Reprocessing Bio-Nylon: Effects on Molecular Weight and Properties — Best Practices

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-Nylon Reprocessing Background and Objectives

Bio-nylon, a sustainable alternative to conventional petroleum-based nylon, has gained significant attention in recent years due to its eco-friendly properties and potential to reduce environmental impact. The reprocessing of bio-nylon has emerged as a critical area of research and development, aiming to enhance the material's lifecycle and improve its overall sustainability profile.

The evolution of bio-nylon technology can be traced back to the early 2000s when researchers began exploring bio-based alternatives to traditional synthetic polymers. Since then, the field has witnessed remarkable progress, with advancements in biotechnology and materials science driving innovation in bio-nylon production and reprocessing techniques.

The primary objective of bio-nylon reprocessing is to maintain or enhance the material's molecular weight and properties through multiple cycles of use and recycling. This goal aligns with the broader principles of circular economy and sustainable materials management, which seek to minimize waste and maximize resource efficiency.

Reprocessing bio-nylon presents unique challenges compared to conventional nylon recycling. The biological origin of the polymer introduces additional complexities in terms of molecular structure and stability during reprocessing. Researchers and industry professionals are focusing on developing methods that can effectively break down and reconstitute bio-nylon without compromising its desirable properties.

The technological trajectory in this field is moving towards more efficient and less energy-intensive reprocessing techniques. Current research is exploring various approaches, including chemical depolymerization, mechanical recycling, and enzymatic degradation, each with its own set of advantages and limitations.

As the demand for sustainable materials continues to grow across industries such as textiles, automotive, and packaging, the importance of effective bio-nylon reprocessing becomes increasingly apparent. The ability to maintain high molecular weight and preserve key properties through multiple reprocessing cycles is crucial for the long-term viability and widespread adoption of bio-nylon as a sustainable material solution.

Understanding the effects of reprocessing on bio-nylon's molecular weight and properties is essential for developing best practices in the field. This knowledge will inform the design of more robust bio-nylon formulations, optimize reprocessing parameters, and ultimately lead to the creation of closed-loop systems for bio-nylon production and recycling.

The evolution of bio-nylon technology can be traced back to the early 2000s when researchers began exploring bio-based alternatives to traditional synthetic polymers. Since then, the field has witnessed remarkable progress, with advancements in biotechnology and materials science driving innovation in bio-nylon production and reprocessing techniques.

The primary objective of bio-nylon reprocessing is to maintain or enhance the material's molecular weight and properties through multiple cycles of use and recycling. This goal aligns with the broader principles of circular economy and sustainable materials management, which seek to minimize waste and maximize resource efficiency.

Reprocessing bio-nylon presents unique challenges compared to conventional nylon recycling. The biological origin of the polymer introduces additional complexities in terms of molecular structure and stability during reprocessing. Researchers and industry professionals are focusing on developing methods that can effectively break down and reconstitute bio-nylon without compromising its desirable properties.

The technological trajectory in this field is moving towards more efficient and less energy-intensive reprocessing techniques. Current research is exploring various approaches, including chemical depolymerization, mechanical recycling, and enzymatic degradation, each with its own set of advantages and limitations.

As the demand for sustainable materials continues to grow across industries such as textiles, automotive, and packaging, the importance of effective bio-nylon reprocessing becomes increasingly apparent. The ability to maintain high molecular weight and preserve key properties through multiple reprocessing cycles is crucial for the long-term viability and widespread adoption of bio-nylon as a sustainable material solution.

Understanding the effects of reprocessing on bio-nylon's molecular weight and properties is essential for developing best practices in the field. This knowledge will inform the design of more robust bio-nylon formulations, optimize reprocessing parameters, and ultimately lead to the creation of closed-loop systems for bio-nylon production and recycling.

Market Analysis for Recycled Bio-Nylon

The market for recycled bio-nylon is experiencing significant growth, driven by increasing environmental awareness and the push for sustainable materials in various industries. Bio-nylon, derived from renewable resources such as castor oil, offers a more eco-friendly alternative to traditional petroleum-based nylon. The reprocessing of bio-nylon further enhances its sustainability profile, making it an attractive option for environmentally conscious consumers and businesses.

The global bio-nylon market is projected to expand at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is primarily fueled by the rising demand in key sectors such as automotive, textiles, and packaging. The automotive industry, in particular, is showing strong interest in recycled bio-nylon for interior components and under-the-hood applications, as it helps manufacturers meet stringent environmental regulations and reduce their carbon footprint.

In the textile sector, recycled bio-nylon is gaining traction in the production of sustainable apparel and accessories. Major fashion brands are increasingly incorporating this material into their product lines to appeal to eco-conscious consumers. The packaging industry is also adopting recycled bio-nylon for flexible packaging solutions, driven by the need for recyclable and biodegradable materials.

Geographically, Europe and North America are leading the market for recycled bio-nylon, with Asia-Pacific expected to show the fastest growth in the coming years. This regional growth is attributed to increasing industrialization, stringent environmental regulations, and growing consumer awareness about sustainable products.

The market for recycled bio-nylon faces some challenges, including higher production costs compared to conventional nylon and the need for advanced recycling technologies. However, ongoing research and development efforts are focused on improving the reprocessing techniques to maintain the molecular weight and properties of bio-nylon during recycling, which is crucial for expanding its applications and market acceptance.

Key market players are investing in the development of innovative recycling technologies and expanding their production capacities to meet the growing demand. Collaborations between material suppliers, manufacturers, and end-users are becoming more common, fostering the development of closed-loop recycling systems for bio-nylon.

As sustainability continues to be a priority for businesses and consumers alike, the market for recycled bio-nylon is expected to witness sustained growth. The material's potential to reduce environmental impact while maintaining performance characteristics positions it as a promising solution for various industries seeking to improve their sustainability credentials.

The global bio-nylon market is projected to expand at a compound annual growth rate (CAGR) of over 20% in the coming years. This growth is primarily fueled by the rising demand in key sectors such as automotive, textiles, and packaging. The automotive industry, in particular, is showing strong interest in recycled bio-nylon for interior components and under-the-hood applications, as it helps manufacturers meet stringent environmental regulations and reduce their carbon footprint.

In the textile sector, recycled bio-nylon is gaining traction in the production of sustainable apparel and accessories. Major fashion brands are increasingly incorporating this material into their product lines to appeal to eco-conscious consumers. The packaging industry is also adopting recycled bio-nylon for flexible packaging solutions, driven by the need for recyclable and biodegradable materials.

Geographically, Europe and North America are leading the market for recycled bio-nylon, with Asia-Pacific expected to show the fastest growth in the coming years. This regional growth is attributed to increasing industrialization, stringent environmental regulations, and growing consumer awareness about sustainable products.

The market for recycled bio-nylon faces some challenges, including higher production costs compared to conventional nylon and the need for advanced recycling technologies. However, ongoing research and development efforts are focused on improving the reprocessing techniques to maintain the molecular weight and properties of bio-nylon during recycling, which is crucial for expanding its applications and market acceptance.

Key market players are investing in the development of innovative recycling technologies and expanding their production capacities to meet the growing demand. Collaborations between material suppliers, manufacturers, and end-users are becoming more common, fostering the development of closed-loop recycling systems for bio-nylon.

As sustainability continues to be a priority for businesses and consumers alike, the market for recycled bio-nylon is expected to witness sustained growth. The material's potential to reduce environmental impact while maintaining performance characteristics positions it as a promising solution for various industries seeking to improve their sustainability credentials.

Current Challenges in Bio-Nylon Reprocessing

The reprocessing of bio-nylon presents several significant challenges that hinder its widespread adoption and efficient recycling. One of the primary issues is the degradation of molecular weight during the reprocessing stages. This degradation occurs due to the breaking of polymer chains, which can lead to a reduction in the material's mechanical properties, such as tensile strength and impact resistance.

Another major challenge is the presence of contaminants in recycled bio-nylon. These contaminants can include additives, dyes, and other materials that were incorporated into the original product. Removing these impurities without further damaging the polymer structure is a complex task that requires advanced separation techniques.

The heterogeneity of bio-nylon waste streams also poses a significant obstacle. Different grades and types of bio-nylon may have varying chemical compositions and additives, making it difficult to develop a standardized reprocessing method that can effectively handle all varieties. This diversity in feedstock can lead to inconsistencies in the quality of the recycled material.

Moisture absorption is another critical issue in bio-nylon reprocessing. Bio-nylon is hygroscopic, meaning it readily absorbs moisture from the environment. This absorbed moisture can cause hydrolysis during reprocessing, further contributing to the degradation of molecular weight and mechanical properties. Effective drying processes are essential but can be energy-intensive and time-consuming.

The thermal sensitivity of bio-nylon compounds the challenges in reprocessing. The material can undergo thermal degradation if exposed to high temperatures for extended periods during recycling processes. This sensitivity limits the processing window and requires precise temperature control throughout the reprocessing stages.

Furthermore, the cost-effectiveness of bio-nylon reprocessing remains a significant hurdle. The complex purification and reconditioning steps required to maintain the quality of recycled bio-nylon can be expensive, potentially making virgin bio-nylon more economically attractive. This economic barrier hinders the widespread adoption of recycling practices in the industry.

Lastly, there is a lack of standardized methods for assessing the quality and properties of reprocessed bio-nylon. This absence of universal benchmarks makes it difficult for manufacturers and consumers to trust and value recycled bio-nylon products, further impeding the growth of the recycling market for this material.

Another major challenge is the presence of contaminants in recycled bio-nylon. These contaminants can include additives, dyes, and other materials that were incorporated into the original product. Removing these impurities without further damaging the polymer structure is a complex task that requires advanced separation techniques.

The heterogeneity of bio-nylon waste streams also poses a significant obstacle. Different grades and types of bio-nylon may have varying chemical compositions and additives, making it difficult to develop a standardized reprocessing method that can effectively handle all varieties. This diversity in feedstock can lead to inconsistencies in the quality of the recycled material.

Moisture absorption is another critical issue in bio-nylon reprocessing. Bio-nylon is hygroscopic, meaning it readily absorbs moisture from the environment. This absorbed moisture can cause hydrolysis during reprocessing, further contributing to the degradation of molecular weight and mechanical properties. Effective drying processes are essential but can be energy-intensive and time-consuming.

The thermal sensitivity of bio-nylon compounds the challenges in reprocessing. The material can undergo thermal degradation if exposed to high temperatures for extended periods during recycling processes. This sensitivity limits the processing window and requires precise temperature control throughout the reprocessing stages.

Furthermore, the cost-effectiveness of bio-nylon reprocessing remains a significant hurdle. The complex purification and reconditioning steps required to maintain the quality of recycled bio-nylon can be expensive, potentially making virgin bio-nylon more economically attractive. This economic barrier hinders the widespread adoption of recycling practices in the industry.

Lastly, there is a lack of standardized methods for assessing the quality and properties of reprocessed bio-nylon. This absence of universal benchmarks makes it difficult for manufacturers and consumers to trust and value recycled bio-nylon products, further impeding the growth of the recycling market for this material.

Existing Bio-Nylon Reprocessing Methods

01 Molecular weight control in bio-nylon synthesis

Various methods are employed to control the molecular weight of bio-nylon during synthesis. These include adjusting reaction conditions, using specific catalysts, and implementing precise polymerization techniques. Controlling molecular weight is crucial for achieving desired mechanical and thermal properties in bio-nylon materials.- Molecular weight control in bio-nylon synthesis: Various methods are employed to control the molecular weight of bio-nylon during synthesis. These include adjusting reaction conditions, using specific catalysts, and implementing post-polymerization treatments. Controlling molecular weight is crucial for achieving desired mechanical and thermal properties in bio-nylon materials.

- Bio-nylon blends and composites: Bio-nylon is often blended with other polymers or reinforced with fillers to create composites with tailored molecular weights and enhanced properties. These blends and composites can exhibit improved strength, flexibility, and thermal stability compared to pure bio-nylon.

- Characterization techniques for bio-nylon molecular weight: Various analytical techniques are used to determine the molecular weight of bio-nylon, including gel permeation chromatography (GPC), viscometry, and light scattering methods. These techniques help in quality control and optimization of bio-nylon production processes.

- Effect of molecular weight on bio-nylon properties: The molecular weight of bio-nylon significantly influences its mechanical, thermal, and processing properties. Higher molecular weights generally result in improved tensile strength and impact resistance, while lower molecular weights can enhance processability and flexibility.

- Bio-nylon molecular weight modification techniques: Post-polymerization techniques are employed to modify the molecular weight of bio-nylon. These include solid-state polymerization, chain extension reactions, and controlled degradation processes. Such modifications allow for fine-tuning of bio-nylon properties for specific applications.

02 Bio-nylon blends and composites

Bio-nylon is often blended with other polymers or reinforced with various materials to create composites with enhanced properties. The molecular weight of bio-nylon plays a significant role in determining the compatibility and performance of these blends and composites.Expand Specific Solutions03 Characterization techniques for bio-nylon molecular weight

Various analytical methods are used to determine the molecular weight of bio-nylon, including gel permeation chromatography (GPC), viscometry, and light scattering techniques. These methods help in quality control and ensuring consistent properties of bio-nylon products.Expand Specific Solutions04 Impact of molecular weight on bio-nylon properties

The molecular weight of bio-nylon significantly influences its mechanical, thermal, and chemical properties. Higher molecular weights generally result in improved strength, toughness, and heat resistance, while lower molecular weights may offer better processability and flexibility.Expand Specific Solutions05 Bio-nylon molecular weight modification post-synthesis

Post-synthesis treatments can be applied to modify the molecular weight of bio-nylon. These include solid-state polymerization, chain extension reactions, and controlled degradation processes. Such modifications allow for fine-tuning of bio-nylon properties for specific applications.Expand Specific Solutions

Key Players in Bio-Nylon Reprocessing Industry

The reprocessing of bio-nylon is an emerging field within the broader sustainable materials industry, currently in its early growth stage. The market size is expanding as more companies seek eco-friendly alternatives to traditional petroleum-based nylon. While the technology is still evolving, several key players are making significant strides in developing and commercializing bio-nylon reprocessing techniques. Companies like Aquafil SpA, Genomatica, and Circ LLC are at the forefront, leveraging their expertise in circular economy principles and bio-based materials. Established chemical giants such as DuPont, BASF, and Lanxess are also investing in this area, indicating growing industry interest and potential for scalability.

Aquafil SpA

Technical Solution: Aquafil SpA has developed the ECONYL® Regeneration System, a revolutionary process for recycling nylon waste into new nylon 6 polymer with no loss of quality[1]. This closed-loop system involves collecting nylon waste, such as fishing nets and carpet flooring, then depolymerizing and purifying the material to extract nylon 6. The purified caprolactam is then polymerized into new ECONYL® nylon 6 yarn. This process can be repeated infinitely without degradation in polymer quality or molecular weight[2]. Aquafil's technology allows for the production of 100% recycled nylon with performance equivalent to virgin nylon, while reducing the environmental impact by up to 90% compared to nylon made from oil[3].

Strengths: Infinite recyclability without quality loss, significant environmental benefits, applicable to various nylon waste sources. Weaknesses: Potentially higher production costs compared to virgin nylon, reliance on consistent waste collection infrastructure.

Genomatica, Inc.

Technical Solution: Genomatica has developed a bio-based process for producing caprolactam, the key monomer for nylon 6, using renewable feedstocks instead of petroleum[1]. Their technology employs engineered microorganisms to ferment plant-based sugars into caprolactam. This bio-nylon can be processed using existing equipment and integrated into current supply chains. The process significantly reduces greenhouse gas emissions and eliminates the use of toxic chemicals typically associated with conventional nylon production[2]. Genomatica's approach maintains the molecular weight and properties of the resulting nylon while offering a more sustainable production method. The company has successfully scaled this technology and partnered with major nylon producers to commercialize bio-based nylon 6[3].

Strengths: Renewable feedstock usage, reduced environmental impact, drop-in replacement for conventional nylon. Weaknesses: Potential higher production costs, dependence on agricultural feedstocks.

Molecular Weight Control Innovations

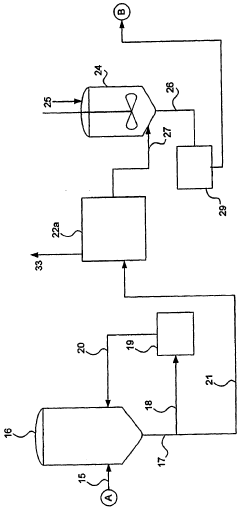

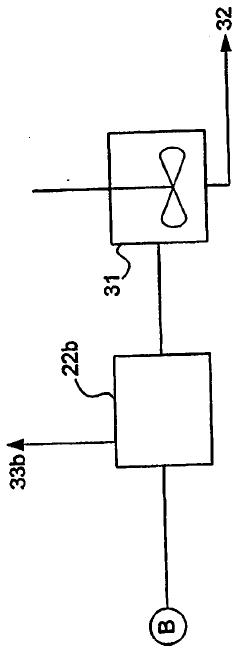

Molecular weight increasing of polyamides

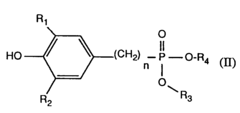

PatentInactiveEP0604367A1

Innovation

- A process involving the heating of polyamides above their melting point with a mixture of polyfunctional epoxy resin and sterically hindered hydroxyphenyl-alkyl-phosphonic acid ester or half-ester, which significantly increases the molecular weight and enhances material properties.

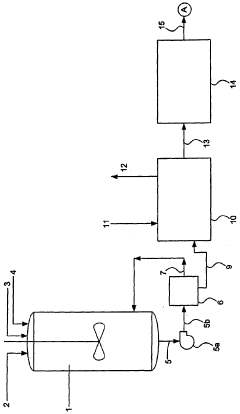

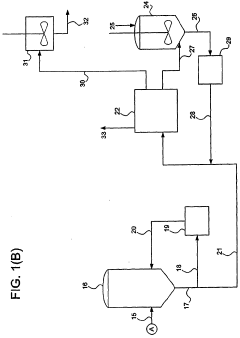

Method for extracting nylon from waste materials

PatentInactiveAU2012216811A1

Innovation

- A method involving contacting nylon waste with an alkanol-containing solvent at elevated temperature and pressure, which reduces the dissolution temperature and time, allowing for the recovery of nylon without significant molecular weight degradation, and using high-efficiency filtration and processing techniques to minimize clogging and enhance recycling efficiency.

Environmental Impact Assessment

The environmental impact assessment of reprocessing bio-nylon is a critical aspect to consider in the context of sustainable materials management. Bio-nylon, derived from renewable resources, offers potential advantages over conventional petroleum-based nylon in terms of reduced carbon footprint and decreased reliance on fossil fuels. However, the reprocessing of bio-nylon presents both opportunities and challenges from an environmental perspective.

One of the primary environmental benefits of reprocessing bio-nylon is the reduction of waste and the conservation of resources. By extending the lifecycle of bio-nylon products through reprocessing, the demand for virgin materials is decreased, leading to lower energy consumption and reduced greenhouse gas emissions associated with raw material extraction and production.

The reprocessing of bio-nylon also contributes to the circular economy model, promoting a more sustainable approach to material use. This closed-loop system helps minimize the environmental impact of bio-nylon by reducing the need for landfill disposal and incineration, which can release harmful emissions and contribute to soil and water pollution.

However, the reprocessing of bio-nylon is not without environmental concerns. The process often involves the use of chemicals and energy-intensive procedures, which can have negative environmental impacts if not properly managed. The use of solvents and other chemical agents in the reprocessing of bio-nylon may lead to air and water pollution if appropriate containment and treatment measures are not implemented.

Energy consumption during the reprocessing of bio-nylon is another significant environmental factor to consider. The heating, melting, and re-extrusion processes required for reprocessing can be energy-intensive, potentially offsetting some of the environmental benefits gained from recycling the material. Implementing energy-efficient technologies and utilizing renewable energy sources in the reprocessing facilities can help mitigate this impact.

Water usage is also a concern in the reprocessing of bio-nylon. The cleaning and purification steps often require substantial amounts of water, which can strain local water resources and generate wastewater that requires treatment before release into the environment. Implementing water recycling systems and optimizing water use efficiency in the reprocessing facilities can help address this issue.

The transportation of bio-nylon materials for reprocessing can contribute to increased carbon emissions, particularly if the reprocessing facilities are located far from the collection points. Developing localized reprocessing infrastructure and optimizing logistics can help minimize the environmental impact associated with transportation.

In conclusion, while the reprocessing of bio-nylon offers significant environmental benefits in terms of waste reduction and resource conservation, it is crucial to carefully manage the potential negative impacts associated with the process. Implementing best practices in chemical management, energy efficiency, water conservation, and transportation logistics is essential to maximize the environmental benefits of bio-nylon reprocessing while minimizing its ecological footprint.

One of the primary environmental benefits of reprocessing bio-nylon is the reduction of waste and the conservation of resources. By extending the lifecycle of bio-nylon products through reprocessing, the demand for virgin materials is decreased, leading to lower energy consumption and reduced greenhouse gas emissions associated with raw material extraction and production.

The reprocessing of bio-nylon also contributes to the circular economy model, promoting a more sustainable approach to material use. This closed-loop system helps minimize the environmental impact of bio-nylon by reducing the need for landfill disposal and incineration, which can release harmful emissions and contribute to soil and water pollution.

However, the reprocessing of bio-nylon is not without environmental concerns. The process often involves the use of chemicals and energy-intensive procedures, which can have negative environmental impacts if not properly managed. The use of solvents and other chemical agents in the reprocessing of bio-nylon may lead to air and water pollution if appropriate containment and treatment measures are not implemented.

Energy consumption during the reprocessing of bio-nylon is another significant environmental factor to consider. The heating, melting, and re-extrusion processes required for reprocessing can be energy-intensive, potentially offsetting some of the environmental benefits gained from recycling the material. Implementing energy-efficient technologies and utilizing renewable energy sources in the reprocessing facilities can help mitigate this impact.

Water usage is also a concern in the reprocessing of bio-nylon. The cleaning and purification steps often require substantial amounts of water, which can strain local water resources and generate wastewater that requires treatment before release into the environment. Implementing water recycling systems and optimizing water use efficiency in the reprocessing facilities can help address this issue.

The transportation of bio-nylon materials for reprocessing can contribute to increased carbon emissions, particularly if the reprocessing facilities are located far from the collection points. Developing localized reprocessing infrastructure and optimizing logistics can help minimize the environmental impact associated with transportation.

In conclusion, while the reprocessing of bio-nylon offers significant environmental benefits in terms of waste reduction and resource conservation, it is crucial to carefully manage the potential negative impacts associated with the process. Implementing best practices in chemical management, energy efficiency, water conservation, and transportation logistics is essential to maximize the environmental benefits of bio-nylon reprocessing while minimizing its ecological footprint.

Quality Control Measures for Recycled Bio-Nylon

Quality control measures are crucial for ensuring the consistency and reliability of recycled bio-nylon products. These measures encompass various stages of the reprocessing process, from raw material selection to final product testing. One of the primary quality control measures is the implementation of rigorous sorting and cleaning procedures for the incoming bio-nylon waste. This step is essential to remove contaminants and ensure a homogeneous feedstock for reprocessing.

Molecular weight analysis is a critical quality control measure for recycled bio-nylon. Regular testing of the molecular weight distribution using techniques such as gel permeation chromatography (GPC) helps monitor the degradation of polymer chains during reprocessing. This information is vital for maintaining the desired mechanical properties of the recycled material.

Thermal analysis techniques, including differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are employed to assess the thermal stability and crystallinity of recycled bio-nylon. These tests provide insights into the material's melting behavior, glass transition temperature, and overall thermal performance, which are essential for ensuring consistent processing and end-use properties.

Mechanical testing is another crucial aspect of quality control for recycled bio-nylon. Tensile strength, elongation at break, and impact resistance tests are routinely performed to verify that the recycled material meets the required specifications. These tests help identify any potential degradation in mechanical properties resulting from the reprocessing steps.

Chemical composition analysis, such as Fourier-transform infrared spectroscopy (FTIR) and nuclear magnetic resonance (NMR) spectroscopy, is used to detect any chemical changes or impurities in the recycled bio-nylon. These techniques can identify the presence of unwanted additives or degradation products that may affect the material's performance or safety.

Rheological measurements are employed to assess the flow behavior of recycled bio-nylon during processing. Melt flow index (MFI) testing and capillary rheometry provide valuable information about the material's processability and help optimize processing parameters for consistent product quality.

Moisture content analysis is particularly important for bio-nylon, as excessive moisture can lead to hydrolysis and degradation during reprocessing. Implementing proper drying procedures and regular moisture content checks helps maintain the quality and stability of the recycled material.

Finally, establishing a comprehensive traceability system is essential for quality control in recycled bio-nylon production. This system should track the material from its source through various reprocessing stages to the final product, enabling quick identification and resolution of any quality issues that may arise.

Molecular weight analysis is a critical quality control measure for recycled bio-nylon. Regular testing of the molecular weight distribution using techniques such as gel permeation chromatography (GPC) helps monitor the degradation of polymer chains during reprocessing. This information is vital for maintaining the desired mechanical properties of the recycled material.

Thermal analysis techniques, including differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), are employed to assess the thermal stability and crystallinity of recycled bio-nylon. These tests provide insights into the material's melting behavior, glass transition temperature, and overall thermal performance, which are essential for ensuring consistent processing and end-use properties.

Mechanical testing is another crucial aspect of quality control for recycled bio-nylon. Tensile strength, elongation at break, and impact resistance tests are routinely performed to verify that the recycled material meets the required specifications. These tests help identify any potential degradation in mechanical properties resulting from the reprocessing steps.

Chemical composition analysis, such as Fourier-transform infrared spectroscopy (FTIR) and nuclear magnetic resonance (NMR) spectroscopy, is used to detect any chemical changes or impurities in the recycled bio-nylon. These techniques can identify the presence of unwanted additives or degradation products that may affect the material's performance or safety.

Rheological measurements are employed to assess the flow behavior of recycled bio-nylon during processing. Melt flow index (MFI) testing and capillary rheometry provide valuable information about the material's processability and help optimize processing parameters for consistent product quality.

Moisture content analysis is particularly important for bio-nylon, as excessive moisture can lead to hydrolysis and degradation during reprocessing. Implementing proper drying procedures and regular moisture content checks helps maintain the quality and stability of the recycled material.

Finally, establishing a comprehensive traceability system is essential for quality control in recycled bio-nylon production. This system should track the material from its source through various reprocessing stages to the final product, enabling quick identification and resolution of any quality issues that may arise.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!