PA11 for Electrical Insulation: Dielectric Properties and Testing Methods

AUG 20, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PA11 Insulation Background

Polyamide 11 (PA11), also known as Nylon 11, has emerged as a significant material in the field of electrical insulation. This high-performance engineering plastic, derived from renewable castor oil, has gained attention for its unique combination of properties that make it suitable for various electrical applications.

The development of PA11 for electrical insulation can be traced back to the mid-20th century when the demand for advanced polymeric materials in the electrical industry began to grow. As electrical systems became more complex and operating conditions more demanding, there was a need for insulation materials that could withstand higher temperatures, resist chemical degradation, and maintain excellent electrical properties over extended periods.

PA11's journey in electrical insulation started with its introduction as a potential alternative to traditional materials such as polyethylene and polyvinyl chloride. Its bio-based origin and sustainable production process aligned well with the growing environmental concerns in the industry. This aspect, combined with its superior mechanical and thermal properties, made PA11 an attractive option for researchers and manufacturers alike.

Over the years, the focus on PA11 for electrical insulation has intensified, driven by the material's ability to meet the evolving requirements of modern electrical systems. Its low moisture absorption, excellent chemical resistance, and good dimensional stability have contributed to its adoption in various electrical components, including wire and cable insulation, connectors, and switchgear.

The electrical insulation properties of PA11 have been a subject of continuous research and development. Scientists and engineers have worked on enhancing its dielectric strength, volume resistivity, and breakdown voltage to meet the stringent standards of the electrical industry. This ongoing research has led to the development of specialized grades of PA11 tailored specifically for electrical insulation applications.

As the demand for more efficient and reliable electrical systems has grown, so has the importance of understanding and optimizing the dielectric properties of PA11. This has led to the development of sophisticated testing methods to evaluate its performance under various electrical, thermal, and environmental conditions. These testing methodologies have played a crucial role in validating PA11's suitability for different electrical insulation applications and in driving further improvements in its formulation and processing.

The development of PA11 for electrical insulation can be traced back to the mid-20th century when the demand for advanced polymeric materials in the electrical industry began to grow. As electrical systems became more complex and operating conditions more demanding, there was a need for insulation materials that could withstand higher temperatures, resist chemical degradation, and maintain excellent electrical properties over extended periods.

PA11's journey in electrical insulation started with its introduction as a potential alternative to traditional materials such as polyethylene and polyvinyl chloride. Its bio-based origin and sustainable production process aligned well with the growing environmental concerns in the industry. This aspect, combined with its superior mechanical and thermal properties, made PA11 an attractive option for researchers and manufacturers alike.

Over the years, the focus on PA11 for electrical insulation has intensified, driven by the material's ability to meet the evolving requirements of modern electrical systems. Its low moisture absorption, excellent chemical resistance, and good dimensional stability have contributed to its adoption in various electrical components, including wire and cable insulation, connectors, and switchgear.

The electrical insulation properties of PA11 have been a subject of continuous research and development. Scientists and engineers have worked on enhancing its dielectric strength, volume resistivity, and breakdown voltage to meet the stringent standards of the electrical industry. This ongoing research has led to the development of specialized grades of PA11 tailored specifically for electrical insulation applications.

As the demand for more efficient and reliable electrical systems has grown, so has the importance of understanding and optimizing the dielectric properties of PA11. This has led to the development of sophisticated testing methods to evaluate its performance under various electrical, thermal, and environmental conditions. These testing methodologies have played a crucial role in validating PA11's suitability for different electrical insulation applications and in driving further improvements in its formulation and processing.

Market Demand Analysis

The market demand for PA11 (Polyamide 11) in electrical insulation applications has been steadily growing due to its exceptional dielectric properties and performance in challenging environments. This bio-based polymer, derived from castor oil, has gained significant traction in the electrical and electronics industry, particularly in high-voltage and high-temperature applications.

The global electrical insulation market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026, with PA11 playing an increasingly important role. The automotive sector, especially with the rise of electric vehicles (EVs), has become a major driver for PA11 demand. As EVs require high-performance insulation materials for their battery systems and power electronics, PA11's excellent thermal stability and electrical resistance make it an ideal choice.

In the renewable energy sector, particularly wind and solar power generation, PA11 is seeing increased adoption for insulating components in turbines and photovoltaic systems. The material's resistance to harsh environmental conditions, including UV radiation and moisture, contributes to its growing popularity in these applications.

The telecommunications industry is another significant market for PA11 electrical insulation. With the ongoing rollout of 5G networks and the expansion of data centers, there is a rising demand for high-performance insulation materials that can withstand the increased power densities and frequencies associated with these technologies.

Industrial automation and robotics represent emerging markets for PA11 electrical insulation. As manufacturing processes become more sophisticated and automated, the need for reliable insulation materials in sensors, actuators, and control systems has increased. PA11's combination of electrical properties and mechanical strength makes it well-suited for these applications.

The aerospace and defense sectors are also driving demand for PA11 in electrical insulation. The material's lightweight nature, coupled with its excellent dielectric properties, makes it attractive for use in aircraft wiring systems and military electronics where weight reduction and performance are critical factors.

As sustainability becomes a key focus across industries, PA11's bio-based origin provides an additional market advantage. Companies seeking to reduce their carbon footprint and meet environmental regulations are increasingly turning to renewable materials like PA11 for their electrical insulation needs.

The global electrical insulation market is projected to expand at a compound annual growth rate (CAGR) of over 6% from 2021 to 2026, with PA11 playing an increasingly important role. The automotive sector, especially with the rise of electric vehicles (EVs), has become a major driver for PA11 demand. As EVs require high-performance insulation materials for their battery systems and power electronics, PA11's excellent thermal stability and electrical resistance make it an ideal choice.

In the renewable energy sector, particularly wind and solar power generation, PA11 is seeing increased adoption for insulating components in turbines and photovoltaic systems. The material's resistance to harsh environmental conditions, including UV radiation and moisture, contributes to its growing popularity in these applications.

The telecommunications industry is another significant market for PA11 electrical insulation. With the ongoing rollout of 5G networks and the expansion of data centers, there is a rising demand for high-performance insulation materials that can withstand the increased power densities and frequencies associated with these technologies.

Industrial automation and robotics represent emerging markets for PA11 electrical insulation. As manufacturing processes become more sophisticated and automated, the need for reliable insulation materials in sensors, actuators, and control systems has increased. PA11's combination of electrical properties and mechanical strength makes it well-suited for these applications.

The aerospace and defense sectors are also driving demand for PA11 in electrical insulation. The material's lightweight nature, coupled with its excellent dielectric properties, makes it attractive for use in aircraft wiring systems and military electronics where weight reduction and performance are critical factors.

As sustainability becomes a key focus across industries, PA11's bio-based origin provides an additional market advantage. Companies seeking to reduce their carbon footprint and meet environmental regulations are increasingly turning to renewable materials like PA11 for their electrical insulation needs.

Technical Challenges

The development of PA11 for electrical insulation faces several technical challenges that need to be addressed to fully realize its potential in this application. One of the primary challenges is achieving consistent and optimal dielectric properties across different manufacturing batches and environmental conditions. The dielectric strength and breakdown voltage of PA11 can be influenced by factors such as moisture content, temperature, and processing methods, making it crucial to develop robust manufacturing processes that ensure uniform electrical insulation performance.

Another significant challenge lies in the long-term stability of PA11's dielectric properties under various operational conditions. Electrical insulation materials are often subjected to thermal, mechanical, and electrical stresses over extended periods. Understanding and mitigating the degradation of PA11's insulating capabilities over time, especially in harsh environments or under high voltage conditions, is essential for its widespread adoption in electrical applications.

The development of standardized testing methods specifically tailored for PA11 in electrical insulation applications presents another technical hurdle. While general dielectric testing procedures exist, creating protocols that accurately assess PA11's unique properties and performance characteristics in electrical insulation scenarios is crucial. This includes developing tests that can reliably measure dielectric strength, volume resistivity, and dielectric loss factor under conditions that simulate real-world usage.

Furthermore, enhancing PA11's dielectric properties without compromising its other beneficial characteristics, such as mechanical strength and chemical resistance, poses a significant challenge. Researchers and engineers must find ways to optimize the material's electrical insulation capabilities while maintaining or improving its overall performance profile. This may involve exploring various additives, fillers, or surface treatments that can enhance dielectric properties without negatively impacting other critical attributes.

The integration of PA11 into existing electrical insulation manufacturing processes and applications also presents technical challenges. Adapting current production lines and application techniques to accommodate PA11's unique processing requirements and material properties requires careful consideration and potentially significant modifications to established practices.

Lastly, ensuring the compatibility of PA11 with other materials commonly used in electrical systems, such as conductors, connectors, and other insulating components, is crucial. This involves studying potential chemical interactions, thermal expansion mismatches, and long-term compatibility issues that could affect the overall performance and reliability of electrical systems incorporating PA11 insulation.

Another significant challenge lies in the long-term stability of PA11's dielectric properties under various operational conditions. Electrical insulation materials are often subjected to thermal, mechanical, and electrical stresses over extended periods. Understanding and mitigating the degradation of PA11's insulating capabilities over time, especially in harsh environments or under high voltage conditions, is essential for its widespread adoption in electrical applications.

The development of standardized testing methods specifically tailored for PA11 in electrical insulation applications presents another technical hurdle. While general dielectric testing procedures exist, creating protocols that accurately assess PA11's unique properties and performance characteristics in electrical insulation scenarios is crucial. This includes developing tests that can reliably measure dielectric strength, volume resistivity, and dielectric loss factor under conditions that simulate real-world usage.

Furthermore, enhancing PA11's dielectric properties without compromising its other beneficial characteristics, such as mechanical strength and chemical resistance, poses a significant challenge. Researchers and engineers must find ways to optimize the material's electrical insulation capabilities while maintaining or improving its overall performance profile. This may involve exploring various additives, fillers, or surface treatments that can enhance dielectric properties without negatively impacting other critical attributes.

The integration of PA11 into existing electrical insulation manufacturing processes and applications also presents technical challenges. Adapting current production lines and application techniques to accommodate PA11's unique processing requirements and material properties requires careful consideration and potentially significant modifications to established practices.

Lastly, ensuring the compatibility of PA11 with other materials commonly used in electrical systems, such as conductors, connectors, and other insulating components, is crucial. This involves studying potential chemical interactions, thermal expansion mismatches, and long-term compatibility issues that could affect the overall performance and reliability of electrical systems incorporating PA11 insulation.

Current Dielectric Solutions

01 Dielectric properties measurement of PA11

Various methods and devices are used to measure the dielectric properties of PA11 (Polyamide 11). These techniques may include impedance analyzers, dielectric spectroscopy, and capacitance measurements. The dielectric constant and loss factor of PA11 can be determined across different frequencies and temperatures, providing insights into its electrical insulation characteristics and potential applications.- Dielectric properties measurement of PA11: Various methods and devices are used to measure the dielectric properties of PA11 (Polyamide 11). These techniques involve analyzing the material's response to electric fields, including its permittivity and dielectric loss. Such measurements are crucial for understanding PA11's electrical insulation capabilities and its potential applications in electronic components.

- Modification of PA11 to enhance dielectric properties: Researchers have explored ways to modify PA11 to improve its dielectric properties. This includes incorporating additives, nanoparticles, or creating composites with other materials. These modifications aim to enhance the material's dielectric strength, reduce dielectric loss, or tailor its properties for specific applications in electrical and electronic industries.

- Application of PA11 in dielectric devices: PA11's dielectric properties make it suitable for various applications in electrical and electronic devices. It is used in the production of insulating components, capacitors, and other dielectric elements. The material's unique combination of mechanical and dielectric properties allows for its use in demanding environments and specialized applications.

- Temperature and frequency dependence of PA11 dielectric properties: The dielectric properties of PA11 are known to vary with temperature and frequency. Studies have been conducted to characterize these relationships, providing important data for engineers and designers working with PA11 in various applications. Understanding these dependencies is crucial for predicting the material's performance under different operating conditions.

- Comparison of PA11 dielectric properties with other materials: Research has been conducted to compare the dielectric properties of PA11 with other polymers and materials. These comparisons help in material selection for specific applications and in understanding the unique advantages or limitations of PA11 in terms of its dielectric behavior. Such studies often involve analyzing factors like dielectric constant, loss tangent, and breakdown strength across different materials.

02 Modification of PA11 for improved dielectric properties

Researchers have explored ways to enhance the dielectric properties of PA11 through various modifications. These may include the addition of fillers, nanoparticles, or other additives to improve the material's dielectric strength, reduce dielectric loss, or tailor its permittivity. Such modifications can lead to PA11 composites with superior electrical insulation characteristics for specific applications.Expand Specific Solutions03 Application of PA11 in dielectric devices

PA11's dielectric properties make it suitable for various applications in electrical and electronic devices. It can be used in capacitors, insulators, and other components where good dielectric characteristics are required. The material's combination of mechanical strength, chemical resistance, and dielectric properties makes it valuable in industries such as automotive, aerospace, and telecommunications.Expand Specific Solutions04 Temperature and frequency dependence of PA11 dielectric properties

The dielectric properties of PA11 can vary with temperature and frequency. Studies have been conducted to understand how factors such as temperature fluctuations and varying frequencies affect the material's dielectric constant, loss tangent, and overall performance. This knowledge is crucial for designing PA11-based components for specific operating conditions.Expand Specific Solutions05 Comparison of PA11 dielectric properties with other materials

Researchers have compared the dielectric properties of PA11 with other polymers and materials to assess its relative performance. These comparisons help in material selection for specific applications and can guide the development of new PA11-based composites or blends with enhanced dielectric characteristics. Understanding how PA11 compares to alternatives is essential for optimizing its use in various electrical and electronic applications.Expand Specific Solutions

Key Industry Players

The market for PA11 electrical insulation materials is in a growth phase, driven by increasing demand for high-performance dielectric materials in various industries. The global market size for specialty polyamides, including PA11, is projected to reach several billion dollars by 2025. While the technology is relatively mature, ongoing research focuses on enhancing dielectric properties and testing methods. Key players like Solvay, Sumitomo Electric, and TDK are investing in R&D to improve PA11's performance for electrical applications. Universities and research institutes, such as Xi'an Jiaotong University and North China Electric Power University, are also contributing to advancements in dielectric testing and characterization of PA11 materials.

Solvay SA

Technical Solution: Solvay has developed advanced PA11 formulations specifically for electrical insulation applications. Their PA11 materials exhibit excellent dielectric properties, including high dielectric strength and low dielectric loss. Solvay's PA11 for electrical insulation undergoes rigorous testing methods, including breakdown voltage tests, volume resistivity measurements, and dielectric spectroscopy analysis. The company has optimized their PA11 to maintain stable dielectric properties across a wide temperature range, making it suitable for demanding electrical applications[1][3]. Solvay's PA11 also demonstrates good resistance to partial discharge and electrical treeing, enhancing its long-term reliability in high-voltage environments[2].

Strengths: Excellent dielectric properties, wide temperature range stability, and good resistance to electrical degradation. Weaknesses: Potentially higher cost compared to traditional insulation materials, and limited track record in some specific electrical applications.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has been actively researching and implementing PA11 for electrical insulation in their power transmission and distribution systems. They have conducted extensive field tests on PA11-based insulation materials, focusing on their performance in high-voltage applications. State Grid has developed proprietary testing methodologies to evaluate the dielectric properties of PA11 under various environmental conditions, including humidity, temperature cycling, and electrical stress[4]. Their research has led to the development of PA11 composites with enhanced dielectric strength and reduced space charge accumulation, which is crucial for HVDC applications[5]. State Grid has also explored the use of nanofillers to further improve the dielectric properties of PA11, resulting in materials with increased breakdown strength and reduced dielectric loss[6].

Strengths: Extensive field testing experience, development of specialized PA11 composites for high-voltage applications. Weaknesses: Potential challenges in large-scale implementation and integration with existing infrastructure.

Core PA11 Innovations

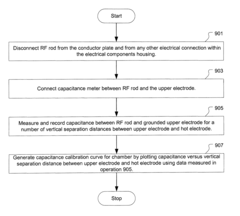

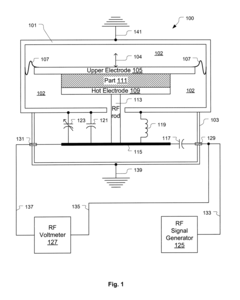

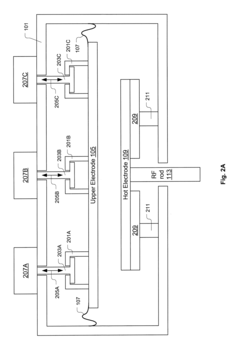

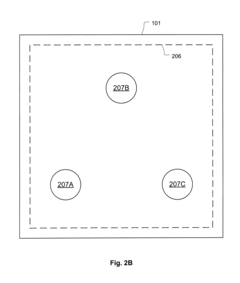

Methods for measuring dielectric properties of parts

PatentActiveUS7973539B1

Innovation

- A method involving an apparatus with an electrically grounded chamber, a lower electrode connected to an RF transmission rod, and an upper electrode, which uses a capacitance meter to measure capacitance between the RF rod and the upper electrode at various separation distances, allowing for the determination of dielectric constant and loss tangent by simulating the resonance frequency and calculating the capacitance of the part.

Method for the inspection of dielectric properties in electrical insulators

PatentWO2013079250A1

Innovation

- A method using electromagnetic waves in the microwave or terahertz range to irradiate insulation components, measuring the attenuation and deriving a two-dimensional or three-dimensional spatial distribution of dielectric property values, which allows for the detection of metal impurities and dielectric inhomogeneities that cause field distortions, thereby identifying potential failure points.

Regulatory Compliance

Regulatory compliance is a critical aspect of utilizing PA11 for electrical insulation applications. The use of PA11 in electrical systems must adhere to various international and regional standards to ensure safety, reliability, and performance. The International Electrotechnical Commission (IEC) provides several key standards relevant to PA11 insulation materials, including IEC 60243 for electric strength testing and IEC 60587 for tracking resistance evaluation.

In the United States, the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL) play crucial roles in setting standards for electrical insulation materials. UL 746A, which covers polymeric materials used in electrical equipment, is particularly relevant for PA11 applications. This standard outlines specific requirements for dielectric strength, volume resistivity, and comparative tracking index.

The European Union's Low Voltage Directive (LVD) 2014/35/EU governs the safety of electrical equipment within certain voltage limits, impacting the use of PA11 insulation in various applications. Compliance with this directive often involves meeting harmonized standards such as EN 60664-1 for insulation coordination.

For automotive applications, PA11 must meet stringent requirements set by organizations like the Society of Automotive Engineers (SAE). Standards such as SAE J1128 for low voltage primary cable insulation are relevant when considering PA11 for vehicle electrical systems.

In the aerospace sector, standards from organizations like the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) govern the use of insulation materials. These include requirements for flammability, smoke density, and toxicity as outlined in standards like FAR 25.853 and EASA CS-25.

Manufacturers and users of PA11 for electrical insulation must also consider environmental regulations. The European Union's Restriction of Hazardous Substances (RoHS) Directive and Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impact the production and use of PA11 insulation materials.

Compliance testing for PA11 insulation materials typically involves a range of standardized tests. These may include dielectric breakdown voltage tests, volume and surface resistivity measurements, and long-term thermal aging studies. The specific tests required depend on the intended application and the relevant regulatory framework.

To ensure ongoing compliance, manufacturers must implement robust quality control processes and maintain detailed documentation of test results and material properties. Regular audits and certifications from recognized bodies may be necessary to demonstrate continued adherence to applicable standards and regulations.

In the United States, the National Electrical Manufacturers Association (NEMA) and Underwriters Laboratories (UL) play crucial roles in setting standards for electrical insulation materials. UL 746A, which covers polymeric materials used in electrical equipment, is particularly relevant for PA11 applications. This standard outlines specific requirements for dielectric strength, volume resistivity, and comparative tracking index.

The European Union's Low Voltage Directive (LVD) 2014/35/EU governs the safety of electrical equipment within certain voltage limits, impacting the use of PA11 insulation in various applications. Compliance with this directive often involves meeting harmonized standards such as EN 60664-1 for insulation coordination.

For automotive applications, PA11 must meet stringent requirements set by organizations like the Society of Automotive Engineers (SAE). Standards such as SAE J1128 for low voltage primary cable insulation are relevant when considering PA11 for vehicle electrical systems.

In the aerospace sector, standards from organizations like the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) govern the use of insulation materials. These include requirements for flammability, smoke density, and toxicity as outlined in standards like FAR 25.853 and EASA CS-25.

Manufacturers and users of PA11 for electrical insulation must also consider environmental regulations. The European Union's Restriction of Hazardous Substances (RoHS) Directive and Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impact the production and use of PA11 insulation materials.

Compliance testing for PA11 insulation materials typically involves a range of standardized tests. These may include dielectric breakdown voltage tests, volume and surface resistivity measurements, and long-term thermal aging studies. The specific tests required depend on the intended application and the relevant regulatory framework.

To ensure ongoing compliance, manufacturers must implement robust quality control processes and maintain detailed documentation of test results and material properties. Regular audits and certifications from recognized bodies may be necessary to demonstrate continued adherence to applicable standards and regulations.

Environmental Impact

The environmental impact of PA11 (Polyamide 11) in electrical insulation applications is an important consideration for sustainable engineering practices. PA11, derived from renewable castor oil, offers a more environmentally friendly alternative to traditional petroleum-based polymers. Its production process results in lower greenhouse gas emissions and reduced dependency on fossil fuels, aligning with global efforts to mitigate climate change.

In terms of lifecycle assessment, PA11 demonstrates favorable characteristics. The material's durability and resistance to various environmental factors contribute to extended product lifespans, reducing the frequency of replacement and associated waste generation. Additionally, PA11's lower density compared to some other insulation materials can lead to weight reduction in electrical components, potentially improving energy efficiency in transportation and reducing overall carbon footprint.

PA11's biodegradability is another significant environmental advantage. While it is designed for long-term use in electrical insulation, at the end of its life cycle, PA11 can decompose more readily than many synthetic polymers. This property helps to address concerns about plastic accumulation in landfills and marine environments, although proper disposal and recycling practices are still crucial.

The material's resistance to hydrolysis and chemicals also contributes to its environmental profile. This durability reduces the need for protective coatings or treatments that might introduce additional environmental hazards. Furthermore, PA11's stability under various environmental conditions minimizes the risk of leaching harmful substances into soil or water systems during its operational life.

From a recycling perspective, PA11 presents both opportunities and challenges. While it is theoretically recyclable, the current infrastructure for recycling specialized polymers used in electrical applications is limited. Developing effective recycling processes for PA11 and similar materials is an area requiring further research and investment to fully realize the material's potential for a circular economy.

In the context of electrical insulation, PA11's dielectric properties allow for efficient energy transmission with minimal losses. This efficiency can contribute to overall energy conservation in electrical systems, indirectly reducing the environmental impact associated with power generation and distribution.

As regulations and industry standards increasingly emphasize environmental considerations, the use of PA11 in electrical insulation may become more prevalent. Its favorable environmental profile, combined with its technical performance, positions PA11 as a material that can help manufacturers meet both regulatory requirements and sustainability goals in the electrical industry.

In terms of lifecycle assessment, PA11 demonstrates favorable characteristics. The material's durability and resistance to various environmental factors contribute to extended product lifespans, reducing the frequency of replacement and associated waste generation. Additionally, PA11's lower density compared to some other insulation materials can lead to weight reduction in electrical components, potentially improving energy efficiency in transportation and reducing overall carbon footprint.

PA11's biodegradability is another significant environmental advantage. While it is designed for long-term use in electrical insulation, at the end of its life cycle, PA11 can decompose more readily than many synthetic polymers. This property helps to address concerns about plastic accumulation in landfills and marine environments, although proper disposal and recycling practices are still crucial.

The material's resistance to hydrolysis and chemicals also contributes to its environmental profile. This durability reduces the need for protective coatings or treatments that might introduce additional environmental hazards. Furthermore, PA11's stability under various environmental conditions minimizes the risk of leaching harmful substances into soil or water systems during its operational life.

From a recycling perspective, PA11 presents both opportunities and challenges. While it is theoretically recyclable, the current infrastructure for recycling specialized polymers used in electrical applications is limited. Developing effective recycling processes for PA11 and similar materials is an area requiring further research and investment to fully realize the material's potential for a circular economy.

In the context of electrical insulation, PA11's dielectric properties allow for efficient energy transmission with minimal losses. This efficiency can contribute to overall energy conservation in electrical systems, indirectly reducing the environmental impact associated with power generation and distribution.

As regulations and industry standards increasingly emphasize environmental considerations, the use of PA11 in electrical insulation may become more prevalent. Its favorable environmental profile, combined with its technical performance, positions PA11 as a material that can help manufacturers meet both regulatory requirements and sustainability goals in the electrical industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!