How to Design a Pilot Plant for Bio-PA Compounding at 100–500 kg/day Scale

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-PA Compounding Background and Objectives

Bio-based polyamides (Bio-PAs) have emerged as a sustainable alternative to conventional petroleum-based polyamides, addressing the growing demand for eco-friendly materials in various industries. The development of Bio-PAs represents a significant advancement in polymer science, combining the performance characteristics of traditional polyamides with the environmental benefits of renewable resources.

The evolution of Bio-PA technology can be traced back to the early 2000s when researchers began exploring the potential of bio-based monomers for polyamide synthesis. Since then, the field has witnessed remarkable progress, driven by advancements in biotechnology, process engineering, and material science. The primary objective of Bio-PA development has been to create high-performance materials that can match or exceed the properties of their petroleum-based counterparts while reducing the carbon footprint and dependence on fossil resources.

In recent years, the focus has shifted towards optimizing the production processes for Bio-PAs, with particular emphasis on scalability and cost-effectiveness. The design of pilot plants for Bio-PA compounding at the 100-500 kg/day scale represents a critical step in bridging the gap between laboratory-scale synthesis and full-scale industrial production. This intermediate scale allows for the evaluation of process parameters, quality control measures, and economic feasibility under conditions that more closely resemble industrial operations.

The objectives of designing a pilot plant for Bio-PA compounding at this scale are multifaceted. Firstly, it aims to validate the scalability of laboratory-developed formulations and processes, ensuring that the desired material properties are maintained at larger production volumes. Secondly, it seeks to optimize process conditions, including temperature profiles, mixing parameters, and residence times, to achieve consistent product quality and maximize yield.

Furthermore, the pilot plant serves as a platform for assessing the environmental impact of Bio-PA production, enabling the collection of data on energy consumption, waste generation, and overall sustainability metrics. This information is crucial for refining life cycle assessments and demonstrating the environmental advantages of Bio-PAs over conventional polyamides.

Another key objective is to evaluate the economic viability of Bio-PA production at this intermediate scale. By analyzing factors such as raw material costs, energy requirements, and equipment efficiency, researchers and engineers can make informed decisions about the feasibility of scaling up to full industrial production. Additionally, the pilot plant provides an opportunity to explore potential modifications to the compounding process that could enhance productivity or reduce costs without compromising product quality.

In conclusion, the design of a pilot plant for Bio-PA compounding at the 100-500 kg/day scale represents a critical milestone in the development and commercialization of sustainable polyamide materials. It bridges the gap between laboratory research and industrial application, addressing key technical, environmental, and economic considerations that are essential for the successful adoption of Bio-PAs in various market sectors.

The evolution of Bio-PA technology can be traced back to the early 2000s when researchers began exploring the potential of bio-based monomers for polyamide synthesis. Since then, the field has witnessed remarkable progress, driven by advancements in biotechnology, process engineering, and material science. The primary objective of Bio-PA development has been to create high-performance materials that can match or exceed the properties of their petroleum-based counterparts while reducing the carbon footprint and dependence on fossil resources.

In recent years, the focus has shifted towards optimizing the production processes for Bio-PAs, with particular emphasis on scalability and cost-effectiveness. The design of pilot plants for Bio-PA compounding at the 100-500 kg/day scale represents a critical step in bridging the gap between laboratory-scale synthesis and full-scale industrial production. This intermediate scale allows for the evaluation of process parameters, quality control measures, and economic feasibility under conditions that more closely resemble industrial operations.

The objectives of designing a pilot plant for Bio-PA compounding at this scale are multifaceted. Firstly, it aims to validate the scalability of laboratory-developed formulations and processes, ensuring that the desired material properties are maintained at larger production volumes. Secondly, it seeks to optimize process conditions, including temperature profiles, mixing parameters, and residence times, to achieve consistent product quality and maximize yield.

Furthermore, the pilot plant serves as a platform for assessing the environmental impact of Bio-PA production, enabling the collection of data on energy consumption, waste generation, and overall sustainability metrics. This information is crucial for refining life cycle assessments and demonstrating the environmental advantages of Bio-PAs over conventional polyamides.

Another key objective is to evaluate the economic viability of Bio-PA production at this intermediate scale. By analyzing factors such as raw material costs, energy requirements, and equipment efficiency, researchers and engineers can make informed decisions about the feasibility of scaling up to full industrial production. Additionally, the pilot plant provides an opportunity to explore potential modifications to the compounding process that could enhance productivity or reduce costs without compromising product quality.

In conclusion, the design of a pilot plant for Bio-PA compounding at the 100-500 kg/day scale represents a critical milestone in the development and commercialization of sustainable polyamide materials. It bridges the gap between laboratory research and industrial application, addressing key technical, environmental, and economic considerations that are essential for the successful adoption of Bio-PAs in various market sectors.

Market Analysis for Bio-PA Compounds

The market for bio-based polyamides (Bio-PA) compounds is experiencing significant growth, driven by increasing environmental concerns and the shift towards sustainable materials in various industries. Bio-PA compounds offer a renewable alternative to traditional petroleum-based polyamides, with comparable or superior performance characteristics.

The global Bio-PA market is primarily segmented into Bio-PA 6, Bio-PA 66, and other types. These compounds find applications across multiple sectors, including automotive, textiles, electronics, and consumer goods. The automotive industry, in particular, has shown strong interest in Bio-PA compounds due to their lightweight properties and potential for reducing vehicle emissions.

Market demand for Bio-PA compounds is influenced by several factors. Stringent environmental regulations and sustainability goals set by governments and corporations worldwide are driving the adoption of bio-based materials. Consumers are also becoming more environmentally conscious, leading to increased demand for products made from renewable resources.

The textile industry represents another significant market for Bio-PA compounds. Bio-based fibers derived from these compounds are gaining popularity in sportswear and outdoor apparel due to their moisture-wicking properties and durability. The electronics sector is also exploring Bio-PA compounds for their heat resistance and dimensional stability in various components.

Geographically, Europe leads the Bio-PA compound market, followed by North America and Asia-Pacific. European countries, with their strong focus on sustainability and circular economy principles, have been early adopters of Bio-PA technologies. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing environmental awareness.

Market challenges for Bio-PA compounds include higher production costs compared to conventional polyamides and limited availability of bio-based raw materials. However, ongoing research and development efforts are focused on improving production efficiency and expanding the range of renewable feedstocks.

The Bio-PA compound market is characterized by intense competition among key players, including Arkema, BASF, DuPont, Evonik Industries, and Radici Group. These companies are investing heavily in research and development to enhance their product portfolios and gain a competitive edge.

As the demand for sustainable materials continues to rise, the Bio-PA compound market is projected to grow substantially in the coming years. This growth presents opportunities for companies to innovate and develop new applications for Bio-PA compounds, particularly in emerging sectors such as 3D printing and medical devices.

The global Bio-PA market is primarily segmented into Bio-PA 6, Bio-PA 66, and other types. These compounds find applications across multiple sectors, including automotive, textiles, electronics, and consumer goods. The automotive industry, in particular, has shown strong interest in Bio-PA compounds due to their lightweight properties and potential for reducing vehicle emissions.

Market demand for Bio-PA compounds is influenced by several factors. Stringent environmental regulations and sustainability goals set by governments and corporations worldwide are driving the adoption of bio-based materials. Consumers are also becoming more environmentally conscious, leading to increased demand for products made from renewable resources.

The textile industry represents another significant market for Bio-PA compounds. Bio-based fibers derived from these compounds are gaining popularity in sportswear and outdoor apparel due to their moisture-wicking properties and durability. The electronics sector is also exploring Bio-PA compounds for their heat resistance and dimensional stability in various components.

Geographically, Europe leads the Bio-PA compound market, followed by North America and Asia-Pacific. European countries, with their strong focus on sustainability and circular economy principles, have been early adopters of Bio-PA technologies. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization and increasing environmental awareness.

Market challenges for Bio-PA compounds include higher production costs compared to conventional polyamides and limited availability of bio-based raw materials. However, ongoing research and development efforts are focused on improving production efficiency and expanding the range of renewable feedstocks.

The Bio-PA compound market is characterized by intense competition among key players, including Arkema, BASF, DuPont, Evonik Industries, and Radici Group. These companies are investing heavily in research and development to enhance their product portfolios and gain a competitive edge.

As the demand for sustainable materials continues to rise, the Bio-PA compound market is projected to grow substantially in the coming years. This growth presents opportunities for companies to innovate and develop new applications for Bio-PA compounds, particularly in emerging sectors such as 3D printing and medical devices.

Current Challenges in Bio-PA Pilot Plant Design

The design of a pilot plant for Bio-PA compounding at the 100-500 kg/day scale presents several significant challenges that need to be addressed. One of the primary obstacles is achieving consistent product quality at this intermediate scale. Unlike laboratory-scale production, where conditions can be tightly controlled, or full-scale industrial production with its established processes, pilot plants must bridge the gap while maintaining product integrity.

Scale-up issues are particularly prominent in Bio-PA compounding. The rheological behavior of bio-based polyamides can differ significantly from their petroleum-based counterparts, making it difficult to predict flow characteristics and heat transfer rates accurately. This unpredictability can lead to inconsistencies in mixing, extrusion, and cooling processes, potentially affecting the final product's mechanical and thermal properties.

Another challenge lies in the raw material variability inherent in bio-based feedstocks. Unlike petroleum-based polymers, which have relatively consistent compositions, bio-based materials can vary depending on crop conditions, harvesting methods, and preprocessing techniques. This variability necessitates robust quality control measures and potentially more flexible processing parameters to accommodate batch-to-batch differences.

Equipment design and selection pose additional challenges. Many commercially available compounding systems are optimized for either smaller laboratory scales or larger industrial production. Finding or customizing equipment that can efficiently handle the 100-500 kg/day range while providing the necessary process control and flexibility can be both technically challenging and cost-prohibitive.

Energy efficiency and environmental considerations also present significant hurdles. Bio-PA processing often requires higher temperatures compared to conventional polyamides, which can lead to increased energy consumption. Balancing the need for process efficiency with the environmental benefits of using bio-based materials becomes crucial in pilot plant design.

Lastly, regulatory compliance and safety considerations are paramount. As bio-based materials may have different handling requirements and potential hazards compared to conventional polymers, ensuring that the pilot plant meets all relevant safety standards and regulations while allowing for the flexibility needed in a research and development environment can be complex.

Addressing these challenges requires a multidisciplinary approach, combining expertise in polymer science, process engineering, and sustainable manufacturing. Innovative solutions in process control, equipment design, and material handling will be essential to overcome these obstacles and successfully scale up Bio-PA compounding to the pilot plant level.

Scale-up issues are particularly prominent in Bio-PA compounding. The rheological behavior of bio-based polyamides can differ significantly from their petroleum-based counterparts, making it difficult to predict flow characteristics and heat transfer rates accurately. This unpredictability can lead to inconsistencies in mixing, extrusion, and cooling processes, potentially affecting the final product's mechanical and thermal properties.

Another challenge lies in the raw material variability inherent in bio-based feedstocks. Unlike petroleum-based polymers, which have relatively consistent compositions, bio-based materials can vary depending on crop conditions, harvesting methods, and preprocessing techniques. This variability necessitates robust quality control measures and potentially more flexible processing parameters to accommodate batch-to-batch differences.

Equipment design and selection pose additional challenges. Many commercially available compounding systems are optimized for either smaller laboratory scales or larger industrial production. Finding or customizing equipment that can efficiently handle the 100-500 kg/day range while providing the necessary process control and flexibility can be both technically challenging and cost-prohibitive.

Energy efficiency and environmental considerations also present significant hurdles. Bio-PA processing often requires higher temperatures compared to conventional polyamides, which can lead to increased energy consumption. Balancing the need for process efficiency with the environmental benefits of using bio-based materials becomes crucial in pilot plant design.

Lastly, regulatory compliance and safety considerations are paramount. As bio-based materials may have different handling requirements and potential hazards compared to conventional polymers, ensuring that the pilot plant meets all relevant safety standards and regulations while allowing for the flexibility needed in a research and development environment can be complex.

Addressing these challenges requires a multidisciplinary approach, combining expertise in polymer science, process engineering, and sustainable manufacturing. Innovative solutions in process control, equipment design, and material handling will be essential to overcome these obstacles and successfully scale up Bio-PA compounding to the pilot plant level.

Existing Pilot Plant Designs for Bio-PA

01 Pilot plant design for Bio-PA production

Designing pilot plants for Bio-PA production involves considerations such as equipment selection, process flow optimization, and scale-up strategies. These plants are crucial for testing and refining production processes before full-scale implementation, ensuring efficient and cost-effective manufacturing of bio-based polyamides.- Pilot plant design for Bio-PA production: Specialized pilot plant designs for Bio-PA (bio-based polyamide) production, focusing on optimizing process parameters, equipment layout, and scaling considerations. These designs incorporate features to handle bio-based feedstocks and ensure efficient compounding of Bio-PA materials at a pilot scale.

- Continuous compounding processes for Bio-PA: Development of continuous compounding processes tailored for Bio-PA materials, including extruder configurations, mixing elements, and process control systems. These processes aim to improve the consistency and quality of Bio-PA compounds while maintaining production efficiency at pilot plant scale.

- Feedstock preparation and handling for Bio-PA production: Techniques for preparing and handling bio-based feedstocks used in Bio-PA production, including purification, storage, and feeding systems. These methods ensure consistent quality of raw materials and smooth integration into the pilot plant production process.

- Quality control and characterization methods for Bio-PA compounds: Implementation of quality control measures and characterization techniques specific to Bio-PA compounds produced in pilot plant settings. This includes in-line and off-line testing methods, as well as data analysis tools to ensure consistent product quality and properties.

- Scale-up strategies for Bio-PA compounding: Approaches for scaling up Bio-PA compounding processes from pilot plant to industrial production levels. This includes considerations for equipment sizing, process parameter adjustments, and production capacity optimization while maintaining product quality and consistency.

02 Compounding techniques for Bio-PA materials

Various compounding techniques are employed to enhance the properties of Bio-PA materials. These may include melt blending, reactive extrusion, and the incorporation of additives or reinforcing agents. The choice of compounding method significantly impacts the final product's mechanical, thermal, and chemical properties.Expand Specific Solutions03 Scale-up challenges in Bio-PA production

Scaling up Bio-PA production from laboratory to pilot plant scale presents several challenges. These include maintaining consistent product quality, optimizing reaction conditions, and addressing heat and mass transfer issues. Overcoming these challenges is essential for successful commercial-scale production of bio-based polyamides.Expand Specific Solutions04 Process control and monitoring in Bio-PA pilot plants

Effective process control and monitoring systems are crucial for Bio-PA pilot plant operations. These systems help maintain optimal reaction conditions, ensure product consistency, and facilitate data collection for process improvement. Advanced sensors, real-time analytics, and automation technologies play key roles in achieving efficient pilot plant production.Expand Specific Solutions05 Sustainable practices in Bio-PA pilot plant production

Implementing sustainable practices in Bio-PA pilot plant production is essential for minimizing environmental impact. This includes optimizing energy efficiency, reducing waste generation, and exploring the use of renewable feedstocks. Sustainable approaches not only benefit the environment but also contribute to the overall economic viability of Bio-PA production.Expand Specific Solutions

Key Players in Bio-PA Industry

The bio-PA compounding industry is in a growth phase, driven by increasing demand for sustainable materials. The market size is expanding, with projections indicating significant growth potential. Technologically, the field is advancing rapidly, with companies like Cathay Biotech and Kingfa Sci. & Tech. leading innovation in bio-based polyamides. Cathay Biotech has pioneered commercial production of renewable pentanediamine, while Kingfa focuses on high-performance modified plastics. Other players like Zhejiang Pret and Shanghai PRET are also contributing to the industry's development. The technology's maturity is progressing, but challenges remain in scaling up production to meet growing demand efficiently and cost-effectively.

Kingfa Sci. & Tech. Co., Ltd.

Technical Solution: Kingfa's approach to designing a pilot plant for bio-PA compounding at 100-500 kg/day scale likely leverages their expertise in advanced materials and polymer science. Their design may incorporate a continuous extrusion process for compounding bio-PA with various additives and reinforcements. The pilot plant would likely feature precision dosing systems for accurate material ratios, twin-screw extruders for efficient mixing, and advanced cooling systems for optimal crystallization. Kingfa may implement in-line quality control measures, such as real-time viscosity monitoring and spectroscopic analysis, to ensure consistent product properties. The plant design might also include a flexible setup to accommodate different bio-PA grades and filler combinations, allowing for rapid prototyping and small-batch production[2][4].

Strengths: Extensive experience in polymer compounding, flexible production capabilities. Weaknesses: Potential challenges in sourcing consistent bio-based raw materials, adaptation required for bio-PA specific processing conditions.

Cathay Biotech, Inc.

Technical Solution: Cathay Biotech has developed a proprietary fermentation-based process for producing bio-based polyamides, including PA56 and PA66. Their pilot plant design for bio-PA compounding at 100-500 kg/day scale likely incorporates advanced fermentation technology, utilizing engineered microorganisms to produce bio-based monomers. The process involves precise control of fermentation conditions, including temperature, pH, and nutrient supply, to optimize monomer yield. Post-fermentation, the monomers undergo purification and polymerization steps. The pilot plant likely features modular design for scalability, with automated process control systems for consistent product quality. Cathay Biotech's approach emphasizes sustainability, potentially incorporating waste reduction and energy efficiency measures in the plant design[1][3].

Strengths: Proprietary fermentation technology, scalable process, focus on sustainability. Weaknesses: Potential high initial setup costs, complexity in maintaining optimal fermentation conditions.

Core Technologies for Bio-PA Compounding

Polyamide composition

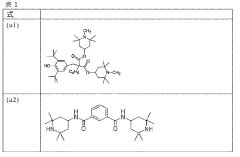

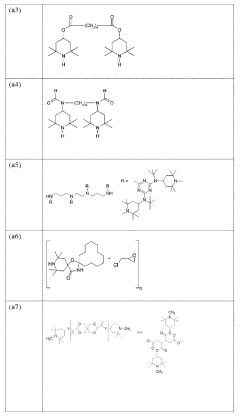

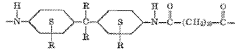

PatentInactiveJP2022550416A

Innovation

- Incorporating specific branched polyamides with a significant excess of amine end groups and defined amounts of heat stabilizers into polyamide compositions, along with optional fillers and impact-modified rubbers, to enhance heat aging stability and fatigue resistance.

Filament containing a biobased polyamide (PA) polymer and its use for additive manufacturing

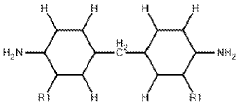

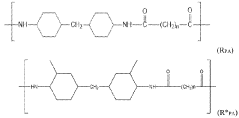

PatentWO2023183553A1

Innovation

- A filament comprising a polymer composition with at least 50% polyamide derived from 4,4'-diaminodicyclohexylmethane and 4,4'-methylene-bis-cyclohexylamine moieties, blended to create a semi-crystalline micro-crystalline polyamide with high glass transition temperature, UV resistance, and biobased content, which is processed into a cylindrical geometry suitable for FFF 3D printing.

Environmental Impact Assessment

The environmental impact assessment of a pilot plant for Bio-PA compounding at 100-500 kg/day scale is a crucial aspect of the project design. This assessment evaluates the potential effects of the plant's operations on the surrounding ecosystem and local community.

Air quality is a primary concern in the environmental impact assessment. The Bio-PA compounding process may release volatile organic compounds (VOCs) and particulate matter into the atmosphere. To mitigate these emissions, the pilot plant design should incorporate advanced air filtration systems and scrubbers. Regular monitoring of air quality parameters will be necessary to ensure compliance with local and national environmental regulations.

Water usage and wastewater management are also significant considerations. The pilot plant will require water for cooling and cleaning processes. Implementing water recycling systems and efficient cooling towers can minimize water consumption. Wastewater treatment facilities should be designed to handle the specific chemical composition of effluents from the Bio-PA compounding process, ensuring that discharged water meets or exceeds environmental standards.

Energy consumption is another critical factor in the environmental impact assessment. The pilot plant's design should prioritize energy efficiency through the use of modern equipment, optimized process controls, and potentially renewable energy sources. Conducting a comprehensive energy audit during the design phase can identify opportunities for reducing the plant's carbon footprint.

Waste management is an essential component of the environmental strategy. The pilot plant will generate various types of waste, including packaging materials, off-spec products, and chemical residues. Implementing a robust waste segregation and recycling program can minimize the amount of waste sent to landfills. For hazardous waste, proper storage, handling, and disposal protocols must be established in accordance with regulatory requirements.

Noise pollution is another environmental concern that needs addressing. The compounding equipment and associated machinery can generate significant noise levels. The plant design should incorporate sound insulation measures and consider the placement of noisy equipment to minimize impact on nearby residential or sensitive areas.

Biodiversity and habitat protection should also be considered in the environmental impact assessment. If the pilot plant is to be located in an area with significant ecological value, measures should be taken to minimize disruption to local flora and fauna. This may include creating buffer zones, implementing wildlife corridors, or supporting local conservation efforts.

Lastly, the environmental impact assessment should consider the potential for accidental releases or spills. The pilot plant design must include robust containment systems, emergency response plans, and staff training programs to minimize the risk and impact of such incidents on the surrounding environment.

Air quality is a primary concern in the environmental impact assessment. The Bio-PA compounding process may release volatile organic compounds (VOCs) and particulate matter into the atmosphere. To mitigate these emissions, the pilot plant design should incorporate advanced air filtration systems and scrubbers. Regular monitoring of air quality parameters will be necessary to ensure compliance with local and national environmental regulations.

Water usage and wastewater management are also significant considerations. The pilot plant will require water for cooling and cleaning processes. Implementing water recycling systems and efficient cooling towers can minimize water consumption. Wastewater treatment facilities should be designed to handle the specific chemical composition of effluents from the Bio-PA compounding process, ensuring that discharged water meets or exceeds environmental standards.

Energy consumption is another critical factor in the environmental impact assessment. The pilot plant's design should prioritize energy efficiency through the use of modern equipment, optimized process controls, and potentially renewable energy sources. Conducting a comprehensive energy audit during the design phase can identify opportunities for reducing the plant's carbon footprint.

Waste management is an essential component of the environmental strategy. The pilot plant will generate various types of waste, including packaging materials, off-spec products, and chemical residues. Implementing a robust waste segregation and recycling program can minimize the amount of waste sent to landfills. For hazardous waste, proper storage, handling, and disposal protocols must be established in accordance with regulatory requirements.

Noise pollution is another environmental concern that needs addressing. The compounding equipment and associated machinery can generate significant noise levels. The plant design should incorporate sound insulation measures and consider the placement of noisy equipment to minimize impact on nearby residential or sensitive areas.

Biodiversity and habitat protection should also be considered in the environmental impact assessment. If the pilot plant is to be located in an area with significant ecological value, measures should be taken to minimize disruption to local flora and fauna. This may include creating buffer zones, implementing wildlife corridors, or supporting local conservation efforts.

Lastly, the environmental impact assessment should consider the potential for accidental releases or spills. The pilot plant design must include robust containment systems, emergency response plans, and staff training programs to minimize the risk and impact of such incidents on the surrounding environment.

Safety Protocols for Bio-PA Handling

Safety protocols for handling Bio-PA in a pilot plant setting are crucial to ensure the well-being of personnel and the integrity of the production process. These protocols should address the specific characteristics and potential hazards associated with Bio-PA materials.

Personal protective equipment (PPE) is a fundamental aspect of safety protocols. Operators must wear appropriate PPE, including chemical-resistant gloves, safety goggles, and protective clothing. Respiratory protection may be necessary depending on the specific Bio-PA formulation and processing conditions. Regular training on proper PPE usage and maintenance is essential to ensure its effectiveness.

Proper ventilation is critical in Bio-PA handling areas. The pilot plant should be equipped with adequate local exhaust ventilation systems to remove any potentially harmful vapors or particulates. Regular monitoring of air quality and ventilation system performance should be implemented to maintain a safe working environment.

Storage and handling procedures for Bio-PA materials must be clearly defined and strictly followed. Raw materials should be stored in appropriate containers in designated areas with proper temperature and humidity control. Segregation of incompatible materials is crucial to prevent potential reactions. Clear labeling and inventory management systems should be in place to minimize the risk of mishandling or misuse.

Spill response protocols are an integral part of safety measures. Designated spill kits should be readily available, and personnel must be trained in their proper use. Procedures for containment, cleanup, and disposal of Bio-PA spills should be clearly documented and regularly reviewed.

Fire safety is another critical consideration. Bio-PA materials may present specific fire hazards, and appropriate fire suppression systems should be installed. Fire extinguishers suitable for chemical fires should be strategically placed throughout the pilot plant. Regular fire drills and evacuation procedures should be conducted to ensure preparedness.

Waste management protocols for Bio-PA processing must be established. Proper disposal methods for waste materials, including any potentially hazardous byproducts, should be clearly defined and in compliance with local regulations. Recycling and reuse options should be explored where feasible to minimize environmental impact.

Regular safety audits and inspections should be conducted to ensure compliance with established protocols. These audits should include equipment checks, review of safety documentation, and assessment of personnel adherence to safety procedures. Any identified issues should be promptly addressed and corrective actions implemented.

Emergency response plans specific to Bio-PA handling incidents must be developed and regularly updated. These plans should outline procedures for various scenarios, including chemical exposures, fires, and spills. Clear communication channels and emergency contact information should be readily available to all personnel.

Personal protective equipment (PPE) is a fundamental aspect of safety protocols. Operators must wear appropriate PPE, including chemical-resistant gloves, safety goggles, and protective clothing. Respiratory protection may be necessary depending on the specific Bio-PA formulation and processing conditions. Regular training on proper PPE usage and maintenance is essential to ensure its effectiveness.

Proper ventilation is critical in Bio-PA handling areas. The pilot plant should be equipped with adequate local exhaust ventilation systems to remove any potentially harmful vapors or particulates. Regular monitoring of air quality and ventilation system performance should be implemented to maintain a safe working environment.

Storage and handling procedures for Bio-PA materials must be clearly defined and strictly followed. Raw materials should be stored in appropriate containers in designated areas with proper temperature and humidity control. Segregation of incompatible materials is crucial to prevent potential reactions. Clear labeling and inventory management systems should be in place to minimize the risk of mishandling or misuse.

Spill response protocols are an integral part of safety measures. Designated spill kits should be readily available, and personnel must be trained in their proper use. Procedures for containment, cleanup, and disposal of Bio-PA spills should be clearly documented and regularly reviewed.

Fire safety is another critical consideration. Bio-PA materials may present specific fire hazards, and appropriate fire suppression systems should be installed. Fire extinguishers suitable for chemical fires should be strategically placed throughout the pilot plant. Regular fire drills and evacuation procedures should be conducted to ensure preparedness.

Waste management protocols for Bio-PA processing must be established. Proper disposal methods for waste materials, including any potentially hazardous byproducts, should be clearly defined and in compliance with local regulations. Recycling and reuse options should be explored where feasible to minimize environmental impact.

Regular safety audits and inspections should be conducted to ensure compliance with established protocols. These audits should include equipment checks, review of safety documentation, and assessment of personnel adherence to safety procedures. Any identified issues should be promptly addressed and corrective actions implemented.

Emergency response plans specific to Bio-PA handling incidents must be developed and regularly updated. These plans should outline procedures for various scenarios, including chemical exposures, fires, and spills. Clear communication channels and emergency contact information should be readily available to all personnel.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!