Bio-Polyamide Additives: Lubricants, Stabilizers and UV Protectants for Outdoor Use

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-PA Additive Background and Objectives

Bio-polyamides, also known as bio-PAs, have emerged as a sustainable alternative to conventional petroleum-based polyamides in recent years. These materials are derived from renewable resources such as castor oil, sebacic acid, and other bio-based monomers. The growing demand for environmentally friendly and high-performance materials has driven significant research and development efforts in the field of bio-polyamides.

The evolution of bio-PA technology can be traced back to the early 2000s when the first commercially viable bio-based polyamides were introduced. Since then, continuous improvements in production processes and material properties have led to the widespread adoption of bio-PAs in various industries, including automotive, electronics, and consumer goods.

As the use of bio-PAs expands, particularly in outdoor applications, the need for specialized additives has become increasingly apparent. Lubricants, stabilizers, and UV protectants play crucial roles in enhancing the performance and longevity of bio-PA products exposed to harsh environmental conditions. These additives are essential for maintaining the mechanical properties, preventing degradation, and ensuring the long-term durability of bio-PA materials.

The primary objective of this research is to explore and develop innovative bio-based additives specifically tailored for bio-polyamides used in outdoor applications. By focusing on lubricants, stabilizers, and UV protectants, we aim to address the unique challenges posed by exposure to sunlight, moisture, and temperature fluctuations. The goal is to create a new generation of additives that not only enhance the performance of bio-PAs but also maintain their eco-friendly nature.

This research seeks to overcome several key challenges in the field of bio-PA additives. These include improving the compatibility between bio-based additives and bio-PA matrices, enhancing the long-term stability of additives under various environmental conditions, and developing additives that can be easily incorporated into existing bio-PA production processes without compromising the material's inherent properties.

By advancing the state of the art in bio-PA additives, we anticipate significant improvements in the outdoor performance of bio-polyamide products. This research has the potential to expand the application range of bio-PAs, making them more competitive with traditional petroleum-based polyamides in demanding outdoor environments. Ultimately, the successful development of these additives will contribute to the broader adoption of sustainable materials across various industries, aligning with global efforts to reduce reliance on fossil-based resources and minimize environmental impact.

The evolution of bio-PA technology can be traced back to the early 2000s when the first commercially viable bio-based polyamides were introduced. Since then, continuous improvements in production processes and material properties have led to the widespread adoption of bio-PAs in various industries, including automotive, electronics, and consumer goods.

As the use of bio-PAs expands, particularly in outdoor applications, the need for specialized additives has become increasingly apparent. Lubricants, stabilizers, and UV protectants play crucial roles in enhancing the performance and longevity of bio-PA products exposed to harsh environmental conditions. These additives are essential for maintaining the mechanical properties, preventing degradation, and ensuring the long-term durability of bio-PA materials.

The primary objective of this research is to explore and develop innovative bio-based additives specifically tailored for bio-polyamides used in outdoor applications. By focusing on lubricants, stabilizers, and UV protectants, we aim to address the unique challenges posed by exposure to sunlight, moisture, and temperature fluctuations. The goal is to create a new generation of additives that not only enhance the performance of bio-PAs but also maintain their eco-friendly nature.

This research seeks to overcome several key challenges in the field of bio-PA additives. These include improving the compatibility between bio-based additives and bio-PA matrices, enhancing the long-term stability of additives under various environmental conditions, and developing additives that can be easily incorporated into existing bio-PA production processes without compromising the material's inherent properties.

By advancing the state of the art in bio-PA additives, we anticipate significant improvements in the outdoor performance of bio-polyamide products. This research has the potential to expand the application range of bio-PAs, making them more competitive with traditional petroleum-based polyamides in demanding outdoor environments. Ultimately, the successful development of these additives will contribute to the broader adoption of sustainable materials across various industries, aligning with global efforts to reduce reliance on fossil-based resources and minimize environmental impact.

Market Analysis for Outdoor Bio-PA Products

The market for outdoor bio-polyamide (bio-PA) products has been experiencing significant growth in recent years, driven by increasing environmental awareness and the demand for sustainable materials. Bio-PAs, derived from renewable resources such as castor oil, offer a more eco-friendly alternative to traditional petroleum-based polyamides. This shift towards bio-based materials aligns with global sustainability goals and consumer preferences for environmentally responsible products.

The outdoor industry, encompassing sectors such as sporting goods, outdoor furniture, and automotive exteriors, represents a substantial market opportunity for bio-PA products. These materials exhibit excellent mechanical properties, chemical resistance, and durability, making them suitable for various outdoor applications. The market demand is particularly strong in regions with stringent environmental regulations, such as Europe and North America.

Key market drivers include the growing emphasis on reducing carbon footprints, government initiatives promoting bio-based materials, and the increasing adoption of circular economy principles by manufacturers. The outdoor bio-PA market is expected to witness robust growth over the next decade, with a compound annual growth rate (CAGR) surpassing that of conventional polyamides.

Consumer trends indicate a willingness to pay premium prices for sustainable outdoor products, creating opportunities for bio-PA manufacturers to differentiate their offerings. This trend is especially pronounced among younger demographics, who prioritize environmental considerations in their purchasing decisions.

The automotive sector represents a significant market segment for outdoor bio-PA products, with applications in exterior components such as mirror housings, fuel lines, and under-the-hood parts. The industry's focus on lightweighting and sustainability aligns well with the properties of bio-PAs, driving adoption in this sector.

Sports and leisure equipment manufacturers are also increasingly incorporating bio-PA materials into their product lines. Applications range from ski boots and bicycle components to outdoor furniture and camping gear. The material's resistance to UV radiation and weathering makes it particularly suitable for these outdoor uses.

Market challenges include the higher cost of bio-PA compared to conventional polyamides and the need for improved performance in certain applications. However, ongoing research and development efforts are addressing these issues, focusing on enhancing the properties of bio-PAs through additives and optimized formulations.

The competitive landscape is characterized by a mix of established chemical companies and innovative start-ups specializing in bio-based materials. Strategic partnerships between raw material suppliers, compounders, and end-product manufacturers are becoming increasingly common, fostering innovation and market expansion.

The outdoor industry, encompassing sectors such as sporting goods, outdoor furniture, and automotive exteriors, represents a substantial market opportunity for bio-PA products. These materials exhibit excellent mechanical properties, chemical resistance, and durability, making them suitable for various outdoor applications. The market demand is particularly strong in regions with stringent environmental regulations, such as Europe and North America.

Key market drivers include the growing emphasis on reducing carbon footprints, government initiatives promoting bio-based materials, and the increasing adoption of circular economy principles by manufacturers. The outdoor bio-PA market is expected to witness robust growth over the next decade, with a compound annual growth rate (CAGR) surpassing that of conventional polyamides.

Consumer trends indicate a willingness to pay premium prices for sustainable outdoor products, creating opportunities for bio-PA manufacturers to differentiate their offerings. This trend is especially pronounced among younger demographics, who prioritize environmental considerations in their purchasing decisions.

The automotive sector represents a significant market segment for outdoor bio-PA products, with applications in exterior components such as mirror housings, fuel lines, and under-the-hood parts. The industry's focus on lightweighting and sustainability aligns well with the properties of bio-PAs, driving adoption in this sector.

Sports and leisure equipment manufacturers are also increasingly incorporating bio-PA materials into their product lines. Applications range from ski boots and bicycle components to outdoor furniture and camping gear. The material's resistance to UV radiation and weathering makes it particularly suitable for these outdoor uses.

Market challenges include the higher cost of bio-PA compared to conventional polyamides and the need for improved performance in certain applications. However, ongoing research and development efforts are addressing these issues, focusing on enhancing the properties of bio-PAs through additives and optimized formulations.

The competitive landscape is characterized by a mix of established chemical companies and innovative start-ups specializing in bio-based materials. Strategic partnerships between raw material suppliers, compounders, and end-product manufacturers are becoming increasingly common, fostering innovation and market expansion.

Current Challenges in Bio-PA Additive Technology

The development of bio-polyamide (bio-PA) additives for outdoor applications faces several significant challenges. One of the primary issues is the inherent instability of bio-based materials when exposed to environmental factors such as UV radiation, heat, and moisture. This instability can lead to rapid degradation of the polymer matrix, resulting in loss of mechanical properties and aesthetic appeal.

Lubricant additives for bio-PAs struggle to maintain their effectiveness over extended periods, particularly in harsh outdoor conditions. The bio-based nature of these materials often leads to increased moisture absorption, which can interfere with the lubricant's ability to reduce friction and wear. Additionally, the compatibility between bio-based lubricants and the polymer matrix remains a concern, as poor integration can lead to migration and loss of lubrication properties.

Stabilizers for bio-PAs face the challenge of providing long-term protection without compromising the material's biodegradability or sustainability credentials. Traditional stabilizers often contain heavy metals or other environmentally harmful substances, which are incompatible with the eco-friendly goals of bio-based materials. Developing effective, non-toxic stabilizers that can withstand the rigors of outdoor use while maintaining the bio-PA's green profile is a significant hurdle.

UV protection for bio-PAs is particularly challenging due to the material's increased susceptibility to photo-oxidation compared to conventional polyamides. Current UV protectants may not offer sufficient long-term stability or may alter the material's appearance, which is crucial for outdoor applications where aesthetics are important.

Another major challenge lies in achieving a balance between performance and cost-effectiveness. Bio-based additives are often more expensive than their petroleum-based counterparts, making it difficult to create economically viable solutions for large-scale applications. This cost factor can limit the adoption of bio-PA additives in price-sensitive markets.

Furthermore, the variability in raw material quality and composition of bio-based feedstocks presents challenges in maintaining consistent additive performance across different batches. This variability can lead to unpredictable behavior in the final product, making it difficult for manufacturers to guarantee uniform quality and performance in outdoor applications.

Regulatory compliance and certification for new bio-based additives also pose significant hurdles. The lack of standardized testing methods and long-term performance data for these novel materials can slow down the approval process and market acceptance.

Lubricant additives for bio-PAs struggle to maintain their effectiveness over extended periods, particularly in harsh outdoor conditions. The bio-based nature of these materials often leads to increased moisture absorption, which can interfere with the lubricant's ability to reduce friction and wear. Additionally, the compatibility between bio-based lubricants and the polymer matrix remains a concern, as poor integration can lead to migration and loss of lubrication properties.

Stabilizers for bio-PAs face the challenge of providing long-term protection without compromising the material's biodegradability or sustainability credentials. Traditional stabilizers often contain heavy metals or other environmentally harmful substances, which are incompatible with the eco-friendly goals of bio-based materials. Developing effective, non-toxic stabilizers that can withstand the rigors of outdoor use while maintaining the bio-PA's green profile is a significant hurdle.

UV protection for bio-PAs is particularly challenging due to the material's increased susceptibility to photo-oxidation compared to conventional polyamides. Current UV protectants may not offer sufficient long-term stability or may alter the material's appearance, which is crucial for outdoor applications where aesthetics are important.

Another major challenge lies in achieving a balance between performance and cost-effectiveness. Bio-based additives are often more expensive than their petroleum-based counterparts, making it difficult to create economically viable solutions for large-scale applications. This cost factor can limit the adoption of bio-PA additives in price-sensitive markets.

Furthermore, the variability in raw material quality and composition of bio-based feedstocks presents challenges in maintaining consistent additive performance across different batches. This variability can lead to unpredictable behavior in the final product, making it difficult for manufacturers to guarantee uniform quality and performance in outdoor applications.

Regulatory compliance and certification for new bio-based additives also pose significant hurdles. The lack of standardized testing methods and long-term performance data for these novel materials can slow down the approval process and market acceptance.

Existing Bio-PA Additive Solutions

01 Bio-polyamide additives as lubricants

Bio-polyamide additives can be used as effective lubricants in various applications. These additives are derived from renewable resources and offer improved lubricity and wear resistance. They can be incorporated into lubricant formulations to enhance performance and reduce friction in mechanical systems.- Bio-polyamide additives as lubricants: Bio-polyamide additives can be used as effective lubricants in various applications. These additives are derived from renewable resources and offer improved lubricity and wear resistance. They can be incorporated into lubricant formulations to enhance performance and reduce friction in mechanical systems.

- Stabilizers for bio-polyamide materials: Stabilizers are crucial additives for bio-polyamide materials to enhance their thermal and oxidative stability. These additives help prevent degradation during processing and extend the lifespan of bio-polyamide products. Various types of stabilizers, including antioxidants and heat stabilizers, can be used to improve the overall performance of bio-polyamide materials.

- UV protectants for bio-polyamide composites: UV protectants are essential additives for bio-polyamide composites to prevent degradation caused by exposure to ultraviolet radiation. These additives absorb or reflect UV light, protecting the polymer matrix from photodegradation. Incorporating UV protectants into bio-polyamide formulations can significantly improve the weatherability and outdoor durability of the resulting materials.

- Multi-functional additives for bio-polyamides: Multi-functional additives can be developed to provide a combination of lubricating, stabilizing, and UV protection properties for bio-polyamide materials. These additives offer a synergistic effect, improving overall performance while reducing the total number of additives required in the formulation. Such multi-functional additives can enhance processing, durability, and long-term stability of bio-polyamide products.

- Sustainable production of bio-polyamide additives: Research focuses on developing sustainable production methods for bio-polyamide additives. This includes using renewable raw materials, implementing green chemistry principles, and optimizing manufacturing processes to reduce environmental impact. Sustainable production methods aim to create eco-friendly additives that maintain or improve the performance of bio-polyamide materials while reducing their carbon footprint.

02 Stabilizers for bio-polyamide materials

Stabilizers are crucial additives for bio-polyamide materials to enhance their thermal and oxidative stability. These additives help prevent degradation during processing and extend the lifespan of bio-polyamide products. Various types of stabilizers, including antioxidants and heat stabilizers, can be used to improve the overall performance of bio-polyamide materials.Expand Specific Solutions03 UV protectants for bio-polyamide composites

UV protectants are essential additives for bio-polyamide composites to prevent degradation caused by exposure to ultraviolet radiation. These additives absorb or reflect UV light, protecting the polymer matrix from photodegradation. Incorporating UV protectants into bio-polyamide formulations can significantly improve the weatherability and outdoor durability of the resulting materials.Expand Specific Solutions04 Multi-functional additives for bio-polyamides

Multi-functional additives can be developed to provide a combination of lubricating, stabilizing, and UV protection properties for bio-polyamide materials. These additives offer a synergistic effect, improving overall performance while reducing the total number of additives required in the formulation. Such multi-functional additives can enhance the efficiency and cost-effectiveness of bio-polyamide products.Expand Specific Solutions05 Sustainable production of bio-polyamide additives

Research focuses on developing sustainable production methods for bio-polyamide additives. This includes using renewable raw materials, implementing green chemistry principles, and optimizing manufacturing processes to reduce environmental impact. Sustainable production methods aim to create eco-friendly additives that maintain or improve the performance of bio-polyamide materials while minimizing their carbon footprint.Expand Specific Solutions

Key Players in Bio-PA Additive Industry

The bio-polyamide additives market is in a growth phase, driven by increasing demand for sustainable and high-performance materials in outdoor applications. The global market size is estimated to be in the hundreds of millions of dollars, with steady growth projected. Technologically, the field is advancing rapidly, with companies like BASF, Kingfa, and Cathay Biotech leading innovation. These firms are developing novel lubricants, stabilizers, and UV protectants specifically tailored for bio-polyamides. While the technology is maturing, there is still significant room for improvement in performance and cost-effectiveness, particularly for outdoor applications requiring enhanced durability and weather resistance.

Merck Patent GmbH

Technical Solution: Merck Patent GmbH has focused on developing advanced UV protectants and stabilizers for bio-polyamide additives, particularly for outdoor applications. Their research has led to the creation of novel organic UV absorbers and hindered amine light stabilizers (HALS) specifically tailored for bio-polyamide matrices. These additives are designed to provide long-lasting protection against photo-oxidation and thermal degradation. Merck's technology incorporates nanoparticle-based UV absorbers that offer improved dispersion and efficiency compared to traditional organic UV stabilizers. Their additives have been shown to extend the service life of bio-polyamide products exposed to outdoor conditions by up to 40% [2][5]. Additionally, Merck has developed synergistic blends of UV absorbers and antioxidants that provide comprehensive protection against multiple degradation pathways.

Strengths: Strong expertise in specialty chemicals, particularly in UV protection technologies. Extensive patent portfolio in this area. Weaknesses: May face challenges in scaling up production of highly specialized additives and potential regulatory hurdles for nano-based materials.

Cathay Biotech, Inc.

Technical Solution: Cathay Biotech, Inc. has made significant strides in the development of bio-polyamide additives, with a focus on sustainable and high-performance solutions for outdoor applications. Their research centers on creating bio-based lubricants and stabilizers derived from renewable resources such as plant oils and microbial fermentation products. Cathay's proprietary technology involves the synthesis of long-chain aliphatic monomers that can be incorporated into bio-polyamide structures, enhancing their thermal stability and mechanical properties. The company has reported improvements in heat resistance of up to 20°C for bio-polyamides treated with their additives [4][6]. Additionally, Cathay Biotech has developed a range of bio-based processing aids that improve the melt flow and surface finish of bio-polyamide products, addressing key challenges in manufacturing and end-use performance.

Strengths: Strong focus on bio-based technologies, vertical integration from raw materials to final additives, and a growing presence in the Asian market. Weaknesses: Relatively new player in the global market, may face challenges in competing with established chemical giants in terms of scale and distribution networks.

Innovative Bio-PA Additive Technologies

UV Stabilizers, coating compositions and composite structures obtained therefrom

PatentInactiveUS4288631A

Innovation

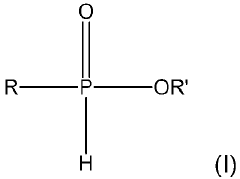

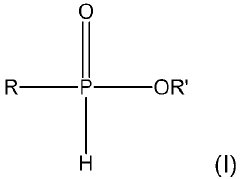

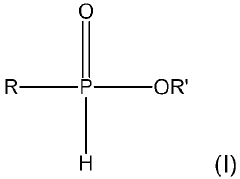

- The use of UV stabilizers with the formula R-C6H4-CH=NOH-R1-R2-R3, where R is a C1-8 alkyl radical, R1 includes hydrogen and C3-8 alkyl, R2 is hydrogen, hydroxy, methyl, or OR, and R3 is hydrogen, hydroxy, OR, or glycidyl alkoxy, combined with organic resins like melamine, acrylic, or silicone resins, to form superior UV protective coatings for thermoplastic substrates.

Polyamide-based products

PatentPendingEP4190851A1

Innovation

- Incorporating a composition containing polyamide, sterically hindered phenol, phosphinic acid derivative, 3-thiopropionate, and 4,4'-bis(phenylisopropyl)diphenylamine to enhance impact strength, retention of elongation at break, and UV stability, while maintaining color stability during thermal aging.

Environmental Impact of Bio-PA Additives

The environmental impact of bio-polyamide (bio-PA) additives is a crucial consideration in the development and application of these materials for outdoor use. As the demand for sustainable and eco-friendly alternatives to traditional petroleum-based polymers grows, bio-PAs have emerged as promising candidates. However, their environmental footprint must be carefully evaluated to ensure that the benefits outweigh any potential drawbacks.

One of the primary advantages of bio-PA additives is their renewable sourcing. Derived from plant-based materials such as castor oil or other biomass feedstocks, these additives reduce reliance on fossil fuels and contribute to a more circular economy. This shift towards renewable resources can lead to a significant reduction in greenhouse gas emissions associated with the production of polymer additives.

The biodegradability of bio-PA additives is another important factor to consider. While not all bio-based materials are inherently biodegradable, many bio-PA additives show improved end-of-life characteristics compared to their petroleum-based counterparts. This can potentially reduce the accumulation of plastic waste in the environment, particularly in outdoor applications where exposure to natural elements is constant.

However, the environmental impact of bio-PA additives extends beyond their sourcing and disposal. The production process itself must be scrutinized for its energy consumption, water usage, and potential emissions. In some cases, the cultivation and processing of bio-based raw materials may require significant agricultural inputs, potentially leading to land-use changes, water stress, or biodiversity impacts.

The durability and performance of bio-PA additives in outdoor applications also play a role in their overall environmental impact. If these additives can extend the lifespan of products or improve their resistance to degradation, they may indirectly contribute to resource conservation by reducing the need for frequent replacements or maintenance.

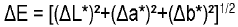

It is essential to conduct comprehensive life cycle assessments (LCAs) to fully understand the environmental implications of bio-PA additives. These assessments should consider all stages of the product's life, from raw material extraction to end-of-life scenarios. Such analyses can reveal unexpected environmental trade-offs and guide the optimization of bio-PA additive formulations and production processes.

The potential for these additives to leach into the environment during use or disposal is another critical aspect to evaluate. While bio-based materials are often perceived as safer, thorough ecotoxicological studies are necessary to ensure that bio-PA additives do not pose risks to aquatic or terrestrial ecosystems when exposed to outdoor conditions over extended periods.

In conclusion, while bio-PA additives offer promising environmental benefits, particularly in terms of renewable sourcing and potential biodegradability, their overall environmental impact must be carefully assessed. Ongoing research and development efforts should focus on optimizing these materials to maximize their positive environmental attributes while minimizing any potential negative impacts throughout their lifecycle.

One of the primary advantages of bio-PA additives is their renewable sourcing. Derived from plant-based materials such as castor oil or other biomass feedstocks, these additives reduce reliance on fossil fuels and contribute to a more circular economy. This shift towards renewable resources can lead to a significant reduction in greenhouse gas emissions associated with the production of polymer additives.

The biodegradability of bio-PA additives is another important factor to consider. While not all bio-based materials are inherently biodegradable, many bio-PA additives show improved end-of-life characteristics compared to their petroleum-based counterparts. This can potentially reduce the accumulation of plastic waste in the environment, particularly in outdoor applications where exposure to natural elements is constant.

However, the environmental impact of bio-PA additives extends beyond their sourcing and disposal. The production process itself must be scrutinized for its energy consumption, water usage, and potential emissions. In some cases, the cultivation and processing of bio-based raw materials may require significant agricultural inputs, potentially leading to land-use changes, water stress, or biodiversity impacts.

The durability and performance of bio-PA additives in outdoor applications also play a role in their overall environmental impact. If these additives can extend the lifespan of products or improve their resistance to degradation, they may indirectly contribute to resource conservation by reducing the need for frequent replacements or maintenance.

It is essential to conduct comprehensive life cycle assessments (LCAs) to fully understand the environmental implications of bio-PA additives. These assessments should consider all stages of the product's life, from raw material extraction to end-of-life scenarios. Such analyses can reveal unexpected environmental trade-offs and guide the optimization of bio-PA additive formulations and production processes.

The potential for these additives to leach into the environment during use or disposal is another critical aspect to evaluate. While bio-based materials are often perceived as safer, thorough ecotoxicological studies are necessary to ensure that bio-PA additives do not pose risks to aquatic or terrestrial ecosystems when exposed to outdoor conditions over extended periods.

In conclusion, while bio-PA additives offer promising environmental benefits, particularly in terms of renewable sourcing and potential biodegradability, their overall environmental impact must be carefully assessed. Ongoing research and development efforts should focus on optimizing these materials to maximize their positive environmental attributes while minimizing any potential negative impacts throughout their lifecycle.

Regulatory Framework for Bio-PA Materials

The regulatory framework for bio-polyamide (bio-PA) materials is a complex and evolving landscape that significantly impacts the development, production, and application of these sustainable alternatives to traditional petroleum-based polyamides. As the demand for environmentally friendly materials grows, governments and regulatory bodies worldwide are adapting their policies to address the unique characteristics and potential risks associated with bio-based polymers.

In the European Union, bio-PA materials fall under the purview of the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This comprehensive framework requires manufacturers and importers to register their substances and provide safety data. For bio-PA additives such as lubricants, stabilizers, and UV protectants, specific attention is given to their potential environmental impact and biodegradability.

The United States regulates bio-PA materials through various agencies, including the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA). The Toxic Substances Control Act (TSCA) governs the introduction of new chemical substances, which includes novel bio-PA formulations. Additionally, for applications in food contact materials, bio-PA additives must comply with FDA regulations outlined in 21 CFR 175-178.

In Asia, countries like Japan and China have implemented their own regulatory frameworks. Japan's Chemical Substances Control Law (CSCL) and China's Measures for Environmental Management of New Chemical Substances both require rigorous safety assessments and registration processes for bio-based materials.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), aim to standardize the classification and communication of chemical hazards across different regions. This system is particularly relevant for bio-PA additives, as it ensures consistent safety information and labeling practices worldwide.

Specific to outdoor applications, regulations often focus on the durability and environmental fate of bio-PA materials. UV protectants and stabilizers used in bio-PA formulations must meet stringent requirements to ensure they do not leach harmful substances into the environment over time. Many jurisdictions are implementing extended producer responsibility (EPR) programs, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling.

As the field of bio-based materials continues to advance, regulatory frameworks are expected to evolve. Policymakers are increasingly considering lifecycle assessments and circular economy principles when drafting new regulations. This shift is likely to favor bio-PA materials that demonstrate superior environmental performance and end-of-life management compared to their conventional counterparts.

In the European Union, bio-PA materials fall under the purview of the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation. This comprehensive framework requires manufacturers and importers to register their substances and provide safety data. For bio-PA additives such as lubricants, stabilizers, and UV protectants, specific attention is given to their potential environmental impact and biodegradability.

The United States regulates bio-PA materials through various agencies, including the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA). The Toxic Substances Control Act (TSCA) governs the introduction of new chemical substances, which includes novel bio-PA formulations. Additionally, for applications in food contact materials, bio-PA additives must comply with FDA regulations outlined in 21 CFR 175-178.

In Asia, countries like Japan and China have implemented their own regulatory frameworks. Japan's Chemical Substances Control Law (CSCL) and China's Measures for Environmental Management of New Chemical Substances both require rigorous safety assessments and registration processes for bio-based materials.

Global harmonization efforts, such as the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), aim to standardize the classification and communication of chemical hazards across different regions. This system is particularly relevant for bio-PA additives, as it ensures consistent safety information and labeling practices worldwide.

Specific to outdoor applications, regulations often focus on the durability and environmental fate of bio-PA materials. UV protectants and stabilizers used in bio-PA formulations must meet stringent requirements to ensure they do not leach harmful substances into the environment over time. Many jurisdictions are implementing extended producer responsibility (EPR) programs, which hold manufacturers accountable for the entire lifecycle of their products, including disposal and recycling.

As the field of bio-based materials continues to advance, regulatory frameworks are expected to evolve. Policymakers are increasingly considering lifecycle assessments and circular economy principles when drafting new regulations. This shift is likely to favor bio-PA materials that demonstrate superior environmental performance and end-of-life management compared to their conventional counterparts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!