How to Optimize Extrusion Die Design for Bio-PA Film Production

AUG 20, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-PA Film Extrusion Background and Objectives

Bio-based polyamide (Bio-PA) film extrusion has emerged as a significant area of interest in the polymer industry, driven by the growing demand for sustainable and environmentally friendly packaging solutions. The development of Bio-PA films represents a convergence of biopolymer technology and traditional film extrusion processes, aiming to create high-performance materials with reduced environmental impact.

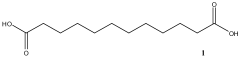

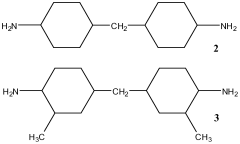

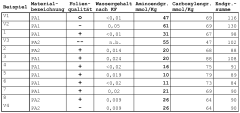

The evolution of Bio-PA film technology can be traced back to the early 2000s when researchers began exploring alternatives to petroleum-based polyamides. Initial efforts focused on developing Bio-PA resins from renewable resources such as castor oil, sebacic acid, and other bio-based monomers. As the technology progressed, the emphasis shifted towards optimizing the extrusion process to achieve film properties comparable to or surpassing those of conventional polyamide films.

The primary objective in Bio-PA film extrusion is to create a uniform, defect-free film with excellent mechanical, barrier, and optical properties. This requires a delicate balance between material formulation, processing parameters, and die design. The extrusion die, in particular, plays a crucial role in determining the final film quality and production efficiency.

Current technological trends in Bio-PA film extrusion include the development of multi-layer structures to enhance specific properties, the incorporation of nanofillers to improve barrier characteristics, and the optimization of processing conditions to reduce energy consumption and material waste. Additionally, there is a growing focus on enhancing the biodegradability and compostability of Bio-PA films to further improve their environmental profile.

The optimization of extrusion die design for Bio-PA film production presents several unique challenges. These include managing the rheological behavior of Bio-PA resins, which can differ significantly from their petroleum-based counterparts, controlling film thickness uniformity across the width of the die, and minimizing die lines and other surface defects. Furthermore, the die design must accommodate the potential for higher processing temperatures and pressures often associated with Bio-PA materials.

Looking ahead, the Bio-PA film extrusion industry aims to achieve several key technological goals. These include developing dies capable of producing ultra-thin films with enhanced strength and barrier properties, improving die design to facilitate easier cleaning and material changeovers, and integrating smart technologies for real-time process monitoring and control. Additionally, there is a push towards more sustainable manufacturing practices, such as reducing energy consumption and minimizing material waste during the extrusion process.

In conclusion, the optimization of extrusion die design for Bio-PA film production represents a critical area of research and development in the sustainable packaging industry. By addressing the unique challenges posed by Bio-PA materials and leveraging advanced manufacturing technologies, the industry seeks to create high-performance, environmentally friendly films that meet the growing demand for sustainable packaging solutions.

The evolution of Bio-PA film technology can be traced back to the early 2000s when researchers began exploring alternatives to petroleum-based polyamides. Initial efforts focused on developing Bio-PA resins from renewable resources such as castor oil, sebacic acid, and other bio-based monomers. As the technology progressed, the emphasis shifted towards optimizing the extrusion process to achieve film properties comparable to or surpassing those of conventional polyamide films.

The primary objective in Bio-PA film extrusion is to create a uniform, defect-free film with excellent mechanical, barrier, and optical properties. This requires a delicate balance between material formulation, processing parameters, and die design. The extrusion die, in particular, plays a crucial role in determining the final film quality and production efficiency.

Current technological trends in Bio-PA film extrusion include the development of multi-layer structures to enhance specific properties, the incorporation of nanofillers to improve barrier characteristics, and the optimization of processing conditions to reduce energy consumption and material waste. Additionally, there is a growing focus on enhancing the biodegradability and compostability of Bio-PA films to further improve their environmental profile.

The optimization of extrusion die design for Bio-PA film production presents several unique challenges. These include managing the rheological behavior of Bio-PA resins, which can differ significantly from their petroleum-based counterparts, controlling film thickness uniformity across the width of the die, and minimizing die lines and other surface defects. Furthermore, the die design must accommodate the potential for higher processing temperatures and pressures often associated with Bio-PA materials.

Looking ahead, the Bio-PA film extrusion industry aims to achieve several key technological goals. These include developing dies capable of producing ultra-thin films with enhanced strength and barrier properties, improving die design to facilitate easier cleaning and material changeovers, and integrating smart technologies for real-time process monitoring and control. Additionally, there is a push towards more sustainable manufacturing practices, such as reducing energy consumption and minimizing material waste during the extrusion process.

In conclusion, the optimization of extrusion die design for Bio-PA film production represents a critical area of research and development in the sustainable packaging industry. By addressing the unique challenges posed by Bio-PA materials and leveraging advanced manufacturing technologies, the industry seeks to create high-performance, environmentally friendly films that meet the growing demand for sustainable packaging solutions.

Market Analysis for Bio-PA Films

The market for Bio-PA (Bio-based Polyamide) films is experiencing significant growth, driven by increasing environmental concerns and the shift towards sustainable packaging solutions. Bio-PA films, derived from renewable resources such as castor oil, offer a promising alternative to traditional petroleum-based plastics. The global Bio-PA market is expected to expand at a compound annual growth rate (CAGR) of over 14% from 2021 to 2026, with the film segment playing a crucial role in this growth.

The packaging industry represents the largest application sector for Bio-PA films, accounting for a substantial share of the market. The food and beverage sector, in particular, is driving demand due to the material's excellent barrier properties, which help extend product shelf life. Additionally, the automotive and textile industries are emerging as significant consumers of Bio-PA films, utilizing them for various applications such as interior components and performance apparel.

Geographically, Europe leads the Bio-PA film market, with countries like Germany, France, and Italy at the forefront of adoption. This is largely due to stringent environmental regulations and a strong consumer preference for eco-friendly products. North America follows closely, with the United States showing rapid growth in Bio-PA film usage across multiple industries. The Asia-Pacific region, particularly China and Japan, is expected to witness the fastest growth in the coming years, driven by increasing industrialization and a growing awareness of sustainable materials.

Consumer trends are heavily influencing the Bio-PA film market. There is a rising demand for transparent, flexible packaging that maintains product visibility while ensuring sustainability. This has led to innovations in Bio-PA film formulations to enhance clarity and printability. Furthermore, the trend towards lightweight packaging in the automotive and aerospace industries is boosting the adoption of Bio-PA films as a replacement for heavier materials.

Despite the positive outlook, the Bio-PA film market faces challenges. The higher cost of production compared to conventional plastics remains a significant barrier to widespread adoption. However, as production scales up and technologies improve, this cost gap is expected to narrow. Additionally, the limited availability of raw materials for Bio-PA production poses a potential constraint on market growth, prompting research into alternative feedstocks and more efficient production methods.

The competitive landscape of the Bio-PA film market is characterized by a mix of established chemical companies and innovative start-ups. Key players are investing heavily in research and development to improve film properties and reduce production costs. Collaborations between raw material suppliers, film manufacturers, and end-users are becoming increasingly common, fostering innovation and market expansion.

The packaging industry represents the largest application sector for Bio-PA films, accounting for a substantial share of the market. The food and beverage sector, in particular, is driving demand due to the material's excellent barrier properties, which help extend product shelf life. Additionally, the automotive and textile industries are emerging as significant consumers of Bio-PA films, utilizing them for various applications such as interior components and performance apparel.

Geographically, Europe leads the Bio-PA film market, with countries like Germany, France, and Italy at the forefront of adoption. This is largely due to stringent environmental regulations and a strong consumer preference for eco-friendly products. North America follows closely, with the United States showing rapid growth in Bio-PA film usage across multiple industries. The Asia-Pacific region, particularly China and Japan, is expected to witness the fastest growth in the coming years, driven by increasing industrialization and a growing awareness of sustainable materials.

Consumer trends are heavily influencing the Bio-PA film market. There is a rising demand for transparent, flexible packaging that maintains product visibility while ensuring sustainability. This has led to innovations in Bio-PA film formulations to enhance clarity and printability. Furthermore, the trend towards lightweight packaging in the automotive and aerospace industries is boosting the adoption of Bio-PA films as a replacement for heavier materials.

Despite the positive outlook, the Bio-PA film market faces challenges. The higher cost of production compared to conventional plastics remains a significant barrier to widespread adoption. However, as production scales up and technologies improve, this cost gap is expected to narrow. Additionally, the limited availability of raw materials for Bio-PA production poses a potential constraint on market growth, prompting research into alternative feedstocks and more efficient production methods.

The competitive landscape of the Bio-PA film market is characterized by a mix of established chemical companies and innovative start-ups. Key players are investing heavily in research and development to improve film properties and reduce production costs. Collaborations between raw material suppliers, film manufacturers, and end-users are becoming increasingly common, fostering innovation and market expansion.

Current Challenges in Bio-PA Extrusion Die Design

The extrusion die design for Bio-PA film production faces several significant challenges that hinder optimal performance and product quality. One of the primary issues is the complex rheological behavior of Bio-PA materials. These biopolymers often exhibit non-Newtonian flow characteristics, making it difficult to predict and control the flow distribution within the die. This can lead to inconsistencies in film thickness and properties across the width of the extruded sheet.

Temperature control presents another major challenge in Bio-PA extrusion die design. Bio-PA materials are typically more sensitive to thermal degradation compared to conventional polyamides. Maintaining a uniform temperature profile across the die is crucial to prevent material degradation and ensure consistent film properties. However, achieving this uniformity is complicated by the die's geometry and the heat generated during the extrusion process.

Die swell, a phenomenon where the extrudate expands upon exiting the die, is particularly problematic for Bio-PA film production. The extent of die swell can vary depending on the specific Bio-PA formulation and processing conditions, making it challenging to design dies that consistently produce films with the desired dimensions and surface quality.

The design of the die land, the final section of the die where the polymer melt is shaped into a film, poses additional challenges. Optimizing the land length and geometry is critical for achieving the desired film properties, but this optimization is complicated by the unique flow characteristics of Bio-PA materials. Balancing the need for sufficient residence time to impart the desired orientation and crystallinity with the risk of thermal degradation requires careful consideration.

Melt fracture and sharkskin effects, surface defects that can occur during high-speed extrusion, are also significant concerns in Bio-PA film production. These defects can severely impact the film's appearance and mechanical properties. Designing dies that minimize these effects while maintaining high production rates is a complex task that requires a deep understanding of the material's behavior under various shear rates and temperatures.

Furthermore, the die design must account for the potential variability in Bio-PA raw materials. Unlike conventional polyamides, Bio-PA formulations can exhibit more batch-to-batch variation due to the natural origin of their feedstocks. This variability can affect the material's flow properties and processing window, necessitating more flexible and adaptable die designs.

Lastly, the challenge of scaling up laboratory or pilot-scale die designs to industrial production levels is particularly acute for Bio-PA films. The behavior of these materials can change significantly with increased throughput and die size, requiring careful consideration of flow channel geometries and manifold designs to maintain uniform flow distribution and product quality at larger scales.

Temperature control presents another major challenge in Bio-PA extrusion die design. Bio-PA materials are typically more sensitive to thermal degradation compared to conventional polyamides. Maintaining a uniform temperature profile across the die is crucial to prevent material degradation and ensure consistent film properties. However, achieving this uniformity is complicated by the die's geometry and the heat generated during the extrusion process.

Die swell, a phenomenon where the extrudate expands upon exiting the die, is particularly problematic for Bio-PA film production. The extent of die swell can vary depending on the specific Bio-PA formulation and processing conditions, making it challenging to design dies that consistently produce films with the desired dimensions and surface quality.

The design of the die land, the final section of the die where the polymer melt is shaped into a film, poses additional challenges. Optimizing the land length and geometry is critical for achieving the desired film properties, but this optimization is complicated by the unique flow characteristics of Bio-PA materials. Balancing the need for sufficient residence time to impart the desired orientation and crystallinity with the risk of thermal degradation requires careful consideration.

Melt fracture and sharkskin effects, surface defects that can occur during high-speed extrusion, are also significant concerns in Bio-PA film production. These defects can severely impact the film's appearance and mechanical properties. Designing dies that minimize these effects while maintaining high production rates is a complex task that requires a deep understanding of the material's behavior under various shear rates and temperatures.

Furthermore, the die design must account for the potential variability in Bio-PA raw materials. Unlike conventional polyamides, Bio-PA formulations can exhibit more batch-to-batch variation due to the natural origin of their feedstocks. This variability can affect the material's flow properties and processing window, necessitating more flexible and adaptable die designs.

Lastly, the challenge of scaling up laboratory or pilot-scale die designs to industrial production levels is particularly acute for Bio-PA films. The behavior of these materials can change significantly with increased throughput and die size, requiring careful consideration of flow channel geometries and manifold designs to maintain uniform flow distribution and product quality at larger scales.

Existing Die Design Solutions for Bio-PA Films

01 Computational modeling and simulation

Utilizing advanced computational modeling and simulation techniques to optimize extrusion die designs. This approach allows for the prediction of material flow behavior, pressure distribution, and other critical parameters, enabling engineers to refine die designs before physical prototyping. These methods can significantly reduce development time and costs while improving the overall performance of the extrusion process.- Computational modeling and simulation: Utilizing advanced computational modeling and simulation techniques to optimize extrusion die designs. This approach allows for the prediction of material flow behavior, pressure distribution, and other critical parameters, enabling engineers to refine die designs before physical prototyping. These methods can significantly reduce development time and costs while improving the overall quality of extruded products.

- Adjustable die geometry: Implementing adjustable or flexible die geometries that can be modified during the extrusion process. This innovation allows for real-time optimization of die performance, accommodating variations in material properties or desired product specifications. Adjustable dies can feature movable sections, interchangeable components, or adaptive control systems to fine-tune the extrusion process.

- Material flow optimization: Focusing on optimizing material flow within the die to achieve uniform velocity distribution and minimize pressure drops. This involves careful design of flow channels, land lengths, and transition zones. Improved material flow can lead to better product quality, reduced energy consumption, and increased production efficiency.

- Thermal management techniques: Incorporating advanced thermal management techniques into die design to control temperature distribution and heat transfer. This can include the use of heating/cooling channels, insulation materials, or temperature sensors integrated into the die structure. Effective thermal management can improve product consistency, prevent material degradation, and optimize the overall extrusion process.

- Surface treatment and coatings: Applying specialized surface treatments or coatings to die components to enhance wear resistance, reduce friction, and improve material flow. These treatments can include various hardening processes, application of low-friction coatings, or surface texturing techniques. Improved surface properties can extend die life, reduce maintenance requirements, and enhance product quality.

02 Adjustable die geometry

Implementing adjustable die geometry features to allow for real-time optimization during the extrusion process. This can include movable die lips, adjustable land lengths, or variable choker bar positions. Such adaptability enables fine-tuning of the die performance to accommodate different materials or production requirements without the need for complete die replacement.Expand Specific Solutions03 Material flow analysis and rheology

Focusing on detailed analysis of material flow behavior and rheological properties to inform die design. This involves studying how different materials behave under various extrusion conditions and using this knowledge to optimize die channel geometries, land lengths, and flow distribution. By understanding material characteristics, designers can create dies that produce more uniform and consistent extruded products.Expand Specific Solutions04 Thermal management and cooling system design

Optimizing the thermal management aspects of extrusion dies, including innovative cooling system designs. This involves strategically placing cooling channels, selecting appropriate materials for heat dissipation, and implementing temperature control mechanisms. Effective thermal management can prevent die deformation, improve product quality, and extend die lifespan.Expand Specific Solutions05 Surface treatment and coating technologies

Applying advanced surface treatment and coating technologies to extrusion die surfaces to enhance performance and longevity. This can include techniques such as nitriding, chrome plating, or the application of specialized wear-resistant coatings. These treatments can reduce friction, prevent material buildup, and increase the overall efficiency and lifespan of the extrusion die.Expand Specific Solutions

Key Players in Bio-PA Film Extrusion Industry

The optimization of extrusion die design for Bio-PA film production is in a developing stage, with the market showing significant growth potential due to increasing demand for sustainable packaging solutions. The technology is advancing rapidly, with several key players driving innovation. Companies like DuPont de Nemours, Evonik Operations, and Kaneka Corp. are at the forefront, leveraging their expertise in polymer science and manufacturing processes. The market is characterized by a mix of established chemical giants and specialized firms, such as Lam'On Ltd., focusing on bio-based materials. As the technology matures, we can expect increased competition and further refinements in die design, leading to improved efficiency and quality in Bio-PA film production.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed an advanced extrusion die design for Bio-PA film production, incorporating a multi-manifold system with adjustable lip gap control. This design utilizes computational fluid dynamics (CFD) modeling to optimize melt flow distribution and reduce residence time[1]. The die features a modular construction allowing for easy maintenance and quick product changeovers. DuPont's system also includes an integrated thermal management solution to maintain precise temperature control across the die width, ensuring uniform film thickness and properties[3]. The company has implemented a novel die lip design that minimizes edge bead formation, resulting in improved film quality and reduced trim waste[5].

Strengths: Excellent melt flow distribution, reduced residence time, and easy maintenance. Weaknesses: Higher initial investment cost and potential complexity in operation for less experienced users.

Evonik Operations GmbH

Technical Solution: Evonik has innovated a specialized extrusion die design for Bio-PA film production, focusing on sustainability and efficiency. Their design incorporates a unique flow channel geometry that enhances melt distribution while minimizing shear stress on the bio-based polymer[2]. The die features an advanced thermal regulation system using microwave-assisted heating, allowing for precise temperature control and rapid adjustments[4]. Evonik's design also includes a self-cleaning mechanism that reduces downtime for maintenance. The company has implemented a smart sensor array within the die to provide real-time feedback on melt pressure, temperature, and viscosity, enabling dynamic adjustments during production[6]. This data-driven approach allows for consistent film quality across various Bio-PA formulations.

Strengths: Excellent thermal control, reduced maintenance downtime, and adaptability to different Bio-PA formulations. Weaknesses: Higher complexity and potential cost increase due to advanced sensor and control systems.

Innovative Die Design Approaches for Bio-PA

Chemical-resistant films of high optical quality

PatentWO2011113644A1

Innovation

- A novel film extrusion process for polyamide films, specifically using polyamides with low end group content and a temperature-controlled film die where the die lip is 10°C to 100°C higher than the nozzle body, preventing solid deposits and maintaining high optical quality and chemical resistance.

Chemical-resistant films of high optical quality

PatentActiveEP2547719A1

Innovation

- A novel film extrusion process using polyamides with low end group content and a temperature-controlled film die, where the die lip is 10°C to 100°C higher than the nozzle body, prevents solid deposits and maintains high optical quality and chemical resistance.

Environmental Impact of Bio-PA Film Production

The environmental impact of Bio-PA film production is a critical consideration in the optimization of extrusion die design. Bio-PA, or bio-based polyamide, offers a more sustainable alternative to traditional petroleum-based polymers. However, its production process still carries environmental implications that must be carefully evaluated and mitigated.

The primary environmental benefit of Bio-PA film production lies in its renewable feedstock. Derived from plant-based sources such as castor oil or corn, Bio-PA reduces dependency on fossil fuels and potentially lowers the carbon footprint of film production. This shift towards bio-based materials aligns with global efforts to combat climate change and reduce greenhouse gas emissions.

Despite these advantages, the production of Bio-PA films still requires significant energy input, particularly during the extrusion process. The optimization of extrusion die design plays a crucial role in minimizing energy consumption and, consequently, reducing the overall environmental impact. Efficient die designs can lead to lower processing temperatures, reduced pressure requirements, and improved material flow, all of which contribute to energy savings and decreased emissions.

Water usage is another environmental concern in Bio-PA film production. The extrusion process often involves cooling systems that consume substantial amounts of water. By optimizing die design to enhance heat transfer efficiency, manufacturers can potentially reduce water requirements and minimize wastewater generation. This not only conserves a valuable resource but also decreases the environmental burden associated with water treatment and disposal.

The durability and recyclability of Bio-PA films also factor into their environmental impact. Optimized extrusion die designs can improve film quality, potentially extending product lifespan and reducing waste. Additionally, enhanced material properties achieved through optimized extrusion may facilitate easier recycling processes, promoting a more circular economy approach to film production and usage.

Consideration must also be given to the potential land-use changes associated with the cultivation of bio-based feedstocks. While Bio-PA offers advantages over petroleum-based alternatives, the agricultural practices involved in producing raw materials can have significant environmental implications, including deforestation, biodiversity loss, and soil degradation. Balancing these factors requires a holistic approach to sustainability that extends beyond the immediate production process.

In conclusion, the environmental impact of Bio-PA film production is multifaceted, encompassing aspects of resource consumption, energy use, emissions, and waste management. Optimizing extrusion die design represents a key opportunity to enhance the sustainability of this process, offering potential improvements in energy efficiency, material utilization, and product quality. As the industry continues to evolve, ongoing research and innovation in die design will play a crucial role in minimizing the environmental footprint of Bio-PA film production while maximizing its potential as a sustainable alternative to conventional plastics.

The primary environmental benefit of Bio-PA film production lies in its renewable feedstock. Derived from plant-based sources such as castor oil or corn, Bio-PA reduces dependency on fossil fuels and potentially lowers the carbon footprint of film production. This shift towards bio-based materials aligns with global efforts to combat climate change and reduce greenhouse gas emissions.

Despite these advantages, the production of Bio-PA films still requires significant energy input, particularly during the extrusion process. The optimization of extrusion die design plays a crucial role in minimizing energy consumption and, consequently, reducing the overall environmental impact. Efficient die designs can lead to lower processing temperatures, reduced pressure requirements, and improved material flow, all of which contribute to energy savings and decreased emissions.

Water usage is another environmental concern in Bio-PA film production. The extrusion process often involves cooling systems that consume substantial amounts of water. By optimizing die design to enhance heat transfer efficiency, manufacturers can potentially reduce water requirements and minimize wastewater generation. This not only conserves a valuable resource but also decreases the environmental burden associated with water treatment and disposal.

The durability and recyclability of Bio-PA films also factor into their environmental impact. Optimized extrusion die designs can improve film quality, potentially extending product lifespan and reducing waste. Additionally, enhanced material properties achieved through optimized extrusion may facilitate easier recycling processes, promoting a more circular economy approach to film production and usage.

Consideration must also be given to the potential land-use changes associated with the cultivation of bio-based feedstocks. While Bio-PA offers advantages over petroleum-based alternatives, the agricultural practices involved in producing raw materials can have significant environmental implications, including deforestation, biodiversity loss, and soil degradation. Balancing these factors requires a holistic approach to sustainability that extends beyond the immediate production process.

In conclusion, the environmental impact of Bio-PA film production is multifaceted, encompassing aspects of resource consumption, energy use, emissions, and waste management. Optimizing extrusion die design represents a key opportunity to enhance the sustainability of this process, offering potential improvements in energy efficiency, material utilization, and product quality. As the industry continues to evolve, ongoing research and innovation in die design will play a crucial role in minimizing the environmental footprint of Bio-PA film production while maximizing its potential as a sustainable alternative to conventional plastics.

Quality Control in Bio-PA Film Extrusion Process

Quality control is a critical aspect of the Bio-PA film extrusion process, ensuring the production of high-quality, consistent films that meet industry standards and customer specifications. The extrusion process for Bio-PA films involves several key parameters that must be carefully monitored and controlled to maintain product quality.

One of the primary quality control measures in Bio-PA film extrusion is the continuous monitoring of film thickness. This is typically achieved through the use of advanced thickness gauges, such as beta or X-ray gauges, which provide real-time measurements across the width of the film. These systems allow for immediate adjustments to the die gap or extrusion speed to maintain consistent thickness throughout the production run.

Temperature control is another crucial factor in ensuring quality during the extrusion process. The polymer melt temperature must be precisely regulated to achieve optimal viscosity and flow characteristics. This is accomplished through the use of multiple heating zones along the extruder barrel and die, each equipped with temperature sensors and control systems. Maintaining the correct temperature profile prevents issues such as thermal degradation of the Bio-PA material or inconsistencies in film properties.

Melt pressure is also closely monitored as it directly affects the film's uniformity and surface quality. Pressure transducers installed at various points in the extrusion system provide continuous feedback, allowing operators to make necessary adjustments to screw speed, material feed rate, or die design to maintain optimal pressure levels.

Visual inspection systems play a significant role in quality control, employing high-resolution cameras and advanced image processing algorithms to detect surface defects, gels, or contamination in real-time. These systems can automatically flag or mark defective areas for later removal or alert operators to potential issues in the extrusion process.

Mechanical properties of the extruded Bio-PA film are regularly tested to ensure compliance with specifications. This includes tensile strength, elongation, tear resistance, and impact strength. Samples are taken at predetermined intervals and subjected to standardized testing procedures, with results compared against established quality benchmarks.

Chemical composition and molecular weight distribution of the Bio-PA material are also monitored throughout the extrusion process. Techniques such as Fourier-transform infrared spectroscopy (FTIR) and gel permeation chromatography (GPC) are employed to verify material consistency and detect any potential degradation or contamination.

Implementing statistical process control (SPC) methods allows for the continuous monitoring of key quality parameters, enabling early detection of trends or deviations from target values. This proactive approach to quality control helps minimize waste and optimize production efficiency in Bio-PA film extrusion.

One of the primary quality control measures in Bio-PA film extrusion is the continuous monitoring of film thickness. This is typically achieved through the use of advanced thickness gauges, such as beta or X-ray gauges, which provide real-time measurements across the width of the film. These systems allow for immediate adjustments to the die gap or extrusion speed to maintain consistent thickness throughout the production run.

Temperature control is another crucial factor in ensuring quality during the extrusion process. The polymer melt temperature must be precisely regulated to achieve optimal viscosity and flow characteristics. This is accomplished through the use of multiple heating zones along the extruder barrel and die, each equipped with temperature sensors and control systems. Maintaining the correct temperature profile prevents issues such as thermal degradation of the Bio-PA material or inconsistencies in film properties.

Melt pressure is also closely monitored as it directly affects the film's uniformity and surface quality. Pressure transducers installed at various points in the extrusion system provide continuous feedback, allowing operators to make necessary adjustments to screw speed, material feed rate, or die design to maintain optimal pressure levels.

Visual inspection systems play a significant role in quality control, employing high-resolution cameras and advanced image processing algorithms to detect surface defects, gels, or contamination in real-time. These systems can automatically flag or mark defective areas for later removal or alert operators to potential issues in the extrusion process.

Mechanical properties of the extruded Bio-PA film are regularly tested to ensure compliance with specifications. This includes tensile strength, elongation, tear resistance, and impact strength. Samples are taken at predetermined intervals and subjected to standardized testing procedures, with results compared against established quality benchmarks.

Chemical composition and molecular weight distribution of the Bio-PA material are also monitored throughout the extrusion process. Techniques such as Fourier-transform infrared spectroscopy (FTIR) and gel permeation chromatography (GPC) are employed to verify material consistency and detect any potential degradation or contamination.

Implementing statistical process control (SPC) methods allows for the continuous monitoring of key quality parameters, enabling early detection of trends or deviations from target values. This proactive approach to quality control helps minimize waste and optimize production efficiency in Bio-PA film extrusion.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!