How to Measure Moisture Uptake in Bio-PA and its Effect on Mechanical Tests

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-PA Moisture Uptake Background and Objectives

Bio-based polyamides (Bio-PAs) have emerged as a sustainable alternative to conventional petroleum-based polyamides, offering improved environmental performance and comparable mechanical properties. However, the inherent hydrophilic nature of Bio-PAs presents unique challenges, particularly in terms of moisture uptake and its subsequent effects on mechanical properties. This technical investigation aims to explore the methodologies for measuring moisture absorption in Bio-PAs and to understand how this absorption impacts mechanical test results.

The development of Bio-PAs represents a significant advancement in the field of sustainable polymers. Derived from renewable resources such as castor oil, these materials have gained traction in various industries, including automotive, electronics, and consumer goods. As the demand for eco-friendly materials continues to grow, understanding the behavior of Bio-PAs under different environmental conditions becomes crucial for their successful implementation in diverse applications.

Moisture uptake is a critical factor affecting the performance of Bio-PAs. Unlike their petroleum-based counterparts, Bio-PAs typically exhibit higher moisture absorption rates due to the presence of more polar groups in their molecular structure. This characteristic can lead to changes in dimensional stability, mechanical properties, and long-term durability of Bio-PA components. Therefore, accurately measuring and quantifying moisture uptake is essential for predicting the material's behavior in real-world applications and optimizing its use in various products.

The primary objective of this investigation is to establish reliable methods for measuring moisture uptake in Bio-PAs. This includes exploring both traditional gravimetric techniques and advanced analytical methods such as spectroscopy and thermal analysis. By developing standardized procedures for moisture measurement, we aim to provide industry professionals with tools to assess and compare different Bio-PA grades effectively.

Furthermore, this study seeks to elucidate the relationship between moisture absorption and mechanical properties in Bio-PAs. Understanding how varying levels of moisture content affect tensile strength, impact resistance, and other key mechanical parameters is crucial for designing components that maintain their performance over time and under different environmental conditions. This knowledge will enable engineers and material scientists to make informed decisions when selecting Bio-PAs for specific applications and to develop strategies for mitigating the effects of moisture absorption.

By addressing these objectives, this technical investigation aims to contribute to the broader understanding of Bio-PA behavior and to support the continued adoption of these sustainable materials across various industries. The insights gained from this study will not only enhance the reliability of Bio-PA applications but also pave the way for future innovations in bio-based polymer technology.

The development of Bio-PAs represents a significant advancement in the field of sustainable polymers. Derived from renewable resources such as castor oil, these materials have gained traction in various industries, including automotive, electronics, and consumer goods. As the demand for eco-friendly materials continues to grow, understanding the behavior of Bio-PAs under different environmental conditions becomes crucial for their successful implementation in diverse applications.

Moisture uptake is a critical factor affecting the performance of Bio-PAs. Unlike their petroleum-based counterparts, Bio-PAs typically exhibit higher moisture absorption rates due to the presence of more polar groups in their molecular structure. This characteristic can lead to changes in dimensional stability, mechanical properties, and long-term durability of Bio-PA components. Therefore, accurately measuring and quantifying moisture uptake is essential for predicting the material's behavior in real-world applications and optimizing its use in various products.

The primary objective of this investigation is to establish reliable methods for measuring moisture uptake in Bio-PAs. This includes exploring both traditional gravimetric techniques and advanced analytical methods such as spectroscopy and thermal analysis. By developing standardized procedures for moisture measurement, we aim to provide industry professionals with tools to assess and compare different Bio-PA grades effectively.

Furthermore, this study seeks to elucidate the relationship between moisture absorption and mechanical properties in Bio-PAs. Understanding how varying levels of moisture content affect tensile strength, impact resistance, and other key mechanical parameters is crucial for designing components that maintain their performance over time and under different environmental conditions. This knowledge will enable engineers and material scientists to make informed decisions when selecting Bio-PAs for specific applications and to develop strategies for mitigating the effects of moisture absorption.

By addressing these objectives, this technical investigation aims to contribute to the broader understanding of Bio-PA behavior and to support the continued adoption of these sustainable materials across various industries. The insights gained from this study will not only enhance the reliability of Bio-PA applications but also pave the way for future innovations in bio-based polymer technology.

Market Demand for Bio-PA Moisture Resistance

The market demand for moisture-resistant Bio-PA (bio-based polyamide) has been steadily increasing in recent years, driven by the growing emphasis on sustainable materials and the need for high-performance polymers in various industries. Bio-PA, derived from renewable resources such as castor oil, has gained significant attention as an eco-friendly alternative to traditional petroleum-based polyamides.

One of the primary factors fueling the demand for moisture-resistant Bio-PA is the automotive industry's shift towards lightweight and sustainable materials. As automakers strive to reduce vehicle weight and improve fuel efficiency, Bio-PA offers an attractive solution due to its excellent mechanical properties and lower environmental impact. However, the susceptibility of Bio-PA to moisture absorption has been a concern, as it can affect the material's dimensional stability and mechanical performance.

The packaging industry has also shown a growing interest in moisture-resistant Bio-PA. With the increasing consumer awareness of environmental issues, there is a rising demand for sustainable packaging solutions that can maintain product integrity. Bio-PA's potential to provide both biodegradability and moisture resistance makes it an appealing option for food packaging, cosmetics, and other moisture-sensitive products.

In the electronics sector, the demand for moisture-resistant Bio-PA is driven by the need for durable and environmentally friendly components. As electronic devices become more compact and exposed to various environmental conditions, the ability of Bio-PA to withstand moisture while maintaining its electrical and mechanical properties is highly valued.

The textile industry is another significant market for moisture-resistant Bio-PA. With the growing popularity of performance fabrics and sustainable fashion, Bio-PA fibers that can repel moisture while offering comfort and durability are in high demand. This is particularly relevant for sportswear, outdoor apparel, and technical textiles used in various applications.

The construction industry has also recognized the potential of moisture-resistant Bio-PA in applications such as pipes, fittings, and insulation materials. The ability to withstand moisture exposure while maintaining structural integrity is crucial in these applications, making Bio-PA an attractive alternative to traditional materials.

As environmental regulations become more stringent and consumers increasingly prioritize sustainable products, the demand for moisture-resistant Bio-PA is expected to continue its upward trajectory. Manufacturers and researchers are actively working on improving the moisture resistance of Bio-PA through various techniques, including blending with other polymers, surface treatments, and the development of new grades specifically designed for moisture-sensitive applications.

One of the primary factors fueling the demand for moisture-resistant Bio-PA is the automotive industry's shift towards lightweight and sustainable materials. As automakers strive to reduce vehicle weight and improve fuel efficiency, Bio-PA offers an attractive solution due to its excellent mechanical properties and lower environmental impact. However, the susceptibility of Bio-PA to moisture absorption has been a concern, as it can affect the material's dimensional stability and mechanical performance.

The packaging industry has also shown a growing interest in moisture-resistant Bio-PA. With the increasing consumer awareness of environmental issues, there is a rising demand for sustainable packaging solutions that can maintain product integrity. Bio-PA's potential to provide both biodegradability and moisture resistance makes it an appealing option for food packaging, cosmetics, and other moisture-sensitive products.

In the electronics sector, the demand for moisture-resistant Bio-PA is driven by the need for durable and environmentally friendly components. As electronic devices become more compact and exposed to various environmental conditions, the ability of Bio-PA to withstand moisture while maintaining its electrical and mechanical properties is highly valued.

The textile industry is another significant market for moisture-resistant Bio-PA. With the growing popularity of performance fabrics and sustainable fashion, Bio-PA fibers that can repel moisture while offering comfort and durability are in high demand. This is particularly relevant for sportswear, outdoor apparel, and technical textiles used in various applications.

The construction industry has also recognized the potential of moisture-resistant Bio-PA in applications such as pipes, fittings, and insulation materials. The ability to withstand moisture exposure while maintaining structural integrity is crucial in these applications, making Bio-PA an attractive alternative to traditional materials.

As environmental regulations become more stringent and consumers increasingly prioritize sustainable products, the demand for moisture-resistant Bio-PA is expected to continue its upward trajectory. Manufacturers and researchers are actively working on improving the moisture resistance of Bio-PA through various techniques, including blending with other polymers, surface treatments, and the development of new grades specifically designed for moisture-sensitive applications.

Current Challenges in Bio-PA Moisture Measurement

The measurement of moisture uptake in bio-based polyamides (Bio-PA) and its impact on mechanical properties presents several significant challenges in the field of biopolymer research and development. One of the primary difficulties lies in the inherent hygroscopic nature of Bio-PA materials, which makes them particularly susceptible to moisture absorption from the environment. This characteristic complicates the accurate quantification of moisture content and its distribution within the polymer matrix.

Traditional gravimetric methods, while widely used, often fall short in providing real-time, in-situ measurements of moisture uptake. These methods typically involve weighing samples before and after exposure to humid conditions, which can be time-consuming and may not capture the dynamic nature of moisture absorption and desorption processes. Furthermore, the potential for moisture loss during sample handling and measurement introduces additional uncertainties in the results.

Another challenge is the non-uniform distribution of moisture within Bio-PA samples. The heterogeneous structure of these materials, often resulting from varying degrees of crystallinity and the presence of additives, can lead to localized variations in moisture content. This non-uniformity makes it difficult to obtain representative measurements and necessitates the development of techniques capable of mapping moisture distribution across the sample volume.

The effect of moisture on the mechanical properties of Bio-PA is complex and multifaceted, presenting further challenges in measurement and analysis. Moisture uptake can lead to plasticization, altering the material's viscoelastic behavior and potentially masking or exacerbating other environmental effects. This complexity requires sophisticated testing protocols that can isolate the impact of moisture from other variables and account for time-dependent changes in mechanical properties.

Moreover, the relationship between moisture content and mechanical performance is often non-linear, with critical thresholds that can dramatically alter material behavior. Identifying these thresholds and understanding the underlying mechanisms requires precise control over environmental conditions during testing, which can be technically challenging and resource-intensive.

The development of standardized testing procedures for moisture uptake in Bio-PA is hindered by the diversity of Bio-PA formulations available in the market. Different grades of Bio-PA can exhibit varying moisture absorption characteristics, necessitating tailored measurement approaches. This lack of standardization makes it difficult to compare results across different studies and impedes the establishment of industry-wide benchmarks for moisture-related performance.

Lastly, the integration of moisture uptake measurements with mechanical testing poses significant experimental design challenges. Ensuring that samples maintain their moisture content during mechanical testing, particularly in dynamic or high-strain rate tests, requires innovative sample preparation and testing apparatus designs. These challenges underscore the need for advanced, multidisciplinary approaches to fully characterize the moisture-dependent behavior of Bio-PA materials.

Traditional gravimetric methods, while widely used, often fall short in providing real-time, in-situ measurements of moisture uptake. These methods typically involve weighing samples before and after exposure to humid conditions, which can be time-consuming and may not capture the dynamic nature of moisture absorption and desorption processes. Furthermore, the potential for moisture loss during sample handling and measurement introduces additional uncertainties in the results.

Another challenge is the non-uniform distribution of moisture within Bio-PA samples. The heterogeneous structure of these materials, often resulting from varying degrees of crystallinity and the presence of additives, can lead to localized variations in moisture content. This non-uniformity makes it difficult to obtain representative measurements and necessitates the development of techniques capable of mapping moisture distribution across the sample volume.

The effect of moisture on the mechanical properties of Bio-PA is complex and multifaceted, presenting further challenges in measurement and analysis. Moisture uptake can lead to plasticization, altering the material's viscoelastic behavior and potentially masking or exacerbating other environmental effects. This complexity requires sophisticated testing protocols that can isolate the impact of moisture from other variables and account for time-dependent changes in mechanical properties.

Moreover, the relationship between moisture content and mechanical performance is often non-linear, with critical thresholds that can dramatically alter material behavior. Identifying these thresholds and understanding the underlying mechanisms requires precise control over environmental conditions during testing, which can be technically challenging and resource-intensive.

The development of standardized testing procedures for moisture uptake in Bio-PA is hindered by the diversity of Bio-PA formulations available in the market. Different grades of Bio-PA can exhibit varying moisture absorption characteristics, necessitating tailored measurement approaches. This lack of standardization makes it difficult to compare results across different studies and impedes the establishment of industry-wide benchmarks for moisture-related performance.

Lastly, the integration of moisture uptake measurements with mechanical testing poses significant experimental design challenges. Ensuring that samples maintain their moisture content during mechanical testing, particularly in dynamic or high-strain rate tests, requires innovative sample preparation and testing apparatus designs. These challenges underscore the need for advanced, multidisciplinary approaches to fully characterize the moisture-dependent behavior of Bio-PA materials.

Existing Methods for Bio-PA Moisture Uptake Quantification

01 Moisture absorption properties of Bio-PA materials

Bio-based polyamides (Bio-PA) exhibit unique moisture absorption characteristics. These materials can absorb and retain moisture from the environment, which affects their mechanical and physical properties. The moisture uptake of Bio-PA is influenced by factors such as chemical structure, crystallinity, and environmental conditions.- Moisture absorption properties of Bio-PA materials: Bio-based polyamides (Bio-PA) exhibit unique moisture absorption characteristics. These materials can absorb and retain moisture from the environment, which affects their mechanical and physical properties. The moisture uptake of Bio-PA is influenced by factors such as chemical composition, molecular structure, and environmental conditions.

- Methods for measuring moisture uptake in Bio-PA: Various techniques are employed to measure moisture uptake in Bio-PA materials. These methods include gravimetric analysis, spectroscopic techniques, and specialized moisture analyzers. Accurate measurement of moisture content is crucial for understanding the material's behavior and optimizing its performance in different applications.

- Strategies to control moisture uptake in Bio-PA: Researchers have developed strategies to control moisture uptake in Bio-PA materials. These approaches include modifying the polymer structure, incorporating hydrophobic additives, and applying surface treatments. By controlling moisture absorption, the dimensional stability and mechanical properties of Bio-PA can be improved for specific applications.

- Impact of moisture uptake on Bio-PA properties: Moisture absorption significantly affects the properties of Bio-PA materials. It can influence mechanical strength, dimensional stability, electrical properties, and thermal behavior. Understanding these effects is crucial for designing products and selecting appropriate Bio-PA grades for specific applications, especially in environments with varying humidity levels.

- Applications leveraging moisture uptake of Bio-PA: The moisture absorption properties of Bio-PA are being exploited in various applications. These include moisture-sensitive sensors, smart textiles, and biomedical devices. By utilizing the material's ability to absorb and release moisture, innovative products are being developed that respond to changes in environmental humidity or body moisture levels.

02 Methods for measuring moisture uptake in Bio-PA

Various techniques are employed to measure moisture uptake in Bio-PA materials. These include gravimetric analysis, spectroscopic methods, and specialized moisture analyzers. The measurement protocols often involve exposing samples to controlled humidity environments and monitoring weight changes over time.Expand Specific Solutions03 Strategies to control moisture uptake in Bio-PA

Researchers have developed strategies to control moisture uptake in Bio-PA materials. These include modifying the polymer structure, incorporating hydrophobic additives, and applying surface treatments. Such approaches aim to enhance the material's stability and performance in humid environments.Expand Specific Solutions04 Applications leveraging Bio-PA moisture uptake properties

The moisture uptake properties of Bio-PA materials are utilized in various applications. These include moisture-sensitive packaging, humidity sensors, and biomedical devices. The ability of Bio-PA to absorb and release moisture in a controlled manner is exploited in these applications.Expand Specific Solutions05 Impact of moisture uptake on Bio-PA performance

Moisture uptake significantly influences the performance of Bio-PA materials. It affects mechanical properties, dimensional stability, and electrical characteristics. Understanding these impacts is crucial for designing products and selecting appropriate Bio-PA grades for specific applications.Expand Specific Solutions

Key Players in Bio-PA and Moisture Analysis Industry

The market for measuring moisture uptake in Bio-PA and its effect on mechanical tests is in a growth phase, driven by increasing demand for sustainable materials in various industries. The global bio-based polyamide market is expected to reach $2.5 billion by 2025, with a CAGR of 12.5%. Technologically, the field is advancing rapidly, with companies like DuPont, Evonik, and Cathay Biotech leading innovation. These firms are developing sophisticated moisture measurement techniques and exploring the relationship between moisture content and mechanical properties. While the technology is maturing, there's still room for improvement in standardization and real-time monitoring methods, presenting opportunities for new entrants and collaborations among existing players.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced techniques for measuring moisture uptake in Bio-PA materials. They utilize a combination of gravimetric analysis and dynamic vapor sorption (DVS) to accurately quantify moisture absorption[1]. Their method involves precise weight measurements before and after exposure to controlled humidity environments. Additionally, they employ differential scanning calorimetry (DSC) to assess the impact of moisture on the material's thermal properties, providing insights into how water uptake affects the polymer structure[2]. For mechanical testing, Evonik uses environmental chambers to condition samples at specific humidity levels before conducting tensile, flexural, and impact tests[3].

Strengths: Comprehensive approach combining multiple analytical techniques. Precise control over environmental conditions. Weaknesses: Potentially time-consuming process. May require specialized equipment not readily available in all labs.

DuPont de Nemours, Inc.

Technical Solution: DuPont employs a multi-faceted approach to measure moisture uptake in Bio-PA and its effects on mechanical properties. They use a combination of weight gain measurements and Karl Fischer titration for accurate moisture content determination[4]. For assessing the impact on mechanical properties, DuPont utilizes dynamic mechanical analysis (DMA) to measure changes in viscoelastic properties as a function of moisture content[5]. They also conduct creep tests under various humidity conditions to evaluate long-term performance. DuPont's method includes the use of nuclear magnetic resonance (NMR) spectroscopy to study the molecular-level interactions between water and the Bio-PA matrix[6].

Strengths: Comprehensive analysis of both macro and molecular-level effects. Ability to predict long-term performance under various humidity conditions. Weaknesses: Some techniques like NMR may be costly and require specialized expertise.

Innovative Approaches in Moisture-Mechanical Property Correlation

Filament containing polyamide (PA) polymer and its use for additive manufacturing

PatentWO2023180534A1

Innovation

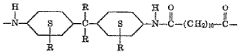

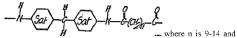

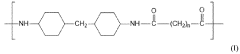

- A filament composed of a polymer composition with at least 50% polyamide comprising recurring units derived from 4,4'-diaminodicyclohexylmethane in a trans/trans configuration, combined with thermoplastic polymers and additives, which provides improved thermal and mechanical properties, reduced water uptake, and UV resistance.

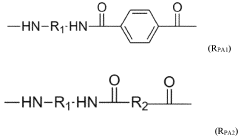

Bio based polyamides and corresponding polymer compositions

PatentWO2024061921A1

Innovation

- A semi-aromatic copolyamide is developed with a specific composition of diamines and dicarboxylic acids, including biobased components, which provides a balance of thermal properties, processability, and moisture resistance through polycondensation, resulting in a polyamide with a melting point between 238°C and 300°C, a glass transition temperature of at least 115°C, and a bio-content of at least 30%, along with limited water uptake.

Environmental Factors Affecting Bio-PA Moisture Uptake

The moisture uptake in Bio-PA (bio-based polyamides) is significantly influenced by various environmental factors, which play a crucial role in determining the material's performance and mechanical properties. Temperature is one of the primary factors affecting moisture absorption in Bio-PA. Higher temperatures generally accelerate the rate of moisture uptake, as the increased thermal energy enhances the mobility of water molecules, allowing them to penetrate the polymer matrix more easily. Conversely, lower temperatures tend to slow down the moisture absorption process.

Relative humidity (RH) is another critical environmental factor that directly impacts the moisture uptake in Bio-PA. As the RH increases, the concentration gradient of water vapor between the environment and the material becomes more pronounced, driving higher rates of moisture absorption. Bio-PA exposed to high humidity environments will typically absorb more moisture compared to those in low humidity conditions.

The duration of exposure to these environmental conditions also plays a significant role in moisture uptake. Longer exposure times allow for more moisture to be absorbed by the Bio-PA, potentially reaching equilibrium moisture content if given sufficient time. This time-dependent behavior is essential to consider when evaluating the material's long-term performance in various applications.

Surface area to volume ratio of the Bio-PA sample or component is another factor that can influence moisture uptake rates. Samples with higher surface area to volume ratios tend to absorb moisture more rapidly due to increased exposure to the surrounding environment. This factor is particularly important when considering different geometries and sizes of Bio-PA parts in practical applications.

Environmental cycling, such as alternating periods of high and low humidity or temperature fluctuations, can also affect moisture uptake patterns in Bio-PA. These cyclic conditions can lead to complex moisture absorption and desorption behaviors, potentially causing cumulative effects on the material's properties over time.

The presence of other environmental factors, such as UV radiation or chemical exposure, may indirectly influence moisture uptake by altering the surface properties or chemical structure of the Bio-PA. These factors can potentially create additional pathways for moisture ingress or modify the material's affinity for water molecules.

Understanding and accounting for these environmental factors is crucial when designing experiments to measure moisture uptake in Bio-PA and evaluating its effects on mechanical properties. Controlled environmental chambers and standardized testing protocols are often employed to ensure consistent and reproducible results across different studies and applications.

Relative humidity (RH) is another critical environmental factor that directly impacts the moisture uptake in Bio-PA. As the RH increases, the concentration gradient of water vapor between the environment and the material becomes more pronounced, driving higher rates of moisture absorption. Bio-PA exposed to high humidity environments will typically absorb more moisture compared to those in low humidity conditions.

The duration of exposure to these environmental conditions also plays a significant role in moisture uptake. Longer exposure times allow for more moisture to be absorbed by the Bio-PA, potentially reaching equilibrium moisture content if given sufficient time. This time-dependent behavior is essential to consider when evaluating the material's long-term performance in various applications.

Surface area to volume ratio of the Bio-PA sample or component is another factor that can influence moisture uptake rates. Samples with higher surface area to volume ratios tend to absorb moisture more rapidly due to increased exposure to the surrounding environment. This factor is particularly important when considering different geometries and sizes of Bio-PA parts in practical applications.

Environmental cycling, such as alternating periods of high and low humidity or temperature fluctuations, can also affect moisture uptake patterns in Bio-PA. These cyclic conditions can lead to complex moisture absorption and desorption behaviors, potentially causing cumulative effects on the material's properties over time.

The presence of other environmental factors, such as UV radiation or chemical exposure, may indirectly influence moisture uptake by altering the surface properties or chemical structure of the Bio-PA. These factors can potentially create additional pathways for moisture ingress or modify the material's affinity for water molecules.

Understanding and accounting for these environmental factors is crucial when designing experiments to measure moisture uptake in Bio-PA and evaluating its effects on mechanical properties. Controlled environmental chambers and standardized testing protocols are often employed to ensure consistent and reproducible results across different studies and applications.

Standardization of Moisture-Related Mechanical Tests for Bio-PA

The standardization of moisture-related mechanical tests for Bio-PA is crucial for ensuring consistent and reliable results across different laboratories and research institutions. This process involves establishing uniform procedures for sample preparation, conditioning, and testing methodologies that account for the unique moisture absorption characteristics of bio-based polyamides.

One of the primary challenges in standardizing these tests is the variability in moisture uptake rates and equilibrium moisture content among different Bio-PA formulations. To address this, a comprehensive approach to moisture conditioning is necessary. This typically involves exposing samples to controlled humidity environments for specified periods, with regular weight measurements to track moisture absorption until equilibrium is reached.

The development of standardized testing protocols must consider the influence of moisture on various mechanical properties, including tensile strength, flexural modulus, and impact resistance. These protocols should specify precise environmental conditions, such as temperature and relative humidity, during both conditioning and testing phases. Additionally, they must define acceptable ranges for moisture content in test specimens to ensure comparability of results.

Interlaboratory studies play a crucial role in validating and refining these standardized methods. These collaborative efforts help identify potential sources of variability and establish reproducibility limits for moisture-related mechanical tests on Bio-PA materials. The results of such studies contribute to the development of robust testing standards that can be widely adopted by the industry.

Another important aspect of standardization is the selection and calibration of appropriate testing equipment. This includes humidity chambers for conditioning, precision balances for moisture content determination, and mechanical testing machines equipped with environmental controls. Standardized procedures for equipment calibration and maintenance are essential to minimize measurement uncertainties.

The standardization process also involves establishing clear guidelines for reporting test results. This includes specifying the format for presenting moisture content data, mechanical property values, and relevant testing conditions. Standardized reporting practices facilitate easier comparison of results across different studies and aid in the development of material databases for Bio-PA.

As the field of bio-based polymers continues to evolve, these standardization efforts must remain dynamic. Regular reviews and updates to testing standards are necessary to incorporate new insights into the moisture behavior of Bio-PA materials and advancements in testing technologies. This ongoing process ensures that standardized methods remain relevant and effective in characterizing the performance of these materials under various moisture conditions.

One of the primary challenges in standardizing these tests is the variability in moisture uptake rates and equilibrium moisture content among different Bio-PA formulations. To address this, a comprehensive approach to moisture conditioning is necessary. This typically involves exposing samples to controlled humidity environments for specified periods, with regular weight measurements to track moisture absorption until equilibrium is reached.

The development of standardized testing protocols must consider the influence of moisture on various mechanical properties, including tensile strength, flexural modulus, and impact resistance. These protocols should specify precise environmental conditions, such as temperature and relative humidity, during both conditioning and testing phases. Additionally, they must define acceptable ranges for moisture content in test specimens to ensure comparability of results.

Interlaboratory studies play a crucial role in validating and refining these standardized methods. These collaborative efforts help identify potential sources of variability and establish reproducibility limits for moisture-related mechanical tests on Bio-PA materials. The results of such studies contribute to the development of robust testing standards that can be widely adopted by the industry.

Another important aspect of standardization is the selection and calibration of appropriate testing equipment. This includes humidity chambers for conditioning, precision balances for moisture content determination, and mechanical testing machines equipped with environmental controls. Standardized procedures for equipment calibration and maintenance are essential to minimize measurement uncertainties.

The standardization process also involves establishing clear guidelines for reporting test results. This includes specifying the format for presenting moisture content data, mechanical property values, and relevant testing conditions. Standardized reporting practices facilitate easier comparison of results across different studies and aid in the development of material databases for Bio-PA.

As the field of bio-based polymers continues to evolve, these standardization efforts must remain dynamic. Regular reviews and updates to testing standards are necessary to incorporate new insights into the moisture behavior of Bio-PA materials and advancements in testing technologies. This ongoing process ensures that standardized methods remain relevant and effective in characterizing the performance of these materials under various moisture conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!