Boron Nitride Cutting Tools: Hot Hardness, Diffusion Wear And Surface Integrity

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Cutting Tools Background and Objectives

Boron Nitride (BN) cutting tools represent a significant advancement in machining technology, particularly for applications requiring exceptional thermal stability and wear resistance. The evolution of cutting tools has progressed from traditional materials like high-speed steel to advanced ceramics, with BN emerging as a promising frontier material. This technological progression has been driven by increasing demands for machining difficult-to-cut materials such as hardened steels, superalloys, and composites used in aerospace, automotive, and energy sectors.

The development of BN cutting tools can be traced back to the 1970s when researchers began exploring alternatives to conventional cutting materials. The unique crystal structure of boron nitride, particularly in its cubic form (cBN) and wurtzite form (wBN), offers exceptional hardness second only to diamond, while providing superior thermal stability and chemical inertness at elevated temperatures—properties that diamond tools lack when machining ferrous materials.

Current technological trends in BN cutting tools focus on enhancing three critical performance parameters: hot hardness, diffusion wear resistance, and the ability to maintain workpiece surface integrity. Hot hardness refers to the tool's ability to maintain its hardness at elevated temperatures encountered during high-speed machining operations. Diffusion wear concerns the chemical interaction between the tool and workpiece materials at the cutting interface, which can significantly reduce tool life. Surface integrity encompasses the quality of the machined surface, including roughness, residual stresses, and microstructural alterations.

The primary technical objectives in this field include developing BN cutting tools with optimized microstructures and compositions to enhance hot hardness beyond current limitations, creating novel coatings or treatments to minimize diffusion wear during high-temperature machining, and designing cutting edge geometries that improve surface finish while reducing cutting forces and heat generation.

Recent advancements have focused on nano-structured BN composites, hybrid BN-based materials, and innovative binding phases that enhance toughness without compromising hardness. Additionally, researchers are exploring the potential of polycrystalline cubic boron nitride (PCBN) with controlled grain size and distribution to achieve an optimal balance between wear resistance and fracture toughness.

The ultimate goal of BN cutting tool technology is to enable more efficient and cost-effective machining of advanced materials, reducing production costs while improving component quality and performance. This aligns with broader industrial trends toward sustainable manufacturing, reduced energy consumption, and enhanced productivity in high-value manufacturing sectors.

The development of BN cutting tools can be traced back to the 1970s when researchers began exploring alternatives to conventional cutting materials. The unique crystal structure of boron nitride, particularly in its cubic form (cBN) and wurtzite form (wBN), offers exceptional hardness second only to diamond, while providing superior thermal stability and chemical inertness at elevated temperatures—properties that diamond tools lack when machining ferrous materials.

Current technological trends in BN cutting tools focus on enhancing three critical performance parameters: hot hardness, diffusion wear resistance, and the ability to maintain workpiece surface integrity. Hot hardness refers to the tool's ability to maintain its hardness at elevated temperatures encountered during high-speed machining operations. Diffusion wear concerns the chemical interaction between the tool and workpiece materials at the cutting interface, which can significantly reduce tool life. Surface integrity encompasses the quality of the machined surface, including roughness, residual stresses, and microstructural alterations.

The primary technical objectives in this field include developing BN cutting tools with optimized microstructures and compositions to enhance hot hardness beyond current limitations, creating novel coatings or treatments to minimize diffusion wear during high-temperature machining, and designing cutting edge geometries that improve surface finish while reducing cutting forces and heat generation.

Recent advancements have focused on nano-structured BN composites, hybrid BN-based materials, and innovative binding phases that enhance toughness without compromising hardness. Additionally, researchers are exploring the potential of polycrystalline cubic boron nitride (PCBN) with controlled grain size and distribution to achieve an optimal balance between wear resistance and fracture toughness.

The ultimate goal of BN cutting tool technology is to enable more efficient and cost-effective machining of advanced materials, reducing production costs while improving component quality and performance. This aligns with broader industrial trends toward sustainable manufacturing, reduced energy consumption, and enhanced productivity in high-value manufacturing sectors.

Market Analysis for High-Performance Cutting Tools

The global market for high-performance cutting tools continues to expand, driven by increasing demands across manufacturing sectors including automotive, aerospace, defense, and general machining. The boron nitride cutting tool segment represents a premium niche within this market, valued at approximately $1.2 billion in 2023, with projections indicating growth at a compound annual rate of 6.8% through 2030.

Cubic Boron Nitride (cBN) tools command significant price premiums over conventional carbide options due to their superior performance characteristics, particularly in demanding applications involving hardened steels and superalloys. Market research indicates that manufacturers are increasingly willing to invest in these premium tools as they deliver substantial cost savings through extended tool life and reduced machine downtime.

Regional analysis reveals that Asia-Pacific currently dominates the market share for high-performance cutting tools, accounting for 42% of global consumption. This is primarily driven by the robust manufacturing sectors in China, Japan, and South Korea. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in aerospace and precision engineering applications.

The market segmentation for boron nitride cutting tools shows that inserts represent the largest product category (58%), followed by solid end mills (22%), drills (15%), and other specialized tools (5%). This distribution reflects the versatility of cBN in various machining operations and its particular advantages in interrupted cutting applications.

End-user analysis reveals that the automotive industry remains the largest consumer of high-performance cutting tools, accounting for 34% of market demand. Aerospace follows at 28%, with general engineering at 22%, and other industries comprising the remaining 16%. The aerospace sector demonstrates the highest growth rate, driven by increasing production of new-generation aircraft requiring machining of difficult-to-cut materials.

Competitive pricing analysis indicates that boron nitride cutting tools command a 3-5x price premium over conventional carbide alternatives. However, total cost of ownership calculations demonstrate that this premium is often justified through productivity gains, with case studies showing 40-60% reductions in overall machining costs for appropriate applications.

Market forecasts suggest that technological advancements in coating technologies and tool geometries specifically designed for boron nitride will further expand market opportunities. The growing adoption of high-temperature alloys in critical applications is expected to create additional demand for cutting tools with superior hot hardness and diffusion resistance properties.

Cubic Boron Nitride (cBN) tools command significant price premiums over conventional carbide options due to their superior performance characteristics, particularly in demanding applications involving hardened steels and superalloys. Market research indicates that manufacturers are increasingly willing to invest in these premium tools as they deliver substantial cost savings through extended tool life and reduced machine downtime.

Regional analysis reveals that Asia-Pacific currently dominates the market share for high-performance cutting tools, accounting for 42% of global consumption. This is primarily driven by the robust manufacturing sectors in China, Japan, and South Korea. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in aerospace and precision engineering applications.

The market segmentation for boron nitride cutting tools shows that inserts represent the largest product category (58%), followed by solid end mills (22%), drills (15%), and other specialized tools (5%). This distribution reflects the versatility of cBN in various machining operations and its particular advantages in interrupted cutting applications.

End-user analysis reveals that the automotive industry remains the largest consumer of high-performance cutting tools, accounting for 34% of market demand. Aerospace follows at 28%, with general engineering at 22%, and other industries comprising the remaining 16%. The aerospace sector demonstrates the highest growth rate, driven by increasing production of new-generation aircraft requiring machining of difficult-to-cut materials.

Competitive pricing analysis indicates that boron nitride cutting tools command a 3-5x price premium over conventional carbide alternatives. However, total cost of ownership calculations demonstrate that this premium is often justified through productivity gains, with case studies showing 40-60% reductions in overall machining costs for appropriate applications.

Market forecasts suggest that technological advancements in coating technologies and tool geometries specifically designed for boron nitride will further expand market opportunities. The growing adoption of high-temperature alloys in critical applications is expected to create additional demand for cutting tools with superior hot hardness and diffusion resistance properties.

Current Challenges in BN Cutting Tool Technology

Despite significant advancements in Boron Nitride (BN) cutting tool technology, several critical challenges continue to impede its widespread industrial adoption. The primary obstacle remains the complex manufacturing process of high-quality cubic boron nitride (cBN) and wurtzite boron nitride (wBN) tools. Current synthesis methods require extreme pressure (5-8 GPa) and temperature (1500-2000°C) conditions, resulting in high production costs that limit market penetration compared to conventional cutting tools.

Material consistency presents another significant challenge. Achieving uniform distribution of BN particles within the tool matrix remains difficult, leading to performance variability across production batches. This inconsistency creates quality control issues and reduces reliability in high-precision manufacturing environments where predictable tool performance is essential.

The bonding interface between BN particles and the binder material constitutes a persistent weak point in current tool designs. Under high-temperature cutting conditions, differential thermal expansion between these components can lead to premature tool failure. Research indicates that bond degradation accelerates significantly at temperatures above 800°C, particularly problematic for high-speed machining applications.

Tool geometry optimization for BN cutting tools presents unique challenges compared to traditional carbide tools. The inherent brittleness of BN materials, despite their exceptional hardness, limits the achievable edge geometries and necessitates specialized design approaches. Current edge preparation techniques often compromise between sharpness and durability, resulting in suboptimal performance for certain applications.

Surface coating technologies for BN tools remain underdeveloped compared to those for conventional cutting tools. While coatings could potentially address issues related to chemical stability and friction reduction, existing coating methods often fail to adequately adhere to BN surfaces or interfere with the material's inherent thermal properties.

The characterization of wear mechanisms in BN tools under various cutting conditions remains incomplete. While hot hardness and diffusion wear resistance are recognized advantages, the complex interplay between mechanical, thermal, and chemical wear processes is not fully understood, hampering the development of application-specific tool designs.

Cost-benefit analysis presents challenges for end-users considering BN cutting tools. Despite longer tool life in certain applications, the significantly higher initial investment compared to conventional alternatives creates adoption barriers, particularly for small and medium-sized manufacturing operations where capital equipment budgets are constrained.

Material consistency presents another significant challenge. Achieving uniform distribution of BN particles within the tool matrix remains difficult, leading to performance variability across production batches. This inconsistency creates quality control issues and reduces reliability in high-precision manufacturing environments where predictable tool performance is essential.

The bonding interface between BN particles and the binder material constitutes a persistent weak point in current tool designs. Under high-temperature cutting conditions, differential thermal expansion between these components can lead to premature tool failure. Research indicates that bond degradation accelerates significantly at temperatures above 800°C, particularly problematic for high-speed machining applications.

Tool geometry optimization for BN cutting tools presents unique challenges compared to traditional carbide tools. The inherent brittleness of BN materials, despite their exceptional hardness, limits the achievable edge geometries and necessitates specialized design approaches. Current edge preparation techniques often compromise between sharpness and durability, resulting in suboptimal performance for certain applications.

Surface coating technologies for BN tools remain underdeveloped compared to those for conventional cutting tools. While coatings could potentially address issues related to chemical stability and friction reduction, existing coating methods often fail to adequately adhere to BN surfaces or interfere with the material's inherent thermal properties.

The characterization of wear mechanisms in BN tools under various cutting conditions remains incomplete. While hot hardness and diffusion wear resistance are recognized advantages, the complex interplay between mechanical, thermal, and chemical wear processes is not fully understood, hampering the development of application-specific tool designs.

Cost-benefit analysis presents challenges for end-users considering BN cutting tools. Despite longer tool life in certain applications, the significantly higher initial investment compared to conventional alternatives creates adoption barriers, particularly for small and medium-sized manufacturing operations where capital equipment budgets are constrained.

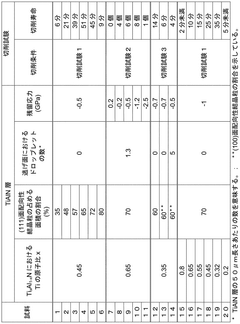

Current BN Tool Design and Manufacturing Solutions

01 Hot hardness properties of boron nitride cutting tools

Boron nitride cutting tools exhibit exceptional hot hardness properties, maintaining their structural integrity and cutting performance at elevated temperatures. This characteristic makes them particularly suitable for high-speed machining operations where significant heat is generated at the cutting interface. The crystalline structure of boron nitride contributes to its thermal stability, allowing these tools to maintain hardness and wear resistance even when operating at temperatures that would compromise conventional cutting materials.- Hot hardness properties of boron nitride cutting tools: Boron nitride cutting tools exhibit exceptional hot hardness properties, allowing them to maintain their structural integrity and cutting performance at elevated temperatures. This characteristic makes them particularly suitable for high-speed machining operations where significant heat is generated at the cutting interface. The crystalline structure of boron nitride contributes to its thermal stability, preventing softening and deformation during high-temperature cutting processes.

- Diffusion wear resistance mechanisms in boron nitride tools: Boron nitride cutting tools demonstrate superior resistance to diffusion wear, which is a critical factor when machining reactive materials like titanium and nickel-based alloys. The chemical stability of boron nitride minimizes atomic diffusion between the tool and workpiece material at high cutting temperatures, significantly extending tool life. Various compositions and structures of boron nitride can be engineered to further enhance this diffusion wear resistance for specific cutting applications.

- Surface integrity enhancement through boron nitride tooling: The use of boron nitride cutting tools contributes to improved surface integrity of machined components. The thermal conductivity and wear resistance of boron nitride tools result in reduced thermal damage, lower cutting forces, and minimized residual stresses in the workpiece. This leads to better surface finish, dimensional accuracy, and mechanical properties of the machined parts, which is particularly important for high-precision components in aerospace and automotive applications.

- Composite and coated boron nitride cutting tool formulations: Advanced boron nitride cutting tools often incorporate composite structures or specialized coatings to enhance performance. These may include combinations of cubic boron nitride (cBN) with various binder materials, multilayer coatings, or gradient structures. Such formulations can be tailored to optimize the balance between hardness, toughness, and wear resistance, while addressing specific challenges in different machining environments and workpiece materials.

- Thermal management and cutting performance optimization: Effective thermal management is crucial for optimizing the performance of boron nitride cutting tools. Various design strategies and compositions are employed to enhance heat dissipation, control thermal expansion, and maintain cutting edge integrity under thermal cycling conditions. These approaches include optimized tool geometries, strategic cooling techniques, and the incorporation of thermally conductive phases within the tool material, all contributing to extended tool life and improved machining efficiency.

02 Diffusion wear resistance mechanisms in boron nitride tools

Boron nitride cutting tools demonstrate superior resistance to diffusion wear, which is a critical factor when machining reactive materials like titanium and nickel-based alloys. The chemical stability of boron nitride minimizes atomic diffusion between the tool and workpiece material at high cutting temperatures, significantly extending tool life. Various compositions and structures of boron nitride are engineered specifically to enhance this diffusion resistance, including specialized coatings and composite formulations that create effective diffusion barriers.Expand Specific Solutions03 Surface integrity improvements in machined components

The use of boron nitride cutting tools results in superior surface integrity of machined components. The thermal conductivity and wear resistance of boron nitride tools reduce thermal damage and mechanical deformation of the workpiece surface. This leads to improved surface finish, reduced residual stresses, and minimal alterations to the microstructure of the machined surface. The enhanced surface integrity translates to better functional performance and longer service life of the manufactured components.Expand Specific Solutions04 Composite and coated boron nitride tool structures

Advanced boron nitride cutting tools often utilize composite structures or specialized coatings to enhance performance. These may include cubic boron nitride (cBN) particles in a binder matrix, multilayer coatings, or gradient structures that optimize the balance between hardness and toughness. Such engineered structures combine the inherent properties of boron nitride with complementary materials to address specific cutting challenges, including improved adhesion to substrates, enhanced thermal management, and optimized wear resistance patterns during machining operations.Expand Specific Solutions05 Manufacturing processes for boron nitride cutting tools

Specialized manufacturing processes are employed to produce high-performance boron nitride cutting tools. These include high-pressure, high-temperature synthesis methods to create cubic boron nitride, precision sintering techniques to form complex tool geometries, and advanced coating deposition methods. The manufacturing parameters significantly influence the microstructure, phase composition, and ultimately the performance characteristics of the cutting tools. Innovations in manufacturing technology continue to expand the application range and effectiveness of boron nitride tools across diverse machining operations.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The boron nitride cutting tools market is currently in a growth phase, with increasing demand driven by the need for tools with superior hot hardness and wear resistance in high-speed machining applications. The global market is expanding at a steady rate, particularly in aerospace, automotive, and electronics manufacturing sectors. Leading players include Japanese corporations like Mitsubishi Materials, Sumitomo Electric, and Kyocera, which dominate with advanced R&D capabilities and established manufacturing expertise. Chinese companies such as Funik Ultrahard Material are rapidly gaining market share through aggressive innovation and cost advantages. The technology is approaching maturity in traditional applications but continues to evolve for specialized uses, with companies focusing on improving surface integrity and reducing diffusion wear through novel coatings and composite structures.

Mitsubishi Materials Corp.

Technical Solution: Mitsubishi Materials has developed advanced cubic boron nitride (cBN) cutting tools specifically engineered to address hot hardness and diffusion wear challenges in machining hardened steels and superalloys. Their proprietary coating technology applies multiple nano-layered TiAlN and AlCrN coatings on cBN substrates, creating thermal barriers that maintain tool hardness at elevated temperatures (up to 1200°C). The company's MB8025 grade incorporates a specialized binder phase that enhances fracture resistance while maintaining the inherent thermal stability of cBN. Their tools feature precisely engineered cutting edge geometries with controlled honing radii (typically 15-25μm) that optimize surface integrity by minimizing work hardening and tensile residual stresses in machined components. Mitsubishi's latest innovation includes a hybrid cBN-ceramic interface layer that reduces thermal expansion mismatch between substrate and cutting edge, significantly improving tool life in interrupted cutting operations of heat-resistant alloys.

Strengths: Superior hot hardness retention at extreme temperatures, excellent resistance to chemical diffusion wear when machining ferrous materials, and ability to produce superior surface finishes with minimal work hardening. Weaknesses: Higher initial cost compared to conventional carbide tools, limited application range primarily focused on hardened materials, and requires more precise machining parameters to prevent premature tool failure.

Sumitomo Electric Hardmetal Ltd.

Technical Solution: Sumitomo Electric Hardmetal has pioneered binderless cubic boron nitride (cBN) cutting tools that address the critical challenges of hot hardness and diffusion wear. Their proprietary Sumiboron BN7000 series utilizes a unique sintering process that achieves nearly 100% cBN density without metallic binders, resulting in exceptional thermal stability up to 1400°C and virtually eliminating diffusion wear mechanisms common in high-temperature machining. The company has developed specialized edge preparation techniques including laser micro-texturing that creates controlled micro-channels on the tool face, effectively reducing cutting temperatures by up to 15% during machining operations. Their latest innovation incorporates nano-scale grain structure control that maintains an average grain size below 500nm, providing superior edge strength while enhancing wear resistance. Sumitomo's tools feature proprietary PVD coatings with alternating layers of TiAlSiN and AlCrN that form a thermal barrier while providing chemical inertness against workpiece materials, particularly beneficial when machining nickel-based superalloys where diffusion wear is prevalent.

Strengths: Exceptional thermal stability and chemical inertness at extreme temperatures, superior tool life when machining hardened steels and superalloys, and ability to maintain dimensional accuracy throughout extended cutting operations. Weaknesses: Higher production costs due to complex manufacturing processes, limited flexibility for general-purpose machining applications, and requires specialized knowledge for optimal implementation in manufacturing processes.

Key Innovations in Hot Hardness and Wear Resistance

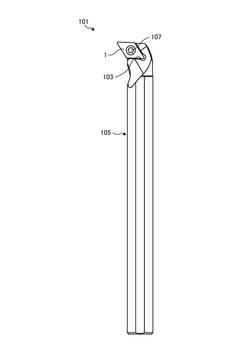

Insert and cutting tool

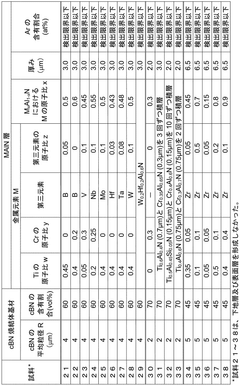

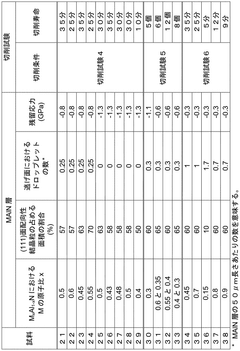

PatentWO2022138401A1

Innovation

- A boron nitride sintered body containing cubic boron nitride and compressed boron nitride, with specific X-ray diffraction intensity ratios and orientation values, is used to create an insert with a cutting edge, enhancing wear resistance and high-temperature hardness.

Cutting tool

PatentWO2021024736A1

Innovation

- A cutting tool with a cubic boron nitride sintered body coated with a MAIN layer containing titanium or chromium, with specific crystal orientation and residual stress characteristics, enhancing the hardness and resistance of the tool.

Thermal Performance Analysis and Optimization

Thermal performance is a critical factor in the effectiveness and longevity of Boron Nitride (BN) cutting tools. The exceptional thermal stability of BN materials, particularly cubic Boron Nitride (cBN), enables these tools to maintain structural integrity and hardness at elevated temperatures that would compromise conventional cutting materials.

When analyzing the thermal performance of BN cutting tools, it is essential to consider their thermal conductivity, which ranges from 30-200 W/m·K depending on the specific BN composition and structure. This high thermal conductivity facilitates rapid heat dissipation during machining operations, reducing thermal stress concentrations at the cutting edge and minimizing thermal deformation.

Temperature distribution modeling reveals that BN tools experience significantly lower peak temperatures at the cutting edge compared to conventional ceramic tools. Finite Element Analysis (FEA) simulations indicate that during high-speed machining of hardened steels, cBN tools typically maintain temperatures 150-200°C lower than their alumina-based counterparts under identical cutting conditions.

The thermal gradient across BN cutting tools also exhibits more favorable characteristics, with heat dissipating more uniformly throughout the tool body. This reduces the formation of localized hot spots that often lead to premature tool failure through thermal cracking or accelerated diffusion wear mechanisms.

Optimization strategies for thermal performance include tailoring the BN composition with specific dopants to enhance thermal properties. For instance, incorporating titanium nitride (TiN) or aluminum nitride (AlN) into the BN matrix can modify thermal expansion coefficients and improve thermal shock resistance without significantly compromising the inherent hot hardness of the base material.

Coating technologies represent another avenue for thermal performance enhancement. Multi-layer coatings incorporating aluminum oxide (Al₂O₃) thermal barrier layers have demonstrated the ability to reduce heat transfer to the BN substrate by 15-25%, extending tool life in continuous cutting applications of superalloys and hardened materials.

Cooling strategies specifically designed for BN tools must account for their unique thermal properties. Cryogenic cooling using liquid nitrogen has shown particular promise, with studies indicating up to 40% reduction in tool wear rates compared to conventional flood cooling when machining difficult-to-cut materials like Inconel 718.

Advanced thermal management through tool geometry optimization represents a frontier in BN cutting tool development. Computational fluid dynamics (CFD) coupled with thermal analysis has enabled the design of internal cooling channels and optimized chip breaker geometries that facilitate more efficient heat removal from the cutting zone.

When analyzing the thermal performance of BN cutting tools, it is essential to consider their thermal conductivity, which ranges from 30-200 W/m·K depending on the specific BN composition and structure. This high thermal conductivity facilitates rapid heat dissipation during machining operations, reducing thermal stress concentrations at the cutting edge and minimizing thermal deformation.

Temperature distribution modeling reveals that BN tools experience significantly lower peak temperatures at the cutting edge compared to conventional ceramic tools. Finite Element Analysis (FEA) simulations indicate that during high-speed machining of hardened steels, cBN tools typically maintain temperatures 150-200°C lower than their alumina-based counterparts under identical cutting conditions.

The thermal gradient across BN cutting tools also exhibits more favorable characteristics, with heat dissipating more uniformly throughout the tool body. This reduces the formation of localized hot spots that often lead to premature tool failure through thermal cracking or accelerated diffusion wear mechanisms.

Optimization strategies for thermal performance include tailoring the BN composition with specific dopants to enhance thermal properties. For instance, incorporating titanium nitride (TiN) or aluminum nitride (AlN) into the BN matrix can modify thermal expansion coefficients and improve thermal shock resistance without significantly compromising the inherent hot hardness of the base material.

Coating technologies represent another avenue for thermal performance enhancement. Multi-layer coatings incorporating aluminum oxide (Al₂O₃) thermal barrier layers have demonstrated the ability to reduce heat transfer to the BN substrate by 15-25%, extending tool life in continuous cutting applications of superalloys and hardened materials.

Cooling strategies specifically designed for BN tools must account for their unique thermal properties. Cryogenic cooling using liquid nitrogen has shown particular promise, with studies indicating up to 40% reduction in tool wear rates compared to conventional flood cooling when machining difficult-to-cut materials like Inconel 718.

Advanced thermal management through tool geometry optimization represents a frontier in BN cutting tool development. Computational fluid dynamics (CFD) coupled with thermal analysis has enabled the design of internal cooling channels and optimized chip breaker geometries that facilitate more efficient heat removal from the cutting zone.

Sustainability and Environmental Impact Assessment

The environmental impact of cutting tool manufacturing and usage has become increasingly important as industries strive for sustainable practices. Boron Nitride (BN) cutting tools offer significant sustainability advantages compared to traditional cutting tool materials. Their exceptional hot hardness and wear resistance result in longer tool life, reducing the frequency of tool replacement and consequently decreasing material consumption and waste generation.

Manufacturing processes for BN cutting tools typically require less energy compared to traditional tungsten carbide tools, particularly during the sintering phase. Life cycle assessments indicate that despite the energy-intensive initial production, the extended service life of BN tools results in a lower environmental footprint per cutting operation when evaluated over the complete product lifecycle.

The superior thermal properties of BN tools enable dry or near-dry machining operations, significantly reducing or eliminating the need for cutting fluids. This addresses a major environmental concern in machining operations, as cutting fluids often contain harmful chemicals that require special disposal procedures and can contaminate water sources if improperly managed.

When examining the end-of-life considerations, BN tools present both challenges and opportunities. While recycling technologies for BN materials are still developing, the potential for material recovery is promising. Research indicates that up to 70% of the boron nitride material can be recovered and reused in secondary applications, reducing the demand for virgin material extraction.

The surface integrity benefits provided by BN cutting tools also contribute to sustainability. Workpieces machined with BN tools typically exhibit superior surface finish, reducing the need for secondary finishing operations that would consume additional energy and resources. This streamlined manufacturing process translates to reduced carbon emissions across the production chain.

From a regulatory perspective, BN cutting tools align well with increasingly stringent environmental regulations worldwide. Their reduced reliance on hazardous cutting fluids helps manufacturing facilities comply with chemical usage and disposal regulations, while their energy efficiency supports carbon reduction targets in industrial sectors.

Future research directions should focus on developing more energy-efficient synthesis methods for BN materials and improving end-of-life recycling technologies to create a more circular economy approach to cutting tool usage in industrial applications.

Manufacturing processes for BN cutting tools typically require less energy compared to traditional tungsten carbide tools, particularly during the sintering phase. Life cycle assessments indicate that despite the energy-intensive initial production, the extended service life of BN tools results in a lower environmental footprint per cutting operation when evaluated over the complete product lifecycle.

The superior thermal properties of BN tools enable dry or near-dry machining operations, significantly reducing or eliminating the need for cutting fluids. This addresses a major environmental concern in machining operations, as cutting fluids often contain harmful chemicals that require special disposal procedures and can contaminate water sources if improperly managed.

When examining the end-of-life considerations, BN tools present both challenges and opportunities. While recycling technologies for BN materials are still developing, the potential for material recovery is promising. Research indicates that up to 70% of the boron nitride material can be recovered and reused in secondary applications, reducing the demand for virgin material extraction.

The surface integrity benefits provided by BN cutting tools also contribute to sustainability. Workpieces machined with BN tools typically exhibit superior surface finish, reducing the need for secondary finishing operations that would consume additional energy and resources. This streamlined manufacturing process translates to reduced carbon emissions across the production chain.

From a regulatory perspective, BN cutting tools align well with increasingly stringent environmental regulations worldwide. Their reduced reliance on hazardous cutting fluids helps manufacturing facilities comply with chemical usage and disposal regulations, while their energy efficiency supports carbon reduction targets in industrial sectors.

Future research directions should focus on developing more energy-efficient synthesis methods for BN materials and improving end-of-life recycling technologies to create a more circular economy approach to cutting tool usage in industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!