Life-Cycle Assessment of Bio-Nylon Components: Data and Methodology

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-Nylon LCA Background and Objectives

Bio-nylon, a sustainable alternative to conventional petroleum-based nylon, has gained significant attention in recent years due to its potential to reduce environmental impacts across various industries. The life-cycle assessment (LCA) of bio-nylon components has become a crucial area of study, aiming to comprehensively evaluate the environmental performance of these materials throughout their entire life cycle.

The development of bio-nylon can be traced back to the early 2000s when researchers began exploring bio-based alternatives to traditional synthetic polymers. As environmental concerns grew and sustainability became a key focus for industries, the demand for eco-friendly materials accelerated the research and development of bio-nylon. This innovative material is derived from renewable resources such as castor oil, corn sugar, or other plant-based feedstocks, offering a promising solution to reduce dependency on fossil fuels.

The primary objective of conducting a life-cycle assessment for bio-nylon components is to quantify and compare the environmental impacts associated with their production, use, and disposal against conventional nylon products. This comprehensive analysis encompasses various environmental indicators, including greenhouse gas emissions, energy consumption, water usage, and waste generation. By examining these factors, researchers and industry professionals can make informed decisions regarding the sustainability and viability of bio-nylon in different applications.

Another critical goal of the LCA is to identify potential areas for improvement in the bio-nylon production process. By analyzing each stage of the life cycle, from raw material extraction to end-of-life scenarios, researchers can pinpoint hotspots where environmental impacts are most significant. This information is invaluable for guiding future research and development efforts, as well as optimizing production processes to further enhance the sustainability profile of bio-nylon components.

Furthermore, the LCA of bio-nylon components aims to provide a standardized methodology for assessing the environmental performance of these materials. This standardization is crucial for ensuring consistency and comparability across different studies and applications. By establishing a robust framework for data collection, analysis, and interpretation, the LCA contributes to the broader understanding of bio-based materials and their potential to mitigate environmental challenges in various industries.

As the demand for sustainable materials continues to grow, the insights gained from bio-nylon LCA studies will play a pivotal role in shaping future policies, industry standards, and consumer preferences. The assessment not only serves as a tool for environmental evaluation but also as a catalyst for innovation in material science and manufacturing processes, driving the transition towards a more sustainable and circular economy.

The development of bio-nylon can be traced back to the early 2000s when researchers began exploring bio-based alternatives to traditional synthetic polymers. As environmental concerns grew and sustainability became a key focus for industries, the demand for eco-friendly materials accelerated the research and development of bio-nylon. This innovative material is derived from renewable resources such as castor oil, corn sugar, or other plant-based feedstocks, offering a promising solution to reduce dependency on fossil fuels.

The primary objective of conducting a life-cycle assessment for bio-nylon components is to quantify and compare the environmental impacts associated with their production, use, and disposal against conventional nylon products. This comprehensive analysis encompasses various environmental indicators, including greenhouse gas emissions, energy consumption, water usage, and waste generation. By examining these factors, researchers and industry professionals can make informed decisions regarding the sustainability and viability of bio-nylon in different applications.

Another critical goal of the LCA is to identify potential areas for improvement in the bio-nylon production process. By analyzing each stage of the life cycle, from raw material extraction to end-of-life scenarios, researchers can pinpoint hotspots where environmental impacts are most significant. This information is invaluable for guiding future research and development efforts, as well as optimizing production processes to further enhance the sustainability profile of bio-nylon components.

Furthermore, the LCA of bio-nylon components aims to provide a standardized methodology for assessing the environmental performance of these materials. This standardization is crucial for ensuring consistency and comparability across different studies and applications. By establishing a robust framework for data collection, analysis, and interpretation, the LCA contributes to the broader understanding of bio-based materials and their potential to mitigate environmental challenges in various industries.

As the demand for sustainable materials continues to grow, the insights gained from bio-nylon LCA studies will play a pivotal role in shaping future policies, industry standards, and consumer preferences. The assessment not only serves as a tool for environmental evaluation but also as a catalyst for innovation in material science and manufacturing processes, driving the transition towards a more sustainable and circular economy.

Market Demand for Sustainable Polymers

The market demand for sustainable polymers, particularly bio-nylon components, has been experiencing significant growth in recent years. This surge is driven by increasing environmental awareness, stringent regulations, and a shift towards circular economy principles across various industries. Bio-nylon, derived from renewable resources, offers a promising alternative to conventional petroleum-based nylon, addressing concerns related to resource depletion and carbon footprint.

The automotive sector has emerged as a key driver for sustainable polymers, with manufacturers seeking lightweight, durable, and eco-friendly materials to improve fuel efficiency and reduce emissions. Bio-nylon components are increasingly being adopted in interior parts, under-the-hood applications, and exterior trim, contributing to the overall sustainability goals of vehicle production.

The textile and apparel industry has also shown a strong inclination towards bio-nylon, particularly in sportswear and outdoor gear. Consumers are increasingly demanding sustainable products, pushing brands to incorporate bio-based materials in their offerings. This trend has led to collaborations between polymer manufacturers and fashion brands to develop innovative, high-performance bio-nylon fabrics.

In the packaging sector, there is a growing interest in bio-nylon films and coatings as alternatives to traditional plastic packaging. The food and beverage industry, in particular, is exploring bio-nylon solutions to address concerns about plastic waste and marine pollution. The material's barrier properties and potential biodegradability make it an attractive option for flexible packaging applications.

The electronics industry is another significant market for bio-nylon components, with manufacturers seeking sustainable materials for casings, connectors, and other parts. As consumer electronics companies strive to improve their environmental credentials, the demand for bio-based polymers in this sector is expected to rise.

The construction industry is also showing interest in bio-nylon for applications such as insulation, piping, and reinforcement materials. The material's durability, chemical resistance, and potential for recycling align well with the industry's sustainability goals.

As the market for sustainable polymers continues to expand, there is an increasing need for comprehensive life-cycle assessments to validate the environmental benefits of bio-nylon components. This demand is driving research and development efforts to improve production processes, enhance material properties, and optimize end-of-life scenarios for bio-nylon products.

The automotive sector has emerged as a key driver for sustainable polymers, with manufacturers seeking lightweight, durable, and eco-friendly materials to improve fuel efficiency and reduce emissions. Bio-nylon components are increasingly being adopted in interior parts, under-the-hood applications, and exterior trim, contributing to the overall sustainability goals of vehicle production.

The textile and apparel industry has also shown a strong inclination towards bio-nylon, particularly in sportswear and outdoor gear. Consumers are increasingly demanding sustainable products, pushing brands to incorporate bio-based materials in their offerings. This trend has led to collaborations between polymer manufacturers and fashion brands to develop innovative, high-performance bio-nylon fabrics.

In the packaging sector, there is a growing interest in bio-nylon films and coatings as alternatives to traditional plastic packaging. The food and beverage industry, in particular, is exploring bio-nylon solutions to address concerns about plastic waste and marine pollution. The material's barrier properties and potential biodegradability make it an attractive option for flexible packaging applications.

The electronics industry is another significant market for bio-nylon components, with manufacturers seeking sustainable materials for casings, connectors, and other parts. As consumer electronics companies strive to improve their environmental credentials, the demand for bio-based polymers in this sector is expected to rise.

The construction industry is also showing interest in bio-nylon for applications such as insulation, piping, and reinforcement materials. The material's durability, chemical resistance, and potential for recycling align well with the industry's sustainability goals.

As the market for sustainable polymers continues to expand, there is an increasing need for comprehensive life-cycle assessments to validate the environmental benefits of bio-nylon components. This demand is driving research and development efforts to improve production processes, enhance material properties, and optimize end-of-life scenarios for bio-nylon products.

Current Challenges in Bio-Nylon LCA

The Life-Cycle Assessment (LCA) of bio-nylon components faces several significant challenges that hinder accurate and comprehensive evaluations. One of the primary obstacles is the lack of standardized and reliable data across the entire production chain. Bio-nylon, being a relatively new material, suffers from limited availability of consistent and comparable datasets, especially in the early stages of raw material sourcing and processing.

The complexity of bio-based feedstock production introduces variability in environmental impacts, depending on factors such as cultivation methods, land use changes, and regional agricultural practices. This variability makes it difficult to establish a uniform baseline for comparison with conventional nylon production. Additionally, the allocation of environmental burdens between bio-nylon and its co-products or by-products remains a contentious issue, leading to potential inconsistencies in LCA results.

Another significant challenge lies in the methodology used for assessing the end-of-life phase of bio-nylon components. The biodegradability and compostability of these materials under various conditions are not yet fully understood, making it challenging to accurately model their environmental impact post-use. The lack of established recycling infrastructure for bio-based materials further complicates the assessment of circular economy potential.

The dynamic nature of the bio-nylon industry, with rapidly evolving production technologies and scaling processes, poses a challenge in maintaining up-to-date LCA data. As production methods improve and become more efficient, older LCA studies may quickly become obsolete, necessitating frequent updates to maintain relevance.

Furthermore, the assessment of indirect land use change (ILUC) impacts associated with bio-based feedstock production remains a contentious and methodologically challenging aspect of bio-nylon LCA. The long-term effects of shifting land use from food crops to industrial biomass production are complex and not easily quantifiable within the typical scope of an LCA study.

Lastly, the comparative assessment between bio-nylon and conventional petroleum-based nylon faces challenges in ensuring a fair and equivalent functional unit for comparison. Differences in material properties, durability, and performance characteristics between bio-based and conventional nylons can lead to discrepancies in how products are used and disposed of, potentially skewing LCA results.

These challenges collectively underscore the need for continued research, methodological refinement, and data collection efforts in the field of bio-nylon LCA. Addressing these issues will be crucial for providing more accurate and reliable assessments to guide sustainable development in the bio-based materials sector.

The complexity of bio-based feedstock production introduces variability in environmental impacts, depending on factors such as cultivation methods, land use changes, and regional agricultural practices. This variability makes it difficult to establish a uniform baseline for comparison with conventional nylon production. Additionally, the allocation of environmental burdens between bio-nylon and its co-products or by-products remains a contentious issue, leading to potential inconsistencies in LCA results.

Another significant challenge lies in the methodology used for assessing the end-of-life phase of bio-nylon components. The biodegradability and compostability of these materials under various conditions are not yet fully understood, making it challenging to accurately model their environmental impact post-use. The lack of established recycling infrastructure for bio-based materials further complicates the assessment of circular economy potential.

The dynamic nature of the bio-nylon industry, with rapidly evolving production technologies and scaling processes, poses a challenge in maintaining up-to-date LCA data. As production methods improve and become more efficient, older LCA studies may quickly become obsolete, necessitating frequent updates to maintain relevance.

Furthermore, the assessment of indirect land use change (ILUC) impacts associated with bio-based feedstock production remains a contentious and methodologically challenging aspect of bio-nylon LCA. The long-term effects of shifting land use from food crops to industrial biomass production are complex and not easily quantifiable within the typical scope of an LCA study.

Lastly, the comparative assessment between bio-nylon and conventional petroleum-based nylon faces challenges in ensuring a fair and equivalent functional unit for comparison. Differences in material properties, durability, and performance characteristics between bio-based and conventional nylons can lead to discrepancies in how products are used and disposed of, potentially skewing LCA results.

These challenges collectively underscore the need for continued research, methodological refinement, and data collection efforts in the field of bio-nylon LCA. Addressing these issues will be crucial for providing more accurate and reliable assessments to guide sustainable development in the bio-based materials sector.

Existing LCA Methodologies for Bio-Nylon

01 Bio-based nylon production methods

Various methods for producing bio-based nylon components are described, including the use of renewable resources and environmentally friendly processes. These methods aim to reduce the carbon footprint of nylon production while maintaining or improving the material's properties.- Bio-based nylon production methods: Various methods for producing bio-based nylon components using renewable resources. These processes often involve fermentation of biomass to create precursor molecules, which are then polymerized to form nylon. The resulting bio-nylon materials offer sustainable alternatives to traditional petroleum-based nylons while maintaining similar properties.

- Nylon composites with natural fibers: Development of nylon composites incorporating natural fibers such as cellulose, hemp, or bamboo. These bio-nylon composites combine the strength and durability of nylon with the eco-friendly properties of natural fibers, resulting in materials with improved sustainability and potentially enhanced mechanical properties.

- Biodegradable nylon formulations: Creation of biodegradable nylon formulations that can break down in natural environments. These materials often incorporate specific additives or modified polymer structures to enhance their biodegradability while maintaining the desired physical properties of traditional nylon during use.

- Bio-nylon applications in textiles: Utilization of bio-based nylon components in textile applications, including clothing, upholstery, and industrial fabrics. These materials offer sustainable alternatives to conventional synthetic fibers while providing comparable performance in terms of strength, durability, and comfort.

- Recycling and upcycling of bio-nylon materials: Development of processes for recycling and upcycling bio-nylon materials to create new products or components. These methods aim to extend the lifecycle of bio-nylon materials, reduce waste, and further improve the overall sustainability of nylon-based products.

02 Nylon composites with enhanced properties

Development of nylon composites incorporating bio-based materials or additives to enhance specific properties such as strength, durability, or heat resistance. These composites aim to expand the application range of bio-nylon in various industries.Expand Specific Solutions03 Biodegradable nylon formulations

Research into biodegradable nylon formulations that maintain the desired mechanical properties while allowing for easier environmental breakdown. These formulations often involve blending nylon with other biodegradable polymers or incorporating specific additives to enhance degradability.Expand Specific Solutions04 Nylon recycling and upcycling techniques

Innovative methods for recycling and upcycling nylon materials, including chemical and mechanical processes. These techniques aim to reduce waste and create a circular economy for nylon products, potentially incorporating bio-based components in the recycling process.Expand Specific Solutions05 Bio-nylon applications in textiles and fibers

Exploration of bio-nylon components in textile and fiber applications, focusing on improving sustainability, performance, and comfort. This includes the development of bio-based nylon fibers and their integration into various textile products.Expand Specific Solutions

Key Players in Bio-Nylon Industry

The Life-Cycle Assessment of Bio-Nylon Components market is in a growth phase, driven by increasing demand for sustainable materials across industries. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is advancing rapidly, with companies like BASF Corp. and Agilent Technologies leading innovation in bio-based nylon production and assessment methodologies. However, the technology is not yet fully mature, as evidenced by ongoing research at institutions like Changzhou University and the Technical University of Denmark. Key players such as IHI Corp. and Kolon Industries are investing in R&D to improve production efficiency and reduce environmental impact, indicating a competitive landscape with significant potential for further development and market expansion.

BASF Corp.

Technical Solution: BASF has developed a comprehensive Life-Cycle Assessment (LCA) methodology for bio-nylon components, focusing on their Ultramid® Ccycled product line. This approach involves a cradle-to-gate analysis, considering raw material extraction, production processes, and end-of-life scenarios. BASF utilizes advanced software tools and databases to collect and analyze data on energy consumption, emissions, and resource use throughout the bio-nylon lifecycle. The company has implemented a mass balance approach to accurately allocate environmental impacts of bio-based feedstocks in their production processes[1]. BASF's LCA methodology also incorporates sensitivity analyses to account for uncertainties in data and regional variations in production conditions[3].

Strengths: Comprehensive cradle-to-gate analysis, advanced software tools for data collection and analysis, mass balance approach for accurate impact allocation. Weaknesses: Potential data gaps in certain regions, complexity in accounting for end-of-life scenarios of bio-nylon products.

Kolon Industries, Inc.

Technical Solution: Kolon Industries has developed a robust Life-Cycle Assessment methodology for their bio-nylon components, particularly focusing on their eco-friendly nylon 6 made from renewable resources. Their approach includes a detailed inventory analysis of raw material inputs, energy consumption, and emissions throughout the production process. Kolon utilizes specialized LCA software to model the environmental impacts across various impact categories, including global warming potential, eutrophication, and resource depletion. The company has implemented a system for continuous data collection from their production facilities, ensuring up-to-date and accurate information for their LCA studies[2]. Kolon's methodology also incorporates scenario analyses to evaluate potential improvements in their bio-nylon production processes[4].

Strengths: Specialized focus on eco-friendly nylon 6, continuous data collection system, scenario analyses for process improvements. Weaknesses: Limited public disclosure of detailed LCA results, potential challenges in assessing long-term environmental impacts of bio-based materials.

Critical Data Sources for Bio-Nylon LCA

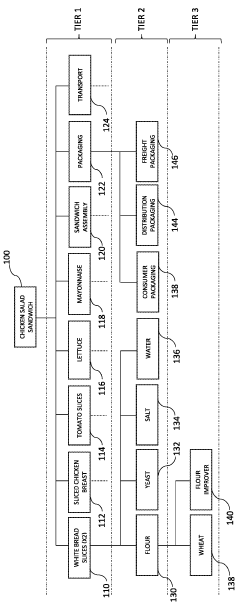

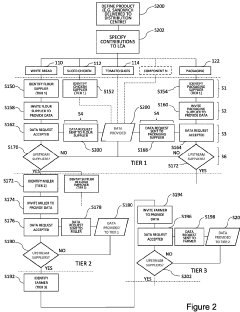

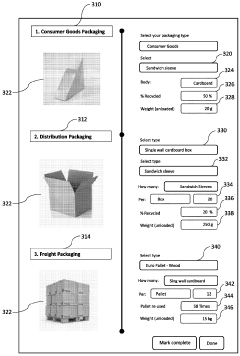

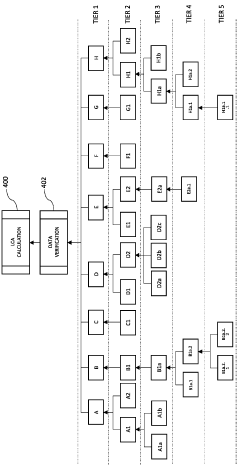

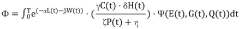

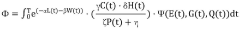

Method of calculating life cycle assessment

PatentInactiveGB2614243A

Innovation

- A method that automatically retrieves and calculates LCA data from a product information database, devolving data collection to suppliers in the supply chain, allowing for more accurate and up-to-date information specific to each component and process, reducing the need for manual intervention and reliance on third-party databases.

Straw-based bioethanol life cycle evaluation method and system

PatentActiveCN117727361A

Innovation

- By collecting straw biometric data, we establish a straw quality assessment model, optimize the raw material pretreatment and fermentation process, establish a life cycle assessment system, and regularly update and optimize the bioethanol production process.

Environmental Regulations Impact

Environmental regulations play a crucial role in shaping the development and implementation of bio-nylon components and their life-cycle assessment methodologies. The increasing global focus on sustainability and environmental protection has led to the establishment of stringent regulations that directly impact the production, use, and disposal of bio-based materials.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has significant implications for bio-nylon manufacturers. This regulation requires companies to register chemical substances and provide detailed information on their environmental and health impacts. As a result, manufacturers must conduct thorough life-cycle assessments to ensure compliance and demonstrate the environmental benefits of their bio-nylon products.

The United States Environmental Protection Agency (EPA) has also implemented regulations that affect bio-nylon production and assessment. The Toxic Substances Control Act (TSCA) requires manufacturers to report new chemical substances and provide data on their potential environmental and health effects. This regulation has prompted the development of more comprehensive life-cycle assessment methodologies for bio-nylon components.

International standards, such as ISO 14040 and ISO 14044, provide guidelines for conducting life-cycle assessments. These standards have been widely adopted and influence the methodologies used in assessing bio-nylon components. Compliance with these standards ensures consistency and comparability in life-cycle assessment results across different regions and industries.

The Paris Agreement and subsequent national climate policies have indirectly impacted the bio-nylon industry by promoting the use of renewable and low-carbon materials. This has led to increased interest in bio-based alternatives to traditional petroleum-derived nylons and has driven the need for more accurate and comprehensive life-cycle assessment methodologies to quantify the environmental benefits of these materials.

Waste management regulations, such as the EU Waste Framework Directive, have also influenced the life-cycle assessment of bio-nylon components. These regulations emphasize the importance of considering end-of-life scenarios and recycling potential in product design and assessment. As a result, life-cycle assessment methodologies for bio-nylon components have evolved to include more detailed analysis of disposal and recycling options.

The growing emphasis on circular economy principles in environmental regulations has further shaped the development of life-cycle assessment methodologies for bio-nylon components. Regulations promoting resource efficiency and waste reduction have led to the incorporation of circularity metrics and indicators in life-cycle assessments, providing a more holistic view of the environmental impact of bio-nylon products throughout their entire life cycle.

In the European Union, the REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation has significant implications for bio-nylon manufacturers. This regulation requires companies to register chemical substances and provide detailed information on their environmental and health impacts. As a result, manufacturers must conduct thorough life-cycle assessments to ensure compliance and demonstrate the environmental benefits of their bio-nylon products.

The United States Environmental Protection Agency (EPA) has also implemented regulations that affect bio-nylon production and assessment. The Toxic Substances Control Act (TSCA) requires manufacturers to report new chemical substances and provide data on their potential environmental and health effects. This regulation has prompted the development of more comprehensive life-cycle assessment methodologies for bio-nylon components.

International standards, such as ISO 14040 and ISO 14044, provide guidelines for conducting life-cycle assessments. These standards have been widely adopted and influence the methodologies used in assessing bio-nylon components. Compliance with these standards ensures consistency and comparability in life-cycle assessment results across different regions and industries.

The Paris Agreement and subsequent national climate policies have indirectly impacted the bio-nylon industry by promoting the use of renewable and low-carbon materials. This has led to increased interest in bio-based alternatives to traditional petroleum-derived nylons and has driven the need for more accurate and comprehensive life-cycle assessment methodologies to quantify the environmental benefits of these materials.

Waste management regulations, such as the EU Waste Framework Directive, have also influenced the life-cycle assessment of bio-nylon components. These regulations emphasize the importance of considering end-of-life scenarios and recycling potential in product design and assessment. As a result, life-cycle assessment methodologies for bio-nylon components have evolved to include more detailed analysis of disposal and recycling options.

The growing emphasis on circular economy principles in environmental regulations has further shaped the development of life-cycle assessment methodologies for bio-nylon components. Regulations promoting resource efficiency and waste reduction have led to the incorporation of circularity metrics and indicators in life-cycle assessments, providing a more holistic view of the environmental impact of bio-nylon products throughout their entire life cycle.

Circular Economy Integration

The integration of circular economy principles into the life-cycle assessment of bio-nylon components represents a significant shift towards sustainable manufacturing practices. This approach aligns with the growing global emphasis on reducing environmental impact and maximizing resource efficiency. By incorporating circular economy concepts, the assessment methodology can be expanded to consider not only the traditional linear production model but also the potential for material recovery, reuse, and regeneration.

In the context of bio-nylon components, circular economy integration involves examining opportunities for closed-loop systems throughout the product lifecycle. This includes evaluating the potential for bio-based feedstocks to be sustainably sourced and regenerated, as well as exploring end-of-life scenarios that prioritize material reclamation and recycling. The assessment methodology should account for the environmental benefits of circular practices, such as reduced virgin material consumption and minimized waste generation.

One key aspect of integrating circular economy principles is the consideration of design for circularity. This involves assessing the potential for bio-nylon components to be easily disassembled, repaired, or remanufactured, thereby extending their useful life and reducing the need for new production. The life-cycle assessment should also evaluate the energy and resource implications of these circular strategies compared to traditional linear production methods.

Furthermore, the integration of circular economy concepts necessitates a broader system boundary for the life-cycle assessment. This expanded scope should encompass the entire value chain, including reverse logistics for material recovery and the infrastructure required to support circular material flows. By doing so, the assessment can provide a more comprehensive understanding of the environmental impacts and potential benefits associated with circular bio-nylon production.

Data collection and analysis methodologies must also be adapted to capture circular economy metrics. This may include developing new indicators to measure circularity performance, such as material circularity index, recycled content percentage, and product lifespan extension factors. These metrics can complement traditional life-cycle assessment indicators to provide a more holistic view of environmental performance within a circular economy framework.

Lastly, the integration of circular economy principles into the life-cycle assessment of bio-nylon components should consider the potential for cascading use of materials. This involves evaluating how bio-nylon materials can be repurposed or downcycled into other applications at the end of their primary use phase, thereby maximizing resource utilization and minimizing waste. The assessment methodology should be capable of quantifying the environmental benefits of such cascading material flows across multiple product life cycles.

In the context of bio-nylon components, circular economy integration involves examining opportunities for closed-loop systems throughout the product lifecycle. This includes evaluating the potential for bio-based feedstocks to be sustainably sourced and regenerated, as well as exploring end-of-life scenarios that prioritize material reclamation and recycling. The assessment methodology should account for the environmental benefits of circular practices, such as reduced virgin material consumption and minimized waste generation.

One key aspect of integrating circular economy principles is the consideration of design for circularity. This involves assessing the potential for bio-nylon components to be easily disassembled, repaired, or remanufactured, thereby extending their useful life and reducing the need for new production. The life-cycle assessment should also evaluate the energy and resource implications of these circular strategies compared to traditional linear production methods.

Furthermore, the integration of circular economy concepts necessitates a broader system boundary for the life-cycle assessment. This expanded scope should encompass the entire value chain, including reverse logistics for material recovery and the infrastructure required to support circular material flows. By doing so, the assessment can provide a more comprehensive understanding of the environmental impacts and potential benefits associated with circular bio-nylon production.

Data collection and analysis methodologies must also be adapted to capture circular economy metrics. This may include developing new indicators to measure circularity performance, such as material circularity index, recycled content percentage, and product lifespan extension factors. These metrics can complement traditional life-cycle assessment indicators to provide a more holistic view of environmental performance within a circular economy framework.

Lastly, the integration of circular economy principles into the life-cycle assessment of bio-nylon components should consider the potential for cascading use of materials. This involves evaluating how bio-nylon materials can be repurposed or downcycled into other applications at the end of their primary use phase, thereby maximizing resource utilization and minimizing waste. The assessment methodology should be capable of quantifying the environmental benefits of such cascading material flows across multiple product life cycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!