How to Mitigate Hydrolytic Degradation in High-Temperature PA Applications

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PA Hydrolysis Background

Polyamides (PAs), commonly known as nylons, are a class of engineering thermoplastics widely used in various high-temperature applications due to their excellent mechanical properties, chemical resistance, and thermal stability. However, one of the significant challenges faced in these applications is hydrolytic degradation, which can severely impact the performance and longevity of PA-based components.

Hydrolytic degradation in PAs occurs when water molecules react with the amide bonds in the polymer chain, leading to chain scission and a reduction in molecular weight. This process is accelerated at elevated temperatures, making it particularly problematic in high-temperature applications. The susceptibility of PAs to hydrolysis is primarily due to the presence of hydrogen-bonded water molecules within the polymer matrix, which can initiate the degradation process.

The extent of hydrolytic degradation in PAs depends on several factors, including the specific type of polyamide, environmental conditions, and the presence of additives or stabilizers. For instance, PA6 and PA66, two of the most common polyamide types, are more susceptible to hydrolysis compared to other variants like PA11 or PA12, which have longer aliphatic segments between amide groups.

In high-temperature applications, the rate of hydrolytic degradation increases exponentially with temperature. This is particularly concerning in automotive under-hood components, electrical and electronic housings, and industrial machinery parts where operating temperatures can exceed 100°C. The presence of moisture in these environments further exacerbates the problem, leading to a significant reduction in mechanical properties, dimensional stability, and overall performance of PA components.

The consequences of hydrolytic degradation in high-temperature PA applications are multifaceted. At the molecular level, it results in a decrease in the average molecular weight of the polymer, leading to a loss of mechanical strength and toughness. This can manifest as embrittlement, cracking, or even complete failure of the component. Additionally, the degradation process can cause changes in the material's surface properties, affecting its appearance and potentially compromising its barrier properties against chemicals or gases.

Understanding the mechanisms and factors influencing hydrolytic degradation is crucial for developing effective mitigation strategies. Research in this area has focused on various approaches, including the development of more hydrolysis-resistant PA grades, the use of stabilizers and additives, and the implementation of protective coatings or treatments. These efforts aim to extend the service life of PA components in high-temperature, moisture-rich environments while maintaining their desirable properties.

Hydrolytic degradation in PAs occurs when water molecules react with the amide bonds in the polymer chain, leading to chain scission and a reduction in molecular weight. This process is accelerated at elevated temperatures, making it particularly problematic in high-temperature applications. The susceptibility of PAs to hydrolysis is primarily due to the presence of hydrogen-bonded water molecules within the polymer matrix, which can initiate the degradation process.

The extent of hydrolytic degradation in PAs depends on several factors, including the specific type of polyamide, environmental conditions, and the presence of additives or stabilizers. For instance, PA6 and PA66, two of the most common polyamide types, are more susceptible to hydrolysis compared to other variants like PA11 or PA12, which have longer aliphatic segments between amide groups.

In high-temperature applications, the rate of hydrolytic degradation increases exponentially with temperature. This is particularly concerning in automotive under-hood components, electrical and electronic housings, and industrial machinery parts where operating temperatures can exceed 100°C. The presence of moisture in these environments further exacerbates the problem, leading to a significant reduction in mechanical properties, dimensional stability, and overall performance of PA components.

The consequences of hydrolytic degradation in high-temperature PA applications are multifaceted. At the molecular level, it results in a decrease in the average molecular weight of the polymer, leading to a loss of mechanical strength and toughness. This can manifest as embrittlement, cracking, or even complete failure of the component. Additionally, the degradation process can cause changes in the material's surface properties, affecting its appearance and potentially compromising its barrier properties against chemicals or gases.

Understanding the mechanisms and factors influencing hydrolytic degradation is crucial for developing effective mitigation strategies. Research in this area has focused on various approaches, including the development of more hydrolysis-resistant PA grades, the use of stabilizers and additives, and the implementation of protective coatings or treatments. These efforts aim to extend the service life of PA components in high-temperature, moisture-rich environments while maintaining their desirable properties.

Market Demand Analysis

The market demand for high-temperature polyamide (PA) applications has been steadily increasing across various industries, driven by the need for materials that can withstand extreme conditions while maintaining their structural integrity. Automotive, aerospace, and industrial sectors are particularly fueling this growth, as they seek lightweight, durable, and heat-resistant materials to improve performance and efficiency.

In the automotive industry, the shift towards electric vehicles and the continuous push for fuel efficiency have created a significant demand for high-temperature PA components. These materials are used in under-the-hood applications, such as air intake manifolds, engine covers, and cooling systems, where resistance to hydrolytic degradation is crucial for long-term reliability.

The aerospace sector is another major driver of market demand for high-temperature PA applications. As aircraft manufacturers strive to reduce weight and improve fuel efficiency, they are increasingly turning to advanced polymers that can withstand the harsh conditions of flight. High-temperature PAs are utilized in various aircraft components, including interior panels, ducting systems, and structural parts, where resistance to hydrolysis is essential for maintaining safety and performance standards.

Industrial applications, such as oil and gas exploration, chemical processing, and power generation, also contribute significantly to the market demand. In these sectors, high-temperature PAs are valued for their ability to withstand corrosive environments and extreme temperatures, making them ideal for use in pumps, valves, seals, and other critical components.

The global market for high-temperature polyamides is projected to experience substantial growth in the coming years. This growth is attributed to the increasing adoption of these materials in emerging economies, ongoing technological advancements, and the development of new applications across various industries.

However, the market demand for high-temperature PA applications is not without challenges. The primary concern is the susceptibility of these materials to hydrolytic degradation, which can compromise their mechanical properties and long-term performance. This issue has created a pressing need for innovative solutions to mitigate hydrolytic degradation, driving research and development efforts in the field.

As industries continue to push the boundaries of material performance, the demand for high-temperature PAs with enhanced resistance to hydrolytic degradation is expected to grow. This trend is likely to spur further investments in research and development, as well as collaborations between material scientists, engineers, and end-users to address this critical challenge and unlock new opportunities in high-performance polymer applications.

In the automotive industry, the shift towards electric vehicles and the continuous push for fuel efficiency have created a significant demand for high-temperature PA components. These materials are used in under-the-hood applications, such as air intake manifolds, engine covers, and cooling systems, where resistance to hydrolytic degradation is crucial for long-term reliability.

The aerospace sector is another major driver of market demand for high-temperature PA applications. As aircraft manufacturers strive to reduce weight and improve fuel efficiency, they are increasingly turning to advanced polymers that can withstand the harsh conditions of flight. High-temperature PAs are utilized in various aircraft components, including interior panels, ducting systems, and structural parts, where resistance to hydrolysis is essential for maintaining safety and performance standards.

Industrial applications, such as oil and gas exploration, chemical processing, and power generation, also contribute significantly to the market demand. In these sectors, high-temperature PAs are valued for their ability to withstand corrosive environments and extreme temperatures, making them ideal for use in pumps, valves, seals, and other critical components.

The global market for high-temperature polyamides is projected to experience substantial growth in the coming years. This growth is attributed to the increasing adoption of these materials in emerging economies, ongoing technological advancements, and the development of new applications across various industries.

However, the market demand for high-temperature PA applications is not without challenges. The primary concern is the susceptibility of these materials to hydrolytic degradation, which can compromise their mechanical properties and long-term performance. This issue has created a pressing need for innovative solutions to mitigate hydrolytic degradation, driving research and development efforts in the field.

As industries continue to push the boundaries of material performance, the demand for high-temperature PAs with enhanced resistance to hydrolytic degradation is expected to grow. This trend is likely to spur further investments in research and development, as well as collaborations between material scientists, engineers, and end-users to address this critical challenge and unlock new opportunities in high-performance polymer applications.

Current Challenges

Hydrolytic degradation poses significant challenges for high-temperature polyamide (PA) applications, particularly in demanding environments such as automotive, aerospace, and industrial sectors. The primary issue stems from the susceptibility of PA materials to moisture absorption, which can lead to a reduction in mechanical properties, dimensional stability, and overall performance.

One of the main challenges is the accelerated rate of hydrolysis at elevated temperatures. As the temperature increases, the rate of water absorption and subsequent chemical reactions within the polymer matrix intensifies. This results in faster degradation of the material, limiting its long-term durability and reliability in high-temperature applications.

The presence of moisture in PA materials can cause chain scission, leading to a decrease in molecular weight and a consequent reduction in mechanical strength. This phenomenon is particularly problematic in load-bearing components or structural applications where maintaining mechanical integrity is crucial. The loss of strength can compromise the safety and functionality of the final product.

Another significant challenge is the impact of hydrolytic degradation on the thermal properties of PA materials. Moisture absorption can alter the glass transition temperature and crystallinity of the polymer, affecting its thermal stability and heat resistance. This change in thermal behavior can lead to unexpected failures or reduced performance in high-temperature environments.

The dimensional stability of PA components is also compromised due to hydrolytic degradation. Moisture absorption causes swelling of the material, leading to changes in dimensions and potential warpage. This dimensional instability can result in fitment issues, reduced precision, and compromised functionality in applications requiring tight tolerances.

Furthermore, the electrical properties of PA materials can be adversely affected by hydrolytic degradation. Moisture absorption can increase the dielectric constant and dissipation factor, potentially leading to electrical failures or reduced insulation performance in high-temperature electrical applications.

The challenge of mitigating hydrolytic degradation is compounded by the diverse range of PA grades and formulations available in the market. Different PA types exhibit varying levels of moisture sensitivity and hydrolysis resistance, making it difficult to develop a one-size-fits-all solution. This diversity necessitates tailored approaches for specific PA grades and application requirements.

Lastly, the development of effective mitigation strategies is hindered by the complex interplay between hydrolytic degradation and other degradation mechanisms, such as thermal oxidation and mechanical stress. These combined effects can accelerate the overall degradation process, making it challenging to isolate and address the hydrolytic component independently.

One of the main challenges is the accelerated rate of hydrolysis at elevated temperatures. As the temperature increases, the rate of water absorption and subsequent chemical reactions within the polymer matrix intensifies. This results in faster degradation of the material, limiting its long-term durability and reliability in high-temperature applications.

The presence of moisture in PA materials can cause chain scission, leading to a decrease in molecular weight and a consequent reduction in mechanical strength. This phenomenon is particularly problematic in load-bearing components or structural applications where maintaining mechanical integrity is crucial. The loss of strength can compromise the safety and functionality of the final product.

Another significant challenge is the impact of hydrolytic degradation on the thermal properties of PA materials. Moisture absorption can alter the glass transition temperature and crystallinity of the polymer, affecting its thermal stability and heat resistance. This change in thermal behavior can lead to unexpected failures or reduced performance in high-temperature environments.

The dimensional stability of PA components is also compromised due to hydrolytic degradation. Moisture absorption causes swelling of the material, leading to changes in dimensions and potential warpage. This dimensional instability can result in fitment issues, reduced precision, and compromised functionality in applications requiring tight tolerances.

Furthermore, the electrical properties of PA materials can be adversely affected by hydrolytic degradation. Moisture absorption can increase the dielectric constant and dissipation factor, potentially leading to electrical failures or reduced insulation performance in high-temperature electrical applications.

The challenge of mitigating hydrolytic degradation is compounded by the diverse range of PA grades and formulations available in the market. Different PA types exhibit varying levels of moisture sensitivity and hydrolysis resistance, making it difficult to develop a one-size-fits-all solution. This diversity necessitates tailored approaches for specific PA grades and application requirements.

Lastly, the development of effective mitigation strategies is hindered by the complex interplay between hydrolytic degradation and other degradation mechanisms, such as thermal oxidation and mechanical stress. These combined effects can accelerate the overall degradation process, making it challenging to isolate and address the hydrolytic component independently.

Existing Mitigation Methods

01 Mechanisms of polyamide hydrolytic degradation

Polyamide hydrolytic degradation occurs through the breaking of amide bonds in the presence of water. This process is influenced by factors such as temperature, pH, and the presence of catalysts. Understanding these mechanisms is crucial for developing strategies to either prevent or control the degradation process in various applications.- Mechanisms of polyamide hydrolytic degradation: Polyamide hydrolytic degradation involves the breaking of amide bonds in the polymer chain due to water absorption. This process is influenced by factors such as temperature, pH, and the presence of catalysts. Understanding these mechanisms is crucial for developing strategies to prevent or control degradation in various applications.

- Additives to improve hydrolytic stability: Various additives can be incorporated into polyamide formulations to enhance their resistance to hydrolytic degradation. These may include stabilizers, antioxidants, and other compounds that protect the polymer structure from water-induced breakdown. The selection of appropriate additives depends on the specific polyamide type and intended application.

- Surface treatments for enhanced hydrolytic resistance: Surface treatments can be applied to polyamide materials to create a protective barrier against moisture penetration. These treatments may involve chemical modifications or the application of coatings that reduce water absorption and subsequent hydrolytic degradation. Such techniques are particularly useful for polyamide components exposed to harsh environmental conditions.

- Recycling and recovery of degraded polyamides: Methods for recycling and recovering polyamides that have undergone hydrolytic degradation are being developed. These processes aim to restore the mechanical and chemical properties of the degraded material, potentially through chemical treatments or repolymerization techniques. Such approaches contribute to the circular economy and sustainability of polyamide materials.

- Monitoring and predicting hydrolytic degradation: Advanced techniques for monitoring and predicting the hydrolytic degradation of polyamides are being developed. These may include spectroscopic methods, mechanical testing, and computational modeling to assess the extent of degradation and predict the material's lifespan under various conditions. Such tools are valuable for quality control and product development in industries using polyamide materials.

02 Stabilization techniques to prevent hydrolytic degradation

Various stabilization techniques can be employed to prevent or slow down the hydrolytic degradation of polyamides. These may include the use of additives, surface treatments, or modifications to the polymer structure. Such techniques aim to enhance the durability and longevity of polyamide-based products in humid environments.Expand Specific Solutions03 Recycling and recovery of degraded polyamides

Methods for recycling and recovering polyamides that have undergone hydrolytic degradation are important for sustainable material management. These processes may involve chemical or mechanical treatments to restore the polymer properties or to convert the degraded material into useful products or precursors.Expand Specific Solutions04 Applications utilizing controlled hydrolytic degradation

Controlled hydrolytic degradation of polyamides can be advantageous in certain applications, such as in biodegradable materials or drug delivery systems. By tailoring the degradation rate, materials can be designed to break down under specific environmental conditions or to release active ingredients over time.Expand Specific Solutions05 Analysis and characterization of hydrolytic degradation

Techniques for analyzing and characterizing the hydrolytic degradation of polyamides are essential for quality control and material development. These may include spectroscopic methods, thermal analysis, mechanical testing, and microscopy to assess the extent and nature of degradation in polyamide materials.Expand Specific Solutions

Key Industry Players

The market for mitigating hydrolytic degradation in high-temperature polyamide applications is in a growth phase, driven by increasing demand for high-performance materials in automotive, aerospace, and industrial sectors. The global market size for specialty polyamides is projected to reach $3.5 billion by 2025, with a CAGR of 6.2%. Technologically, the field is advancing rapidly, with companies like China Petroleum & Chemical Corp., AGC, Inc., and Nippon Shokubai Co., Ltd. leading innovation in polymer stabilization and additive technologies. These firms are developing novel solutions such as advanced heat stabilizers, moisture-resistant additives, and engineered polyamide blends to enhance the hydrolytic stability of PA materials in high-temperature environments.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a novel approach to mitigate hydrolytic degradation in high-temperature polyamide (PA) applications. Their method involves incorporating nano-silica particles into the PA matrix, which act as moisture barriers and improve the overall thermal stability of the material[1]. The company has also implemented a proprietary heat stabilization process that enhances the polymer's resistance to hydrolysis at elevated temperatures[3]. Additionally, Sinopec has developed a new grade of PA with modified end-group chemistry, reducing the number of hydrolysis-susceptible sites and improving long-term performance in high-temperature environments[5].

Strengths: Improved moisture resistance, enhanced thermal stability, and increased longevity of PA materials in high-temperature applications. Weaknesses: Potential increase in production costs and complexity of manufacturing processes.

AGC, Inc. (Japan)

Technical Solution: AGC, Inc. has developed an innovative solution to address hydrolytic degradation in high-temperature PA applications. Their approach involves the use of a proprietary fluoropolymer coating that is applied to the surface of PA components[2]. This coating acts as a barrier against moisture ingress, significantly reducing the rate of hydrolysis. AGC has also developed a new grade of PA that incorporates fluorine-containing monomers into the polymer backbone, enhancing its inherent hydrolysis resistance[4]. Furthermore, the company has implemented a post-processing treatment that involves exposing PA parts to a controlled environment of fluorine gas, which modifies the surface chemistry and improves hydrolytic stability[6].

Strengths: Excellent moisture barrier properties, improved chemical resistance, and enhanced durability in aggressive environments. Weaknesses: Higher production costs and potential limitations in processing flexibility.

Innovative Stabilizers

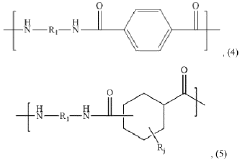

Polyamides and corresponding polymer compositions and articles

PatentWO2020229318A1

Innovation

- A polyamide derived from the polycondensation of a diamine component comprising C4 to C12 aliphatic diamine and bis(aminoalkyl)cyclohexane, and a dicarboxylic acid component with terephthalic acid and cyclohexanedicarboxylic acid, achieving a Tg of at least 145°C, Tm of at least 295°C, and a heat of fusion of at least 30 J/g, enabling improved thermal performance and melt processability.

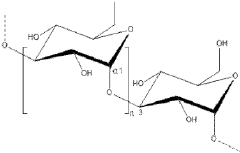

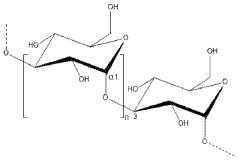

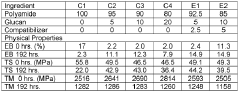

Polyamide compositions

PatentWO2018106574A1

Innovation

- Polyamide compositions comprising poly alpha-1,3-glucan in combination with a compatibilizer, where the polyamide compositions include 20-99 wt.% polyamide, 0.5-40 wt.% poly alpha-1,3-glucan, and 0.5-40 wt.% compatibilizer, enhancing initial elongation at break and hydrolysis resistance.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and application of high-temperature polyamide (PA) materials, particularly in the context of mitigating hydrolytic degradation. These regulations are designed to protect human health and the environment from potential hazards associated with the production, use, and disposal of polymeric materials.

In recent years, there has been an increasing focus on the environmental impact of plastics, including high-temperature PAs. Regulatory bodies worldwide have implemented stricter guidelines for the manufacturing processes, emissions control, and end-of-life management of these materials. For instance, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers to assess and manage the risks associated with substances used in PA production, including those that may contribute to hydrolytic degradation.

The automotive industry, a significant consumer of high-temperature PAs, faces stringent environmental regulations that indirectly influence the development of hydrolysis-resistant materials. For example, the Corporate Average Fuel Economy (CAFE) standards in the United States and similar regulations in other countries push for lighter, more fuel-efficient vehicles. This demand drives the need for high-performance, hydrolysis-resistant PAs that can replace heavier metal components while withstanding harsh under-hood conditions.

Waste management and recycling regulations also impact the development of hydrolysis-resistant PAs. The European Union's End-of-Life Vehicle (ELV) Directive and similar regulations worldwide mandate high recycling rates for automotive components. This has led to increased research into improving the recyclability of high-temperature PAs and developing methods to recover and reuse these materials without compromising their hydrolytic stability.

Water quality regulations indirectly influence the development of hydrolysis-resistant PAs by setting limits on the release of potentially harmful substances into aquatic environments. Manufacturers must ensure that their products do not leach toxic compounds during use or disposal, which could occur as a result of hydrolytic degradation. This regulatory pressure drives innovation in the formulation of more stable and environmentally friendly PA materials.

The growing emphasis on circular economy principles in environmental policy is also shaping the approach to mitigating hydrolytic degradation in high-temperature PA applications. Regulations promoting extended producer responsibility and product stewardship encourage manufacturers to design materials with improved durability and resistance to environmental degradation, including hydrolysis.

As environmental regulations continue to evolve, they are likely to further influence the development of hydrolysis-resistant PAs. Future regulations may focus on promoting bio-based or renewable sources for PA production, reducing the carbon footprint of manufacturing processes, and enhancing the overall sustainability of these materials throughout their lifecycle.

In recent years, there has been an increasing focus on the environmental impact of plastics, including high-temperature PAs. Regulatory bodies worldwide have implemented stricter guidelines for the manufacturing processes, emissions control, and end-of-life management of these materials. For instance, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation requires manufacturers to assess and manage the risks associated with substances used in PA production, including those that may contribute to hydrolytic degradation.

The automotive industry, a significant consumer of high-temperature PAs, faces stringent environmental regulations that indirectly influence the development of hydrolysis-resistant materials. For example, the Corporate Average Fuel Economy (CAFE) standards in the United States and similar regulations in other countries push for lighter, more fuel-efficient vehicles. This demand drives the need for high-performance, hydrolysis-resistant PAs that can replace heavier metal components while withstanding harsh under-hood conditions.

Waste management and recycling regulations also impact the development of hydrolysis-resistant PAs. The European Union's End-of-Life Vehicle (ELV) Directive and similar regulations worldwide mandate high recycling rates for automotive components. This has led to increased research into improving the recyclability of high-temperature PAs and developing methods to recover and reuse these materials without compromising their hydrolytic stability.

Water quality regulations indirectly influence the development of hydrolysis-resistant PAs by setting limits on the release of potentially harmful substances into aquatic environments. Manufacturers must ensure that their products do not leach toxic compounds during use or disposal, which could occur as a result of hydrolytic degradation. This regulatory pressure drives innovation in the formulation of more stable and environmentally friendly PA materials.

The growing emphasis on circular economy principles in environmental policy is also shaping the approach to mitigating hydrolytic degradation in high-temperature PA applications. Regulations promoting extended producer responsibility and product stewardship encourage manufacturers to design materials with improved durability and resistance to environmental degradation, including hydrolysis.

As environmental regulations continue to evolve, they are likely to further influence the development of hydrolysis-resistant PAs. Future regulations may focus on promoting bio-based or renewable sources for PA production, reducing the carbon footprint of manufacturing processes, and enhancing the overall sustainability of these materials throughout their lifecycle.

Lifecycle Assessment

Lifecycle assessment (LCA) plays a crucial role in understanding and mitigating hydrolytic degradation in high-temperature polyamide (PA) applications. This comprehensive approach evaluates the environmental impacts and performance of PA materials throughout their entire lifecycle, from raw material extraction to end-of-life disposal.

In the context of high-temperature PA applications, the LCA process begins with the sourcing and production of raw materials. This stage involves assessing the environmental footprint of extracting and processing the monomers used in PA synthesis. The energy consumption, greenhouse gas emissions, and resource depletion associated with these processes are carefully quantified and analyzed.

The manufacturing phase of high-temperature PA components is a critical stage in the LCA. During this phase, the focus is on evaluating the energy efficiency of production processes, such as injection molding or extrusion. Additionally, the use of additives and stabilizers to enhance hydrolytic resistance is examined, considering their environmental impact and effectiveness in prolonging the material's lifespan.

The use phase of high-temperature PA applications is particularly significant in the LCA. This stage involves assessing the material's performance under various environmental conditions, including exposure to moisture, temperature fluctuations, and mechanical stress. The analysis considers factors such as energy efficiency, durability, and the potential for material degradation over time.

End-of-life considerations are essential in the LCA of high-temperature PA applications. This includes evaluating the recyclability of the material, the energy recovery potential through incineration, and the environmental impact of landfill disposal. The assessment also explores innovative recycling technologies that can effectively process hydrolytically degraded PA materials.

Throughout the LCA, special attention is given to the hydrolytic degradation mechanisms and their environmental implications. This includes analyzing the release of degradation products, such as oligomers and monomers, into the environment and their potential ecological impacts. The assessment also considers the energy and resource requirements for replacing degraded components in various applications.

By conducting a comprehensive LCA, manufacturers and engineers can identify critical points in the lifecycle where hydrolytic degradation has the most significant impact. This information enables the development of targeted strategies to mitigate degradation, such as optimizing material formulations, improving manufacturing processes, or implementing more effective maintenance and replacement schedules.

Furthermore, the LCA provides valuable insights for designing more sustainable high-temperature PA applications. This may involve exploring bio-based alternatives, developing closed-loop recycling systems, or implementing product designs that facilitate easy disassembly and material recovery at the end of life.

In the context of high-temperature PA applications, the LCA process begins with the sourcing and production of raw materials. This stage involves assessing the environmental footprint of extracting and processing the monomers used in PA synthesis. The energy consumption, greenhouse gas emissions, and resource depletion associated with these processes are carefully quantified and analyzed.

The manufacturing phase of high-temperature PA components is a critical stage in the LCA. During this phase, the focus is on evaluating the energy efficiency of production processes, such as injection molding or extrusion. Additionally, the use of additives and stabilizers to enhance hydrolytic resistance is examined, considering their environmental impact and effectiveness in prolonging the material's lifespan.

The use phase of high-temperature PA applications is particularly significant in the LCA. This stage involves assessing the material's performance under various environmental conditions, including exposure to moisture, temperature fluctuations, and mechanical stress. The analysis considers factors such as energy efficiency, durability, and the potential for material degradation over time.

End-of-life considerations are essential in the LCA of high-temperature PA applications. This includes evaluating the recyclability of the material, the energy recovery potential through incineration, and the environmental impact of landfill disposal. The assessment also explores innovative recycling technologies that can effectively process hydrolytically degraded PA materials.

Throughout the LCA, special attention is given to the hydrolytic degradation mechanisms and their environmental implications. This includes analyzing the release of degradation products, such as oligomers and monomers, into the environment and their potential ecological impacts. The assessment also considers the energy and resource requirements for replacing degraded components in various applications.

By conducting a comprehensive LCA, manufacturers and engineers can identify critical points in the lifecycle where hydrolytic degradation has the most significant impact. This information enables the development of targeted strategies to mitigate degradation, such as optimizing material formulations, improving manufacturing processes, or implementing more effective maintenance and replacement schedules.

Furthermore, the LCA provides valuable insights for designing more sustainable high-temperature PA applications. This may involve exploring bio-based alternatives, developing closed-loop recycling systems, or implementing product designs that facilitate easy disassembly and material recovery at the end of life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!