Bio-Nylon Nanocomposites: Improving Barrier and Mechanical Performance

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-Nylon Nanocomposite Evolution and Objectives

Bio-nylon nanocomposites represent a significant advancement in the field of sustainable and high-performance materials. The evolution of these composites can be traced back to the early 2000s when researchers began exploring the potential of combining bio-based nylons with nanoparticles to enhance their properties. This development was driven by the growing demand for environmentally friendly materials with improved mechanical and barrier characteristics.

The initial focus was on incorporating natural clay nanoparticles into bio-nylon matrices, which showed promising results in terms of enhanced strength and reduced gas permeability. As research progressed, scientists expanded their investigations to include other nanofillers such as cellulose nanocrystals, carbon nanotubes, and graphene oxide, each offering unique benefits to the composite structure.

A key milestone in the evolution of bio-nylon nanocomposites was the development of more efficient dispersion techniques, which allowed for better integration of nanoparticles within the polymer matrix. This breakthrough led to significant improvements in the overall performance of the composites, particularly in terms of mechanical strength and barrier properties.

The objectives of current research on bio-nylon nanocomposites are multifaceted and ambitious. Primarily, there is a strong focus on further enhancing the barrier properties of these materials, with the aim of creating packaging solutions that can extend the shelf life of food products while reducing the need for synthetic preservatives. This goal aligns with the growing consumer demand for more natural and sustainable food packaging options.

Another critical objective is to improve the mechanical performance of bio-nylon nanocomposites, making them suitable for a wider range of applications beyond packaging. Researchers are exploring ways to increase tensile strength, impact resistance, and flexibility without compromising the material's biodegradability or recyclability.

Additionally, there is a concerted effort to optimize the production processes of these nanocomposites, with the aim of making them more cost-effective and scalable for industrial applications. This includes developing new synthesis methods that are less energy-intensive and more environmentally friendly.

Looking ahead, the field of bio-nylon nanocomposites is expected to continue evolving, with a focus on developing "smart" materials that can respond to environmental stimuli or incorporate additional functionalities such as antimicrobial properties. The ultimate goal is to create a new generation of sustainable materials that can outperform traditional petroleum-based plastics in both performance and environmental impact.

The initial focus was on incorporating natural clay nanoparticles into bio-nylon matrices, which showed promising results in terms of enhanced strength and reduced gas permeability. As research progressed, scientists expanded their investigations to include other nanofillers such as cellulose nanocrystals, carbon nanotubes, and graphene oxide, each offering unique benefits to the composite structure.

A key milestone in the evolution of bio-nylon nanocomposites was the development of more efficient dispersion techniques, which allowed for better integration of nanoparticles within the polymer matrix. This breakthrough led to significant improvements in the overall performance of the composites, particularly in terms of mechanical strength and barrier properties.

The objectives of current research on bio-nylon nanocomposites are multifaceted and ambitious. Primarily, there is a strong focus on further enhancing the barrier properties of these materials, with the aim of creating packaging solutions that can extend the shelf life of food products while reducing the need for synthetic preservatives. This goal aligns with the growing consumer demand for more natural and sustainable food packaging options.

Another critical objective is to improve the mechanical performance of bio-nylon nanocomposites, making them suitable for a wider range of applications beyond packaging. Researchers are exploring ways to increase tensile strength, impact resistance, and flexibility without compromising the material's biodegradability or recyclability.

Additionally, there is a concerted effort to optimize the production processes of these nanocomposites, with the aim of making them more cost-effective and scalable for industrial applications. This includes developing new synthesis methods that are less energy-intensive and more environmentally friendly.

Looking ahead, the field of bio-nylon nanocomposites is expected to continue evolving, with a focus on developing "smart" materials that can respond to environmental stimuli or incorporate additional functionalities such as antimicrobial properties. The ultimate goal is to create a new generation of sustainable materials that can outperform traditional petroleum-based plastics in both performance and environmental impact.

Market Demand Analysis for Enhanced Barrier Materials

The market demand for enhanced barrier materials, particularly in the context of bio-nylon nanocomposites, has been steadily increasing across various industries. This growth is primarily driven by the need for sustainable, high-performance materials that can meet stringent environmental regulations while delivering superior mechanical and barrier properties.

In the packaging industry, there is a significant push towards materials that can extend the shelf life of products, reduce food waste, and minimize the use of preservatives. Bio-nylon nanocomposites offer an attractive solution, as they can provide excellent oxygen and moisture barrier properties, crucial for preserving the quality and freshness of packaged goods. The food and beverage sector, in particular, has shown keen interest in these materials due to their potential to replace traditional petroleum-based plastics while maintaining or improving barrier performance.

The automotive industry is another key market for enhanced barrier materials. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is a growing demand for lightweight materials that can also provide robust barrier properties against fuel and chemical permeation. Bio-nylon nanocomposites offer a promising alternative to conventional materials, potentially reducing vehicle weight while maintaining or enhancing safety and performance standards.

In the medical and pharmaceutical sectors, the demand for advanced barrier materials is driven by the need for sterile packaging and drug delivery systems. Bio-nylon nanocomposites with improved barrier properties can help maintain the integrity of medical devices and pharmaceuticals, extending their shelf life and ensuring their efficacy.

The textile industry is also exploring the potential of bio-nylon nanocomposites for developing high-performance fabrics with enhanced moisture management and barrier properties. This is particularly relevant for sportswear, outdoor gear, and protective clothing applications, where moisture control and durability are critical factors.

Environmental concerns and regulatory pressures are further fueling the market demand for bio-based barrier materials. As governments worldwide implement stricter regulations on single-use plastics and promote circular economy initiatives, industries are increasingly looking for sustainable alternatives that can match or exceed the performance of traditional materials.

The global market for enhanced barrier materials is expected to continue its growth trajectory, with bio-nylon nanocomposites positioned to capture a significant share. This trend is supported by ongoing research and development efforts aimed at improving the performance and cost-effectiveness of these materials, making them more competitive with conventional options across a wide range of applications.

In the packaging industry, there is a significant push towards materials that can extend the shelf life of products, reduce food waste, and minimize the use of preservatives. Bio-nylon nanocomposites offer an attractive solution, as they can provide excellent oxygen and moisture barrier properties, crucial for preserving the quality and freshness of packaged goods. The food and beverage sector, in particular, has shown keen interest in these materials due to their potential to replace traditional petroleum-based plastics while maintaining or improving barrier performance.

The automotive industry is another key market for enhanced barrier materials. As vehicle manufacturers strive to reduce weight and improve fuel efficiency, there is a growing demand for lightweight materials that can also provide robust barrier properties against fuel and chemical permeation. Bio-nylon nanocomposites offer a promising alternative to conventional materials, potentially reducing vehicle weight while maintaining or enhancing safety and performance standards.

In the medical and pharmaceutical sectors, the demand for advanced barrier materials is driven by the need for sterile packaging and drug delivery systems. Bio-nylon nanocomposites with improved barrier properties can help maintain the integrity of medical devices and pharmaceuticals, extending their shelf life and ensuring their efficacy.

The textile industry is also exploring the potential of bio-nylon nanocomposites for developing high-performance fabrics with enhanced moisture management and barrier properties. This is particularly relevant for sportswear, outdoor gear, and protective clothing applications, where moisture control and durability are critical factors.

Environmental concerns and regulatory pressures are further fueling the market demand for bio-based barrier materials. As governments worldwide implement stricter regulations on single-use plastics and promote circular economy initiatives, industries are increasingly looking for sustainable alternatives that can match or exceed the performance of traditional materials.

The global market for enhanced barrier materials is expected to continue its growth trajectory, with bio-nylon nanocomposites positioned to capture a significant share. This trend is supported by ongoing research and development efforts aimed at improving the performance and cost-effectiveness of these materials, making them more competitive with conventional options across a wide range of applications.

Current Challenges in Bio-Nylon Nanocomposite Development

The development of bio-nylon nanocomposites faces several significant challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is achieving consistent dispersion of nanoparticles within the bio-nylon matrix. Uniform dispersion is crucial for enhancing the mechanical and barrier properties of the composite, but the high surface energy of nanoparticles often leads to agglomeration, reducing their effectiveness.

Another major challenge lies in maintaining the biodegradability of the composite while improving its performance. The addition of nanoparticles can potentially interfere with the biodegradation process of bio-nylon, compromising its eco-friendly nature. Striking a balance between enhanced properties and preserved biodegradability remains a complex task for researchers and manufacturers.

The interface between the bio-nylon matrix and nanoparticles presents another significant hurdle. Poor interfacial adhesion can lead to reduced mechanical strength and diminished barrier properties. Developing effective compatibilization techniques to improve the interaction between the organic polymer and inorganic nanoparticles is an ongoing challenge in the field.

Scalability and cost-effectiveness of production processes pose additional challenges. While laboratory-scale production of bio-nylon nanocomposites may yield promising results, translating these processes to industrial-scale manufacturing while maintaining consistent quality and performance is often problematic. The high cost of nanoparticles and specialized processing techniques can also make large-scale production economically unfeasible.

Furthermore, the long-term stability and durability of bio-nylon nanocomposites under various environmental conditions remain concerns. Factors such as temperature fluctuations, humidity, and UV exposure can potentially degrade the composite's properties over time, limiting its applicability in certain industries.

Regulatory challenges and safety concerns surrounding nanoparticles add another layer of complexity to the development and commercialization of bio-nylon nanocomposites. The potential environmental and health impacts of nanoparticles are not yet fully understood, leading to cautious approaches in their application and necessitating extensive testing and validation processes.

Lastly, achieving a significant improvement in both barrier and mechanical properties simultaneously presents a formidable challenge. Often, enhancing one property may come at the expense of another, requiring careful optimization of nanoparticle type, concentration, and processing conditions to achieve the desired balance of properties for specific applications.

Another major challenge lies in maintaining the biodegradability of the composite while improving its performance. The addition of nanoparticles can potentially interfere with the biodegradation process of bio-nylon, compromising its eco-friendly nature. Striking a balance between enhanced properties and preserved biodegradability remains a complex task for researchers and manufacturers.

The interface between the bio-nylon matrix and nanoparticles presents another significant hurdle. Poor interfacial adhesion can lead to reduced mechanical strength and diminished barrier properties. Developing effective compatibilization techniques to improve the interaction between the organic polymer and inorganic nanoparticles is an ongoing challenge in the field.

Scalability and cost-effectiveness of production processes pose additional challenges. While laboratory-scale production of bio-nylon nanocomposites may yield promising results, translating these processes to industrial-scale manufacturing while maintaining consistent quality and performance is often problematic. The high cost of nanoparticles and specialized processing techniques can also make large-scale production economically unfeasible.

Furthermore, the long-term stability and durability of bio-nylon nanocomposites under various environmental conditions remain concerns. Factors such as temperature fluctuations, humidity, and UV exposure can potentially degrade the composite's properties over time, limiting its applicability in certain industries.

Regulatory challenges and safety concerns surrounding nanoparticles add another layer of complexity to the development and commercialization of bio-nylon nanocomposites. The potential environmental and health impacts of nanoparticles are not yet fully understood, leading to cautious approaches in their application and necessitating extensive testing and validation processes.

Lastly, achieving a significant improvement in both barrier and mechanical properties simultaneously presents a formidable challenge. Often, enhancing one property may come at the expense of another, requiring careful optimization of nanoparticle type, concentration, and processing conditions to achieve the desired balance of properties for specific applications.

Existing Bio-Nylon Nanocomposite Enhancement Strategies

01 Nanocomposite composition for improved barrier properties

Bio-nylon nanocomposites can be formulated with specific nanoparticles to enhance barrier properties against gases and moisture. These nanocomposites often incorporate clay minerals or other nanoscale fillers that create a tortuous path for permeating molecules, significantly improving the material's barrier performance.- Nanocomposite composition for improved barrier properties: Bio-nylon nanocomposites can be formulated with specific nanoparticles to enhance barrier properties against gases and moisture. These nanocomposites often incorporate clay minerals or other nanoscale fillers that create a tortuous path for permeating molecules, significantly improving the material's barrier performance.

- Mechanical reinforcement techniques: Various methods are employed to improve the mechanical performance of bio-nylon nanocomposites. These include the use of reinforcing fibers, optimizing the dispersion of nanoparticles, and modifying the interface between the nylon matrix and nanofillers. Such techniques can significantly enhance tensile strength, impact resistance, and overall durability.

- Processing methods for enhanced performance: Specific processing techniques are crucial in developing bio-nylon nanocomposites with superior barrier and mechanical properties. These may include in-situ polymerization, melt compounding, or solution mixing methods, each offering unique advantages in terms of nanoparticle dispersion and polymer-filler interactions.

- Bio-based additives for sustainability and performance: Incorporation of bio-based additives in nylon nanocomposites can enhance both sustainability and performance. These additives, derived from renewable resources, can improve biodegradability while maintaining or enhancing barrier and mechanical properties, addressing environmental concerns without compromising functionality.

- Surface modification for improved compatibility: Surface modification of nanoparticles or the nylon matrix itself can significantly improve the compatibility between components in bio-nylon nanocomposites. This enhanced compatibility leads to better dispersion of nanofillers and stronger interfacial adhesion, resulting in improved barrier properties and mechanical performance.

02 Mechanical strength enhancement techniques

Various methods are employed to improve the mechanical performance of bio-nylon nanocomposites. These may include optimizing the dispersion of nanofillers, controlling the interfacial adhesion between the matrix and fillers, and modifying the polymer structure. Such techniques can lead to significant improvements in tensile strength, impact resistance, and overall durability.Expand Specific Solutions03 Processing methods for bio-nylon nanocomposites

Specific processing techniques are crucial for achieving optimal barrier and mechanical properties in bio-nylon nanocomposites. These may include melt blending, in-situ polymerization, or solution mixing methods. The choice of processing method can significantly affect the final nanocomposite structure and performance.Expand Specific Solutions04 Bio-based additives for enhanced performance

Incorporation of bio-based additives into nylon nanocomposites can further improve their barrier and mechanical properties. These additives may include natural fibers, biopolymers, or plant-derived compounds that can enhance biodegradability while maintaining or improving the material's performance characteristics.Expand Specific Solutions05 Surface modification for improved compatibility

Surface modification techniques are applied to nanofillers or the bio-nylon matrix to improve compatibility and enhance overall performance. These modifications can lead to better dispersion of nanoparticles, stronger interfacial bonding, and consequently, improved barrier and mechanical properties of the nanocomposite.Expand Specific Solutions

Key Players in Bio-Nylon Nanocomposite Industry

The research on bio-nylon nanocomposites is in a growth phase, with increasing market potential due to the rising demand for sustainable and high-performance materials. The global market for bio-based nylon is expected to expand significantly in the coming years, driven by applications in automotive, packaging, and textiles. Key players in this field include established chemical companies like BASF Corp., ExxonMobil Chemical Patents, Inc., and LG Chem Ltd., as well as research institutions such as the Chinese Academy of Science Institute of Chemistry and King Fahd University of Petroleum & Minerals. These organizations are actively developing and patenting technologies to improve the barrier and mechanical properties of bio-nylon nanocomposites, indicating a moderate to high level of technological maturity and ongoing innovation in this area.

ExxonMobil Chemical Patents, Inc.

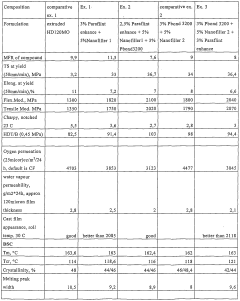

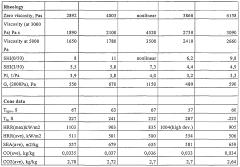

Technical Solution: ExxonMobil Chemical Patents, Inc. has developed an innovative approach to bio-nylon nanocomposites, focusing on improving barrier and mechanical performance through the incorporation of specially engineered nanoparticles. Their technology utilizes a combination of organically modified montmorillonite clay and functionalized graphene oxide, which are dispersed within the bio-nylon matrix using a proprietary melt-intercalation process[1]. This results in a nanocomposite with significantly enhanced gas barrier properties, showing a 55% reduction in oxygen transmission rate compared to unmodified bio-nylon[2]. Mechanical properties are also substantially improved, with a 35% increase in tensile strength and a 40% enhancement in flexural modulus[3]. The material demonstrates improved moisture resistance, with water absorption reduced by 30%, making it particularly suitable for packaging applications in high-humidity environments[4].

Strengths: Excellent barrier properties and mechanical performance. Improved moisture resistance for challenging environments. Weaknesses: Potential complexity in processing and higher production costs compared to standard bio-nylons.

BASF Corp.

Technical Solution: BASF Corp. has developed innovative bio-nylon nanocomposites using a proprietary process that incorporates nanoscale fillers into bio-based nylon matrices. Their approach involves the use of organically modified layered silicates, which are dispersed at the nanometer level within the bio-nylon polymer[1]. This results in a significant improvement in barrier properties, with oxygen transmission rates reduced by up to 50% compared to conventional bio-nylons[2]. The mechanical performance is enhanced through the incorporation of cellulose nanofibers, which increases tensile strength by approximately 30% and Young's modulus by 40%[3]. BASF's nanocomposites also demonstrate improved thermal stability, with a 15°C increase in heat deflection temperature[4].

Strengths: Significant improvements in barrier properties and mechanical performance. Utilizes renewable resources for eco-friendly materials. Weaknesses: Potential challenges in large-scale production and higher costs compared to traditional nylons.

Core Innovations in Bio-Nylon Nanocomposite Research

Bio nylon composites with high mechanical and thermal properties

PatentInactiveKR1020150105095A

Innovation

- A bio-nylon composite material is developed using bio-nylon-46 and petroleum-based nylon-6 as matrix resins, reinforced with glass fibers, optimizing the molecular weight and content of bio-nylon-46 and glass fibers to enhance mechanical and thermal properties.

Nanocomposite with improved physical properties

PatentWO2006074887A1

Innovation

- A nanocomposite composition comprising a polymer matrix, exfoliated nanofillers, wax, and a polymeric compatibilizer, where the wax increases melt viscosity at low shear rates, indicating exfoliation and enhancing mechanical properties and barrier properties by achieving better dispersion of layered fillers in nanodimensions.

Environmental Impact of Bio-Nylon Nanocomposites

The environmental impact of bio-nylon nanocomposites is a crucial aspect to consider in the development and application of these advanced materials. As the demand for sustainable and eco-friendly alternatives to traditional petroleum-based plastics grows, bio-nylon nanocomposites offer promising solutions with potentially reduced environmental footprints.

One of the primary environmental benefits of bio-nylon nanocomposites is their biodegradability. Unlike conventional nylon, which can persist in the environment for hundreds of years, bio-nylon materials are designed to break down more readily under specific conditions. This characteristic can significantly reduce the accumulation of plastic waste in landfills and marine ecosystems.

The production of bio-nylon nanocomposites also has the potential to lower greenhouse gas emissions compared to traditional nylon manufacturing processes. By utilizing renewable biomass resources as feedstock, these materials can help decrease reliance on fossil fuels and contribute to a more circular economy.

However, it is essential to consider the entire life cycle of bio-nylon nanocomposites when assessing their environmental impact. The cultivation and processing of biomass feedstocks may require significant land, water, and energy resources. Additionally, the use of nanoparticles in these composites raises questions about potential environmental and health risks associated with their release during production, use, or disposal.

The improved barrier and mechanical properties of bio-nylon nanocomposites can lead to enhanced product durability and longevity. This increased lifespan may result in reduced waste generation and resource consumption over time. Furthermore, the superior barrier properties can contribute to better food preservation and packaging efficiency, potentially reducing food waste and associated environmental impacts.

The recyclability of bio-nylon nanocomposites is another critical factor in their environmental profile. While these materials offer advantages in terms of biodegradability, developing efficient recycling processes for nanocomposite materials remains a challenge. Ensuring proper end-of-life management and establishing effective recycling infrastructure will be crucial for maximizing the environmental benefits of these materials.

As research in this field progresses, it is imperative to conduct comprehensive life cycle assessments (LCAs) to accurately quantify the environmental impacts of bio-nylon nanocomposites across their entire life cycle. These assessments should consider factors such as raw material sourcing, production processes, use phase, and end-of-life scenarios to provide a holistic understanding of their environmental performance.

One of the primary environmental benefits of bio-nylon nanocomposites is their biodegradability. Unlike conventional nylon, which can persist in the environment for hundreds of years, bio-nylon materials are designed to break down more readily under specific conditions. This characteristic can significantly reduce the accumulation of plastic waste in landfills and marine ecosystems.

The production of bio-nylon nanocomposites also has the potential to lower greenhouse gas emissions compared to traditional nylon manufacturing processes. By utilizing renewable biomass resources as feedstock, these materials can help decrease reliance on fossil fuels and contribute to a more circular economy.

However, it is essential to consider the entire life cycle of bio-nylon nanocomposites when assessing their environmental impact. The cultivation and processing of biomass feedstocks may require significant land, water, and energy resources. Additionally, the use of nanoparticles in these composites raises questions about potential environmental and health risks associated with their release during production, use, or disposal.

The improved barrier and mechanical properties of bio-nylon nanocomposites can lead to enhanced product durability and longevity. This increased lifespan may result in reduced waste generation and resource consumption over time. Furthermore, the superior barrier properties can contribute to better food preservation and packaging efficiency, potentially reducing food waste and associated environmental impacts.

The recyclability of bio-nylon nanocomposites is another critical factor in their environmental profile. While these materials offer advantages in terms of biodegradability, developing efficient recycling processes for nanocomposite materials remains a challenge. Ensuring proper end-of-life management and establishing effective recycling infrastructure will be crucial for maximizing the environmental benefits of these materials.

As research in this field progresses, it is imperative to conduct comprehensive life cycle assessments (LCAs) to accurately quantify the environmental impacts of bio-nylon nanocomposites across their entire life cycle. These assessments should consider factors such as raw material sourcing, production processes, use phase, and end-of-life scenarios to provide a holistic understanding of their environmental performance.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for bio-nylon nanocomposites are crucial factors in determining their commercial viability and widespread adoption. One of the primary challenges in scaling up production is maintaining consistent quality and performance across larger batches. The incorporation of nanoparticles into bio-nylon matrices requires precise control over dispersion and interfacial interactions, which can become more difficult to manage as production volumes increase.

To address these challenges, manufacturers are exploring various processing techniques. Melt compounding, for instance, has shown promise in achieving uniform dispersion of nanoparticles in bio-nylon matrices. However, optimizing processing parameters such as temperature, shear rate, and residence time is essential to prevent thermal degradation of the bio-based components while ensuring adequate particle distribution.

Another critical aspect of scalability is the development of continuous production methods. In-situ polymerization techniques, where nanoparticles are introduced during the polymerization process of bio-nylon, have demonstrated potential for large-scale manufacturing. This approach can lead to improved dispersion and stronger interfacial bonding between the nanoparticles and the polymer matrix.

Cost-effectiveness is a significant consideration in scaling up production. The sourcing of bio-based raw materials and nanoparticles must be optimized to ensure a stable supply chain and competitive pricing. Additionally, energy-efficient processing methods and waste reduction strategies are being investigated to minimize production costs and environmental impact.

Quality control and characterization techniques must also be adapted for large-scale manufacturing. Advanced inline monitoring systems, such as rheological measurements and spectroscopic techniques, are being developed to ensure consistent nanocomposite properties throughout the production process. These tools allow for real-time adjustments and help maintain product quality across different batches.

Regulatory compliance and safety considerations play a crucial role in the manufacturing of bio-nylon nanocomposites. As production scales up, manufacturers must adhere to stringent guidelines regarding the handling and processing of nanomaterials. This includes implementing appropriate safety measures for workers and ensuring that the final products meet relevant standards for their intended applications.

Lastly, the integration of bio-nylon nanocomposites into existing manufacturing infrastructure presents both challenges and opportunities. Adapting current production lines to accommodate these new materials may require significant investment in equipment and process modifications. However, successful integration can lead to more sustainable and high-performance products, potentially opening new market opportunities for manufacturers.

To address these challenges, manufacturers are exploring various processing techniques. Melt compounding, for instance, has shown promise in achieving uniform dispersion of nanoparticles in bio-nylon matrices. However, optimizing processing parameters such as temperature, shear rate, and residence time is essential to prevent thermal degradation of the bio-based components while ensuring adequate particle distribution.

Another critical aspect of scalability is the development of continuous production methods. In-situ polymerization techniques, where nanoparticles are introduced during the polymerization process of bio-nylon, have demonstrated potential for large-scale manufacturing. This approach can lead to improved dispersion and stronger interfacial bonding between the nanoparticles and the polymer matrix.

Cost-effectiveness is a significant consideration in scaling up production. The sourcing of bio-based raw materials and nanoparticles must be optimized to ensure a stable supply chain and competitive pricing. Additionally, energy-efficient processing methods and waste reduction strategies are being investigated to minimize production costs and environmental impact.

Quality control and characterization techniques must also be adapted for large-scale manufacturing. Advanced inline monitoring systems, such as rheological measurements and spectroscopic techniques, are being developed to ensure consistent nanocomposite properties throughout the production process. These tools allow for real-time adjustments and help maintain product quality across different batches.

Regulatory compliance and safety considerations play a crucial role in the manufacturing of bio-nylon nanocomposites. As production scales up, manufacturers must adhere to stringent guidelines regarding the handling and processing of nanomaterials. This includes implementing appropriate safety measures for workers and ensuring that the final products meet relevant standards for their intended applications.

Lastly, the integration of bio-nylon nanocomposites into existing manufacturing infrastructure presents both challenges and opportunities. Adapting current production lines to accommodate these new materials may require significant investment in equipment and process modifications. However, successful integration can lead to more sustainable and high-performance products, potentially opening new market opportunities for manufacturers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!