based polyamides are gaining traction as sustainable alternatives to conventional synthetic fibers. The demand for eco-friendly clothing and accessories has led to increased adoption of these materials in high-performance sportswear, outdoor gear, and fashion items.

The construction sector is also exploring the use of bio-based polyamides in various applications, such as insulation materials and structural components. The materials' durability and resistance to environmental factors make them attractive for long-term use in buildings and infrastructure projects.

However, the widespread adoption of bio-based polyamides faces challenges related to their long-term performance, particularly in terms of creep and fatigue behavior. Industries that require materials to withstand prolonged stress and cyclic loading, such as automotive and aerospace, are particularly concerned about these properties. The ability to accurately evaluate and predict long-term creep and fatigue in bio-based polyamides is crucial for their successful integration into these demanding applications.

As a result, there is a growing demand for advanced testing methodologies and predictive models that can assess the long-term performance of bio-based polyamides under various environmental conditions and stress scenarios. This need is driving research and development efforts in materials science and engineering, with a focus on developing standardized evaluation techniques and accelerated testing protocols.

The market for bio-based polyamides is expected to continue expanding as industries seek sustainable alternatives to traditional materials. However, the rate of adoption and market growth will largely depend on the ability to address concerns regarding long-term performance, including creep and fatigue resistance. As such, the development of reliable evaluation methods for these properties is not only a technical challenge but also a key factor in shaping the future market demand for bio-based polyamides across various industries.

Current Challenges in Bio-PA Testing

The evaluation of long-term creep and fatigue in bio-based polyamides (Bio-PAs) presents several significant challenges that researchers and engineers must address. One of the primary difficulties lies in the inherent variability of bio-based materials, which can lead to inconsistent test results and complicate the establishment of standardized testing protocols.

Bio-PAs, derived from renewable resources, often exhibit more complex molecular structures compared to their petroleum-based counterparts. This complexity can result in a wider range of mechanical properties and behaviors under stress, making it challenging to develop accurate predictive models for long-term performance.

The time-dependent nature of creep and fatigue phenomena further compounds the testing challenges. Traditional accelerated testing methods may not accurately capture the long-term behavior of Bio-PAs, as these materials can undergo structural changes over extended periods that are not easily replicated in short-term tests.

Environmental factors play a crucial role in the performance of Bio-PAs, adding another layer of complexity to testing procedures. Moisture absorption, temperature fluctuations, and exposure to UV radiation can significantly affect the mechanical properties of these materials over time. Developing test protocols that account for these environmental variables while maintaining reproducibility is a major hurdle.

The lack of extensive historical data on Bio-PAs compared to conventional polyamides also poses a challenge. Without a robust database of long-term performance metrics, it becomes difficult to validate new testing methodologies or to establish reliable benchmarks for material evaluation.

Furthermore, the diverse range of Bio-PA formulations available in the market complicates the development of universal testing standards. Each formulation may require specific considerations in test design, making it challenging to create a one-size-fits-all approach to creep and fatigue evaluation.

The integration of advanced measurement techniques, such as digital image correlation and acoustic emission monitoring, into long-term testing setups presents both opportunities and challenges. While these methods offer enhanced data collection capabilities, they also introduce new variables that must be carefully controlled to ensure test validity.

Lastly, the cost and time associated with conducting comprehensive long-term creep and fatigue tests on Bio-PAs can be prohibitive for many organizations. This economic constraint often leads to a reliance on short-term tests and extrapolation methods, which may not always provide accurate predictions of long-term material behavior.

Bio-PAs, derived from renewable resources, often exhibit more complex molecular structures compared to their petroleum-based counterparts. This complexity can result in a wider range of mechanical properties and behaviors under stress, making it challenging to develop accurate predictive models for long-term performance.

The time-dependent nature of creep and fatigue phenomena further compounds the testing challenges. Traditional accelerated testing methods may not accurately capture the long-term behavior of Bio-PAs, as these materials can undergo structural changes over extended periods that are not easily replicated in short-term tests.

Environmental factors play a crucial role in the performance of Bio-PAs, adding another layer of complexity to testing procedures. Moisture absorption, temperature fluctuations, and exposure to UV radiation can significantly affect the mechanical properties of these materials over time. Developing test protocols that account for these environmental variables while maintaining reproducibility is a major hurdle.

The lack of extensive historical data on Bio-PAs compared to conventional polyamides also poses a challenge. Without a robust database of long-term performance metrics, it becomes difficult to validate new testing methodologies or to establish reliable benchmarks for material evaluation.

Furthermore, the diverse range of Bio-PA formulations available in the market complicates the development of universal testing standards. Each formulation may require specific considerations in test design, making it challenging to create a one-size-fits-all approach to creep and fatigue evaluation.

The integration of advanced measurement techniques, such as digital image correlation and acoustic emission monitoring, into long-term testing setups presents both opportunities and challenges. While these methods offer enhanced data collection capabilities, they also introduce new variables that must be carefully controlled to ensure test validity.

Lastly, the cost and time associated with conducting comprehensive long-term creep and fatigue tests on Bio-PAs can be prohibitive for many organizations. This economic constraint often leads to a reliance on short-term tests and extrapolation methods, which may not always provide accurate predictions of long-term material behavior.

Existing Long-Term Testing Protocols

01 Synthesis and properties of bio-based polyamides

Research focuses on developing bio-based polyamides with improved creep and fatigue resistance. These materials are synthesized using renewable resources and are designed to have enhanced mechanical properties, including better resistance to deformation under constant stress (creep) and repeated loading (fatigue).- Composition and synthesis of bio-based polyamides: Bio-based polyamides are synthesized using renewable resources such as plant-derived monomers. These materials are designed to have improved mechanical properties, including creep and fatigue resistance. The synthesis process often involves the polymerization of bio-based diamine and diacid monomers, resulting in environmentally friendly alternatives to traditional petroleum-based polyamides.

- Creep behavior analysis of bio-based polyamides: Studies on the creep behavior of bio-based polyamides focus on their time-dependent deformation under constant stress. Researchers investigate factors affecting creep resistance, such as molecular weight, crystallinity, and reinforcement additives. Advanced testing methods and modeling techniques are employed to predict long-term creep performance and optimize material compositions for improved creep resistance.

- Fatigue performance of bio-based polyamides: The fatigue performance of bio-based polyamides is crucial for applications involving cyclic loading. Research in this area involves studying the fatigue crack propagation, stress-strain behavior under cyclic loading, and the influence of environmental factors on fatigue life. Techniques to enhance fatigue resistance, such as fiber reinforcement or nanoparticle incorporation, are also explored.

- Modification techniques for improved creep and fatigue properties: Various modification techniques are employed to enhance the creep and fatigue properties of bio-based polyamides. These include blending with other polymers, cross-linking, and the addition of nanofillers or reinforcing fibers. Such modifications aim to improve the overall mechanical performance and durability of bio-based polyamides, making them suitable for demanding applications.

- Application-specific tailoring of bio-based polyamides: Bio-based polyamides are tailored for specific applications that require excellent creep and fatigue resistance. This involves optimizing the material composition and processing conditions to meet the demands of industries such as automotive, aerospace, and consumer goods. Researchers focus on developing bio-based polyamides with properties comparable or superior to their petroleum-based counterparts for these applications.

02 Modification techniques for enhancing creep and fatigue performance

Various modification techniques are employed to enhance the creep and fatigue performance of bio-based polyamides. These may include the incorporation of nanofillers, crosslinking agents, or the development of novel copolymer structures to improve the material's resistance to long-term deformation and cyclic loading.Expand Specific Solutions03 Testing and characterization methods for creep and fatigue

Advanced testing and characterization methods are developed to accurately assess the creep and fatigue behavior of bio-based polyamides. These methods may include long-term creep tests, cyclic loading experiments, and advanced imaging techniques to understand the material's response to various stress conditions.Expand Specific Solutions04 Computational modeling and prediction of creep and fatigue

Computational modeling and simulation techniques are utilized to predict the creep and fatigue behavior of bio-based polyamides. These models help in understanding the molecular mechanisms underlying creep and fatigue and aid in the design of improved materials with enhanced long-term performance.Expand Specific Solutions05 Applications of bio-based polyamides with improved creep and fatigue resistance

Bio-based polyamides with enhanced creep and fatigue resistance find applications in various industries, including automotive, aerospace, and consumer goods. These materials offer sustainable alternatives to traditional petroleum-based polymers while maintaining or improving long-term performance under demanding conditions.Expand Specific Solutions

Key Players in Bio-PA Industry

The evaluation of long-term creep and fatigue in bio-based polyamides is a growing field within the broader context of sustainable materials development. The market for bio-based polymers is expanding, driven by environmental concerns and the push for renewable resources. Companies like Cathay Biotech and Evonik Operations are at the forefront of developing and commercializing these materials. The technology is in a transitional phase, moving from research to industrial application. Universities such as East China University of Science & Technology and Nanjing Tech University are contributing to the fundamental understanding of these materials' behavior. The market size is increasing, but still relatively small compared to traditional petroleum-based polyamides. Technical challenges remain in achieving comparable performance to conventional materials, particularly in long-term durability and fatigue resistance.

Cathay Biotech, Inc.

Technical Solution: Cathay Biotech has developed a comprehensive approach to evaluate long-term creep and fatigue in bio-based polyamides. Their method involves a combination of accelerated aging tests and advanced material characterization techniques. The company utilizes dynamic mechanical analysis (DMA) to assess viscoelastic properties over time and temperature ranges relevant to real-world applications[1]. They also employ cyclic loading tests to simulate fatigue conditions, monitoring changes in mechanical properties and microstructure. Cathay Biotech has implemented a novel data-driven predictive model that incorporates machine learning algorithms to extrapolate short-term test results to long-term performance predictions[3]. This approach allows for more accurate estimation of creep and fatigue behavior over extended periods, which is crucial for bio-based polyamides in demanding applications.

Strengths: Comprehensive testing methodology, advanced predictive modeling, expertise in bio-based materials. Weaknesses: Potential limitations in simulating all real-world conditions, time-consuming long-term validation process.

Dow Global Technologies LLC

Technical Solution: Dow has developed a comprehensive approach to evaluate long-term creep and fatigue in bio-based polyamides. Their method combines accelerated aging techniques with advanced material characterization and modeling. The company utilizes a custom-designed environmental chamber to simulate various temperature, humidity, and UV exposure conditions over extended periods[2]. They employ a range of mechanical testing methods, including creep rupture tests, cyclic fatigue tests, and dynamic mechanical analysis (DMA), to assess material behavior under different loading conditions[4]. Dow has also developed a multi-scale modeling approach that integrates molecular dynamics simulations with continuum mechanics to predict long-term performance[5]. This allows for a more fundamental understanding of the degradation mechanisms in bio-based polyamides.

Strengths: Comprehensive environmental simulation, multi-scale modeling approach, extensive polymer expertise. Weaknesses: Potential challenges in accurately replicating complex real-world conditions, high costs associated with long-term testing and advanced modeling.

Innovative Bio-PA Evaluation Techniques

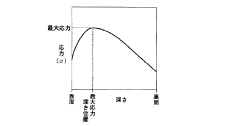

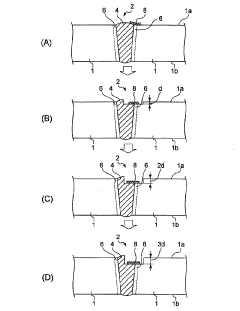

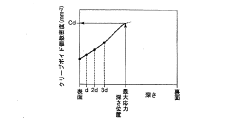

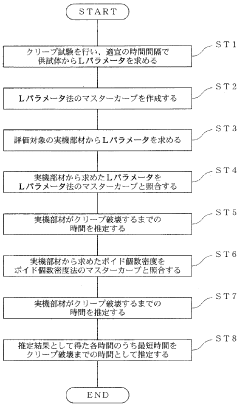

Creep damage evaluation method

PatentActiveJP2014163744A

Innovation

- A method that involves analyzing stress distribution, measuring creep voids at multiple depth positions, and calculating a relational expression between creep void number density and damage rate to accurately estimate the remaining life at the maximum stress depth position, using FEM analysis and replica methods to measure voids.

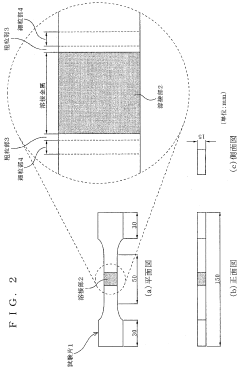

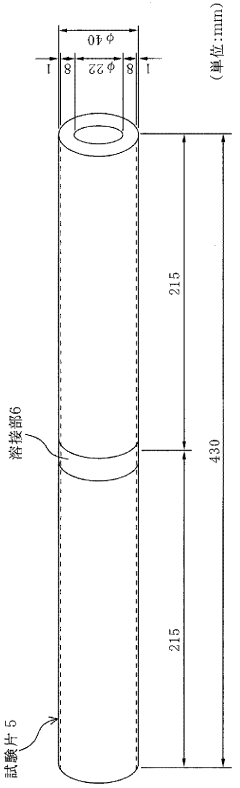

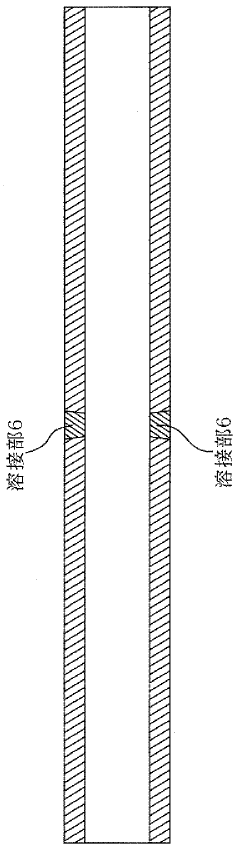

Method of evaluating creep life expectancy or life span

PatentWO2005124314A1

Innovation

- A method that focuses on determining the specific void density by counting voids that extend across multiple grain boundaries and calculating their ratio within a predetermined area, using the L parameter, which is derived from creep tests, to estimate the remaining life of equipment members.

Standardization Efforts for Bio-PA Testing

Standardization efforts for bio-based polyamide (Bio-PA) testing are crucial for ensuring consistent and reliable evaluation of long-term creep and fatigue properties. These efforts aim to establish uniform testing methodologies and criteria across the industry, enabling accurate comparisons between different Bio-PA materials and their petroleum-based counterparts.

Several international organizations are actively involved in developing standardized testing protocols for Bio-PAs. The International Organization for Standardization (ISO) has been working on adapting existing standards for conventional polyamides to accommodate the unique characteristics of bio-based materials. This includes modifications to account for potential variations in moisture absorption and thermal stability inherent to Bio-PAs.

ASTM International has also been at the forefront of Bio-PA standardization efforts. They have initiated the development of new test methods specifically tailored to bio-based polymers, focusing on long-term performance characteristics such as creep resistance and fatigue behavior. These methods aim to provide a comprehensive framework for evaluating the durability and reliability of Bio-PAs under various environmental conditions and stress levels.

The European Committee for Standardization (CEN) has been collaborating with industry partners to establish harmonized testing procedures for Bio-PAs within the European market. Their efforts include the development of accelerated aging protocols that can accurately predict the long-term behavior of these materials, taking into account the potential impact of bio-based components on material degradation over time.

One of the key challenges in standardizing Bio-PA testing is addressing the variability in raw material sources and processing conditions. To overcome this, standardization bodies are working on defining specific criteria for material classification and quality control measures. This includes establishing guidelines for the minimum bio-based content and acceptable ranges for key performance indicators.

Interlaboratory studies are being conducted to validate proposed test methods and ensure reproducibility across different testing facilities. These round-robin tests involve multiple laboratories performing identical experiments on standardized Bio-PA samples, allowing for the identification and resolution of any discrepancies in testing procedures or equipment calibration.

The development of standardized fatigue testing protocols for Bio-PAs is particularly challenging due to the complex nature of fatigue behavior in polymeric materials. Efforts are underway to adapt existing fatigue testing standards, such as those used for metal alloys, to accommodate the viscoelastic properties of Bio-PAs. This includes considerations for frequency effects, temperature dependence, and the influence of moisture on fatigue performance.

As standardization efforts progress, it is expected that a comprehensive suite of test methods will emerge, covering various aspects of Bio-PA performance evaluation. This will likely include standardized procedures for assessing creep behavior under different load conditions, fatigue resistance under cyclic loading, and the impact of environmental factors on long-term material properties.

Several international organizations are actively involved in developing standardized testing protocols for Bio-PAs. The International Organization for Standardization (ISO) has been working on adapting existing standards for conventional polyamides to accommodate the unique characteristics of bio-based materials. This includes modifications to account for potential variations in moisture absorption and thermal stability inherent to Bio-PAs.

ASTM International has also been at the forefront of Bio-PA standardization efforts. They have initiated the development of new test methods specifically tailored to bio-based polymers, focusing on long-term performance characteristics such as creep resistance and fatigue behavior. These methods aim to provide a comprehensive framework for evaluating the durability and reliability of Bio-PAs under various environmental conditions and stress levels.

The European Committee for Standardization (CEN) has been collaborating with industry partners to establish harmonized testing procedures for Bio-PAs within the European market. Their efforts include the development of accelerated aging protocols that can accurately predict the long-term behavior of these materials, taking into account the potential impact of bio-based components on material degradation over time.

One of the key challenges in standardizing Bio-PA testing is addressing the variability in raw material sources and processing conditions. To overcome this, standardization bodies are working on defining specific criteria for material classification and quality control measures. This includes establishing guidelines for the minimum bio-based content and acceptable ranges for key performance indicators.

Interlaboratory studies are being conducted to validate proposed test methods and ensure reproducibility across different testing facilities. These round-robin tests involve multiple laboratories performing identical experiments on standardized Bio-PA samples, allowing for the identification and resolution of any discrepancies in testing procedures or equipment calibration.

The development of standardized fatigue testing protocols for Bio-PAs is particularly challenging due to the complex nature of fatigue behavior in polymeric materials. Efforts are underway to adapt existing fatigue testing standards, such as those used for metal alloys, to accommodate the viscoelastic properties of Bio-PAs. This includes considerations for frequency effects, temperature dependence, and the influence of moisture on fatigue performance.

As standardization efforts progress, it is expected that a comprehensive suite of test methods will emerge, covering various aspects of Bio-PA performance evaluation. This will likely include standardized procedures for assessing creep behavior under different load conditions, fatigue resistance under cyclic loading, and the impact of environmental factors on long-term material properties.

Environmental Impact Assessment

The environmental impact assessment of bio-based polyamides, particularly in the context of long-term creep and fatigue evaluation, is a critical aspect of their development and application. These materials, derived from renewable resources, offer potential advantages in terms of sustainability compared to their petroleum-based counterparts. However, their environmental footprint must be thoroughly examined across their entire lifecycle.

The production of bio-based polyamides typically involves the use of renewable feedstocks such as castor oil, corn, or other plant-based sources. This can lead to reduced dependency on fossil fuels and potentially lower greenhouse gas emissions during the manufacturing process. However, the cultivation of these feedstocks may have implications for land use, water consumption, and biodiversity. It is essential to consider these factors when assessing the overall environmental impact of bio-based polyamides.

In terms of long-term creep and fatigue performance, the environmental impact assessment must take into account the durability and lifespan of products made from these materials. If bio-based polyamides demonstrate superior resistance to creep and fatigue compared to conventional alternatives, this could result in extended product lifespans and reduced waste generation. Conversely, if their performance is inferior, it may lead to more frequent replacements and increased material consumption over time.

The end-of-life phase of bio-based polyamides is another crucial consideration in their environmental impact assessment. Many of these materials are designed to be biodegradable or compostable, which could potentially reduce their environmental burden in waste management scenarios. However, the actual degradation rates and conditions required for effective biodegradation must be carefully evaluated to ensure that these materials do not persist in the environment or contribute to microplastic pollution.

Furthermore, the recyclability of bio-based polyamides should be assessed as part of their environmental impact. If these materials can be effectively recycled, it could significantly reduce their overall environmental footprint by minimizing the need for virgin material production. However, the energy and resources required for the recycling process must also be factored into the assessment.

In conducting a comprehensive environmental impact assessment, it is crucial to employ life cycle assessment (LCA) methodologies. These should encompass all stages from raw material extraction to end-of-life disposal or recycling. Such analyses can provide valuable insights into the comparative environmental performance of bio-based polyamides versus traditional petroleum-based alternatives, particularly when considering long-term creep and fatigue characteristics.

The production of bio-based polyamides typically involves the use of renewable feedstocks such as castor oil, corn, or other plant-based sources. This can lead to reduced dependency on fossil fuels and potentially lower greenhouse gas emissions during the manufacturing process. However, the cultivation of these feedstocks may have implications for land use, water consumption, and biodiversity. It is essential to consider these factors when assessing the overall environmental impact of bio-based polyamides.

In terms of long-term creep and fatigue performance, the environmental impact assessment must take into account the durability and lifespan of products made from these materials. If bio-based polyamides demonstrate superior resistance to creep and fatigue compared to conventional alternatives, this could result in extended product lifespans and reduced waste generation. Conversely, if their performance is inferior, it may lead to more frequent replacements and increased material consumption over time.

The end-of-life phase of bio-based polyamides is another crucial consideration in their environmental impact assessment. Many of these materials are designed to be biodegradable or compostable, which could potentially reduce their environmental burden in waste management scenarios. However, the actual degradation rates and conditions required for effective biodegradation must be carefully evaluated to ensure that these materials do not persist in the environment or contribute to microplastic pollution.

Furthermore, the recyclability of bio-based polyamides should be assessed as part of their environmental impact. If these materials can be effectively recycled, it could significantly reduce their overall environmental footprint by minimizing the need for virgin material production. However, the energy and resources required for the recycling process must also be factored into the assessment.

In conducting a comprehensive environmental impact assessment, it is crucial to employ life cycle assessment (LCA) methodologies. These should encompass all stages from raw material extraction to end-of-life disposal or recycling. Such analyses can provide valuable insights into the comparative environmental performance of bio-based polyamides versus traditional petroleum-based alternatives, particularly when considering long-term creep and fatigue characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!