How to Use Rheology Data to Optimize Bio-PA Melt Processing

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-PA Rheology Background and Objectives

Bio-based polyamides (Bio-PAs) have emerged as a sustainable alternative to conventional petroleum-based polyamides, offering comparable mechanical properties while reducing environmental impact. The development and optimization of Bio-PA processing techniques have become increasingly important in recent years, with rheology playing a crucial role in understanding and improving melt processing.

Rheology, the study of flow and deformation of matter, is fundamental to polymer processing. In the context of Bio-PAs, rheological data provides invaluable insights into the material's behavior during melt processing, enabling manufacturers to optimize processing conditions and enhance product quality. The primary objective of utilizing rheology data in Bio-PA melt processing is to achieve optimal flow characteristics, thermal stability, and final product properties.

The evolution of Bio-PA technology has been marked by significant advancements in both material composition and processing techniques. Early Bio-PAs faced challenges related to thermal stability and processability, which limited their widespread adoption. However, recent developments in bio-based monomers and polymerization techniques have led to improved Bio-PA grades with enhanced melt stability and processability.

Current trends in Bio-PA rheology research focus on understanding the relationship between molecular structure, processing conditions, and final product properties. This includes investigating the effects of bio-based content, molecular weight distribution, and branching on melt viscosity, elasticity, and thermal sensitivity. Additionally, there is growing interest in developing predictive models that can correlate rheological data with processing parameters and end-use performance.

The ultimate goal of leveraging rheology data in Bio-PA melt processing is to establish a comprehensive framework for process optimization. This involves developing strategies to control and manipulate melt behavior during various processing operations, such as extrusion, injection molding, and film blowing. By fine-tuning processing parameters based on rheological insights, manufacturers can achieve improved product consistency, reduced cycle times, and enhanced material efficiency.

Furthermore, the integration of rheology data into Bio-PA processing aims to expand the application range of these sustainable materials. As the demand for eco-friendly alternatives continues to grow across industries, optimizing Bio-PA melt processing through rheological analysis becomes crucial for meeting diverse performance requirements and competing with traditional petroleum-based polymers.

In conclusion, the utilization of rheology data in Bio-PA melt processing represents a critical area of research and development in the field of sustainable polymers. By advancing our understanding of Bio-PA rheology and its implications for processing, we can unlock new possibilities for these materials and accelerate their adoption in various industrial applications.

Rheology, the study of flow and deformation of matter, is fundamental to polymer processing. In the context of Bio-PAs, rheological data provides invaluable insights into the material's behavior during melt processing, enabling manufacturers to optimize processing conditions and enhance product quality. The primary objective of utilizing rheology data in Bio-PA melt processing is to achieve optimal flow characteristics, thermal stability, and final product properties.

The evolution of Bio-PA technology has been marked by significant advancements in both material composition and processing techniques. Early Bio-PAs faced challenges related to thermal stability and processability, which limited their widespread adoption. However, recent developments in bio-based monomers and polymerization techniques have led to improved Bio-PA grades with enhanced melt stability and processability.

Current trends in Bio-PA rheology research focus on understanding the relationship between molecular structure, processing conditions, and final product properties. This includes investigating the effects of bio-based content, molecular weight distribution, and branching on melt viscosity, elasticity, and thermal sensitivity. Additionally, there is growing interest in developing predictive models that can correlate rheological data with processing parameters and end-use performance.

The ultimate goal of leveraging rheology data in Bio-PA melt processing is to establish a comprehensive framework for process optimization. This involves developing strategies to control and manipulate melt behavior during various processing operations, such as extrusion, injection molding, and film blowing. By fine-tuning processing parameters based on rheological insights, manufacturers can achieve improved product consistency, reduced cycle times, and enhanced material efficiency.

Furthermore, the integration of rheology data into Bio-PA processing aims to expand the application range of these sustainable materials. As the demand for eco-friendly alternatives continues to grow across industries, optimizing Bio-PA melt processing through rheological analysis becomes crucial for meeting diverse performance requirements and competing with traditional petroleum-based polymers.

In conclusion, the utilization of rheology data in Bio-PA melt processing represents a critical area of research and development in the field of sustainable polymers. By advancing our understanding of Bio-PA rheology and its implications for processing, we can unlock new possibilities for these materials and accelerate their adoption in various industrial applications.

Market Analysis for Bio-PA Applications

The market for Bio-PA (Bio-based Polyamides) applications has been experiencing significant growth in recent years, driven by increasing environmental awareness and the push for sustainable alternatives to traditional petroleum-based polymers. Bio-PAs offer a unique combination of performance characteristics and eco-friendliness, making them attractive for various industries.

The automotive sector represents a major market for Bio-PA applications. As automakers strive to reduce vehicle weight and improve fuel efficiency, Bio-PAs are increasingly used in under-the-hood components, interior parts, and exterior applications. The material's high heat resistance, chemical stability, and mechanical strength make it suitable for replacing metal parts, contributing to overall weight reduction and improved fuel economy.

In the electronics industry, Bio-PAs are gaining traction due to their excellent electrical insulation properties and dimensional stability. These materials are used in connectors, housings, and other electronic components, offering a sustainable alternative to conventional plastics while maintaining the required performance standards.

The packaging industry is another significant market for Bio-PA applications. With growing consumer demand for eco-friendly packaging solutions, Bio-PAs are being utilized in flexible and rigid packaging materials. Their barrier properties, transparency, and biodegradability make them suitable for food packaging, cosmetics containers, and other consumer goods packaging.

The textile and apparel industry is also exploring Bio-PA applications, particularly in the production of sustainable fibers. These bio-based fibers offer properties similar to traditional synthetic fibers but with a reduced environmental footprint. They are being used in sportswear, outdoor gear, and high-performance textiles.

Market analysis indicates that the global Bio-PA market is expected to grow at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is attributed to increasing regulations on plastic use, rising consumer awareness about sustainability, and ongoing technological advancements in Bio-PA production and processing.

Geographically, Europe leads the Bio-PA market, followed by North America and Asia-Pacific. European countries, with their stringent environmental regulations and strong focus on sustainable materials, have been early adopters of Bio-PAs. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization and increasing environmental concerns in countries like China and India.

The market landscape for Bio-PA applications is characterized by a mix of established chemical companies and innovative start-ups. Key players are investing heavily in research and development to improve the performance and cost-effectiveness of Bio-PAs, aiming to expand their application range and market share.

The automotive sector represents a major market for Bio-PA applications. As automakers strive to reduce vehicle weight and improve fuel efficiency, Bio-PAs are increasingly used in under-the-hood components, interior parts, and exterior applications. The material's high heat resistance, chemical stability, and mechanical strength make it suitable for replacing metal parts, contributing to overall weight reduction and improved fuel economy.

In the electronics industry, Bio-PAs are gaining traction due to their excellent electrical insulation properties and dimensional stability. These materials are used in connectors, housings, and other electronic components, offering a sustainable alternative to conventional plastics while maintaining the required performance standards.

The packaging industry is another significant market for Bio-PA applications. With growing consumer demand for eco-friendly packaging solutions, Bio-PAs are being utilized in flexible and rigid packaging materials. Their barrier properties, transparency, and biodegradability make them suitable for food packaging, cosmetics containers, and other consumer goods packaging.

The textile and apparel industry is also exploring Bio-PA applications, particularly in the production of sustainable fibers. These bio-based fibers offer properties similar to traditional synthetic fibers but with a reduced environmental footprint. They are being used in sportswear, outdoor gear, and high-performance textiles.

Market analysis indicates that the global Bio-PA market is expected to grow at a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is attributed to increasing regulations on plastic use, rising consumer awareness about sustainability, and ongoing technological advancements in Bio-PA production and processing.

Geographically, Europe leads the Bio-PA market, followed by North America and Asia-Pacific. European countries, with their stringent environmental regulations and strong focus on sustainable materials, have been early adopters of Bio-PAs. However, the Asia-Pacific region is expected to witness the fastest growth, driven by rapid industrialization and increasing environmental concerns in countries like China and India.

The market landscape for Bio-PA applications is characterized by a mix of established chemical companies and innovative start-ups. Key players are investing heavily in research and development to improve the performance and cost-effectiveness of Bio-PAs, aiming to expand their application range and market share.

Current Challenges in Bio-PA Melt Processing

Bio-PA (Bio-based Polyamide) melt processing faces several significant challenges that hinder its widespread adoption and optimal performance in various applications. One of the primary issues is the inherent variability in the raw materials used for bio-based polymers. Unlike traditional petroleum-based polyamides, bio-PA sources can vary significantly in composition and quality, leading to inconsistencies in the final product's properties and performance.

The thermal sensitivity of bio-PA presents another major challenge. These materials often have a narrower processing window compared to their conventional counterparts, making them more susceptible to degradation during melt processing. This sensitivity can result in reduced mechanical properties, discoloration, and even the formation of harmful by-products if not carefully controlled.

Moisture absorption is a critical factor that complicates bio-PA melt processing. These materials tend to absorb moisture from the environment more readily than traditional polyamides, which can lead to hydrolysis during processing. This not only affects the material's molecular weight but also impacts its flow behavior and final properties, potentially causing defects in the finished product.

The rheological behavior of bio-PA melts poses unique challenges in processing optimization. The flow characteristics of these materials can be highly sensitive to temperature, shear rate, and molecular weight distribution. This sensitivity makes it difficult to achieve consistent processing conditions across different batches or production runs, potentially leading to variations in product quality.

Another significant challenge lies in the limited availability of comprehensive rheological data for bio-PA materials. Unlike well-established synthetic polymers, the database of rheological properties for bio-PAs is still evolving. This lack of data makes it challenging for processors to predict and optimize melt behavior accurately, often resulting in a trial-and-error approach that can be both time-consuming and costly.

The interaction between bio-PA and processing equipment surfaces presents additional complications. These materials may exhibit different adhesion or release properties compared to conventional polyamides, potentially leading to issues such as die build-up or inconsistent extrusion rates. This can result in production inefficiencies and quality control problems that are difficult to anticipate and mitigate without extensive experimentation.

Lastly, the challenge of achieving consistent color and appearance in bio-PA products cannot be overlooked. The natural variations in bio-based raw materials can lead to color inconsistencies, which are particularly problematic in applications where aesthetic qualities are crucial. Overcoming these color-related challenges often requires specialized additives or processing techniques, adding complexity to the melt processing operation.

The thermal sensitivity of bio-PA presents another major challenge. These materials often have a narrower processing window compared to their conventional counterparts, making them more susceptible to degradation during melt processing. This sensitivity can result in reduced mechanical properties, discoloration, and even the formation of harmful by-products if not carefully controlled.

Moisture absorption is a critical factor that complicates bio-PA melt processing. These materials tend to absorb moisture from the environment more readily than traditional polyamides, which can lead to hydrolysis during processing. This not only affects the material's molecular weight but also impacts its flow behavior and final properties, potentially causing defects in the finished product.

The rheological behavior of bio-PA melts poses unique challenges in processing optimization. The flow characteristics of these materials can be highly sensitive to temperature, shear rate, and molecular weight distribution. This sensitivity makes it difficult to achieve consistent processing conditions across different batches or production runs, potentially leading to variations in product quality.

Another significant challenge lies in the limited availability of comprehensive rheological data for bio-PA materials. Unlike well-established synthetic polymers, the database of rheological properties for bio-PAs is still evolving. This lack of data makes it challenging for processors to predict and optimize melt behavior accurately, often resulting in a trial-and-error approach that can be both time-consuming and costly.

The interaction between bio-PA and processing equipment surfaces presents additional complications. These materials may exhibit different adhesion or release properties compared to conventional polyamides, potentially leading to issues such as die build-up or inconsistent extrusion rates. This can result in production inefficiencies and quality control problems that are difficult to anticipate and mitigate without extensive experimentation.

Lastly, the challenge of achieving consistent color and appearance in bio-PA products cannot be overlooked. The natural variations in bio-based raw materials can lead to color inconsistencies, which are particularly problematic in applications where aesthetic qualities are crucial. Overcoming these color-related challenges often requires specialized additives or processing techniques, adding complexity to the melt processing operation.

Existing Rheological Data Interpretation Methods

01 Melt processing techniques for Bio-PA

Various melt processing techniques are employed for Bio-PA, including extrusion, injection molding, and compression molding. These methods involve heating the bio-based polyamide to its melting point and shaping it into desired forms. The processing parameters, such as temperature, pressure, and cooling rate, are optimized to achieve the desired properties in the final product.- Melt processing techniques for Bio-PA: Various melt processing techniques are employed for Bio-PA, including extrusion, injection molding, and compression molding. These methods involve heating the bio-based polyamide to its melting point and shaping it into desired forms. The processing parameters, such as temperature, pressure, and cooling rate, are optimized to achieve the desired properties in the final product.

- Additives and blends for improved melt processing: Incorporating additives or blending Bio-PA with other polymers can enhance its melt processing characteristics. These additions can improve flow properties, thermal stability, and mechanical properties of the bio-based polyamide during and after melt processing. Common additives include plasticizers, nucleating agents, and compatibilizers.

- Moisture control in Bio-PA melt processing: Controlling moisture content is crucial in Bio-PA melt processing. Excessive moisture can lead to hydrolysis and degradation of the polymer during high-temperature processing. Proper drying techniques and moisture management systems are implemented to ensure optimal melt processing conditions and maintain the quality of the final product.

- Sustainable production methods for Bio-PA: Developing sustainable production methods for Bio-PA is a focus area, aiming to reduce environmental impact and improve overall efficiency. This includes using renewable feedstocks, optimizing energy consumption during melt processing, and implementing closed-loop recycling systems. These approaches contribute to the eco-friendly nature of bio-based polyamides.

- Characterization and quality control of melt-processed Bio-PA: Various characterization techniques and quality control measures are employed to assess the properties of melt-processed Bio-PA. These include thermal analysis, mechanical testing, and spectroscopic methods. Monitoring and controlling the melt flow index, crystallinity, and molecular weight distribution are essential for ensuring consistent product quality and performance in different applications.

02 Additives and blends for improved processability

Incorporating additives or blending Bio-PA with other polymers can enhance its melt processing characteristics. Plasticizers, lubricants, and flow modifiers are used to improve flowability and reduce processing temperatures. Compatibilizers may be added when blending Bio-PA with other polymers to ensure uniform mixing and optimal properties in the final product.Expand Specific Solutions03 Moisture control during melt processing

Controlling moisture content is crucial in Bio-PA melt processing. Proper drying of the material before processing is essential to prevent hydrolysis and maintain the polymer's molecular weight. Specialized drying equipment and techniques are employed to ensure optimal moisture levels for processing.Expand Specific Solutions04 Fiber and film production from Bio-PA

Bio-PA can be melt-processed into fibers and films for various applications. Melt spinning techniques are used for fiber production, while extrusion and casting methods are employed for film manufacturing. The processing conditions are tailored to achieve the desired fiber or film properties, such as strength, flexibility, and barrier characteristics.Expand Specific Solutions05 Recycling and reprocessing of Bio-PA

Recycling and reprocessing of Bio-PA through melt processing techniques are explored to improve sustainability. Methods for collecting, sorting, and reprocessing Bio-PA waste are developed. The impact of multiple processing cycles on the material properties is studied, and strategies to maintain or enhance the quality of recycled Bio-PA are implemented.Expand Specific Solutions

Key Players in Bio-PA and Rheology Industry

The optimization of bio-PA melt processing using rheology data is an emerging field in the advanced materials sector. This technology is in its early development stage, with a growing market driven by the increasing demand for sustainable and high-performance polymers. The global bio-based polyamide market is expected to expand significantly in the coming years. Companies like Evonik Operations GmbH, Arkema France SA, and SABIC Global Technologies BV are at the forefront of this technology, investing in research and development to improve processing techniques. While the technology is still evolving, these key players are making strides in enhancing the efficiency and quality of bio-PA production, indicating a moderate level of technological maturity with room for further advancements.

Evonik Operations GmbH

Technical Solution: Evonik has developed a comprehensive approach to optimize Bio-PA melt processing using rheology data. Their method involves utilizing advanced rheometers to measure complex viscosity, storage modulus, and loss modulus across a range of temperatures and shear rates[1]. This data is then used to create master curves and determine the activation energy of the Bio-PA melt. Evonik's process incorporates the Cox-Merz rule to correlate dynamic and steady-state viscosities, enabling more accurate predictions of processing behavior[3]. They have also implemented inline rheology measurements during extrusion to provide real-time feedback for process optimization[5].

Strengths: Comprehensive rheological characterization, real-time process monitoring, and optimization. Weaknesses: May require specialized equipment and expertise, potentially increasing production costs.

Arkema France SA

Technical Solution: Arkema has developed a sophisticated approach to Bio-PA melt processing optimization using rheology data. Their method involves a combination of offline and online rheological measurements. Offline, they use rotational and capillary rheometers to characterize the Bio-PA's viscoelastic properties over a wide range of temperatures and shear rates[2]. This data is used to create flow curves and determine the material's sensitivity to temperature and shear. Online, Arkema employs in-line rheometers during extrusion to monitor melt viscosity and elasticity in real-time[4]. They have also developed proprietary software that uses this rheological data to predict and optimize processing parameters such as screw speed, temperature profile, and die design[6].

Strengths: Comprehensive rheological analysis, real-time monitoring, and predictive modeling capabilities. Weaknesses: High initial investment in specialized equipment and software development.

Advanced Rheological Models for Bio-PA

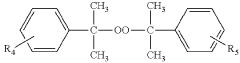

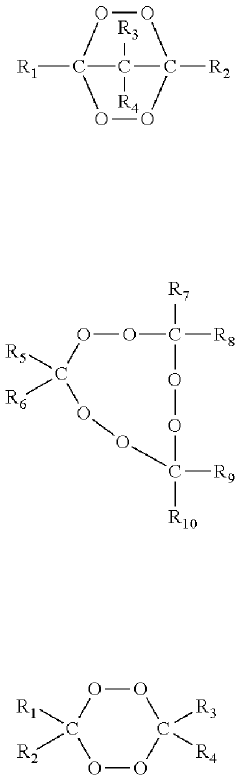

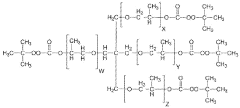

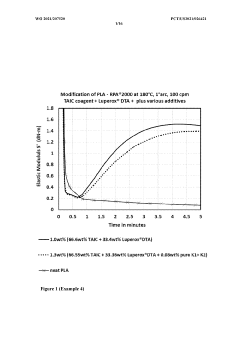

Organic peroxide formulations for modification of BIO-based and biodegradable polymers

PatentWO2021207520A1

Innovation

- An organic peroxide formulation combined with reactive bio-based additives is used to enhance the melt strength, tensile strength, and compatibility of bio-based polymers like PLA, allowing for improved processing and compatibility with petroleum-based polymers through chemical reactions that modify the polymer properties.

Rheology additives based on di- or tri-amides and mixtures thereof

PatentWO2019102087A1

Innovation

- Development of multifunctional di- and triamides based on primary polyamines with polyether segments and hydroxylated fatty acids, which can be easily soluble in plasticizers and binders without preactivation, offering improved compatibility and rheological performance.

Sustainability Aspects of Bio-PA Production

The sustainability aspects of Bio-PA production are becoming increasingly important as industries seek to reduce their environmental impact and meet growing consumer demand for eco-friendly products. Bio-based polyamides (Bio-PAs) offer a promising alternative to traditional petroleum-based polyamides, with potential benefits in terms of reduced carbon footprint and renewable resource utilization.

One of the key sustainability advantages of Bio-PA production is the use of renewable feedstocks. These materials are typically derived from plant-based sources such as castor oil, corn, or other agricultural products. By utilizing renewable resources, Bio-PA production helps to reduce dependence on finite fossil fuel resources and potentially lowers overall greenhouse gas emissions associated with the polymer lifecycle.

The production process of Bio-PAs can also contribute to improved sustainability metrics. Many Bio-PA manufacturing methods employ more energy-efficient processes compared to their petroleum-based counterparts. This can lead to reduced energy consumption and lower carbon emissions during the production phase. Additionally, some Bio-PA production techniques incorporate principles of green chemistry, minimizing the use of harmful solvents and reducing waste generation.

Biodegradability and end-of-life considerations are important aspects of Bio-PA sustainability. While not all Bio-PAs are inherently biodegradable, some variants have been developed with enhanced biodegradability properties. This characteristic can potentially reduce the environmental impact of Bio-PA products at the end of their lifecycle, particularly in applications where recycling may be challenging.

The recyclability of Bio-PAs is another crucial factor in their sustainability profile. Many Bio-PAs can be mechanically recycled, similar to conventional polyamides. This allows for the recovery and reuse of materials, extending their useful life and reducing the need for virgin polymer production. Some advanced recycling technologies, such as chemical recycling, are also being explored for Bio-PAs, which could further enhance their circular economy potential.

Water usage and land use impacts are additional considerations in Bio-PA sustainability. The cultivation of feedstock crops for Bio-PA production may require significant water resources and agricultural land. Sustainable farming practices and efficient water management systems are essential to mitigate these impacts and ensure the long-term viability of Bio-PA production.

As the Bio-PA industry continues to evolve, ongoing research and development efforts are focused on further improving the sustainability aspects of production. This includes optimizing feedstock selection, enhancing process efficiencies, and developing new Bio-PA formulations with improved environmental performance. By addressing these sustainability challenges, the Bio-PA industry aims to position itself as a key player in the transition towards more sustainable and circular polymer solutions.

One of the key sustainability advantages of Bio-PA production is the use of renewable feedstocks. These materials are typically derived from plant-based sources such as castor oil, corn, or other agricultural products. By utilizing renewable resources, Bio-PA production helps to reduce dependence on finite fossil fuel resources and potentially lowers overall greenhouse gas emissions associated with the polymer lifecycle.

The production process of Bio-PAs can also contribute to improved sustainability metrics. Many Bio-PA manufacturing methods employ more energy-efficient processes compared to their petroleum-based counterparts. This can lead to reduced energy consumption and lower carbon emissions during the production phase. Additionally, some Bio-PA production techniques incorporate principles of green chemistry, minimizing the use of harmful solvents and reducing waste generation.

Biodegradability and end-of-life considerations are important aspects of Bio-PA sustainability. While not all Bio-PAs are inherently biodegradable, some variants have been developed with enhanced biodegradability properties. This characteristic can potentially reduce the environmental impact of Bio-PA products at the end of their lifecycle, particularly in applications where recycling may be challenging.

The recyclability of Bio-PAs is another crucial factor in their sustainability profile. Many Bio-PAs can be mechanically recycled, similar to conventional polyamides. This allows for the recovery and reuse of materials, extending their useful life and reducing the need for virgin polymer production. Some advanced recycling technologies, such as chemical recycling, are also being explored for Bio-PAs, which could further enhance their circular economy potential.

Water usage and land use impacts are additional considerations in Bio-PA sustainability. The cultivation of feedstock crops for Bio-PA production may require significant water resources and agricultural land. Sustainable farming practices and efficient water management systems are essential to mitigate these impacts and ensure the long-term viability of Bio-PA production.

As the Bio-PA industry continues to evolve, ongoing research and development efforts are focused on further improving the sustainability aspects of production. This includes optimizing feedstock selection, enhancing process efficiencies, and developing new Bio-PA formulations with improved environmental performance. By addressing these sustainability challenges, the Bio-PA industry aims to position itself as a key player in the transition towards more sustainable and circular polymer solutions.

Quality Control Strategies for Bio-PA Manufacturing

Quality control strategies play a crucial role in ensuring the consistent production of high-quality Bio-PA (Bio-based Polyamide) materials. These strategies encompass various aspects of the manufacturing process, from raw material selection to final product testing. One key element in optimizing Bio-PA melt processing is the effective use of rheology data.

Rheological measurements provide valuable insights into the flow behavior and processability of Bio-PA materials. By analyzing rheology data, manufacturers can fine-tune processing parameters to achieve optimal melt flow characteristics and end-product properties. This approach involves monitoring and controlling viscosity, shear rate, and temperature dependencies throughout the production process.

Implementing in-line rheometry systems allows for real-time monitoring of melt viscosity during extrusion or injection molding. This continuous data collection enables rapid adjustments to processing conditions, ensuring consistent melt behavior and product quality. Additionally, offline rheological testing of raw materials and finished products helps establish quality benchmarks and detect any deviations from desired specifications.

Another critical aspect of quality control in Bio-PA manufacturing is the careful selection and characterization of bio-based raw materials. Variations in feedstock composition can significantly impact the final product properties. Implementing rigorous testing protocols for incoming raw materials, including chemical composition analysis and rheological profiling, helps maintain consistency in the production process.

Process control systems play a vital role in maintaining stable manufacturing conditions. Advanced control algorithms can utilize rheology data to automatically adjust processing parameters such as temperature, pressure, and screw speed in response to variations in melt behavior. This closed-loop control approach minimizes product variability and reduces the likelihood of off-spec production.

Quality control strategies should also incorporate comprehensive product testing protocols. These may include mechanical property testing, thermal analysis, and chemical composition verification. Establishing clear acceptance criteria based on rheological and other relevant data ensures that only products meeting specified quality standards are released to customers.

Implementing statistical process control (SPC) techniques allows manufacturers to track key quality parameters over time, identify trends, and proactively address potential issues before they lead to quality deviations. By correlating rheology data with other process variables and final product properties, manufacturers can develop predictive models to further enhance process control and product consistency.

Rheological measurements provide valuable insights into the flow behavior and processability of Bio-PA materials. By analyzing rheology data, manufacturers can fine-tune processing parameters to achieve optimal melt flow characteristics and end-product properties. This approach involves monitoring and controlling viscosity, shear rate, and temperature dependencies throughout the production process.

Implementing in-line rheometry systems allows for real-time monitoring of melt viscosity during extrusion or injection molding. This continuous data collection enables rapid adjustments to processing conditions, ensuring consistent melt behavior and product quality. Additionally, offline rheological testing of raw materials and finished products helps establish quality benchmarks and detect any deviations from desired specifications.

Another critical aspect of quality control in Bio-PA manufacturing is the careful selection and characterization of bio-based raw materials. Variations in feedstock composition can significantly impact the final product properties. Implementing rigorous testing protocols for incoming raw materials, including chemical composition analysis and rheological profiling, helps maintain consistency in the production process.

Process control systems play a vital role in maintaining stable manufacturing conditions. Advanced control algorithms can utilize rheology data to automatically adjust processing parameters such as temperature, pressure, and screw speed in response to variations in melt behavior. This closed-loop control approach minimizes product variability and reduces the likelihood of off-spec production.

Quality control strategies should also incorporate comprehensive product testing protocols. These may include mechanical property testing, thermal analysis, and chemical composition verification. Establishing clear acceptance criteria based on rheological and other relevant data ensures that only products meeting specified quality standards are released to customers.

Implementing statistical process control (SPC) techniques allows manufacturers to track key quality parameters over time, identify trends, and proactively address potential issues before they lead to quality deviations. By correlating rheology data with other process variables and final product properties, manufacturers can develop predictive models to further enhance process control and product consistency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!