How to Improve Thermal Stability of Bio-Based Polyamides: Polymer Blending Techniques

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Stability Challenges and Objectives

Bio-based polyamides have gained significant attention in recent years due to their potential as sustainable alternatives to petroleum-based polymers. However, one of the major challenges hindering their widespread adoption is their relatively poor thermal stability compared to conventional polyamides. This limitation restricts their use in high-temperature applications and reduces their overall performance in various industrial sectors.

The primary objective of improving the thermal stability of bio-based polyamides is to enhance their resistance to degradation at elevated temperatures. This improvement would expand their applicability in sectors such as automotive, electronics, and aerospace, where high-temperature resistance is crucial. Additionally, enhanced thermal stability would lead to better processing characteristics, allowing for a wider range of manufacturing techniques to be employed.

Current bio-based polyamides typically exhibit lower melting points and glass transition temperatures compared to their petroleum-based counterparts. This results in reduced dimensional stability, decreased mechanical properties, and accelerated aging at elevated temperatures. The goal is to develop bio-based polyamides that can maintain their structural integrity and mechanical properties at temperatures comparable to or exceeding those of conventional polyamides.

Polymer blending techniques offer a promising approach to address these thermal stability challenges. By combining bio-based polyamides with other polymers or additives, it is possible to create synergistic effects that enhance overall thermal performance. The objective is to identify optimal blending partners and ratios that can significantly improve heat resistance without compromising other desirable properties of bio-based polyamides, such as their biodegradability and renewable nature.

Another critical aspect of this research is to understand the underlying mechanisms of thermal degradation in bio-based polyamides. This knowledge will guide the development of targeted strategies to mitigate these degradation processes. The aim is to design polymer blends that can effectively inhibit chain scission, cross-linking, and other thermal degradation pathways specific to bio-based polyamides.

Furthermore, the research seeks to explore novel processing techniques that can be used in conjunction with polymer blending to further enhance thermal stability. This may include the investigation of reactive extrusion processes, the incorporation of nanofillers, or the development of new copolymerization strategies tailored for bio-based polyamides.

Ultimately, the overarching goal is to bridge the performance gap between bio-based and petroleum-based polyamides in terms of thermal stability. Success in this endeavor would not only expand the market potential for bio-based polyamides but also contribute significantly to the broader transition towards more sustainable and environmentally friendly materials in various industries.

The primary objective of improving the thermal stability of bio-based polyamides is to enhance their resistance to degradation at elevated temperatures. This improvement would expand their applicability in sectors such as automotive, electronics, and aerospace, where high-temperature resistance is crucial. Additionally, enhanced thermal stability would lead to better processing characteristics, allowing for a wider range of manufacturing techniques to be employed.

Current bio-based polyamides typically exhibit lower melting points and glass transition temperatures compared to their petroleum-based counterparts. This results in reduced dimensional stability, decreased mechanical properties, and accelerated aging at elevated temperatures. The goal is to develop bio-based polyamides that can maintain their structural integrity and mechanical properties at temperatures comparable to or exceeding those of conventional polyamides.

Polymer blending techniques offer a promising approach to address these thermal stability challenges. By combining bio-based polyamides with other polymers or additives, it is possible to create synergistic effects that enhance overall thermal performance. The objective is to identify optimal blending partners and ratios that can significantly improve heat resistance without compromising other desirable properties of bio-based polyamides, such as their biodegradability and renewable nature.

Another critical aspect of this research is to understand the underlying mechanisms of thermal degradation in bio-based polyamides. This knowledge will guide the development of targeted strategies to mitigate these degradation processes. The aim is to design polymer blends that can effectively inhibit chain scission, cross-linking, and other thermal degradation pathways specific to bio-based polyamides.

Furthermore, the research seeks to explore novel processing techniques that can be used in conjunction with polymer blending to further enhance thermal stability. This may include the investigation of reactive extrusion processes, the incorporation of nanofillers, or the development of new copolymerization strategies tailored for bio-based polyamides.

Ultimately, the overarching goal is to bridge the performance gap between bio-based and petroleum-based polyamides in terms of thermal stability. Success in this endeavor would not only expand the market potential for bio-based polyamides but also contribute significantly to the broader transition towards more sustainable and environmentally friendly materials in various industries.

Market Demand for Bio-Based Polyamides

The market demand for bio-based polyamides has been steadily increasing in recent years, driven by growing environmental concerns and the push for sustainable alternatives to petroleum-based plastics. Bio-based polyamides, derived from renewable resources such as castor oil, offer a more eco-friendly option with reduced carbon footprint compared to their conventional counterparts.

The automotive industry has emerged as a significant driver of demand for bio-based polyamides. As automakers strive to meet stringent emissions regulations and improve fuel efficiency, they are increasingly turning to lightweight materials. Bio-based polyamides provide an excellent balance of strength, durability, and weight reduction, making them ideal for various automotive components such as engine covers, air intake manifolds, and fuel lines.

Another key market for bio-based polyamides is the packaging industry. With consumers becoming more environmentally conscious, there is a growing demand for sustainable packaging solutions. Bio-based polyamides offer excellent barrier properties and mechanical strength, making them suitable for food packaging, flexible films, and bottles. The ability to create compostable or biodegradable packaging using these materials further enhances their appeal in this sector.

The electronics industry is also showing increased interest in bio-based polyamides. These materials offer good thermal stability and electrical insulation properties, making them suitable for various electronic components and housings. As the industry moves towards more sustainable practices, the demand for bio-based alternatives in electronic applications is expected to grow.

In the textile sector, bio-based polyamides are gaining traction as sustainable alternatives to traditional synthetic fibers. They are being used in the production of sportswear, outdoor gear, and high-performance textiles, offering properties such as moisture-wicking, durability, and comfort.

The global market for bio-based polyamides is projected to experience substantial growth in the coming years. Factors contributing to this growth include increasing environmental regulations, consumer preference for sustainable products, and ongoing research and development efforts to improve the performance and cost-effectiveness of these materials.

However, challenges remain in terms of production costs and scalability. Bio-based polyamides are generally more expensive to produce than their petroleum-based counterparts, which can limit their adoption in price-sensitive markets. Additionally, the limited availability of bio-based feedstocks and the need for specialized processing techniques pose challenges to large-scale production.

The automotive industry has emerged as a significant driver of demand for bio-based polyamides. As automakers strive to meet stringent emissions regulations and improve fuel efficiency, they are increasingly turning to lightweight materials. Bio-based polyamides provide an excellent balance of strength, durability, and weight reduction, making them ideal for various automotive components such as engine covers, air intake manifolds, and fuel lines.

Another key market for bio-based polyamides is the packaging industry. With consumers becoming more environmentally conscious, there is a growing demand for sustainable packaging solutions. Bio-based polyamides offer excellent barrier properties and mechanical strength, making them suitable for food packaging, flexible films, and bottles. The ability to create compostable or biodegradable packaging using these materials further enhances their appeal in this sector.

The electronics industry is also showing increased interest in bio-based polyamides. These materials offer good thermal stability and electrical insulation properties, making them suitable for various electronic components and housings. As the industry moves towards more sustainable practices, the demand for bio-based alternatives in electronic applications is expected to grow.

In the textile sector, bio-based polyamides are gaining traction as sustainable alternatives to traditional synthetic fibers. They are being used in the production of sportswear, outdoor gear, and high-performance textiles, offering properties such as moisture-wicking, durability, and comfort.

The global market for bio-based polyamides is projected to experience substantial growth in the coming years. Factors contributing to this growth include increasing environmental regulations, consumer preference for sustainable products, and ongoing research and development efforts to improve the performance and cost-effectiveness of these materials.

However, challenges remain in terms of production costs and scalability. Bio-based polyamides are generally more expensive to produce than their petroleum-based counterparts, which can limit their adoption in price-sensitive markets. Additionally, the limited availability of bio-based feedstocks and the need for specialized processing techniques pose challenges to large-scale production.

Current Limitations in Thermal Stability

Bio-based polyamides have gained significant attention in recent years due to their potential as sustainable alternatives to petroleum-based polymers. However, their widespread adoption is hindered by limitations in thermal stability, which is crucial for various high-performance applications. The current thermal stability of bio-based polyamides falls short of industry requirements, particularly in sectors such as automotive, electronics, and aerospace.

One of the primary challenges is the lower decomposition temperature of bio-based polyamides compared to their petroleum-based counterparts. This limitation restricts their use in high-temperature processing and end-use applications. The onset of thermal degradation in bio-based polyamides typically occurs at lower temperatures, leading to a narrower processing window and reduced durability under elevated temperature conditions.

Another significant issue is the tendency of bio-based polyamides to undergo rapid oxidative degradation when exposed to high temperatures. This results in a faster deterioration of mechanical properties, color changes, and potential release of volatile organic compounds. The oxidative instability is often attributed to the presence of unsaturated bonds and reactive end groups in the bio-based polymer chains, which are more susceptible to thermal oxidation.

The crystallization behavior of bio-based polyamides also contributes to their thermal stability limitations. Many bio-based polyamides exhibit lower crystallinity and slower crystallization rates compared to conventional polyamides. This affects their heat resistance and dimensional stability at elevated temperatures, leading to softening and deformation at lower temperatures than desired for certain applications.

Furthermore, the moisture sensitivity of bio-based polyamides exacerbates their thermal stability issues. These materials tend to absorb more moisture from the environment, which can lead to hydrolytic degradation at high temperatures. This not only affects the mechanical properties but also accelerates thermal decomposition, further limiting their use in high-temperature and high-humidity environments.

The current limitations in thermal stability also extend to the long-term performance of bio-based polyamides. Under prolonged exposure to elevated temperatures, these materials often show accelerated aging, manifested as embrittlement, discoloration, and loss of mechanical strength. This poses challenges for applications requiring extended service life under thermal stress, such as in automotive under-hood components or electrical insulation materials.

Addressing these thermal stability limitations is crucial for expanding the application range of bio-based polyamides and realizing their full potential as sustainable alternatives. Polymer blending techniques offer a promising approach to overcome these challenges, potentially enhancing the thermal stability while maintaining the eco-friendly attributes of bio-based polyamides.

One of the primary challenges is the lower decomposition temperature of bio-based polyamides compared to their petroleum-based counterparts. This limitation restricts their use in high-temperature processing and end-use applications. The onset of thermal degradation in bio-based polyamides typically occurs at lower temperatures, leading to a narrower processing window and reduced durability under elevated temperature conditions.

Another significant issue is the tendency of bio-based polyamides to undergo rapid oxidative degradation when exposed to high temperatures. This results in a faster deterioration of mechanical properties, color changes, and potential release of volatile organic compounds. The oxidative instability is often attributed to the presence of unsaturated bonds and reactive end groups in the bio-based polymer chains, which are more susceptible to thermal oxidation.

The crystallization behavior of bio-based polyamides also contributes to their thermal stability limitations. Many bio-based polyamides exhibit lower crystallinity and slower crystallization rates compared to conventional polyamides. This affects their heat resistance and dimensional stability at elevated temperatures, leading to softening and deformation at lower temperatures than desired for certain applications.

Furthermore, the moisture sensitivity of bio-based polyamides exacerbates their thermal stability issues. These materials tend to absorb more moisture from the environment, which can lead to hydrolytic degradation at high temperatures. This not only affects the mechanical properties but also accelerates thermal decomposition, further limiting their use in high-temperature and high-humidity environments.

The current limitations in thermal stability also extend to the long-term performance of bio-based polyamides. Under prolonged exposure to elevated temperatures, these materials often show accelerated aging, manifested as embrittlement, discoloration, and loss of mechanical strength. This poses challenges for applications requiring extended service life under thermal stress, such as in automotive under-hood components or electrical insulation materials.

Addressing these thermal stability limitations is crucial for expanding the application range of bio-based polyamides and realizing their full potential as sustainable alternatives. Polymer blending techniques offer a promising approach to overcome these challenges, potentially enhancing the thermal stability while maintaining the eco-friendly attributes of bio-based polyamides.

Existing Thermal Stability Enhancement Methods

01 Incorporation of stabilizing additives

Various additives can be incorporated into bio-based polyamides to enhance their thermal stability. These additives may include antioxidants, heat stabilizers, and flame retardants. By carefully selecting and combining these additives, the thermal properties of bio-based polyamides can be significantly improved, making them suitable for high-temperature applications.- Incorporation of bio-based monomers: Bio-based monomers derived from renewable resources are incorporated into polyamide structures to enhance thermal stability. These monomers can include bio-based dicarboxylic acids or diamines, which contribute to improved heat resistance and overall thermal properties of the resulting polyamides.

- Use of nanofillers and reinforcing agents: Nanofillers and reinforcing agents are added to bio-based polyamides to improve their thermal stability. These additives can include nanoclays, carbon nanotubes, or natural fibers, which enhance the heat resistance and mechanical properties of the polyamide composites.

- Chemical modification of polyamide structure: The thermal stability of bio-based polyamides is enhanced through chemical modifications of their structure. This can involve crosslinking, copolymerization with other monomers, or the introduction of thermally stable functional groups to improve heat resistance.

- Blending with high-performance polymers: Bio-based polyamides are blended with high-performance polymers to create composites with improved thermal stability. These blends can combine the bio-based nature of polyamides with the superior thermal properties of other polymers, resulting in materials with enhanced heat resistance.

- Optimization of processing conditions: The thermal stability of bio-based polyamides is improved through optimization of processing conditions. This includes adjusting parameters such as temperature, pressure, and cooling rates during manufacturing to enhance the crystallinity and thermal properties of the final product.

02 Modification of polymer structure

The thermal stability of bio-based polyamides can be enhanced by modifying their molecular structure. This may involve techniques such as cross-linking, copolymerization, or the introduction of specific functional groups. These modifications can increase the melting point, glass transition temperature, and overall heat resistance of the polymer.Expand Specific Solutions03 Blending with other polymers

Blending bio-based polyamides with other thermally stable polymers can improve their overall thermal properties. This approach allows for the creation of composite materials that combine the desirable characteristics of both components, potentially resulting in enhanced thermal stability and mechanical properties.Expand Specific Solutions04 Nanocomposite formulation

Incorporating nanoparticles or nanofillers into bio-based polyamides can significantly improve their thermal stability. Materials such as nanoclay, carbon nanotubes, or metal oxide nanoparticles can be dispersed within the polymer matrix, creating nanocomposites with enhanced heat resistance and reduced thermal degradation.Expand Specific Solutions05 Processing and manufacturing techniques

Optimizing the processing and manufacturing techniques for bio-based polyamides can contribute to improved thermal stability. This may include adjusting parameters such as extrusion temperature, cooling rate, and mold design. Additionally, post-processing treatments like annealing or heat-setting can further enhance the thermal properties of the final product.Expand Specific Solutions

Key Players in Bio-Based Polyamide Industry

The thermal stability improvement of bio-based polyamides through polymer blending techniques is an emerging field in the advanced materials sector. The market is in its growth phase, with increasing demand for sustainable and high-performance polymers. Major players like BASF, DuPont, and Solvay are actively involved in research and development, leveraging their expertise in polymer science. The technology's maturity is progressing, with academic institutions such as Beijing University of Chemical Technology and Osaka University contributing to fundamental research. Companies like Rhodia Operations and Clariant are focusing on specialized applications, while emerging players like Cathay Biotech are exploring innovative bio-based solutions. The market size is expanding as industries seek eco-friendly alternatives to traditional petroleum-based polyamides.

BASF Corp.

Technical Solution: BASF has developed a novel polymer blending technique to improve the thermal stability of bio-based polyamides. Their approach involves creating a blend of bio-based polyamides with high-performance synthetic polymers, such as polyphenylene sulfide (PPS) or polyetheretherketone (PEEK). This blend combines the renewable nature of bio-based polyamides with the excellent thermal properties of the synthetic polymers. The company utilizes a proprietary compatibilizer to ensure optimal miscibility between the two components, resulting in a homogeneous blend with enhanced thermal stability[1][3]. BASF's process also incorporates reactive extrusion techniques, where chain extenders are added during the blending process to increase molecular weight and improve overall thermal resistance[5].

Strengths: Combines sustainability of bio-based materials with high thermal performance. Weaknesses: May increase production costs due to the use of high-performance synthetic polymers and specialized compatibilizers.

DuPont de Nemours, Inc.

Technical Solution: DuPont has pioneered a multi-phase blending technique for enhancing the thermal stability of bio-based polyamides. Their method involves creating a core-shell structure where the bio-based polyamide forms the core, surrounded by a shell of thermally resistant synthetic polymer. This structure is achieved through careful control of the blending process, including precise temperature management and the use of specific interfacial agents[2]. DuPont's technique also incorporates nanofillers, such as clay or carbon nanotubes, which are selectively localized in the interface between the core and shell. This selective localization enhances the overall thermal stability of the blend while maintaining the bio-based content[4]. The company has reported improvements in heat deflection temperature of up to 30°C compared to unmodified bio-based polyamides[6].

Strengths: Significant improvement in thermal properties while maintaining high bio-based content. Weaknesses: Complex processing may lead to higher production costs and potential scalability issues.

Innovative Polymer Blending Approaches

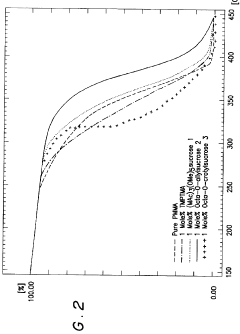

Polymers having enhanced thermal stabilities and methods for their preparation using stabilization agents 1,6,6,-trimethacryloyl 2,3,3,4,4,-penta-o-methylsucrose 1,2,3,3,4,4,6,6,-octa-o-allylsucrose 1,2,3,3,4,4,6,6,-octo-o-crotylsucrose

PatentInactiveUS5789469A

Innovation

- The use of sucrose-based monomers with allyl-containing groups, such as 1',6,6'-trimethacryloyl-2,3,3',4,4'-penta-O-methylsucrose and 1',2,3,3',4,4',6,6'-octa-O-allylsucrose, which enhance crosslinking efficiency and thermal stability by incorporating these monomers into polymerizable mixtures with methacrylate esters, acrylate esters, and styrene monomers, along with a free radical initiator.

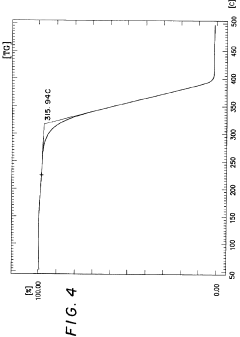

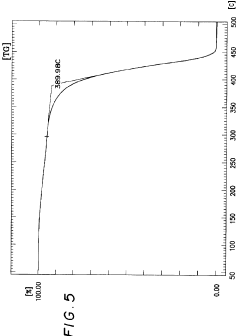

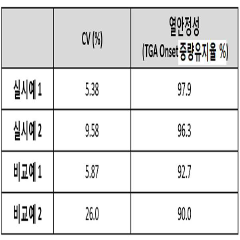

Biodegradable polymer with improved heat stability and method for preparing the same

PatentInactiveKR1020190079860A

Innovation

- A method for producing biodegradable polymers through solid-state polymerization using specific monomers, initiators, and catalysts in controlled conditions, avoiding additional modifications, to achieve improved thermal stability.

Environmental Impact Assessment

The environmental impact assessment of improving the thermal stability of bio-based polyamides through polymer blending techniques is a crucial aspect to consider in the development and implementation of this technology. Bio-based polyamides, derived from renewable resources, offer potential environmental benefits compared to their petroleum-based counterparts. However, the process of enhancing their thermal stability through polymer blending may introduce additional environmental considerations.

One of the primary environmental advantages of bio-based polyamides is their reduced carbon footprint. These materials are derived from renewable sources, such as plant-based feedstocks, which can help mitigate greenhouse gas emissions associated with traditional petroleum-based polymers. By improving the thermal stability of bio-based polyamides, their potential applications expand, potentially replacing more environmentally harmful materials in various industries.

The polymer blending techniques used to enhance thermal stability may have both positive and negative environmental implications. On the positive side, improved thermal stability can lead to longer-lasting products, reducing the need for frequent replacements and minimizing waste generation. This extended product lifespan contributes to resource conservation and waste reduction, aligning with circular economy principles.

However, the blending process itself may require additional energy inputs and potentially introduce new chemical additives. The environmental impact of these additives, including their production, use, and end-of-life disposal, must be carefully evaluated. Some additives may pose risks to ecosystems or human health if not properly managed throughout the product lifecycle.

The end-of-life considerations for thermally stable bio-based polyamide blends are also important. While bio-based materials are often touted for their biodegradability, the addition of stabilizing components may alter their decomposition characteristics. This could potentially impact recycling processes or biodegradation rates in natural environments.

Water usage and pollution are additional factors to assess. The production of bio-based feedstocks may require significant water resources, and the polymer blending process could generate wastewater that needs proper treatment. Ensuring responsible water management practices throughout the supply chain is essential to minimize negative impacts on local water systems.

Land use changes associated with the cultivation of bio-based feedstocks should also be considered. Expanding agricultural production for polymer feedstocks may lead to deforestation or competition with food crops, potentially affecting biodiversity and food security.

In conclusion, while improving the thermal stability of bio-based polyamides through polymer blending techniques offers promising environmental benefits, a comprehensive life cycle assessment is necessary to fully understand and mitigate potential negative impacts. Balancing the advantages of enhanced material properties with environmental considerations will be key to developing truly sustainable solutions in this field.

One of the primary environmental advantages of bio-based polyamides is their reduced carbon footprint. These materials are derived from renewable sources, such as plant-based feedstocks, which can help mitigate greenhouse gas emissions associated with traditional petroleum-based polymers. By improving the thermal stability of bio-based polyamides, their potential applications expand, potentially replacing more environmentally harmful materials in various industries.

The polymer blending techniques used to enhance thermal stability may have both positive and negative environmental implications. On the positive side, improved thermal stability can lead to longer-lasting products, reducing the need for frequent replacements and minimizing waste generation. This extended product lifespan contributes to resource conservation and waste reduction, aligning with circular economy principles.

However, the blending process itself may require additional energy inputs and potentially introduce new chemical additives. The environmental impact of these additives, including their production, use, and end-of-life disposal, must be carefully evaluated. Some additives may pose risks to ecosystems or human health if not properly managed throughout the product lifecycle.

The end-of-life considerations for thermally stable bio-based polyamide blends are also important. While bio-based materials are often touted for their biodegradability, the addition of stabilizing components may alter their decomposition characteristics. This could potentially impact recycling processes or biodegradation rates in natural environments.

Water usage and pollution are additional factors to assess. The production of bio-based feedstocks may require significant water resources, and the polymer blending process could generate wastewater that needs proper treatment. Ensuring responsible water management practices throughout the supply chain is essential to minimize negative impacts on local water systems.

Land use changes associated with the cultivation of bio-based feedstocks should also be considered. Expanding agricultural production for polymer feedstocks may lead to deforestation or competition with food crops, potentially affecting biodiversity and food security.

In conclusion, while improving the thermal stability of bio-based polyamides through polymer blending techniques offers promising environmental benefits, a comprehensive life cycle assessment is necessary to fully understand and mitigate potential negative impacts. Balancing the advantages of enhanced material properties with environmental considerations will be key to developing truly sustainable solutions in this field.

Scalability and Cost Analysis

The scalability and cost analysis of polymer blending techniques for improving the thermal stability of bio-based polyamides is crucial for assessing their commercial viability. The process of scaling up from laboratory experiments to industrial production presents several challenges that must be carefully evaluated.

One of the primary considerations is the availability and cost of raw materials. Bio-based polyamides and their blending components may have limited supply chains, potentially leading to higher costs compared to traditional petroleum-based alternatives. As production scales up, securing a consistent and cost-effective supply of these materials becomes increasingly important.

The complexity of the blending process itself also impacts scalability. Factors such as mixing efficiency, temperature control, and residence time must be optimized for larger batch sizes or continuous production systems. This may require significant investment in specialized equipment and process control systems, which can substantially increase initial capital costs.

Energy consumption is another critical factor in the scalability and cost analysis. The blending process often requires elevated temperatures and mechanical energy input, which can lead to high operational costs at industrial scales. Implementing energy-efficient technologies and heat recovery systems can help mitigate these expenses but may require additional upfront investment.

Quality control and consistency become more challenging as production scales up. Ensuring uniform dispersion of blend components and maintaining the desired thermal stability properties across large production volumes may necessitate advanced monitoring and testing equipment, further adding to the overall cost.

Regulatory compliance and certification processes for bio-based materials can also impact scalability and costs. As production increases, meeting stringent quality and safety standards may require additional testing and documentation, potentially slowing down the scaling process and increasing associated expenses.

The potential for waste generation and the need for recycling or disposal of off-spec materials must also be considered. Implementing efficient recycling processes or finding alternative uses for waste products can help improve the overall cost-effectiveness of large-scale production.

Market demand and competition play a significant role in determining the economic viability of scaling up production. The ability to produce at a cost that allows for competitive pricing while maintaining profitability is essential for long-term success. This may require ongoing process optimization and cost reduction efforts as production scales increase.

In conclusion, while polymer blending techniques show promise for improving the thermal stability of bio-based polyamides, careful analysis of scalability and costs is essential. Balancing the technical requirements with economic considerations will be crucial for successfully transitioning these techniques from laboratory research to commercial-scale production.

One of the primary considerations is the availability and cost of raw materials. Bio-based polyamides and their blending components may have limited supply chains, potentially leading to higher costs compared to traditional petroleum-based alternatives. As production scales up, securing a consistent and cost-effective supply of these materials becomes increasingly important.

The complexity of the blending process itself also impacts scalability. Factors such as mixing efficiency, temperature control, and residence time must be optimized for larger batch sizes or continuous production systems. This may require significant investment in specialized equipment and process control systems, which can substantially increase initial capital costs.

Energy consumption is another critical factor in the scalability and cost analysis. The blending process often requires elevated temperatures and mechanical energy input, which can lead to high operational costs at industrial scales. Implementing energy-efficient technologies and heat recovery systems can help mitigate these expenses but may require additional upfront investment.

Quality control and consistency become more challenging as production scales up. Ensuring uniform dispersion of blend components and maintaining the desired thermal stability properties across large production volumes may necessitate advanced monitoring and testing equipment, further adding to the overall cost.

Regulatory compliance and certification processes for bio-based materials can also impact scalability and costs. As production increases, meeting stringent quality and safety standards may require additional testing and documentation, potentially slowing down the scaling process and increasing associated expenses.

The potential for waste generation and the need for recycling or disposal of off-spec materials must also be considered. Implementing efficient recycling processes or finding alternative uses for waste products can help improve the overall cost-effectiveness of large-scale production.

Market demand and competition play a significant role in determining the economic viability of scaling up production. The ability to produce at a cost that allows for competitive pricing while maintaining profitability is essential for long-term success. This may require ongoing process optimization and cost reduction efforts as production scales increase.

In conclusion, while polymer blending techniques show promise for improving the thermal stability of bio-based polyamides, careful analysis of scalability and costs is essential. Balancing the technical requirements with economic considerations will be crucial for successfully transitioning these techniques from laboratory research to commercial-scale production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!