How to Improve Impact Strength of Bio-PA via Additives and Reinforcements

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-PA Impact Strength Enhancement Goals

Bio-based polyamides (Bio-PAs) have gained significant attention in recent years due to their potential to replace conventional petroleum-based polyamides in various applications. However, one of the major challenges in the widespread adoption of Bio-PAs is their relatively lower impact strength compared to their fossil-based counterparts. This limitation hinders their use in high-performance applications where impact resistance is crucial.

The primary goal of enhancing the impact strength of Bio-PAs is to expand their applicability in industries such as automotive, electronics, and consumer goods. By improving impact resistance, Bio-PAs can compete more effectively with traditional engineering plastics while maintaining their eco-friendly profile. This enhancement aims to address the growing demand for sustainable materials without compromising on performance.

A key objective is to achieve a significant increase in impact strength, targeting improvements of at least 30-50% compared to unmodified Bio-PAs. This level of enhancement would position Bio-PAs as viable alternatives in applications currently dominated by high-performance petroleum-based polymers. The focus is on developing solutions that not only improve impact resistance but also maintain or enhance other critical properties such as tensile strength, thermal stability, and chemical resistance.

Another important goal is to develop cost-effective methods for impact strength enhancement. The additives and reinforcements used should be economically viable to ensure that the final Bio-PA products remain competitive in the market. This involves exploring a range of options, from inexpensive mineral fillers to more advanced nanocomposites, to find the optimal balance between performance improvement and cost.

Sustainability remains a core consideration in this enhancement process. The additives and reinforcements selected should align with the eco-friendly nature of Bio-PAs. This means prioritizing bio-based or renewable additives where possible and ensuring that the overall environmental footprint of the enhanced Bio-PA remains favorable compared to conventional plastics.

The research and development efforts aim to establish standardized methods for incorporating these impact-enhancing additives and reinforcements into Bio-PAs. This includes optimizing processing conditions, developing new compounding techniques, and ensuring compatibility between the additives and the Bio-PA matrix. The goal is to create robust, reproducible processes that can be scaled up for industrial production.

Ultimately, the enhancement of Bio-PA impact strength is expected to open up new market opportunities and drive innovation in sustainable materials. By addressing this key limitation, the research aims to accelerate the adoption of Bio-PAs across various industries, contributing to the broader goal of reducing dependence on fossil-based plastics and promoting a more sustainable materials economy.

The primary goal of enhancing the impact strength of Bio-PAs is to expand their applicability in industries such as automotive, electronics, and consumer goods. By improving impact resistance, Bio-PAs can compete more effectively with traditional engineering plastics while maintaining their eco-friendly profile. This enhancement aims to address the growing demand for sustainable materials without compromising on performance.

A key objective is to achieve a significant increase in impact strength, targeting improvements of at least 30-50% compared to unmodified Bio-PAs. This level of enhancement would position Bio-PAs as viable alternatives in applications currently dominated by high-performance petroleum-based polymers. The focus is on developing solutions that not only improve impact resistance but also maintain or enhance other critical properties such as tensile strength, thermal stability, and chemical resistance.

Another important goal is to develop cost-effective methods for impact strength enhancement. The additives and reinforcements used should be economically viable to ensure that the final Bio-PA products remain competitive in the market. This involves exploring a range of options, from inexpensive mineral fillers to more advanced nanocomposites, to find the optimal balance between performance improvement and cost.

Sustainability remains a core consideration in this enhancement process. The additives and reinforcements selected should align with the eco-friendly nature of Bio-PAs. This means prioritizing bio-based or renewable additives where possible and ensuring that the overall environmental footprint of the enhanced Bio-PA remains favorable compared to conventional plastics.

The research and development efforts aim to establish standardized methods for incorporating these impact-enhancing additives and reinforcements into Bio-PAs. This includes optimizing processing conditions, developing new compounding techniques, and ensuring compatibility between the additives and the Bio-PA matrix. The goal is to create robust, reproducible processes that can be scaled up for industrial production.

Ultimately, the enhancement of Bio-PA impact strength is expected to open up new market opportunities and drive innovation in sustainable materials. By addressing this key limitation, the research aims to accelerate the adoption of Bio-PAs across various industries, contributing to the broader goal of reducing dependence on fossil-based plastics and promoting a more sustainable materials economy.

Market Demand Analysis for High-Impact Bio-PA

The market demand for high-impact Bio-PA (bio-based polyamide) has been steadily increasing due to the growing emphasis on sustainable and eco-friendly materials across various industries. This trend is driven by stringent environmental regulations, consumer preferences for green products, and corporate sustainability initiatives. The automotive sector, in particular, has shown significant interest in high-impact Bio-PA as a potential replacement for conventional petroleum-based plastics in vehicle components.

The global Bio-PA market is expected to experience robust growth in the coming years, with a compound annual growth rate (CAGR) projected to exceed that of traditional polyamides. This growth is primarily attributed to the material's unique combination of bio-based origin and enhanced impact strength, which addresses both environmental concerns and performance requirements in demanding applications.

In the automotive industry, high-impact Bio-PA is gaining traction for use in interior and exterior parts, such as door panels, dashboard components, and under-the-hood applications. The material's improved impact resistance, coupled with its lightweight properties, aligns well with the industry's push for fuel efficiency and reduced carbon emissions. Additionally, the aerospace sector is exploring high-impact Bio-PA for non-structural components, leveraging its durability and weight-saving characteristics.

The packaging industry represents another significant market for high-impact Bio-PA, particularly in the food and beverage sector. The material's enhanced impact strength makes it suitable for reusable containers and bottles, addressing the growing demand for durable, eco-friendly packaging solutions. The electronics industry is also showing interest in high-impact Bio-PA for casings and protective components in consumer devices, capitalizing on its combination of strength and sustainability.

Despite the positive market outlook, challenges remain in scaling up production and reducing costs to compete more effectively with traditional petroleum-based plastics. The availability of bio-based feedstocks and the need for consistent quality in large-scale production are key factors influencing market growth. However, ongoing research and development efforts focused on improving the impact strength of Bio-PA through additives and reinforcements are expected to address these challenges and further expand market opportunities.

As sustainability becomes increasingly central to corporate strategies and consumer choices, the demand for high-impact Bio-PA is anticipated to grow across multiple sectors. This trend is likely to drive innovation in material science and manufacturing processes, potentially leading to new applications and market segments for high-performance, bio-based polymers.

The global Bio-PA market is expected to experience robust growth in the coming years, with a compound annual growth rate (CAGR) projected to exceed that of traditional polyamides. This growth is primarily attributed to the material's unique combination of bio-based origin and enhanced impact strength, which addresses both environmental concerns and performance requirements in demanding applications.

In the automotive industry, high-impact Bio-PA is gaining traction for use in interior and exterior parts, such as door panels, dashboard components, and under-the-hood applications. The material's improved impact resistance, coupled with its lightweight properties, aligns well with the industry's push for fuel efficiency and reduced carbon emissions. Additionally, the aerospace sector is exploring high-impact Bio-PA for non-structural components, leveraging its durability and weight-saving characteristics.

The packaging industry represents another significant market for high-impact Bio-PA, particularly in the food and beverage sector. The material's enhanced impact strength makes it suitable for reusable containers and bottles, addressing the growing demand for durable, eco-friendly packaging solutions. The electronics industry is also showing interest in high-impact Bio-PA for casings and protective components in consumer devices, capitalizing on its combination of strength and sustainability.

Despite the positive market outlook, challenges remain in scaling up production and reducing costs to compete more effectively with traditional petroleum-based plastics. The availability of bio-based feedstocks and the need for consistent quality in large-scale production are key factors influencing market growth. However, ongoing research and development efforts focused on improving the impact strength of Bio-PA through additives and reinforcements are expected to address these challenges and further expand market opportunities.

As sustainability becomes increasingly central to corporate strategies and consumer choices, the demand for high-impact Bio-PA is anticipated to grow across multiple sectors. This trend is likely to drive innovation in material science and manufacturing processes, potentially leading to new applications and market segments for high-performance, bio-based polymers.

Current Limitations in Bio-PA Impact Resistance

Bio-based polyamides (Bio-PAs) have gained significant attention in recent years due to their potential to replace petroleum-based counterparts in various applications. However, one of the major limitations hindering their widespread adoption is their relatively low impact strength compared to conventional polyamides.

The impact strength of Bio-PAs is typically lower than that of their petroleum-based counterparts due to several factors. Firstly, the molecular structure of Bio-PAs often exhibits a higher degree of crystallinity, which can lead to increased brittleness and reduced impact resistance. This is particularly evident in Bio-PAs derived from long-chain monomers, such as those obtained from castor oil or sebacic acid.

Another contributing factor to the limited impact strength of Bio-PAs is the presence of impurities and inconsistencies in the bio-based raw materials. These impurities can act as stress concentrators, initiating crack formation and propagation under impact loading conditions. Additionally, the variability in feedstock quality can lead to inconsistent mechanical properties, making it challenging to achieve reliable and reproducible impact strength values.

The processing conditions used in the manufacture of Bio-PA products also play a crucial role in determining their impact strength. Inadequate control over parameters such as temperature, pressure, and cooling rates during injection molding or extrusion can result in suboptimal molecular orientation and crystallization, further compromising the material's ability to absorb impact energy.

Furthermore, the hygroscopic nature of Bio-PAs poses additional challenges in maintaining consistent impact strength. Moisture absorption can lead to plasticization of the polymer matrix, altering its mechanical properties and potentially reducing impact resistance over time. This necessitates careful consideration of moisture management strategies in both processing and end-use applications.

The limited availability of suitable impact modifiers and reinforcing agents specifically designed for Bio-PAs also contributes to their current impact strength limitations. While conventional impact modifiers used in petroleum-based polyamides can be applied to Bio-PAs, their effectiveness may be reduced due to differences in molecular structure and compatibility.

Addressing these limitations requires a multifaceted approach, combining advancements in raw material processing, polymer design, and additive technologies. Developing Bio-PAs with optimized molecular architectures, such as copolymers or blends, could help balance crystallinity and impact resistance. Additionally, exploring novel impact modifiers and reinforcing agents tailored to the unique characteristics of Bio-PAs holds promise for significant improvements in impact strength.

The impact strength of Bio-PAs is typically lower than that of their petroleum-based counterparts due to several factors. Firstly, the molecular structure of Bio-PAs often exhibits a higher degree of crystallinity, which can lead to increased brittleness and reduced impact resistance. This is particularly evident in Bio-PAs derived from long-chain monomers, such as those obtained from castor oil or sebacic acid.

Another contributing factor to the limited impact strength of Bio-PAs is the presence of impurities and inconsistencies in the bio-based raw materials. These impurities can act as stress concentrators, initiating crack formation and propagation under impact loading conditions. Additionally, the variability in feedstock quality can lead to inconsistent mechanical properties, making it challenging to achieve reliable and reproducible impact strength values.

The processing conditions used in the manufacture of Bio-PA products also play a crucial role in determining their impact strength. Inadequate control over parameters such as temperature, pressure, and cooling rates during injection molding or extrusion can result in suboptimal molecular orientation and crystallization, further compromising the material's ability to absorb impact energy.

Furthermore, the hygroscopic nature of Bio-PAs poses additional challenges in maintaining consistent impact strength. Moisture absorption can lead to plasticization of the polymer matrix, altering its mechanical properties and potentially reducing impact resistance over time. This necessitates careful consideration of moisture management strategies in both processing and end-use applications.

The limited availability of suitable impact modifiers and reinforcing agents specifically designed for Bio-PAs also contributes to their current impact strength limitations. While conventional impact modifiers used in petroleum-based polyamides can be applied to Bio-PAs, their effectiveness may be reduced due to differences in molecular structure and compatibility.

Addressing these limitations requires a multifaceted approach, combining advancements in raw material processing, polymer design, and additive technologies. Developing Bio-PAs with optimized molecular architectures, such as copolymers or blends, could help balance crystallinity and impact resistance. Additionally, exploring novel impact modifiers and reinforcing agents tailored to the unique characteristics of Bio-PAs holds promise for significant improvements in impact strength.

Existing Additive Solutions for Bio-PA

01 Blending with other polymers

Improving the impact strength of Bio-PA by blending it with other polymers such as polyolefins, elastomers, or other compatible materials. This approach can enhance the toughness and impact resistance of the resulting composite material while maintaining the bio-based nature of the product.- Incorporation of reinforcing fibers: Adding reinforcing fibers, such as glass fibers or carbon fibers, to bio-based polyamides can significantly improve their impact strength. These fibers enhance the mechanical properties of the material by distributing stress and preventing crack propagation.

- Blending with impact modifiers: Blending bio-based polyamides with impact modifiers, such as elastomers or rubber particles, can enhance their impact resistance. These modifiers absorb and dissipate energy during impact, preventing brittle failure and improving overall toughness.

- Optimization of molecular structure: Modifying the molecular structure of bio-based polyamides through techniques like copolymerization or chain extension can improve their impact strength. These modifications can enhance chain flexibility, increase molecular weight, or introduce branching, all of which contribute to better impact resistance.

- Surface treatment and compatibilization: Applying surface treatments to reinforcing fibers or using compatibilizers in bio-based polyamide composites can improve the interfacial adhesion between the matrix and reinforcement. This enhanced interaction leads to better stress transfer and improved impact strength of the overall material.

- Processing and molding techniques: Optimizing processing conditions and employing specific molding techniques can significantly influence the impact strength of bio-based polyamides. Factors such as temperature, pressure, cooling rate, and mold design can affect the material's microstructure and crystallinity, which in turn impact its mechanical properties.

02 Incorporation of impact modifiers

Adding specific impact modifiers to Bio-PA formulations to enhance their impact strength. These modifiers can include specially designed additives or nanoparticles that improve the material's ability to absorb and dissipate energy during impact events.Expand Specific Solutions03 Optimization of processing conditions

Adjusting processing parameters such as temperature, pressure, and cooling rates during the manufacturing of Bio-PA products to optimize their molecular structure and crystallinity. This can lead to improved impact strength without the need for additional additives.Expand Specific Solutions04 Surface treatment and coating

Applying surface treatments or coatings to Bio-PA products to enhance their impact resistance. This can include plasma treatments, chemical modifications, or the application of protective layers that improve the material's ability to withstand impacts.Expand Specific Solutions05 Reinforcement with fibers or fillers

Incorporating reinforcing fibers or fillers into Bio-PA matrices to create composite materials with enhanced impact strength. This can include natural fibers, glass fibers, or other reinforcing agents that improve the overall mechanical properties of the material.Expand Specific Solutions

Key Players in Bio-PA and Additives Industry

The competition landscape for improving the impact strength of Bio-PA via additives and reinforcements is characterized by a mature market with significant growth potential. The industry is in a phase of rapid development, driven by increasing demand for sustainable and high-performance materials. Major players like DuPont, Arkema, and Cathay Biotech are investing heavily in research and development to enhance bio-based polyamides' properties. The market size is expanding, with applications spanning automotive, electronics, and consumer goods sectors. Technologically, the field is advancing rapidly, with companies like Kingfa Sci. & Tech. and ExxonMobil Chemical Patents leading innovations in additives and reinforcement techniques. Universities and research institutions are also contributing significantly to technological advancements in this area.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed a range of bio-based polyamides (Bio-PAs) with improved impact strength through innovative additives and reinforcements. Their approach includes incorporating specially engineered impact modifiers and glass fiber reinforcements. The company has introduced Zytel® RS, a bio-based polyamide with up to 60% renewable content[1]. This material utilizes a proprietary impact modification technology that enhances toughness without significantly compromising other mechanical properties. DuPont has also developed a nano-reinforcement technique, incorporating nanoscale particles to improve impact resistance while maintaining the material's lightweight characteristics[2]. Additionally, they have explored the use of bio-based plasticizers derived from renewable resources to enhance the flexibility and impact resistance of their Bio-PAs[3].

Strengths: Extensive experience in polymer science, strong R&D capabilities, and a wide range of existing bio-based products. Weaknesses: Higher production costs compared to traditional polyamides, potential limitations in extreme temperature applications.

Arkema France SA

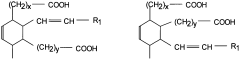

Technical Solution: Arkema has made significant strides in improving the impact strength of Bio-PAs through their Rilsan® product line. Their approach focuses on optimizing the polymer chain structure and incorporating specialized additives. Arkema has developed a unique copolymerization technique that introduces flexible segments into the Bio-PA backbone, enhancing its impact resistance[4]. They have also pioneered the use of bio-based impact modifiers derived from renewable resources, such as modified vegetable oils, which are compatible with the Bio-PA matrix and significantly improve toughness[5]. Furthermore, Arkema has explored the use of hybrid reinforcement systems, combining short glass fibers with nano-fillers, to create a synergistic effect that enhances both impact strength and dimensional stability[6].

Strengths: Strong focus on sustainability, extensive experience with bio-based polymers, and a diverse product portfolio. Weaknesses: Potential challenges in scaling up production of specialized additives, possible trade-offs between impact strength and other mechanical properties.

Innovative Reinforcement Technologies for Bio-PA

Polyamide molding compounds

PatentInactiveEP2758471A1

Innovation

- Incorporating 0.5 to 20% by weight of a compatible copolyester B with specific acid and diol components into the polyamide molding compositions, which enhances both impact and tensile behavior.

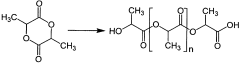

Plasticizable polymer material based on the natural polymers polylactide and/or lignin

PatentWO2012110237A1

Innovation

- Incorporating a polyamide based on dimeric fatty acid into the plastic material, which increases impact strength significantly while maintaining high strength and rigidity, and is biodegradable and processed from renewable resources.

Environmental Impact of Bio-PA Additives

The environmental impact of additives used to improve the impact strength of Bio-PA is a critical consideration in the development and application of these materials. While Bio-PA itself is derived from renewable resources and offers potential environmental benefits, the additives and reinforcements used to enhance its properties may have varying ecological footprints.

One of the primary concerns is the biodegradability of the final composite material. Many additives, particularly synthetic ones, can significantly reduce the biodegradability of Bio-PA, potentially negating one of its key environmental advantages. This is especially true for inorganic fillers and certain polymer blends that are not biodegradable. Consequently, the end-of-life disposal options for Bio-PA products may be limited, potentially increasing their environmental impact.

The production processes for these additives also contribute to their overall environmental footprint. Some additives may require energy-intensive manufacturing methods or involve the use of hazardous chemicals, leading to increased greenhouse gas emissions and potential pollution risks. For instance, the production of carbon fibers, which are sometimes used to reinforce Bio-PA, is known to be energy-intensive and can result in significant CO2 emissions.

However, not all additives have negative environmental impacts. Some bio-based additives, such as cellulose fibers or starch-based fillers, can maintain or even enhance the biodegradability of Bio-PA while improving its mechanical properties. These natural additives often have lower environmental impacts in terms of production and disposal compared to their synthetic counterparts.

The use of recycled materials as additives or reinforcements presents another environmentally friendly option. Incorporating recycled fibers or particles not only improves the impact strength of Bio-PA but also contributes to waste reduction and resource conservation. This approach aligns with circular economy principles and can significantly reduce the overall environmental impact of the material.

It's also important to consider the lifecycle impact of Bio-PA composites. While some additives may increase the initial environmental footprint, they can potentially extend the lifespan of products or improve their performance in ways that result in net environmental benefits over time. For example, additives that enhance durability may reduce the need for frequent replacements, thereby decreasing long-term resource consumption and waste generation.

In conclusion, the environmental impact of additives used in Bio-PA is complex and multifaceted. It requires a careful balance between performance enhancement and ecological considerations. As research in this field progresses, there is a growing focus on developing additives that not only improve the impact strength of Bio-PA but also maintain or enhance its environmental benefits, paving the way for more sustainable and high-performance bio-based materials.

One of the primary concerns is the biodegradability of the final composite material. Many additives, particularly synthetic ones, can significantly reduce the biodegradability of Bio-PA, potentially negating one of its key environmental advantages. This is especially true for inorganic fillers and certain polymer blends that are not biodegradable. Consequently, the end-of-life disposal options for Bio-PA products may be limited, potentially increasing their environmental impact.

The production processes for these additives also contribute to their overall environmental footprint. Some additives may require energy-intensive manufacturing methods or involve the use of hazardous chemicals, leading to increased greenhouse gas emissions and potential pollution risks. For instance, the production of carbon fibers, which are sometimes used to reinforce Bio-PA, is known to be energy-intensive and can result in significant CO2 emissions.

However, not all additives have negative environmental impacts. Some bio-based additives, such as cellulose fibers or starch-based fillers, can maintain or even enhance the biodegradability of Bio-PA while improving its mechanical properties. These natural additives often have lower environmental impacts in terms of production and disposal compared to their synthetic counterparts.

The use of recycled materials as additives or reinforcements presents another environmentally friendly option. Incorporating recycled fibers or particles not only improves the impact strength of Bio-PA but also contributes to waste reduction and resource conservation. This approach aligns with circular economy principles and can significantly reduce the overall environmental impact of the material.

It's also important to consider the lifecycle impact of Bio-PA composites. While some additives may increase the initial environmental footprint, they can potentially extend the lifespan of products or improve their performance in ways that result in net environmental benefits over time. For example, additives that enhance durability may reduce the need for frequent replacements, thereby decreasing long-term resource consumption and waste generation.

In conclusion, the environmental impact of additives used in Bio-PA is complex and multifaceted. It requires a careful balance between performance enhancement and ecological considerations. As research in this field progresses, there is a growing focus on developing additives that not only improve the impact strength of Bio-PA but also maintain or enhance its environmental benefits, paving the way for more sustainable and high-performance bio-based materials.

Cost-Benefit Analysis of Reinforcement Methods

The cost-benefit analysis of reinforcement methods for improving the impact strength of Bio-PA is a crucial consideration for manufacturers and researchers. Various reinforcement techniques offer different advantages and drawbacks, necessitating a thorough evaluation of their economic viability and performance benefits.

Fiber reinforcement, particularly with glass fibers, is a widely adopted method due to its relatively low cost and significant improvement in mechanical properties. The cost of glass fibers typically ranges from $1 to $3 per kilogram, making it an economically attractive option. However, the processing equipment required for fiber incorporation and the potential increase in wear on machinery must be factored into the overall cost analysis. The benefit of glass fiber reinforcement is substantial, often resulting in a 50-100% increase in impact strength, depending on the fiber content and orientation.

Nanoparticle reinforcement, such as the use of nanoclay or carbon nanotubes, offers impressive strength improvements with minimal weight addition. While the cost of nanoparticles can be higher, ranging from $10 to $100 per kilogram, the required quantities are typically lower than traditional fillers. The benefits include not only enhanced impact strength but also improved barrier properties and flame retardancy. However, the dispersion of nanoparticles can be challenging and may require specialized equipment, potentially increasing the overall production cost.

Impact modifiers, such as elastomeric particles or core-shell rubbers, present a balance between cost and performance. These additives are generally priced between $5 and $15 per kilogram and can be easily incorporated into existing production lines with minimal equipment modifications. The impact strength improvement can range from 30% to 80%, depending on the type and concentration of the modifier. The cost-benefit ratio of impact modifiers is often favorable, especially for applications requiring a moderate increase in toughness without significant changes to other material properties.

Hybrid reinforcement systems, combining two or more reinforcement methods, offer a synergistic approach to improving impact strength. While the initial material costs may be higher, the potential for optimizing performance and reducing overall filler content can lead to long-term cost savings. For instance, a combination of short glass fibers and nanoparticles can achieve superior impact strength with lower filler loadings compared to using either reinforcement alone.

When considering the cost-benefit analysis, it is essential to evaluate the entire lifecycle of the product. Higher-cost reinforcement methods that significantly extend the product's lifespan or reduce maintenance requirements may prove more economical in the long run. Additionally, the potential for weight reduction through efficient reinforcement can lead to substantial cost savings in transportation and fuel consumption for certain applications.

In conclusion, the choice of reinforcement method for Bio-PA should be based on a comprehensive cost-benefit analysis that considers not only the immediate material and processing costs but also the long-term performance benefits, product lifecycle, and potential for value addition in specific applications. This holistic approach ensures that the selected reinforcement strategy aligns with both economic constraints and performance requirements.

Fiber reinforcement, particularly with glass fibers, is a widely adopted method due to its relatively low cost and significant improvement in mechanical properties. The cost of glass fibers typically ranges from $1 to $3 per kilogram, making it an economically attractive option. However, the processing equipment required for fiber incorporation and the potential increase in wear on machinery must be factored into the overall cost analysis. The benefit of glass fiber reinforcement is substantial, often resulting in a 50-100% increase in impact strength, depending on the fiber content and orientation.

Nanoparticle reinforcement, such as the use of nanoclay or carbon nanotubes, offers impressive strength improvements with minimal weight addition. While the cost of nanoparticles can be higher, ranging from $10 to $100 per kilogram, the required quantities are typically lower than traditional fillers. The benefits include not only enhanced impact strength but also improved barrier properties and flame retardancy. However, the dispersion of nanoparticles can be challenging and may require specialized equipment, potentially increasing the overall production cost.

Impact modifiers, such as elastomeric particles or core-shell rubbers, present a balance between cost and performance. These additives are generally priced between $5 and $15 per kilogram and can be easily incorporated into existing production lines with minimal equipment modifications. The impact strength improvement can range from 30% to 80%, depending on the type and concentration of the modifier. The cost-benefit ratio of impact modifiers is often favorable, especially for applications requiring a moderate increase in toughness without significant changes to other material properties.

Hybrid reinforcement systems, combining two or more reinforcement methods, offer a synergistic approach to improving impact strength. While the initial material costs may be higher, the potential for optimizing performance and reducing overall filler content can lead to long-term cost savings. For instance, a combination of short glass fibers and nanoparticles can achieve superior impact strength with lower filler loadings compared to using either reinforcement alone.

When considering the cost-benefit analysis, it is essential to evaluate the entire lifecycle of the product. Higher-cost reinforcement methods that significantly extend the product's lifespan or reduce maintenance requirements may prove more economical in the long run. Additionally, the potential for weight reduction through efficient reinforcement can lead to substantial cost savings in transportation and fuel consumption for certain applications.

In conclusion, the choice of reinforcement method for Bio-PA should be based on a comprehensive cost-benefit analysis that considers not only the immediate material and processing costs but also the long-term performance benefits, product lifecycle, and potential for value addition in specific applications. This holistic approach ensures that the selected reinforcement strategy aligns with both economic constraints and performance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!