PA12 Sintering Parameters for Powder Bed Fusion with Bio-PA Powders

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PA12 Sintering Background and Objectives

Polyamide 12 (PA12) has been a cornerstone material in the field of powder bed fusion (PBF) additive manufacturing for decades. Its excellent mechanical properties, chemical resistance, and thermal stability have made it a preferred choice for various industrial applications. The evolution of PA12 sintering technology has been closely tied to the advancement of laser sintering systems and the growing demand for high-performance, customizable parts in industries such as aerospace, automotive, and medical devices.

The development of PA12 sintering parameters has been a continuous process of refinement and optimization. Early research focused on understanding the fundamental relationships between laser power, scan speed, and layer thickness. As the technology matured, attention shifted to more nuanced aspects such as powder particle size distribution, bed temperature control, and cooling rates. These advancements have led to significant improvements in part density, surface finish, and mechanical properties.

In recent years, there has been a growing interest in sustainable and bio-based alternatives to traditional petroleum-derived polymers. This trend has sparked research into bio-based polyamides, including bio-PA12, which offers similar performance characteristics to conventional PA12 while reducing environmental impact. The integration of bio-PA powders into existing PBF systems presents both opportunities and challenges, necessitating a reevaluation of established sintering parameters.

The primary objective of this research is to investigate and optimize the sintering parameters for bio-PA powders in powder bed fusion processes. This involves a comprehensive study of how various process parameters affect the sintering behavior, microstructure, and final properties of parts produced using bio-PA12 powders. Key areas of focus include:

1. Determining the optimal laser power and scan speed combinations for bio-PA12 powders.

2. Investigating the influence of powder bed temperature on sintering quality and part properties.

3. Analyzing the effects of layer thickness and powder particle size distribution on build accuracy and surface finish.

4. Exploring post-processing techniques to enhance the mechanical and thermal properties of bio-PA12 parts.

By addressing these objectives, this research aims to establish a robust set of sintering parameters that enable the effective use of bio-PA12 powders in PBF systems. The ultimate goal is to facilitate the adoption of more sustainable materials in additive manufacturing without compromising on part quality or performance. This work will contribute to the broader efforts in developing environmentally friendly manufacturing processes and expanding the range of materials available for advanced 3D printing applications.

The development of PA12 sintering parameters has been a continuous process of refinement and optimization. Early research focused on understanding the fundamental relationships between laser power, scan speed, and layer thickness. As the technology matured, attention shifted to more nuanced aspects such as powder particle size distribution, bed temperature control, and cooling rates. These advancements have led to significant improvements in part density, surface finish, and mechanical properties.

In recent years, there has been a growing interest in sustainable and bio-based alternatives to traditional petroleum-derived polymers. This trend has sparked research into bio-based polyamides, including bio-PA12, which offers similar performance characteristics to conventional PA12 while reducing environmental impact. The integration of bio-PA powders into existing PBF systems presents both opportunities and challenges, necessitating a reevaluation of established sintering parameters.

The primary objective of this research is to investigate and optimize the sintering parameters for bio-PA powders in powder bed fusion processes. This involves a comprehensive study of how various process parameters affect the sintering behavior, microstructure, and final properties of parts produced using bio-PA12 powders. Key areas of focus include:

1. Determining the optimal laser power and scan speed combinations for bio-PA12 powders.

2. Investigating the influence of powder bed temperature on sintering quality and part properties.

3. Analyzing the effects of layer thickness and powder particle size distribution on build accuracy and surface finish.

4. Exploring post-processing techniques to enhance the mechanical and thermal properties of bio-PA12 parts.

By addressing these objectives, this research aims to establish a robust set of sintering parameters that enable the effective use of bio-PA12 powders in PBF systems. The ultimate goal is to facilitate the adoption of more sustainable materials in additive manufacturing without compromising on part quality or performance. This work will contribute to the broader efforts in developing environmentally friendly manufacturing processes and expanding the range of materials available for advanced 3D printing applications.

Market Analysis for Bio-PA in Additive Manufacturing

The market for bio-based polyamides (Bio-PA) in additive manufacturing is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable materials. Bio-PA, derived from renewable resources such as castor oil, offers a more eco-friendly alternative to traditional petroleum-based polyamides like PA12. This shift aligns with the global trend towards circular economy principles and reduced carbon footprints in manufacturing processes.

The additive manufacturing industry, particularly in the powder bed fusion segment, has shown keen interest in Bio-PA materials. These materials offer comparable mechanical properties to conventional PA12 while providing enhanced sustainability credentials. The market demand is primarily fueled by industries such as automotive, aerospace, and consumer goods, where there is a growing emphasis on lightweight, durable, and environmentally friendly components.

Recent market research indicates that the global Bio-PA market in additive manufacturing is projected to grow at a compound annual growth rate (CAGR) of over 20% in the next five years. This growth is attributed to the increasing adoption of 3D printing technologies across various sectors and the rising demand for sustainable materials. The automotive industry, in particular, has emerged as a key driver, with manufacturers exploring Bio-PA for prototyping and production of interior components, under-hood parts, and structural elements.

The market landscape for Bio-PA in additive manufacturing is characterized by a mix of established chemical companies and innovative startups. Major players are investing heavily in research and development to improve the performance characteristics of Bio-PA powders, focusing on aspects such as thermal stability, powder flowability, and mechanical properties. This investment is crucial for addressing the current limitations of Bio-PA in high-temperature applications and expanding its use in more demanding industrial sectors.

Geographically, Europe leads the Bio-PA market in additive manufacturing, followed by North America and Asia-Pacific. European countries, with their stringent environmental regulations and strong focus on sustainability, have been early adopters of Bio-PA in 3D printing applications. However, rapid growth is expected in the Asia-Pacific region, driven by the expanding manufacturing sector and increasing environmental awareness.

The pricing of Bio-PA powders remains a challenge, as they are currently more expensive than traditional PA12 powders. However, as production scales up and technologies improve, the price gap is expected to narrow, making Bio-PA more competitive in the broader additive manufacturing market. This trend, coupled with the growing emphasis on sustainable practices, is likely to accelerate the adoption of Bio-PA in powder bed fusion and other additive manufacturing technologies in the coming years.

The additive manufacturing industry, particularly in the powder bed fusion segment, has shown keen interest in Bio-PA materials. These materials offer comparable mechanical properties to conventional PA12 while providing enhanced sustainability credentials. The market demand is primarily fueled by industries such as automotive, aerospace, and consumer goods, where there is a growing emphasis on lightweight, durable, and environmentally friendly components.

Recent market research indicates that the global Bio-PA market in additive manufacturing is projected to grow at a compound annual growth rate (CAGR) of over 20% in the next five years. This growth is attributed to the increasing adoption of 3D printing technologies across various sectors and the rising demand for sustainable materials. The automotive industry, in particular, has emerged as a key driver, with manufacturers exploring Bio-PA for prototyping and production of interior components, under-hood parts, and structural elements.

The market landscape for Bio-PA in additive manufacturing is characterized by a mix of established chemical companies and innovative startups. Major players are investing heavily in research and development to improve the performance characteristics of Bio-PA powders, focusing on aspects such as thermal stability, powder flowability, and mechanical properties. This investment is crucial for addressing the current limitations of Bio-PA in high-temperature applications and expanding its use in more demanding industrial sectors.

Geographically, Europe leads the Bio-PA market in additive manufacturing, followed by North America and Asia-Pacific. European countries, with their stringent environmental regulations and strong focus on sustainability, have been early adopters of Bio-PA in 3D printing applications. However, rapid growth is expected in the Asia-Pacific region, driven by the expanding manufacturing sector and increasing environmental awareness.

The pricing of Bio-PA powders remains a challenge, as they are currently more expensive than traditional PA12 powders. However, as production scales up and technologies improve, the price gap is expected to narrow, making Bio-PA more competitive in the broader additive manufacturing market. This trend, coupled with the growing emphasis on sustainable practices, is likely to accelerate the adoption of Bio-PA in powder bed fusion and other additive manufacturing technologies in the coming years.

Current Challenges in PA12 Sintering with Bio-PA

The sintering of PA12 with bio-based polyamide powders presents several significant challenges in the field of powder bed fusion. One of the primary issues is the difference in thermal properties between traditional PA12 and bio-PA powders. Bio-PA materials often have lower melting points and narrower processing windows, making it difficult to achieve optimal sintering conditions without compromising the structural integrity of the final parts.

Another challenge lies in the powder flowability and spreadability of bio-PA materials. These properties are crucial for achieving uniform layer deposition during the powder bed fusion process. Bio-PA powders may exhibit different particle morphologies and surface characteristics compared to conventional PA12, potentially leading to inconsistencies in layer thickness and density across the build platform.

The moisture sensitivity of bio-PA powders poses an additional hurdle. These materials tend to absorb moisture more readily than traditional PA12, which can affect their processability and the quality of the final parts. Moisture absorption can lead to changes in the powder's thermal behavior, potentially causing issues such as porosity, warping, and reduced mechanical properties in the sintered components.

Furthermore, the sintering kinetics of bio-PA powders may differ from those of PA12, requiring adjustments to laser power, scan speed, and other process parameters. Achieving the right balance between energy input and material consolidation is crucial for producing parts with desired mechanical properties and surface finish. The challenge lies in developing a comprehensive understanding of how these parameters interact with bio-PA materials to optimize the sintering process.

Consistency in material properties across different batches of bio-PA powders is another significant concern. Variations in the feedstock can lead to inconsistencies in the final parts, making it difficult to achieve reproducible results in industrial applications. This challenge is particularly pronounced when dealing with bio-based materials, as their properties may be more susceptible to variations in the sourcing and processing of raw materials.

Lastly, the long-term stability and aging characteristics of sintered bio-PA parts remain areas of uncertainty. The potential for changes in mechanical properties, dimensional stability, and color over time needs to be thoroughly investigated to ensure the reliability and durability of components produced using these materials in powder bed fusion processes.

Another challenge lies in the powder flowability and spreadability of bio-PA materials. These properties are crucial for achieving uniform layer deposition during the powder bed fusion process. Bio-PA powders may exhibit different particle morphologies and surface characteristics compared to conventional PA12, potentially leading to inconsistencies in layer thickness and density across the build platform.

The moisture sensitivity of bio-PA powders poses an additional hurdle. These materials tend to absorb moisture more readily than traditional PA12, which can affect their processability and the quality of the final parts. Moisture absorption can lead to changes in the powder's thermal behavior, potentially causing issues such as porosity, warping, and reduced mechanical properties in the sintered components.

Furthermore, the sintering kinetics of bio-PA powders may differ from those of PA12, requiring adjustments to laser power, scan speed, and other process parameters. Achieving the right balance between energy input and material consolidation is crucial for producing parts with desired mechanical properties and surface finish. The challenge lies in developing a comprehensive understanding of how these parameters interact with bio-PA materials to optimize the sintering process.

Consistency in material properties across different batches of bio-PA powders is another significant concern. Variations in the feedstock can lead to inconsistencies in the final parts, making it difficult to achieve reproducible results in industrial applications. This challenge is particularly pronounced when dealing with bio-based materials, as their properties may be more susceptible to variations in the sourcing and processing of raw materials.

Lastly, the long-term stability and aging characteristics of sintered bio-PA parts remain areas of uncertainty. The potential for changes in mechanical properties, dimensional stability, and color over time needs to be thoroughly investigated to ensure the reliability and durability of components produced using these materials in powder bed fusion processes.

Existing PA12 Sintering Parameter Solutions

01 Sintering temperature and time optimization

Optimizing sintering temperature and time is crucial for PA12 and Bio-PA powders. The process typically involves gradually heating the powder to just below its melting point, maintaining this temperature for a specific duration, and then cooling it in a controlled manner. This approach ensures proper fusion of particles and minimizes thermal degradation, resulting in improved mechanical properties of the final product.- Sintering temperature and time optimization: Optimizing sintering temperature and time is crucial for PA12 and Bio-PA powder processing. The ideal temperature range and duration depend on the specific polymer composition and desired properties. Proper control of these parameters ensures optimal fusion of particles and minimizes thermal degradation, resulting in improved mechanical properties and surface finish of the final parts.

- Powder particle size and distribution: The size and distribution of PA12 and Bio-PA powder particles significantly influence the sintering process. Smaller particle sizes generally lead to better packing density and smoother surface finish, while a controlled particle size distribution can improve flowability and layer uniformity. Optimizing these parameters enhances the overall quality and mechanical properties of the sintered parts.

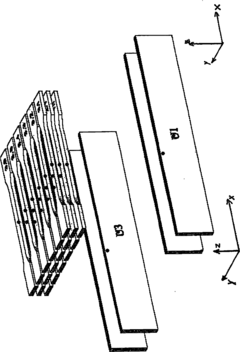

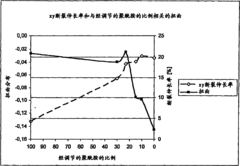

- Energy density and laser parameters: Energy density and laser parameters play a crucial role in the sintering of PA12 and Bio-PA powders. Factors such as laser power, scan speed, and hatch spacing affect the energy input and fusion of particles. Optimizing these parameters is essential for achieving the desired part density, dimensional accuracy, and mechanical properties while minimizing thermal distortion and porosity.

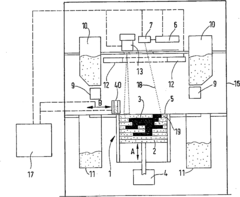

- Powder bed preheating and cooling strategies: Effective preheating and cooling strategies for the powder bed are critical in PA12 and Bio-PA sintering. Proper preheating helps reduce thermal gradients and prevents warpage, while controlled cooling rates influence crystallization and dimensional stability. Optimizing these parameters can lead to improved part quality, reduced residual stresses, and enhanced mechanical properties of the sintered components.

- Post-processing and surface treatment: Post-processing and surface treatment techniques can significantly enhance the properties of sintered PA12 and Bio-PA parts. Methods such as thermal annealing, chemical treatments, and mechanical finishing can improve surface quality, dimensional accuracy, and mechanical properties. These processes help optimize the final characteristics of the sintered components for specific applications.

02 Particle size and distribution control

Controlling particle size and distribution of PA12 and Bio-PA powders is essential for achieving optimal sintering results. Smaller particles generally result in denser parts with smoother surfaces, while a narrow size distribution promotes more uniform sintering. Techniques such as milling, classification, and spray drying are often employed to achieve the desired particle characteristics.Expand Specific Solutions03 Powder bed preheating and cooling strategies

Effective preheating of the powder bed and controlled cooling strategies are critical for successful sintering of PA12 and Bio-PA powders. Preheating helps to reduce thermal gradients and prevent warping, while controlled cooling minimizes residual stresses and improves dimensional accuracy. These strategies often involve the use of infrared heaters, heated build chambers, and gradual cooling cycles.Expand Specific Solutions04 Laser power and scan speed optimization

Optimizing laser power and scan speed is crucial for achieving the desired sintering quality in PA12 and Bio-PA powders. Higher laser power generally results in better fusion but may lead to thermal degradation, while faster scan speeds can increase productivity but may compromise part density. Balancing these parameters is essential for achieving optimal mechanical properties and surface finish.Expand Specific Solutions05 Additives and powder modifications

Incorporating additives or modifying PA12 and Bio-PA powders can enhance their sintering performance. This may include the addition of flow agents to improve powder spreadability, thermal stabilizers to prevent degradation during sintering, or reinforcing materials to enhance mechanical properties. Careful selection and optimization of these additives are crucial for achieving the desired sintering results and final part characteristics.Expand Specific Solutions

Key Players in Bio-PA and PBF Industry

The research on PA12 sintering parameters for powder bed fusion with bio-PA powders is in an emerging stage, reflecting the growing interest in sustainable materials for additive manufacturing. The market for bio-based polymers in 3D printing is expanding, driven by environmental concerns and regulatory pressures. Companies like Evonik, Arkema, and EOS are at the forefront of developing and optimizing bio-PA powders and associated sintering technologies. The technical maturity varies, with established players like EOS and Renishaw having advanced capabilities in powder bed fusion systems, while materials specialists such as Evonik and Arkema focus on refining bio-PA formulations. This competitive landscape indicates a collaborative yet competitive environment, where material suppliers and equipment manufacturers are working to overcome challenges in processability and performance of bio-based materials for additive manufacturing applications.

Evonik Operations GmbH

Technical Solution: Evonik has developed a comprehensive approach to PA12 sintering for powder bed fusion with bio-PA powders. Their research focuses on optimizing particle size distribution, powder flowability, and thermal properties to enhance sintering performance. They have introduced a bio-based PA12 powder called VESTOSINT® Care, which offers improved sustainability without compromising mechanical properties[1]. Evonik's sintering parameters include precise control of bed temperature, laser power, and scan speed, tailored specifically for bio-PA powders to achieve optimal part density and surface finish[2].

Strengths: Extensive experience in PA12 materials, strong focus on sustainability, and advanced powder formulation. Weaknesses: May face challenges in scaling up production of bio-based powders and potential higher costs compared to traditional PA12.

Arkema France SA

Technical Solution: Arkema has developed a comprehensive approach to PA12 sintering for powder bed fusion with bio-PA powders, focusing on their Rilsan® Invent Natural range. Their research emphasizes optimizing sintering parameters such as laser power, scan speed, and layer thickness to achieve optimal mechanical properties and surface finish. Arkema's bio-based PA12 powders are derived from renewable castor oil, offering a more sustainable alternative to traditional petroleum-based powders[3]. They have also developed specialized thermal management techniques to control the sintering process and minimize part warpage[4].

Strengths: Strong expertise in bio-based materials, established market presence in PA12 powders. Weaknesses: May face competition from other established players in the PA12 market, potential challenges in achieving consistent powder quality across batches.

Core Innovations in Bio-PA Powder Development

Use of a polyamide 12 for selective laser sintering

PatentInactiveEP0911142A1

Innovation

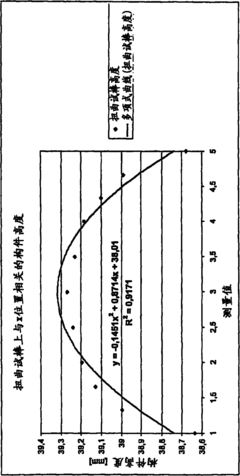

- The use of polyamide 12 (PA 12) powders with specific physical parameters, including a melting temperature of 185-189°C, enthalpy of fusion of 112±17 J/g, and solidification temperature of 138-143°C, which provides a larger temperature difference and higher enthalpy of fusion, reducing shrinkage and enhancing dimensional stability and surface quality.

PA 12 powder for use in generative layer-wise manufacturing method

PatentActiveCN102199348A

Innovation

- By adjusting the ratio of carboxyl end groups to amino end groups in the polyamide 12 powder, ensuring it is between 10% and 30%, combined with appropriate powder mixing and handling methods, a polyamide 12 powder with high elongation at break and low distortion properties is produced. of powder mixture, and control the aging characteristics of the powder during laser sintering to reduce molar weight rise.

Sustainability Impact of Bio-PA in PBF

The integration of bio-based polyamide (Bio-PA) in Powder Bed Fusion (PBF) processes represents a significant step towards enhancing sustainability in additive manufacturing. Bio-PA, derived from renewable resources, offers a more environmentally friendly alternative to traditional petroleum-based polyamides, such as PA12, which are commonly used in PBF applications.

The use of Bio-PA in PBF processes contributes to reducing the carbon footprint of manufactured parts. Bio-based materials typically have lower greenhouse gas emissions associated with their production compared to their fossil-fuel-based counterparts. This reduction in carbon emissions aligns with global efforts to mitigate climate change and promotes more sustainable manufacturing practices.

Furthermore, the adoption of Bio-PA in PBF supports the circular economy concept. As these materials are derived from renewable sources, they help decrease reliance on finite petroleum resources. This shift towards bio-based feedstocks promotes a more sustainable supply chain and reduces the environmental impact of raw material extraction.

Bio-PA also offers potential advantages in terms of end-of-life management for PBF-produced parts. Depending on the specific formulation, some Bio-PA materials may exhibit improved biodegradability or recyclability compared to traditional polyamides. This characteristic can contribute to reducing waste and promoting more efficient resource utilization in the long term.

The implementation of Bio-PA in PBF processes may also drive innovation in material science and manufacturing technologies. As researchers and industry professionals work to optimize Bio-PA formulations for PBF applications, advancements in material properties and processing techniques are likely to emerge. These innovations could lead to improved performance characteristics while maintaining or enhancing sustainability benefits.

However, it is important to consider the potential challenges associated with Bio-PA adoption in PBF. These may include ensuring consistent material quality, optimizing processing parameters, and addressing any differences in mechanical properties compared to traditional polyamides. Overcoming these challenges will be crucial for widespread adoption and maximizing the sustainability benefits of Bio-PA in PBF applications.

The use of Bio-PA in PBF processes contributes to reducing the carbon footprint of manufactured parts. Bio-based materials typically have lower greenhouse gas emissions associated with their production compared to their fossil-fuel-based counterparts. This reduction in carbon emissions aligns with global efforts to mitigate climate change and promotes more sustainable manufacturing practices.

Furthermore, the adoption of Bio-PA in PBF supports the circular economy concept. As these materials are derived from renewable sources, they help decrease reliance on finite petroleum resources. This shift towards bio-based feedstocks promotes a more sustainable supply chain and reduces the environmental impact of raw material extraction.

Bio-PA also offers potential advantages in terms of end-of-life management for PBF-produced parts. Depending on the specific formulation, some Bio-PA materials may exhibit improved biodegradability or recyclability compared to traditional polyamides. This characteristic can contribute to reducing waste and promoting more efficient resource utilization in the long term.

The implementation of Bio-PA in PBF processes may also drive innovation in material science and manufacturing technologies. As researchers and industry professionals work to optimize Bio-PA formulations for PBF applications, advancements in material properties and processing techniques are likely to emerge. These innovations could lead to improved performance characteristics while maintaining or enhancing sustainability benefits.

However, it is important to consider the potential challenges associated with Bio-PA adoption in PBF. These may include ensuring consistent material quality, optimizing processing parameters, and addressing any differences in mechanical properties compared to traditional polyamides. Overcoming these challenges will be crucial for widespread adoption and maximizing the sustainability benefits of Bio-PA in PBF applications.

Quality Control Measures for Bio-PA Sintering

Quality control is paramount in the sintering process of Bio-PA powders for powder bed fusion. Implementing robust measures ensures consistent product quality and optimal performance. A comprehensive quality control system for Bio-PA sintering should encompass several key areas.

Material characterization is the first critical step. Regular testing of the Bio-PA powder's physical and chemical properties is essential. This includes particle size distribution analysis, moisture content measurement, and thermal behavior assessment through differential scanning calorimetry (DSC). These tests help maintain consistency in raw material quality and predict sintering behavior.

Process parameter monitoring and control form the backbone of quality assurance during sintering. Real-time tracking of temperature profiles, laser power, scan speed, and layer thickness is crucial. Advanced systems may incorporate closed-loop feedback mechanisms to make real-time adjustments, ensuring adherence to predetermined optimal parameters.

In-situ monitoring techniques can significantly enhance quality control. Thermal imaging cameras can detect temperature anomalies across the powder bed, while high-speed cameras can capture layer-wise images for defect detection. Machine learning algorithms can be employed to analyze this data in real-time, flagging potential issues before they escalate.

Post-processing quality checks are equally important. Non-destructive testing methods such as X-ray computed tomography (CT) can reveal internal structures and defects. Mechanical testing of sintered parts, including tensile strength, elongation at break, and impact resistance, provides crucial data on the final product's performance.

Traceability is another key aspect of quality control. Implementing a robust system to track each batch of Bio-PA powder from receipt to final part production allows for quick identification and isolation of quality issues. This system should include detailed records of process parameters, operator actions, and quality check results for each production run.

Continuous improvement should be an integral part of the quality control strategy. Regular analysis of quality data can reveal trends and opportunities for process optimization. This may involve fine-tuning sintering parameters, adjusting powder handling procedures, or implementing new monitoring technologies.

Lastly, operator training and standard operating procedures (SOPs) play a crucial role in maintaining quality. Comprehensive training programs ensure that all personnel involved in the sintering process understand the critical aspects of quality control and can effectively implement the established procedures.

Material characterization is the first critical step. Regular testing of the Bio-PA powder's physical and chemical properties is essential. This includes particle size distribution analysis, moisture content measurement, and thermal behavior assessment through differential scanning calorimetry (DSC). These tests help maintain consistency in raw material quality and predict sintering behavior.

Process parameter monitoring and control form the backbone of quality assurance during sintering. Real-time tracking of temperature profiles, laser power, scan speed, and layer thickness is crucial. Advanced systems may incorporate closed-loop feedback mechanisms to make real-time adjustments, ensuring adherence to predetermined optimal parameters.

In-situ monitoring techniques can significantly enhance quality control. Thermal imaging cameras can detect temperature anomalies across the powder bed, while high-speed cameras can capture layer-wise images for defect detection. Machine learning algorithms can be employed to analyze this data in real-time, flagging potential issues before they escalate.

Post-processing quality checks are equally important. Non-destructive testing methods such as X-ray computed tomography (CT) can reveal internal structures and defects. Mechanical testing of sintered parts, including tensile strength, elongation at break, and impact resistance, provides crucial data on the final product's performance.

Traceability is another key aspect of quality control. Implementing a robust system to track each batch of Bio-PA powder from receipt to final part production allows for quick identification and isolation of quality issues. This system should include detailed records of process parameters, operator actions, and quality check results for each production run.

Continuous improvement should be an integral part of the quality control strategy. Regular analysis of quality data can reveal trends and opportunities for process optimization. This may involve fine-tuning sintering parameters, adjusting powder handling procedures, or implementing new monitoring technologies.

Lastly, operator training and standard operating procedures (SOPs) play a crucial role in maintaining quality. Comprehensive training programs ensure that all personnel involved in the sintering process understand the critical aspects of quality control and can effectively implement the established procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!