How to Evaluate Flame Retardancy in Bio-Based Polyamides (testing protocols)

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flame Retardancy Evaluation Background and Objectives

The evaluation of flame retardancy in bio-based polyamides has become increasingly important as the demand for sustainable and environmentally friendly materials continues to grow. Bio-based polyamides, derived from renewable resources, offer a promising alternative to traditional petroleum-based polymers. However, ensuring their fire safety performance is crucial for their widespread adoption in various applications, particularly in industries such as automotive, electronics, and construction.

The primary objective of flame retardancy evaluation in bio-based polyamides is to assess their ability to resist ignition, slow down flame spread, and minimize heat release during combustion. This evaluation process aims to determine whether these materials meet the stringent safety standards required for their intended use. Additionally, it seeks to identify potential areas for improvement in their fire-resistant properties.

Historically, flame retardancy testing has evolved from simple observations to sophisticated analytical techniques. The development of standardized testing protocols has been driven by the need for consistent and reliable methods to compare different materials and formulations. These protocols have been established by various international organizations, such as the International Organization for Standardization (ISO), ASTM International, and Underwriters Laboratories (UL).

The current landscape of flame retardancy evaluation encompasses a wide range of testing methods, each designed to simulate different fire scenarios and measure specific aspects of material performance. These tests typically assess parameters such as ignitability, flame spread, heat release rate, smoke production, and the formation of toxic gases during combustion.

As the field of bio-based polyamides continues to advance, there is a growing need to adapt and refine existing testing protocols to address the unique characteristics of these materials. This includes considering the potential variability in properties due to the natural origin of their raw materials and the impact of bio-based additives on fire performance.

Furthermore, the evaluation of flame retardancy in bio-based polyamides must also take into account the broader context of sustainability. This involves assessing the environmental impact of flame retardant additives, exploring non-halogenated alternatives, and considering the end-of-life disposal or recyclability of these materials.

The ultimate goal of flame retardancy evaluation in bio-based polyamides is to develop materials that not only meet or exceed the fire safety standards of their petroleum-based counterparts but also maintain their eco-friendly credentials. This balance between performance and sustainability presents both challenges and opportunities for innovation in material science and testing methodologies.

The primary objective of flame retardancy evaluation in bio-based polyamides is to assess their ability to resist ignition, slow down flame spread, and minimize heat release during combustion. This evaluation process aims to determine whether these materials meet the stringent safety standards required for their intended use. Additionally, it seeks to identify potential areas for improvement in their fire-resistant properties.

Historically, flame retardancy testing has evolved from simple observations to sophisticated analytical techniques. The development of standardized testing protocols has been driven by the need for consistent and reliable methods to compare different materials and formulations. These protocols have been established by various international organizations, such as the International Organization for Standardization (ISO), ASTM International, and Underwriters Laboratories (UL).

The current landscape of flame retardancy evaluation encompasses a wide range of testing methods, each designed to simulate different fire scenarios and measure specific aspects of material performance. These tests typically assess parameters such as ignitability, flame spread, heat release rate, smoke production, and the formation of toxic gases during combustion.

As the field of bio-based polyamides continues to advance, there is a growing need to adapt and refine existing testing protocols to address the unique characteristics of these materials. This includes considering the potential variability in properties due to the natural origin of their raw materials and the impact of bio-based additives on fire performance.

Furthermore, the evaluation of flame retardancy in bio-based polyamides must also take into account the broader context of sustainability. This involves assessing the environmental impact of flame retardant additives, exploring non-halogenated alternatives, and considering the end-of-life disposal or recyclability of these materials.

The ultimate goal of flame retardancy evaluation in bio-based polyamides is to develop materials that not only meet or exceed the fire safety standards of their petroleum-based counterparts but also maintain their eco-friendly credentials. This balance between performance and sustainability presents both challenges and opportunities for innovation in material science and testing methodologies.

Market Demand for Bio-Based Flame Retardant Polyamides

The market demand for bio-based flame retardant polyamides has been steadily increasing in recent years, driven by a combination of environmental concerns, regulatory pressures, and consumer preferences. This trend is particularly evident in industries such as automotive, electronics, and construction, where there is a growing emphasis on sustainable and eco-friendly materials.

In the automotive sector, the push for lightweight materials to improve fuel efficiency has led to increased adoption of bio-based polyamides. These materials offer the added benefit of flame retardancy, which is crucial for meeting safety standards in vehicle interiors. The market for bio-based flame retardant polyamides in this sector is expected to grow significantly as automakers strive to meet stringent emissions regulations while maintaining safety standards.

The electronics industry is another key driver of demand for bio-based flame retardant polyamides. With the proliferation of electronic devices and the need for fire safety in consumer electronics, there is a growing market for sustainable flame retardant materials. Bio-based polyamides offer an attractive alternative to traditional petroleum-based flame retardants, which have faced scrutiny due to environmental and health concerns.

In the construction industry, the demand for bio-based flame retardant polyamides is being fueled by stricter building codes and a focus on sustainable construction materials. These materials are increasingly being used in insulation, wiring, and other applications where fire safety is paramount.

The market for bio-based flame retardant polyamides is also benefiting from broader sustainability initiatives across various industries. Companies are increasingly looking to incorporate bio-based materials into their products as part of their corporate social responsibility efforts and to appeal to environmentally conscious consumers.

However, the market faces some challenges. The higher cost of bio-based materials compared to traditional petroleum-based alternatives remains a barrier to widespread adoption. Additionally, there are concerns about the performance and durability of bio-based flame retardant polyamides in certain applications, which may limit their use in some high-performance sectors.

Despite these challenges, the overall market trajectory for bio-based flame retardant polyamides remains positive. As research and development efforts continue to improve the performance and cost-effectiveness of these materials, their market penetration is expected to increase. The growing emphasis on circular economy principles and the need to reduce reliance on fossil-based resources are likely to further drive demand for bio-based flame retardant polyamides in the coming years.

In the automotive sector, the push for lightweight materials to improve fuel efficiency has led to increased adoption of bio-based polyamides. These materials offer the added benefit of flame retardancy, which is crucial for meeting safety standards in vehicle interiors. The market for bio-based flame retardant polyamides in this sector is expected to grow significantly as automakers strive to meet stringent emissions regulations while maintaining safety standards.

The electronics industry is another key driver of demand for bio-based flame retardant polyamides. With the proliferation of electronic devices and the need for fire safety in consumer electronics, there is a growing market for sustainable flame retardant materials. Bio-based polyamides offer an attractive alternative to traditional petroleum-based flame retardants, which have faced scrutiny due to environmental and health concerns.

In the construction industry, the demand for bio-based flame retardant polyamides is being fueled by stricter building codes and a focus on sustainable construction materials. These materials are increasingly being used in insulation, wiring, and other applications where fire safety is paramount.

The market for bio-based flame retardant polyamides is also benefiting from broader sustainability initiatives across various industries. Companies are increasingly looking to incorporate bio-based materials into their products as part of their corporate social responsibility efforts and to appeal to environmentally conscious consumers.

However, the market faces some challenges. The higher cost of bio-based materials compared to traditional petroleum-based alternatives remains a barrier to widespread adoption. Additionally, there are concerns about the performance and durability of bio-based flame retardant polyamides in certain applications, which may limit their use in some high-performance sectors.

Despite these challenges, the overall market trajectory for bio-based flame retardant polyamides remains positive. As research and development efforts continue to improve the performance and cost-effectiveness of these materials, their market penetration is expected to increase. The growing emphasis on circular economy principles and the need to reduce reliance on fossil-based resources are likely to further drive demand for bio-based flame retardant polyamides in the coming years.

Current Challenges in Bio-Based Polyamide Flame Retardancy

The development of bio-based polyamides has gained significant attention in recent years due to their potential as sustainable alternatives to petroleum-based counterparts. However, ensuring adequate flame retardancy in these materials remains a critical challenge. The current state of flame retardancy evaluation for bio-based polyamides faces several obstacles that hinder their widespread adoption in various applications.

One of the primary challenges is the lack of standardized testing protocols specifically designed for bio-based polyamides. Existing flame retardancy tests, such as UL 94 and limiting oxygen index (LOI), were originally developed for conventional polymers and may not fully capture the unique characteristics of bio-based materials. This discrepancy can lead to inconsistent results and difficulties in comparing the performance of different bio-based polyamides.

Another significant challenge is the complex interaction between the bio-based polymer matrix and flame retardant additives. Bio-based polyamides often exhibit different thermal decomposition behaviors compared to their petroleum-based counterparts, which can affect the efficacy of traditional flame retardants. This complexity necessitates a deeper understanding of the flame retardancy mechanisms specific to bio-based polyamides.

The environmental impact of flame retardants used in bio-based polyamides also presents a challenge. While the base polymer may be derived from renewable resources, many conventional flame retardants are halogenated compounds that can have adverse environmental effects. Balancing the need for effective flame retardancy with the goal of maintaining the overall sustainability of the material is a delicate task that requires innovative solutions.

Furthermore, the variability in the composition of bio-based polyamides, which can depend on the specific biomass source and processing methods, introduces additional complexity to flame retardancy evaluation. This variability can lead to inconsistencies in test results and makes it difficult to establish universal performance benchmarks for these materials.

The scalability of flame retardancy solutions for bio-based polyamides is another hurdle. Many promising flame retardant systems developed in laboratory settings may face challenges when scaled up for industrial production. Issues such as processability, long-term stability, and cost-effectiveness need to be addressed to ensure the viability of these solutions in real-world applications.

Lastly, the regulatory landscape surrounding flame retardancy in bio-based materials is still evolving. The lack of clear guidelines and standards specific to bio-based polyamides creates uncertainty for manufacturers and end-users alike. This regulatory gap can impede the adoption of these materials in sectors with stringent safety requirements, such as automotive and construction industries.

One of the primary challenges is the lack of standardized testing protocols specifically designed for bio-based polyamides. Existing flame retardancy tests, such as UL 94 and limiting oxygen index (LOI), were originally developed for conventional polymers and may not fully capture the unique characteristics of bio-based materials. This discrepancy can lead to inconsistent results and difficulties in comparing the performance of different bio-based polyamides.

Another significant challenge is the complex interaction between the bio-based polymer matrix and flame retardant additives. Bio-based polyamides often exhibit different thermal decomposition behaviors compared to their petroleum-based counterparts, which can affect the efficacy of traditional flame retardants. This complexity necessitates a deeper understanding of the flame retardancy mechanisms specific to bio-based polyamides.

The environmental impact of flame retardants used in bio-based polyamides also presents a challenge. While the base polymer may be derived from renewable resources, many conventional flame retardants are halogenated compounds that can have adverse environmental effects. Balancing the need for effective flame retardancy with the goal of maintaining the overall sustainability of the material is a delicate task that requires innovative solutions.

Furthermore, the variability in the composition of bio-based polyamides, which can depend on the specific biomass source and processing methods, introduces additional complexity to flame retardancy evaluation. This variability can lead to inconsistencies in test results and makes it difficult to establish universal performance benchmarks for these materials.

The scalability of flame retardancy solutions for bio-based polyamides is another hurdle. Many promising flame retardant systems developed in laboratory settings may face challenges when scaled up for industrial production. Issues such as processability, long-term stability, and cost-effectiveness need to be addressed to ensure the viability of these solutions in real-world applications.

Lastly, the regulatory landscape surrounding flame retardancy in bio-based materials is still evolving. The lack of clear guidelines and standards specific to bio-based polyamides creates uncertainty for manufacturers and end-users alike. This regulatory gap can impede the adoption of these materials in sectors with stringent safety requirements, such as automotive and construction industries.

Existing Flame Retardancy Evaluation Methods for Polyamides

01 Incorporation of flame retardant additives

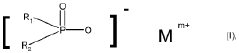

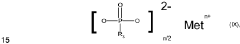

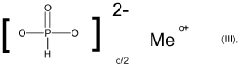

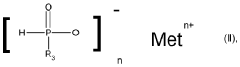

Bio-based polyamides can be made flame retardant by incorporating various additives. These additives can include phosphorus-based compounds, nitrogen-containing substances, or mineral fillers. The additives work by interfering with the combustion process, forming a protective char layer, or releasing flame-inhibiting gases when exposed to heat.- Incorporation of flame retardant additives: Bio-based polyamides can be made flame retardant by incorporating various additives. These additives can include phosphorus-based compounds, nitrogen-containing substances, or mineral fillers. The additives work by interfering with the combustion process, forming a protective char layer, or releasing flame-inhibiting gases.

- Modification of polymer structure: The flame retardancy of bio-based polyamides can be improved by modifying their chemical structure. This can involve introducing flame-retardant groups into the polymer backbone, copolymerization with flame-retardant monomers, or grafting flame-retardant side chains onto the polymer.

- Use of bio-based flame retardants: To maintain the bio-based nature of the polyamides, researchers are exploring the use of bio-derived flame retardants. These can include compounds extracted from plants, modified natural polymers, or bio-based phosphorus compounds. Such additives can enhance flame retardancy while maintaining the renewable aspect of the material.

- Nanocomposite approach: Incorporating nanoparticles or nanostructures into bio-based polyamides can significantly improve their flame retardancy. This approach often involves the use of nanoclays, carbon nanotubes, or metal oxide nanoparticles. These nanofillers can create a barrier effect, improve char formation, and enhance the overall flame resistance of the polymer.

- Synergistic flame retardant systems: Combining multiple flame retardant strategies or additives can lead to synergistic effects, enhancing the overall flame retardancy of bio-based polyamides. This can involve using combinations of different types of flame retardants, or combining flame retardants with other functional additives to achieve optimal performance.

02 Use of bio-based flame retardant monomers

Flame retardancy in bio-based polyamides can be achieved by using monomers that inherently possess flame retardant properties. These monomers can be derived from renewable resources and may contain elements like phosphorus or nitrogen. By incorporating these monomers into the polymer structure, the resulting polyamide exhibits improved flame resistance without the need for additional additives.Expand Specific Solutions03 Surface treatment and coating techniques

Flame retardancy of bio-based polyamides can be enhanced through surface treatments or coatings. These methods involve applying a flame-retardant layer to the surface of the polyamide material. The coatings can be intumescent formulations that expand and form an insulating char when exposed to heat, providing protection to the underlying polymer.Expand Specific Solutions04 Nanocomposite approach for flame retardancy

Incorporating nanoparticles into bio-based polyamides can significantly improve their flame retardant properties. Nanofillers such as clay, graphene, or metal oxides can be dispersed within the polymer matrix. These nanoparticles create a tortuous path for heat and gas diffusion, enhancing the overall flame resistance of the material.Expand Specific Solutions05 Synergistic flame retardant systems

Combining multiple flame retardant strategies can lead to synergistic effects in bio-based polyamides. This approach involves using a combination of different flame retardant additives, surface treatments, or nanofillers. The synergistic system can provide enhanced flame retardancy compared to individual components, while potentially reducing the overall additive loading and maintaining other desirable properties of the polyamide.Expand Specific Solutions

Key Players in Bio-Based Polyamide and Flame Retardant Industry

The flame retardancy evaluation of bio-based polyamides is in a developing stage, with the market showing significant growth potential due to increasing demand for sustainable materials. The technology is progressing towards maturity, but standardization of testing protocols remains a challenge. Key players like Cathay Biotech, Kingfa Sci. & Tech., and BASF are driving innovation in this field. These companies are investing in research and development to improve flame retardant properties while maintaining the eco-friendly aspects of bio-based polyamides. The competitive landscape is characterized by a mix of established chemical companies and emerging biotech firms, each bringing unique expertise to address the technical challenges in flame retardancy testing and performance optimization.

Arkema France SA

Technical Solution: Arkema France SA has developed a unique approach to evaluate flame retardancy in bio-based polyamides, focusing on their Rilsan® range of bio-based polyamides. Their testing protocol incorporates standard fire tests such as UL 94 and LOI, but also includes more specialized tests like the glow-wire test for electrical components[5]. Arkema has pioneered the use of renewable-based flame retardants, including their patented Oleoflamm® technology, which utilizes vegetable oil-based additives to achieve flame retardancy[6]. Their evaluation process also includes advanced thermal analysis techniques such as TGA coupled with FTIR to analyze the gases evolved during combustion, providing insights into the flame retardant mechanism[7]. Arkema's approach emphasizes the importance of maintaining the bio-based nature of the polyamides while improving flame retardancy, often achieving UL 94 V-0 ratings at 0.8mm thickness with their optimized formulations[8].

Strengths: Focus on maintaining bio-based nature, innovative use of renewable flame retardants, and comprehensive thermal analysis. Weaknesses: Potential limitations in extreme high-temperature applications, and possible trade-offs between flame retardancy and other mechanical properties.

Mitsui Chemicals, Inc.

Technical Solution: Mitsui Chemicals, Inc. has developed a sophisticated approach to evaluate flame retardancy in bio-based polyamides, particularly focusing on their ECONYL® range. Their testing protocol includes standard fire tests like UL 94 and LOI, but also incorporates more specialized tests such as the NBS Smoke Chamber test to evaluate smoke density and toxicity[9]. Mitsui has developed a proprietary flame retardant system that combines traditional phosphorus-based additives with novel nanofillers, achieving synergistic effects that enhance flame retardancy while maintaining the bio-based content of the polyamides[10]. Their evaluation process also includes advanced rheological studies to understand the impact of flame retardant additives on the processing behavior of the bio-based polyamides[11]. Mitsui's approach emphasizes the importance of a holistic evaluation, considering not only flame retardancy but also the overall performance and processability of the material[12].

Strengths: Holistic evaluation approach, development of synergistic flame retardant systems, and focus on maintaining processability. Weaknesses: Potential increased complexity in formulation and possible higher costs associated with specialized additives.

Core Innovations in Bio-Based Polyamide Flame Retardancy Testing

Flame-retardant polyamide compositions with a high heat deflection temperature, and use thereof

PatentWO2019011790A1

Innovation

- A flame-retardant polyamide composition comprising a thermoplastic polyamide with a high melting point, glass fibers, diethylphosphinic acid salts, and inorganic phosphonates, optimized with specific weight ratios and additives to enhance heat distortion temperature, electrical insulation, and flame retardancy.

Environmental Impact of Flame Retardants in Bio-Based Polyamides

The environmental impact of flame retardants in bio-based polyamides is a critical consideration in the development and application of these materials. As the demand for sustainable and eco-friendly alternatives to traditional petroleum-based polymers grows, bio-based polyamides have gained significant attention. However, the incorporation of flame retardants into these materials raises important questions about their overall environmental footprint.

One of the primary concerns is the potential release of flame retardants into the environment during the lifecycle of bio-based polyamide products. Some flame retardants, particularly halogenated compounds, have been associated with persistent organic pollutants (POPs) that can accumulate in ecosystems and pose risks to wildlife and human health. This has led to increased scrutiny of flame retardant choices and a push towards more environmentally benign alternatives.

The production process of flame retardants for bio-based polyamides also contributes to their environmental impact. Energy consumption and greenhouse gas emissions associated with the synthesis of these additives must be considered when evaluating the overall sustainability of the final product. Additionally, the extraction and processing of raw materials for both the bio-based polymer and the flame retardants can have significant environmental implications, including land use changes and potential biodiversity impacts.

End-of-life considerations play a crucial role in assessing the environmental impact of flame-retardant bio-based polyamides. The presence of flame retardants can complicate recycling processes, potentially reducing the recyclability of these materials. This may lead to increased waste and the need for specialized disposal methods, which can offset some of the environmental benefits gained from using bio-based materials.

Water pollution is another area of concern, as some flame retardants can leach into aquatic environments during product use or disposal. This can lead to bioaccumulation in aquatic organisms and potential disruption of ecosystems. The development of more stable and less mobile flame retardants is an active area of research aimed at mitigating these risks.

The toxicity profile of flame retardants used in bio-based polyamides is a critical factor in their environmental assessment. Some additives may have unintended consequences on non-target organisms, leading to ecological imbalances. Researchers are increasingly focusing on developing bio-based flame retardants that are inherently less toxic and more compatible with the principles of green chemistry.

As regulations around flame retardants continue to evolve, manufacturers of bio-based polyamides must navigate a complex landscape of environmental standards and certifications. This includes considerations of the entire life cycle of the product, from raw material sourcing to disposal or recycling. The challenge lies in balancing the need for fire safety with environmental protection, driving innovation towards more sustainable flame retardant solutions for bio-based polyamides.

One of the primary concerns is the potential release of flame retardants into the environment during the lifecycle of bio-based polyamide products. Some flame retardants, particularly halogenated compounds, have been associated with persistent organic pollutants (POPs) that can accumulate in ecosystems and pose risks to wildlife and human health. This has led to increased scrutiny of flame retardant choices and a push towards more environmentally benign alternatives.

The production process of flame retardants for bio-based polyamides also contributes to their environmental impact. Energy consumption and greenhouse gas emissions associated with the synthesis of these additives must be considered when evaluating the overall sustainability of the final product. Additionally, the extraction and processing of raw materials for both the bio-based polymer and the flame retardants can have significant environmental implications, including land use changes and potential biodiversity impacts.

End-of-life considerations play a crucial role in assessing the environmental impact of flame-retardant bio-based polyamides. The presence of flame retardants can complicate recycling processes, potentially reducing the recyclability of these materials. This may lead to increased waste and the need for specialized disposal methods, which can offset some of the environmental benefits gained from using bio-based materials.

Water pollution is another area of concern, as some flame retardants can leach into aquatic environments during product use or disposal. This can lead to bioaccumulation in aquatic organisms and potential disruption of ecosystems. The development of more stable and less mobile flame retardants is an active area of research aimed at mitigating these risks.

The toxicity profile of flame retardants used in bio-based polyamides is a critical factor in their environmental assessment. Some additives may have unintended consequences on non-target organisms, leading to ecological imbalances. Researchers are increasingly focusing on developing bio-based flame retardants that are inherently less toxic and more compatible with the principles of green chemistry.

As regulations around flame retardants continue to evolve, manufacturers of bio-based polyamides must navigate a complex landscape of environmental standards and certifications. This includes considerations of the entire life cycle of the product, from raw material sourcing to disposal or recycling. The challenge lies in balancing the need for fire safety with environmental protection, driving innovation towards more sustainable flame retardant solutions for bio-based polyamides.

Standardization of Bio-Based Polyamide Flame Retardancy Tests

The standardization of flame retardancy tests for bio-based polyamides is crucial for ensuring consistent and reliable evaluation of their fire-resistant properties. This standardization process involves the development and implementation of uniform testing protocols that can be applied across different laboratories and research institutions.

One of the primary challenges in standardizing these tests is the inherent variability of bio-based materials. Unlike traditional petroleum-based polyamides, bio-based variants can exhibit differences in composition and structure depending on their source materials and production methods. This variability necessitates the creation of testing protocols that can account for these differences while still providing comparable results.

The standardization process typically begins with a comprehensive review of existing testing methods used for conventional polyamides. These methods are then adapted and refined to address the specific characteristics of bio-based polyamides. Key considerations include the material's thermal decomposition behavior, char formation, and smoke production during combustion.

A critical aspect of standardization is the selection of appropriate test specimens. This involves determining the optimal size, shape, and preparation methods for bio-based polyamide samples to ensure reproducibility and relevance to real-world applications. Factors such as sample thickness, surface finish, and conditioning procedures must be carefully defined to minimize variability between tests.

The development of standardized ignition sources and exposure conditions is another essential component of the process. This may involve specifying the type and intensity of heat sources, flame application methods, and exposure durations. These parameters must be carefully calibrated to simulate realistic fire scenarios while providing consistent and measurable results.

Data collection and analysis procedures also require standardization. This includes defining the specific measurements to be taken during testing, such as time to ignition, heat release rate, and flame spread rate. Standardized methods for data interpretation and reporting are crucial for enabling meaningful comparisons between different bio-based polyamide formulations and conventional materials.

Interlaboratory studies play a vital role in validating and refining standardized testing protocols. These collaborative efforts involve multiple laboratories performing the same tests on identical materials to assess the reproducibility and reliability of the proposed methods. The results of these studies inform further refinements to the testing protocols and help establish acceptable ranges for key performance metrics.

One of the primary challenges in standardizing these tests is the inherent variability of bio-based materials. Unlike traditional petroleum-based polyamides, bio-based variants can exhibit differences in composition and structure depending on their source materials and production methods. This variability necessitates the creation of testing protocols that can account for these differences while still providing comparable results.

The standardization process typically begins with a comprehensive review of existing testing methods used for conventional polyamides. These methods are then adapted and refined to address the specific characteristics of bio-based polyamides. Key considerations include the material's thermal decomposition behavior, char formation, and smoke production during combustion.

A critical aspect of standardization is the selection of appropriate test specimens. This involves determining the optimal size, shape, and preparation methods for bio-based polyamide samples to ensure reproducibility and relevance to real-world applications. Factors such as sample thickness, surface finish, and conditioning procedures must be carefully defined to minimize variability between tests.

The development of standardized ignition sources and exposure conditions is another essential component of the process. This may involve specifying the type and intensity of heat sources, flame application methods, and exposure durations. These parameters must be carefully calibrated to simulate realistic fire scenarios while providing consistent and measurable results.

Data collection and analysis procedures also require standardization. This includes defining the specific measurements to be taken during testing, such as time to ignition, heat release rate, and flame spread rate. Standardized methods for data interpretation and reporting are crucial for enabling meaningful comparisons between different bio-based polyamide formulations and conventional materials.

Interlaboratory studies play a vital role in validating and refining standardized testing protocols. These collaborative efforts involve multiple laboratories performing the same tests on identical materials to assess the reproducibility and reliability of the proposed methods. The results of these studies inform further refinements to the testing protocols and help establish acceptable ranges for key performance metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!