How to Predict Moisture-Induced Dimensional Changes in Bio-PA Parts

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-PA Moisture Sensitivity Background

Bio-based polyamides (Bio-PAs) have gained significant attention in recent years as sustainable alternatives to conventional petroleum-based polyamides. These materials are derived from renewable resources such as castor oil, sebacic acid, and other bio-based monomers. The growing interest in Bio-PAs stems from the increasing demand for environmentally friendly and sustainable materials across various industries, including automotive, electronics, and consumer goods.

One of the key challenges associated with Bio-PAs is their sensitivity to moisture. Like their petroleum-based counterparts, Bio-PAs are hygroscopic materials, meaning they have a tendency to absorb moisture from the environment. This moisture absorption can lead to dimensional changes in Bio-PA parts, affecting their performance, mechanical properties, and overall stability.

The moisture sensitivity of Bio-PAs is primarily attributed to the presence of amide groups (-CONH-) in their molecular structure. These polar groups have a strong affinity for water molecules, forming hydrogen bonds and facilitating moisture absorption. The extent of moisture absorption can vary depending on factors such as the specific Bio-PA grade, environmental conditions, and part geometry.

The dimensional changes induced by moisture absorption in Bio-PA parts can manifest in various ways. Swelling is a common phenomenon, where the absorption of water molecules causes the material to expand. This expansion can lead to changes in part dimensions, potentially affecting fit, function, and assembly tolerances. Conversely, when moisture is desorbed from the material, shrinkage can occur, leading to further dimensional instability.

Understanding and predicting these moisture-induced dimensional changes is crucial for the successful implementation of Bio-PA parts in various applications. Engineers and designers must consider the potential impact of moisture absorption on part performance and durability throughout the product lifecycle. This includes accounting for dimensional changes during storage, transportation, and in-service conditions.

The ability to accurately predict moisture-induced dimensional changes in Bio-PA parts is essential for several reasons. Firstly, it allows for more precise design and engineering of components, ensuring that they maintain their intended dimensions and functionality even under varying moisture conditions. Secondly, it enables the development of appropriate mitigation strategies, such as moisture-resistant coatings or optimized part geometries, to minimize the impact of moisture absorption. Lastly, accurate prediction models can help in establishing realistic tolerances and quality control measures for Bio-PA parts, ensuring consistent performance across different environmental conditions.

One of the key challenges associated with Bio-PAs is their sensitivity to moisture. Like their petroleum-based counterparts, Bio-PAs are hygroscopic materials, meaning they have a tendency to absorb moisture from the environment. This moisture absorption can lead to dimensional changes in Bio-PA parts, affecting their performance, mechanical properties, and overall stability.

The moisture sensitivity of Bio-PAs is primarily attributed to the presence of amide groups (-CONH-) in their molecular structure. These polar groups have a strong affinity for water molecules, forming hydrogen bonds and facilitating moisture absorption. The extent of moisture absorption can vary depending on factors such as the specific Bio-PA grade, environmental conditions, and part geometry.

The dimensional changes induced by moisture absorption in Bio-PA parts can manifest in various ways. Swelling is a common phenomenon, where the absorption of water molecules causes the material to expand. This expansion can lead to changes in part dimensions, potentially affecting fit, function, and assembly tolerances. Conversely, when moisture is desorbed from the material, shrinkage can occur, leading to further dimensional instability.

Understanding and predicting these moisture-induced dimensional changes is crucial for the successful implementation of Bio-PA parts in various applications. Engineers and designers must consider the potential impact of moisture absorption on part performance and durability throughout the product lifecycle. This includes accounting for dimensional changes during storage, transportation, and in-service conditions.

The ability to accurately predict moisture-induced dimensional changes in Bio-PA parts is essential for several reasons. Firstly, it allows for more precise design and engineering of components, ensuring that they maintain their intended dimensions and functionality even under varying moisture conditions. Secondly, it enables the development of appropriate mitigation strategies, such as moisture-resistant coatings or optimized part geometries, to minimize the impact of moisture absorption. Lastly, accurate prediction models can help in establishing realistic tolerances and quality control measures for Bio-PA parts, ensuring consistent performance across different environmental conditions.

Market Demand Analysis

The market demand for predicting moisture-induced dimensional changes in Bio-PA parts has been steadily increasing due to the growing adoption of bio-based polyamides in various industries. Bio-PA, derived from renewable resources, offers environmental benefits and improved performance characteristics compared to traditional petroleum-based polyamides. However, its susceptibility to moisture absorption poses challenges in maintaining dimensional stability, making accurate prediction methods crucial for manufacturers and end-users.

The automotive industry represents a significant market for Bio-PA parts, driven by the need for lightweight, sustainable materials to improve fuel efficiency and reduce carbon emissions. As vehicles incorporate more Bio-PA components in interior and under-the-hood applications, the ability to predict and mitigate moisture-induced dimensional changes becomes critical for ensuring proper fit, function, and longevity of parts.

The aerospace sector also shows increasing demand for Bio-PA parts prediction tools. With stringent safety requirements and the need for high-performance materials, aerospace manufacturers require precise methods to anticipate and control dimensional changes in Bio-PA components exposed to varying humidity levels during flight operations.

Consumer electronics is another rapidly growing market segment for Bio-PA applications. As manufacturers seek eco-friendly alternatives for device casings and internal components, the need for accurate prediction of moisture-induced dimensional changes becomes essential to maintain product quality and reliability.

The packaging industry, particularly in food and beverage applications, presents a substantial market opportunity for Bio-PA parts and related prediction technologies. Bio-PA's barrier properties and sustainability profile make it attractive for packaging solutions, but moisture sensitivity must be carefully managed to ensure package integrity and shelf life.

Medical device manufacturers are increasingly adopting Bio-PA for various applications, from surgical instruments to implantable devices. The ability to predict and control dimensional changes is critical in this sector, where precision and biocompatibility are paramount.

Market analysis indicates that the global Bio-PA market is expected to grow significantly in the coming years, driven by sustainability initiatives and performance advantages. This growth directly correlates with an increased demand for advanced prediction tools and methodologies to address moisture-induced dimensional changes.

The market for prediction technologies is likely to see strong growth in software solutions, simulation tools, and testing equipment designed specifically for Bio-PA materials. Companies offering comprehensive solutions that integrate material characterization, environmental modeling, and predictive algorithms are poised to capture significant market share.

The automotive industry represents a significant market for Bio-PA parts, driven by the need for lightweight, sustainable materials to improve fuel efficiency and reduce carbon emissions. As vehicles incorporate more Bio-PA components in interior and under-the-hood applications, the ability to predict and mitigate moisture-induced dimensional changes becomes critical for ensuring proper fit, function, and longevity of parts.

The aerospace sector also shows increasing demand for Bio-PA parts prediction tools. With stringent safety requirements and the need for high-performance materials, aerospace manufacturers require precise methods to anticipate and control dimensional changes in Bio-PA components exposed to varying humidity levels during flight operations.

Consumer electronics is another rapidly growing market segment for Bio-PA applications. As manufacturers seek eco-friendly alternatives for device casings and internal components, the need for accurate prediction of moisture-induced dimensional changes becomes essential to maintain product quality and reliability.

The packaging industry, particularly in food and beverage applications, presents a substantial market opportunity for Bio-PA parts and related prediction technologies. Bio-PA's barrier properties and sustainability profile make it attractive for packaging solutions, but moisture sensitivity must be carefully managed to ensure package integrity and shelf life.

Medical device manufacturers are increasingly adopting Bio-PA for various applications, from surgical instruments to implantable devices. The ability to predict and control dimensional changes is critical in this sector, where precision and biocompatibility are paramount.

Market analysis indicates that the global Bio-PA market is expected to grow significantly in the coming years, driven by sustainability initiatives and performance advantages. This growth directly correlates with an increased demand for advanced prediction tools and methodologies to address moisture-induced dimensional changes.

The market for prediction technologies is likely to see strong growth in software solutions, simulation tools, and testing equipment designed specifically for Bio-PA materials. Companies offering comprehensive solutions that integrate material characterization, environmental modeling, and predictive algorithms are poised to capture significant market share.

Current Challenges in Bio-PA Dimensional Stability

Bio-based polyamides (Bio-PAs) have gained significant attention in recent years due to their potential as sustainable alternatives to traditional petroleum-based polymers. However, one of the major challenges in the widespread adoption of Bio-PA parts is their susceptibility to moisture-induced dimensional changes. This issue poses significant obstacles in maintaining the dimensional stability of Bio-PA components, particularly in applications where precise tolerances are critical.

The hygroscopic nature of Bio-PAs makes them prone to absorbing moisture from the environment, leading to swelling and dimensional changes. This behavior is particularly problematic in automotive, aerospace, and consumer electronics industries, where dimensional accuracy is paramount for proper assembly and functionality. The extent of moisture absorption and subsequent dimensional changes can vary depending on factors such as the specific Bio-PA grade, part geometry, and environmental conditions.

Current methods for predicting moisture-induced dimensional changes in Bio-PA parts are often inadequate or unreliable. Traditional approaches, such as using linear expansion coefficients, fail to account for the complex, non-linear behavior of Bio-PAs in response to moisture absorption. This limitation leads to inaccurate predictions and potential design failures in real-world applications.

Another significant challenge is the lack of comprehensive data on the long-term behavior of Bio-PA parts under various environmental conditions. While short-term moisture absorption characteristics are relatively well-understood, the cumulative effects of repeated moisture absorption and desorption cycles on dimensional stability remain poorly characterized. This knowledge gap hinders the development of accurate predictive models and design guidelines for Bio-PA components.

The variability in Bio-PA formulations further complicates the prediction of moisture-induced dimensional changes. Different Bio-PA grades can exhibit varying degrees of moisture sensitivity, and the addition of fillers or reinforcements can significantly alter the material's behavior. This diversity in material properties necessitates the development of more sophisticated and adaptable prediction models that can account for these variations.

Moreover, the interaction between moisture absorption and other environmental factors, such as temperature fluctuations and mechanical stress, presents additional complexities in predicting dimensional changes. These synergistic effects can lead to unexpected behavior that is not captured by current prediction methods, potentially resulting in premature failure or underperformance of Bio-PA parts in service.

Addressing these challenges requires a multifaceted approach, combining advanced material characterization techniques, sophisticated modeling algorithms, and extensive empirical testing. The development of more accurate prediction methods for moisture-induced dimensional changes in Bio-PA parts is crucial for expanding their application in high-performance and precision-critical industries.

The hygroscopic nature of Bio-PAs makes them prone to absorbing moisture from the environment, leading to swelling and dimensional changes. This behavior is particularly problematic in automotive, aerospace, and consumer electronics industries, where dimensional accuracy is paramount for proper assembly and functionality. The extent of moisture absorption and subsequent dimensional changes can vary depending on factors such as the specific Bio-PA grade, part geometry, and environmental conditions.

Current methods for predicting moisture-induced dimensional changes in Bio-PA parts are often inadequate or unreliable. Traditional approaches, such as using linear expansion coefficients, fail to account for the complex, non-linear behavior of Bio-PAs in response to moisture absorption. This limitation leads to inaccurate predictions and potential design failures in real-world applications.

Another significant challenge is the lack of comprehensive data on the long-term behavior of Bio-PA parts under various environmental conditions. While short-term moisture absorption characteristics are relatively well-understood, the cumulative effects of repeated moisture absorption and desorption cycles on dimensional stability remain poorly characterized. This knowledge gap hinders the development of accurate predictive models and design guidelines for Bio-PA components.

The variability in Bio-PA formulations further complicates the prediction of moisture-induced dimensional changes. Different Bio-PA grades can exhibit varying degrees of moisture sensitivity, and the addition of fillers or reinforcements can significantly alter the material's behavior. This diversity in material properties necessitates the development of more sophisticated and adaptable prediction models that can account for these variations.

Moreover, the interaction between moisture absorption and other environmental factors, such as temperature fluctuations and mechanical stress, presents additional complexities in predicting dimensional changes. These synergistic effects can lead to unexpected behavior that is not captured by current prediction methods, potentially resulting in premature failure or underperformance of Bio-PA parts in service.

Addressing these challenges requires a multifaceted approach, combining advanced material characterization techniques, sophisticated modeling algorithms, and extensive empirical testing. The development of more accurate prediction methods for moisture-induced dimensional changes in Bio-PA parts is crucial for expanding their application in high-performance and precision-critical industries.

Existing Prediction Methods

01 Moisture absorption and dimensional stability of Bio-PA parts

Bio-based polyamides (Bio-PA) can absorb moisture from the environment, which may lead to dimensional changes in parts. Techniques to improve dimensional stability include optimizing the material composition, using additives, and applying surface treatments to reduce moisture absorption.- Moisture absorption and dimensional stability of Bio-PA parts: Bio-based polyamides (Bio-PA) can absorb moisture from the environment, leading to dimensional changes. This characteristic affects the stability and performance of Bio-PA parts. Techniques to improve dimensional stability include optimizing the molecular structure, adding fillers, or applying surface treatments to reduce moisture absorption.

- Thermal expansion and contraction of Bio-PA components: Bio-PA parts are subject to dimensional changes due to thermal expansion and contraction. This can impact the fit and function of components in various applications. Methods to mitigate these effects include careful material selection, design optimization, and the use of additives to modify the thermal expansion coefficient.

- Processing-induced dimensional changes in Bio-PA parts: Manufacturing processes such as injection molding, extrusion, or 3D printing can induce dimensional changes in Bio-PA parts. Factors like mold shrinkage, cooling rates, and processing parameters significantly influence the final dimensions. Optimizing process conditions and using simulation tools can help predict and control these changes.

- Reinforcement strategies for dimensional stability in Bio-PA composites: Incorporating reinforcing materials such as fibers, nanoparticles, or other polymer blends can enhance the dimensional stability of Bio-PA parts. These reinforcements can reduce moisture absorption, improve thermal stability, and minimize processing-induced dimensional changes, resulting in more consistent and reliable components.

- Measurement and quality control of Bio-PA part dimensions: Accurate measurement and quality control of Bio-PA part dimensions are crucial for ensuring consistent performance. Advanced measurement techniques, such as 3D scanning, laser measurement, and computer vision systems, can be employed to detect and quantify dimensional changes. Implementing robust quality control processes helps maintain dimensional accuracy throughout production.

02 Thermal expansion and contraction of Bio-PA components

Bio-PA parts can experience dimensional changes due to thermal expansion and contraction. Methods to mitigate these effects include careful material selection, design optimization, and the use of fillers or reinforcing agents to reduce the coefficient of thermal expansion.Expand Specific Solutions03 Processing-induced dimensional changes in Bio-PA parts

Manufacturing processes such as injection molding or 3D printing can introduce dimensional changes in Bio-PA parts. Strategies to minimize these changes include optimizing process parameters, using mold flow analysis, and implementing post-processing techniques like annealing.Expand Specific Solutions04 Long-term dimensional stability of Bio-PA components

Bio-PA parts may experience dimensional changes over time due to factors such as creep, stress relaxation, and environmental exposure. Techniques to improve long-term dimensional stability include material modification, design optimization, and the use of protective coatings or treatments.Expand Specific Solutions05 Measurement and analysis of Bio-PA part dimensional changes

Accurate measurement and analysis of dimensional changes in Bio-PA parts are crucial for quality control and performance optimization. Advanced techniques such as 3D scanning, computer vision, and machine learning algorithms can be employed to detect and quantify dimensional variations.Expand Specific Solutions

Key Players in Bio-PA Industry

The market for predicting moisture-induced dimensional changes in Bio-PA parts is in its early growth stage, with increasing demand driven by the automotive and aerospace industries' shift towards sustainable materials. The global bio-plastics market, including Bio-PA, is projected to reach $19.93 billion by 2026, growing at a CAGR of 16.2%. Technologically, the field is rapidly evolving, with companies like Kaneka Corp., Toray Industries, and LG Chem leading research and development efforts. These firms are investing in advanced simulation tools and material characterization techniques to improve prediction accuracy. However, the technology is not yet fully mature, with ongoing challenges in modeling complex environmental interactions and long-term performance.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed advanced bio-based polyamides (Bio-PAs) with improved moisture resistance. Their approach involves incorporating hydrophobic monomers and optimizing the polymer structure to reduce water absorption. They have implemented a multi-scale modeling technique that combines molecular dynamics simulations with finite element analysis to predict moisture-induced dimensional changes in Bio-PA parts [1]. This method allows for accurate prediction of swelling behavior and mechanical property changes under various humidity conditions. Toray has also developed specialized surface treatments and coatings to further enhance moisture resistance of Bio-PA components [3].

Strengths: Comprehensive approach combining material science and computational modeling. Weaknesses: May require significant computational resources for complex part geometries.

GM Global Technology Operations LLC

Technical Solution: GM has focused on developing practical methods for predicting and controlling moisture-induced dimensional changes in Bio-PA parts used in automotive applications. Their approach involves a combination of material selection, part design optimization, and in-situ monitoring techniques. They have implemented a hybrid modeling approach that combines empirical moisture absorption data with simplified FEA models to quickly assess the dimensional stability of complex automotive components [9]. GM has also developed specialized mold designs and injection molding parameters to create Bio-PA parts with improved moisture resistance and dimensional stability [10].

Strengths: Practical approach tailored for automotive industry needs. Weaknesses: May not be as accurate as more complex modeling techniques for highly critical components.

Innovative Moisture Prediction Techniques

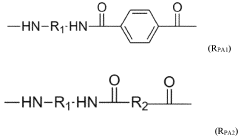

Bio based polyamides and corresponding polymer compositions

PatentWO2024061921A1

Innovation

- A semi-aromatic copolyamide is developed with a specific composition of diamines and dicarboxylic acids, including biobased components, which provides a balance of thermal properties, processability, and moisture resistance through polycondensation, resulting in a polyamide with a melting point between 238°C and 300°C, a glass transition temperature of at least 115°C, and a bio-content of at least 30%, along with limited water uptake.

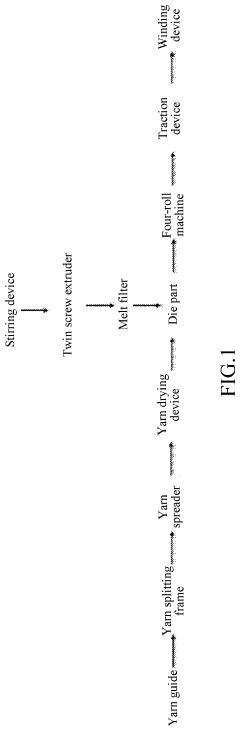

Long-carbon-chain polyamide resin composition and continuous fiber reinforced long-carbon-chain polyamide composite material

PatentPendingUS20240052115A1

Innovation

- A long-carbon-chain polyamide resin composition with low viscosity and good wettability is developed, comprising bio-based polyamide 5X resin, antioxidants, lubricants, compatibilizers, and coupling agents, which is used to create a continuous fiber reinforced composite material with high fiber content and improved mechanical properties.

Environmental Impact Assessment

The environmental impact assessment of predicting moisture-induced dimensional changes in Bio-PA parts is a crucial aspect of sustainable manufacturing practices. Bio-PA, or bio-based polyamide, is derived from renewable resources, making it an attractive alternative to traditional petroleum-based polymers. However, its susceptibility to moisture absorption and subsequent dimensional changes can have significant environmental implications.

Moisture-induced dimensional changes in Bio-PA parts can lead to increased material waste and energy consumption during manufacturing processes. When parts expand or contract due to moisture absorption, they may no longer meet the required specifications, resulting in rejected components. This not only increases the amount of waste material but also necessitates additional production cycles, consuming more energy and resources.

The prediction of these dimensional changes can help optimize manufacturing processes, reducing waste and energy consumption. By accurately forecasting how Bio-PA parts will behave under different moisture conditions, manufacturers can adjust their production parameters, such as molding temperatures and cooling times, to minimize dimensional variations. This proactive approach can significantly reduce the environmental footprint of Bio-PA part production.

Furthermore, the ability to predict moisture-induced dimensional changes can extend the lifespan of Bio-PA parts in various applications. By understanding how these components will behave in different environmental conditions, designers can create more durable and stable products. This increased longevity reduces the need for frequent replacements, thereby decreasing the overall environmental impact associated with product lifecycle and disposal.

The use of predictive models for moisture-induced dimensional changes can also contribute to the development of more efficient recycling processes for Bio-PA parts. By understanding how these materials behave under different moisture conditions, recycling facilities can optimize their processes to recover and reuse Bio-PA more effectively, reducing the amount of material that ends up in landfills or incineration plants.

Additionally, accurate prediction of dimensional changes can lead to improved packaging and transportation strategies for Bio-PA parts. By anticipating how these components may change during storage and shipping, companies can design more appropriate packaging solutions that protect the parts while minimizing excess material use. This can result in reduced packaging waste and more efficient transportation, lowering the overall carbon footprint of the supply chain.

In conclusion, the ability to predict moisture-induced dimensional changes in Bio-PA parts has far-reaching environmental benefits. It enables more efficient manufacturing processes, extends product lifespan, improves recycling capabilities, and optimizes packaging and transportation. These advancements collectively contribute to a more sustainable and environmentally friendly approach to using bio-based materials in various industries.

Moisture-induced dimensional changes in Bio-PA parts can lead to increased material waste and energy consumption during manufacturing processes. When parts expand or contract due to moisture absorption, they may no longer meet the required specifications, resulting in rejected components. This not only increases the amount of waste material but also necessitates additional production cycles, consuming more energy and resources.

The prediction of these dimensional changes can help optimize manufacturing processes, reducing waste and energy consumption. By accurately forecasting how Bio-PA parts will behave under different moisture conditions, manufacturers can adjust their production parameters, such as molding temperatures and cooling times, to minimize dimensional variations. This proactive approach can significantly reduce the environmental footprint of Bio-PA part production.

Furthermore, the ability to predict moisture-induced dimensional changes can extend the lifespan of Bio-PA parts in various applications. By understanding how these components will behave in different environmental conditions, designers can create more durable and stable products. This increased longevity reduces the need for frequent replacements, thereby decreasing the overall environmental impact associated with product lifecycle and disposal.

The use of predictive models for moisture-induced dimensional changes can also contribute to the development of more efficient recycling processes for Bio-PA parts. By understanding how these materials behave under different moisture conditions, recycling facilities can optimize their processes to recover and reuse Bio-PA more effectively, reducing the amount of material that ends up in landfills or incineration plants.

Additionally, accurate prediction of dimensional changes can lead to improved packaging and transportation strategies for Bio-PA parts. By anticipating how these components may change during storage and shipping, companies can design more appropriate packaging solutions that protect the parts while minimizing excess material use. This can result in reduced packaging waste and more efficient transportation, lowering the overall carbon footprint of the supply chain.

In conclusion, the ability to predict moisture-induced dimensional changes in Bio-PA parts has far-reaching environmental benefits. It enables more efficient manufacturing processes, extends product lifespan, improves recycling capabilities, and optimizes packaging and transportation. These advancements collectively contribute to a more sustainable and environmentally friendly approach to using bio-based materials in various industries.

Regulatory Compliance for Bio-PA Products

Regulatory compliance is a critical aspect of developing and manufacturing Bio-PA (Bio-based Polyamide) products, especially when considering moisture-induced dimensional changes. As these materials are increasingly used in various industries, including automotive, electronics, and consumer goods, adherence to relevant regulations and standards is essential to ensure product safety, quality, and market acceptance.

In the context of predicting moisture-induced dimensional changes in Bio-PA parts, regulatory compliance encompasses several key areas. First and foremost, manufacturers must comply with material safety regulations, such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the European Union and TSCA (Toxic Substances Control Act) in the United States. These regulations require thorough documentation of the material's composition, properties, and potential environmental impacts.

Additionally, industry-specific standards play a crucial role in regulatory compliance for Bio-PA products. For instance, in the automotive sector, manufacturers must adhere to standards such as IATF 16949 for quality management systems and VDA 6.3 for process audits. These standards often include requirements for material testing and performance validation, which directly relate to predicting and managing moisture-induced dimensional changes.

Environmental regulations also impact the development and use of Bio-PA parts. As bio-based materials, these products may be subject to specific sustainability and biodegradability standards. Manufacturers must ensure that their products meet these requirements while maintaining dimensional stability under varying moisture conditions.

To achieve regulatory compliance, manufacturers must implement robust quality control and testing procedures. This includes establishing standardized methods for measuring and predicting moisture-induced dimensional changes in Bio-PA parts. These methods should be validated and documented in accordance with relevant industry standards and regulatory guidelines.

Furthermore, compliance extends to product labeling and documentation. Manufacturers must provide accurate information about the material properties, including moisture sensitivity and dimensional stability characteristics. This information is crucial for end-users to make informed decisions about product suitability and to ensure proper handling and storage conditions.

Lastly, regulatory compliance for Bio-PA products involves ongoing monitoring and reporting. Manufacturers must stay informed about changes in regulations and standards, and be prepared to adapt their processes and products accordingly. This may include periodic re-testing of materials, updating documentation, and participating in industry-wide initiatives to improve standards and best practices for managing moisture-induced dimensional changes in bio-based materials.

In the context of predicting moisture-induced dimensional changes in Bio-PA parts, regulatory compliance encompasses several key areas. First and foremost, manufacturers must comply with material safety regulations, such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) in the European Union and TSCA (Toxic Substances Control Act) in the United States. These regulations require thorough documentation of the material's composition, properties, and potential environmental impacts.

Additionally, industry-specific standards play a crucial role in regulatory compliance for Bio-PA products. For instance, in the automotive sector, manufacturers must adhere to standards such as IATF 16949 for quality management systems and VDA 6.3 for process audits. These standards often include requirements for material testing and performance validation, which directly relate to predicting and managing moisture-induced dimensional changes.

Environmental regulations also impact the development and use of Bio-PA parts. As bio-based materials, these products may be subject to specific sustainability and biodegradability standards. Manufacturers must ensure that their products meet these requirements while maintaining dimensional stability under varying moisture conditions.

To achieve regulatory compliance, manufacturers must implement robust quality control and testing procedures. This includes establishing standardized methods for measuring and predicting moisture-induced dimensional changes in Bio-PA parts. These methods should be validated and documented in accordance with relevant industry standards and regulatory guidelines.

Furthermore, compliance extends to product labeling and documentation. Manufacturers must provide accurate information about the material properties, including moisture sensitivity and dimensional stability characteristics. This information is crucial for end-users to make informed decisions about product suitability and to ensure proper handling and storage conditions.

Lastly, regulatory compliance for Bio-PA products involves ongoing monitoring and reporting. Manufacturers must stay informed about changes in regulations and standards, and be prepared to adapt their processes and products accordingly. This may include periodic re-testing of materials, updating documentation, and participating in industry-wide initiatives to improve standards and best practices for managing moisture-induced dimensional changes in bio-based materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!