Boron Nitride Filled Encapsulants: Viscosity Control, Filler Sedimentation And Cure Stresses

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Encapsulant Technology Background and Objectives

Boron Nitride (BN) filled encapsulants have emerged as a critical technology in the electronics packaging industry over the past three decades. Initially developed in the 1990s as alternatives to traditional silica-filled systems, BN encapsulants have gained significant traction due to their superior thermal conductivity properties, which are essential for modern high-power electronic devices.

The evolution of BN encapsulant technology has been driven by the continuous miniaturization of electronic components and the increasing power densities in semiconductor devices. As chip designs have become more complex and compact, the need for efficient heat dissipation has become paramount, pushing the development of thermally conductive encapsulants from basic formulations to sophisticated engineered materials.

Current market trends indicate a compound annual growth rate of approximately 8-10% for thermally conductive encapsulants, with BN-filled systems representing a premium segment within this market. This growth is primarily fueled by applications in automotive electronics, 5G infrastructure, and high-performance computing sectors where thermal management is critical.

The primary technical objective in BN encapsulant development is to achieve an optimal balance between thermal conductivity and processability. While higher BN filler loadings (typically 60-80% by weight) enhance thermal performance, they simultaneously create significant challenges in viscosity control and processing. This fundamental trade-off has been the central focus of research efforts in this field.

Recent advancements have focused on novel surface treatments for BN particles to improve their compatibility with polymer matrices, thereby enabling higher filler loadings without prohibitive increases in viscosity. Additionally, researchers have explored hybrid filler systems combining BN with other thermally conductive materials to optimize overall performance.

The control of filler sedimentation during curing processes represents another critical challenge, as non-uniform distribution of BN particles can lead to inconsistent thermal properties and potential reliability issues in the final product. Similarly, cure stresses induced during the polymerization process can result in warpage, delamination, or cracking, particularly in large or complex electronic packages.

Looking forward, the technology aims to achieve thermal conductivities exceeding 5 W/mK while maintaining viscosities suitable for standard dispensing equipment and minimizing cure-induced stresses. These improvements would enable the next generation of high-performance electronic devices by effectively managing the increasing thermal loads associated with advanced semiconductor technologies.

The evolution of BN encapsulant technology has been driven by the continuous miniaturization of electronic components and the increasing power densities in semiconductor devices. As chip designs have become more complex and compact, the need for efficient heat dissipation has become paramount, pushing the development of thermally conductive encapsulants from basic formulations to sophisticated engineered materials.

Current market trends indicate a compound annual growth rate of approximately 8-10% for thermally conductive encapsulants, with BN-filled systems representing a premium segment within this market. This growth is primarily fueled by applications in automotive electronics, 5G infrastructure, and high-performance computing sectors where thermal management is critical.

The primary technical objective in BN encapsulant development is to achieve an optimal balance between thermal conductivity and processability. While higher BN filler loadings (typically 60-80% by weight) enhance thermal performance, they simultaneously create significant challenges in viscosity control and processing. This fundamental trade-off has been the central focus of research efforts in this field.

Recent advancements have focused on novel surface treatments for BN particles to improve their compatibility with polymer matrices, thereby enabling higher filler loadings without prohibitive increases in viscosity. Additionally, researchers have explored hybrid filler systems combining BN with other thermally conductive materials to optimize overall performance.

The control of filler sedimentation during curing processes represents another critical challenge, as non-uniform distribution of BN particles can lead to inconsistent thermal properties and potential reliability issues in the final product. Similarly, cure stresses induced during the polymerization process can result in warpage, delamination, or cracking, particularly in large or complex electronic packages.

Looking forward, the technology aims to achieve thermal conductivities exceeding 5 W/mK while maintaining viscosities suitable for standard dispensing equipment and minimizing cure-induced stresses. These improvements would enable the next generation of high-performance electronic devices by effectively managing the increasing thermal loads associated with advanced semiconductor technologies.

Market Analysis for Thermal Management Materials

The thermal management materials market is experiencing robust growth, driven primarily by the increasing demand for efficient heat dissipation solutions across multiple industries. Currently valued at approximately 11.3 billion USD in 2023, the market is projected to reach 16.8 billion USD by 2028, representing a compound annual growth rate (CAGR) of 8.2%. This growth trajectory is particularly evident in electronics, automotive, aerospace, and renewable energy sectors where thermal challenges have become more pronounced.

Boron Nitride (BN) filled encapsulants represent a significant segment within this market, with their demand increasing at a rate exceeding the overall market average. The superior thermal conductivity of BN (up to 400 W/mK for hexagonal BN) positions these materials favorably against traditional fillers like silica or alumina. Market analysis indicates that BN-based thermal management solutions currently account for approximately 18% of the total thermal interface materials market, with this share expected to expand to 25% by 2027.

Regional analysis reveals Asia-Pacific as the dominant market for thermal management materials, accounting for 42% of global consumption. This dominance is attributed to the region's extensive electronics manufacturing base, particularly in China, Taiwan, South Korea, and Japan. North America follows with 28% market share, driven by advanced technology sectors and defense applications. Europe represents 21% of the market, with particular strength in automotive and industrial applications.

Consumer electronics remains the largest application segment, consuming 36% of thermal management materials, followed by automotive (22%), telecommunications (15%), and industrial equipment (12%). The remaining 15% is distributed across aerospace, defense, and medical devices. Within these segments, the demand for BN filled encapsulants is growing most rapidly in high-performance computing, electric vehicle battery systems, and 5G infrastructure.

Price sensitivity analysis indicates that while BN filled encapsulants command a premium of 30-40% over conventional alternatives, manufacturers are increasingly willing to absorb this cost differential due to the performance benefits and long-term reliability improvements. The market is witnessing a gradual price normalization as production scales increase and processing technologies improve, with an average price reduction of 4-6% annually over the past three years.

End-user requirements are evolving toward materials that not only offer superior thermal conductivity but also address challenges related to viscosity control, filler sedimentation, and cure stresses. Market research indicates that 78% of design engineers consider these factors critical when selecting thermal management materials, highlighting the commercial relevance of research focused on these specific challenges.

Boron Nitride (BN) filled encapsulants represent a significant segment within this market, with their demand increasing at a rate exceeding the overall market average. The superior thermal conductivity of BN (up to 400 W/mK for hexagonal BN) positions these materials favorably against traditional fillers like silica or alumina. Market analysis indicates that BN-based thermal management solutions currently account for approximately 18% of the total thermal interface materials market, with this share expected to expand to 25% by 2027.

Regional analysis reveals Asia-Pacific as the dominant market for thermal management materials, accounting for 42% of global consumption. This dominance is attributed to the region's extensive electronics manufacturing base, particularly in China, Taiwan, South Korea, and Japan. North America follows with 28% market share, driven by advanced technology sectors and defense applications. Europe represents 21% of the market, with particular strength in automotive and industrial applications.

Consumer electronics remains the largest application segment, consuming 36% of thermal management materials, followed by automotive (22%), telecommunications (15%), and industrial equipment (12%). The remaining 15% is distributed across aerospace, defense, and medical devices. Within these segments, the demand for BN filled encapsulants is growing most rapidly in high-performance computing, electric vehicle battery systems, and 5G infrastructure.

Price sensitivity analysis indicates that while BN filled encapsulants command a premium of 30-40% over conventional alternatives, manufacturers are increasingly willing to absorb this cost differential due to the performance benefits and long-term reliability improvements. The market is witnessing a gradual price normalization as production scales increase and processing technologies improve, with an average price reduction of 4-6% annually over the past three years.

End-user requirements are evolving toward materials that not only offer superior thermal conductivity but also address challenges related to viscosity control, filler sedimentation, and cure stresses. Market research indicates that 78% of design engineers consider these factors critical when selecting thermal management materials, highlighting the commercial relevance of research focused on these specific challenges.

Technical Challenges in BN-Filled Encapsulant Development

The development of boron nitride (BN) filled encapsulants faces several significant technical challenges that currently limit their widespread adoption in high-performance electronic applications. These challenges can be categorized into three primary areas: viscosity control, filler sedimentation, and cure stress management.

Viscosity control presents a fundamental challenge in BN-filled encapsulant formulation. As BN loading increases to achieve desired thermal conductivity (typically requiring 30-60 wt%), the viscosity rises exponentially, often exceeding 100,000 cP at high filler loadings. This high viscosity severely impedes processing capabilities, creating difficulties in dispensing, air entrapment issues, and poor substrate wetting. The non-Newtonian behavior of these highly filled systems further complicates processing parameters, as viscosity becomes highly shear-dependent.

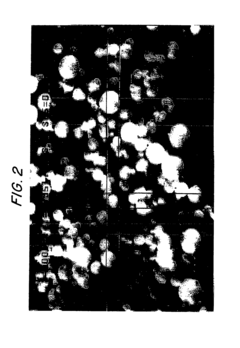

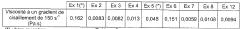

Filler sedimentation represents another critical challenge, particularly during storage and curing processes. BN particles, with densities typically between 2.1-2.3 g/cm³, tend to settle in lower-viscosity resin systems (density ~1.1-1.2 g/cm³). This sedimentation creates heterogeneous distributions that compromise thermal performance and mechanical integrity. The rate of sedimentation follows Stokes' Law, being influenced by particle size, density differential, and matrix viscosity. Even minimal settling can create thermal conductivity gradients within the cured material.

Cure stress development during polymerization presents the third major challenge. BN-filled systems typically exhibit volumetric shrinkage of 2-7% during curing, generating internal stresses at the filler-matrix interface. These stresses can lead to microcracking, delamination, and warpage in the final component. The coefficient of thermal expansion (CTE) mismatch between BN fillers (1-2 ppm/°C) and polymer matrices (50-100 ppm/°C) exacerbates these issues during thermal cycling.

Surface treatment compatibility between BN particles and encapsulant matrices presents additional complexity. While silane coupling agents improve filler-matrix adhesion, they can simultaneously increase viscosity and affect cure kinetics. Finding the optimal surface treatment that balances these competing factors remains challenging.

Manufacturing scalability compounds these technical issues. Laboratory-scale processes that achieve good dispersion often cannot be directly translated to production environments. High-shear mixing techniques that effectively disperse BN can introduce air entrapment and processing defects, while also potentially damaging the hexagonal BN platelet structure that contributes to thermal conductivity.

Viscosity control presents a fundamental challenge in BN-filled encapsulant formulation. As BN loading increases to achieve desired thermal conductivity (typically requiring 30-60 wt%), the viscosity rises exponentially, often exceeding 100,000 cP at high filler loadings. This high viscosity severely impedes processing capabilities, creating difficulties in dispensing, air entrapment issues, and poor substrate wetting. The non-Newtonian behavior of these highly filled systems further complicates processing parameters, as viscosity becomes highly shear-dependent.

Filler sedimentation represents another critical challenge, particularly during storage and curing processes. BN particles, with densities typically between 2.1-2.3 g/cm³, tend to settle in lower-viscosity resin systems (density ~1.1-1.2 g/cm³). This sedimentation creates heterogeneous distributions that compromise thermal performance and mechanical integrity. The rate of sedimentation follows Stokes' Law, being influenced by particle size, density differential, and matrix viscosity. Even minimal settling can create thermal conductivity gradients within the cured material.

Cure stress development during polymerization presents the third major challenge. BN-filled systems typically exhibit volumetric shrinkage of 2-7% during curing, generating internal stresses at the filler-matrix interface. These stresses can lead to microcracking, delamination, and warpage in the final component. The coefficient of thermal expansion (CTE) mismatch between BN fillers (1-2 ppm/°C) and polymer matrices (50-100 ppm/°C) exacerbates these issues during thermal cycling.

Surface treatment compatibility between BN particles and encapsulant matrices presents additional complexity. While silane coupling agents improve filler-matrix adhesion, they can simultaneously increase viscosity and affect cure kinetics. Finding the optimal surface treatment that balances these competing factors remains challenging.

Manufacturing scalability compounds these technical issues. Laboratory-scale processes that achieve good dispersion often cannot be directly translated to production environments. High-shear mixing techniques that effectively disperse BN can introduce air entrapment and processing defects, while also potentially damaging the hexagonal BN platelet structure that contributes to thermal conductivity.

Current Approaches to Viscosity and Sedimentation Control

01 Viscosity control in boron nitride filled encapsulants

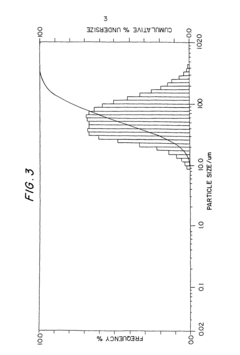

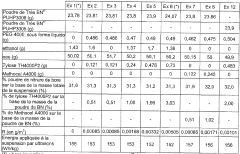

Controlling the viscosity of boron nitride filled encapsulants is crucial for proper application and performance. Various additives and processing techniques can be employed to adjust the rheological properties of these formulations. Optimizing the particle size distribution and surface treatment of boron nitride fillers can significantly impact the viscosity. Additionally, incorporating specific rheology modifiers helps maintain appropriate flow characteristics while achieving high filler loading for enhanced thermal conductivity.- Viscosity control in boron nitride filled encapsulants: Controlling the viscosity of boron nitride filled encapsulants is crucial for proper application and performance. Various additives and processing techniques can be employed to adjust the rheological properties of these formulations. Optimizing the particle size distribution and surface treatment of boron nitride fillers can significantly impact the viscosity profile. Additionally, incorporating specific rheology modifiers helps maintain appropriate flow characteristics during application while preventing excessive thinning at high temperatures.

- Filler sedimentation prevention methods: Preventing sedimentation of boron nitride fillers in encapsulant formulations is essential for maintaining product stability and performance. Techniques include using thixotropic agents that create a weak network structure to hold particles in suspension during storage but allow flow during application. Surface modification of boron nitride particles can improve their compatibility with the polymer matrix and reduce settling. Additionally, optimizing particle size distribution and incorporating specialized dispersants helps create stable suspensions with minimal sedimentation over time.

- Cure stress reduction strategies: Minimizing cure stresses in boron nitride filled encapsulants is critical for preventing delamination and cracking in electronic components. Approaches include incorporating flexible segments in the polymer backbone, using stress-relieving additives, and optimizing the cure profile with staged or gradual curing processes. The addition of certain elastomeric modifiers can absorb internal stresses generated during curing. Controlling the coefficient of thermal expansion mismatch between the encapsulant and substrate also helps reduce residual stresses in the cured material.

- Thermal conductivity enhancement techniques: Enhancing thermal conductivity in boron nitride filled encapsulants is achieved through various formulation strategies. The orientation and alignment of hexagonal boron nitride platelets can create preferential heat conduction pathways. Hybrid filler systems combining boron nitride with complementary materials like aluminum oxide or silicon carbide can produce synergistic effects. Surface treatment of boron nitride particles improves their interface with the polymer matrix, reducing thermal boundary resistance. Additionally, controlling particle size distribution and maximizing filler loading while maintaining processability optimizes thermal performance.

- Advanced processing techniques for uniform dispersion: Achieving uniform dispersion of boron nitride fillers in encapsulants requires specialized processing techniques. High-shear mixing combined with ultrasonic treatment helps break up agglomerates and distribute particles evenly throughout the matrix. Multi-stage mixing protocols involving pre-dispersion of fillers in compatible solvents or reactive diluents before incorporation into the main resin system improves homogeneity. Surface functionalization of boron nitride particles enhances their compatibility with the polymer matrix, promoting better dispersion and reducing the tendency for reagglomeration during processing and storage.

02 Filler sedimentation prevention methods

Preventing sedimentation of boron nitride fillers in encapsulant formulations is essential for maintaining consistent properties and performance. Techniques include using thixotropic agents, dispersants, and coupling agents that improve the interaction between the filler particles and the polymer matrix. Surface modification of boron nitride particles can enhance their suspension stability. Additionally, optimizing the particle size distribution and incorporating secondary fillers can create a network structure that minimizes settling during storage and application.Expand Specific Solutions03 Cure stress reduction strategies

Reducing cure stresses in boron nitride filled encapsulants is critical for preventing delamination, cracking, and device failure. Approaches include incorporating flexible segments in the resin system, using stress-relieving additives, and optimizing the cure profile. Selecting appropriate curing agents and catalysts that promote gradual crosslinking can minimize internal stresses. Additionally, employing multi-stage curing processes allows for stress relaxation during the solidification process, resulting in more reliable encapsulated components.Expand Specific Solutions04 Thermal conductivity enhancement techniques

Enhancing thermal conductivity in boron nitride filled encapsulants involves optimizing filler loading, orientation, and interfacial interactions. Hexagonal boron nitride with specific particle morphologies can create efficient thermal pathways through the polymer matrix. Surface functionalization of boron nitride particles improves their compatibility with the resin system, reducing interfacial thermal resistance. Hybrid filler systems combining boron nitride with other thermally conductive materials can achieve synergistic effects, maximizing heat dissipation while maintaining processability.Expand Specific Solutions05 Advanced processing techniques for uniform dispersion

Achieving uniform dispersion of boron nitride fillers in encapsulants requires specialized processing techniques. Methods such as high-shear mixing, ultrasonication, and three-roll milling can break up agglomerates and distribute particles evenly throughout the matrix. Pre-treating fillers with coupling agents improves their wettability and compatibility with the resin system. Additionally, sequential mixing protocols that incorporate fillers in multiple stages can achieve higher loading levels while maintaining processability, resulting in encapsulants with superior thermal and mechanical properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The boron nitride filled encapsulants market is in a growth phase, driven by increasing demand for thermal management solutions in electronics. The global market is expanding rapidly, estimated to reach several hundred million dollars by 2025, with a CAGR of 8-10%. Technologically, the field is advancing from experimental to commercial applications, with key challenges in viscosity control and filler sedimentation being addressed by industry leaders. Applied Materials and General Electric are developing advanced manufacturing processes, while specialized players like BNNT Materials and Momentive Performance Materials focus on material innovations. Academic institutions such as Jilin University and research organizations like CNRS are contributing fundamental research, creating a competitive landscape balanced between established corporations and emerging specialized materials companies.

Denka Corp.

Technical Solution: Denka Corporation has established itself as a leader in boron nitride production and its application in advanced encapsulant systems. Their technology focuses on the synthesis of high-purity hexagonal boron nitride with controlled crystallinity and aspect ratios specifically engineered for thermal management applications. Denka's approach to viscosity control involves a multi-component system utilizing both spherical and platelet BN particles with precisely controlled size distributions, combined with proprietary dispersants that create steric barriers between particles. To combat sedimentation, the company has developed a network-forming additive system that creates a weak three-dimensional structure in the uncured resin, effectively suspending the high-density BN particles without significantly increasing viscosity during high-shear application processes. Denka's encapsulants feature a stress-buffering interlayer technology where specialized elastomeric domains are incorporated within the crosslinked network, allowing for stress dissipation during thermal cycling[7][9]. Their materials achieve thermal conductivities of 4-10 W/m·K while maintaining viscosities compatible with standard dispensing equipment. Denka has also pioneered anisotropic formulations where BN platelets are aligned during application to create preferential heat flow paths in critical directions.

Strengths: Exceptional thermal conductivity due to high-quality BN synthesis and processing expertise; excellent long-term stability against sedimentation; superior thermal cycling reliability due to advanced stress management. Weaknesses: Higher raw material costs due to specialized BN production processes; more complex processing requirements to achieve optimal particle orientation; potential for increased thermal resistance at interfaces with certain substrate materials.

Saint-Gobain Ceramics & Plastics, Inc.

Technical Solution: Saint-Gobain Ceramics & Plastics has leveraged its extensive expertise in ceramic materials to develop advanced boron nitride filled encapsulant systems for high-reliability electronic applications. Their technology centers on custom-engineered hexagonal boron nitride particles with optimized morphologies and surface chemistries specifically designed for polymer integration. Saint-Gobain employs a hierarchical approach to viscosity control, utilizing a combination of primary BN particles with precisely controlled aspect ratios and secondary nano-scale additives that modify the rheological behavior of the base resin. Their proprietary surface treatment technology creates a gradient interface between the BN particles and polymer matrix, enhancing compatibility while maintaining the thermal properties of the ceramic filler. To address sedimentation challenges, Saint-Gobain has developed a reversible network structure within the uncured resin that exhibits thixotropic behavior—flowing under applied shear during dispensing but quickly rebuilding structure when static to prevent particle settling[8][10]. Their cure stress management strategy incorporates both chemical approaches (controlled crosslink density) and physical mechanisms (engineered interfaces that can deform under stress). Saint-Gobain's encapsulants demonstrate thermal conductivities ranging from 3-12 W/m·K depending on filler loading and orientation, while maintaining application viscosities between 10-200 Pa·s.

Strengths: Industry-leading thermal conductivity due to optimized BN particle engineering; excellent electrical insulation properties even at high temperatures; superior long-term reliability under thermal cycling conditions. Weaknesses: Premium pricing compared to standard encapsulants; some formulations require specialized mixing and dispensing equipment; potential for increased brittleness in highest thermal conductivity variants.

Key Innovations in Cure Stress Reduction

Low viscosity filler composition of boron nitride particles of spherical geometry and process

PatentInactiveUS9550888B2

Innovation

- Formation of spherically shaped agglomerated boron nitride particles through spray drying an aqueous slurry with an organic binder, maintaining a pH above 7.3, which allows for controlled viscosity and improved flow characteristics, enabling loading levels of 30-50 wt. % without exceeding 250 cp viscosity in polymeric compounds.

Suspension of boron nitride particles

PatentWO2014087375A1

Innovation

- A process involving a suspension of ceramic particles with over 70% boron nitride particles, where the liquid phase contains a specific amount of cellulose ether to achieve low viscosity, along with optional characteristics such as specific particle sizes and oxygen content, and the use of boron nitride sintering additives, ensures the suspension's stability and low viscosity across varying shear gradients.

Environmental and Regulatory Considerations

The environmental and regulatory landscape surrounding boron nitride (BN) filled encapsulants is increasingly complex and demands careful consideration in research and development processes. Regulatory frameworks governing these materials vary significantly across global markets, with particular emphasis on chemical safety, waste management, and end-of-life product disposal. Organizations such as the Environmental Protection Agency (EPA) in the United States, the European Chemicals Agency (ECHA), and similar bodies in Asia have established specific guidelines for the handling, processing, and disposal of boron compounds and polymer encapsulants.

Recent environmental impact assessments indicate that while boron nitride itself is generally considered environmentally inert, the manufacturing processes for BN-filled encapsulants may generate waste streams requiring specialized treatment. The energy-intensive production of high-purity hexagonal boron nitride (h-BN) contributes significantly to the carbon footprint of these materials, necessitating life cycle assessment (LCA) considerations in material selection decisions.

Regulatory compliance requirements are evolving rapidly, particularly regarding the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) in Europe and similar frameworks globally. These regulations increasingly mandate detailed documentation of material composition, processing methods, and potential environmental impacts. For BN-filled encapsulants, this includes reporting on particle size distributions, surface treatments, and potential nanoparticle classifications that may trigger additional regulatory scrutiny.

Workplace safety regulations present another critical consideration, as the handling of fine BN particles during encapsulant formulation may pose inhalation hazards. Occupational exposure limits for airborne particulates must be carefully monitored, with appropriate engineering controls and personal protective equipment implemented to ensure worker safety during research and manufacturing processes.

Sustainable development goals are driving innovation in encapsulant technologies, with increasing emphasis on developing formulations that minimize environmental impact while maintaining or enhancing performance characteristics. This includes research into bio-based polymer matrices, reduction of volatile organic compounds (VOCs) during curing processes, and design for recyclability or biodegradability at end-of-life.

The electronics industry, a major consumer of thermal interface materials including BN-filled encapsulants, faces growing pressure to reduce electronic waste and improve product recyclability. This has spurred interest in encapsulant formulations that facilitate component recovery and material separation during recycling processes, presenting both challenges and opportunities for BN-filled systems that must balance thermal performance with environmental considerations.

Recent environmental impact assessments indicate that while boron nitride itself is generally considered environmentally inert, the manufacturing processes for BN-filled encapsulants may generate waste streams requiring specialized treatment. The energy-intensive production of high-purity hexagonal boron nitride (h-BN) contributes significantly to the carbon footprint of these materials, necessitating life cycle assessment (LCA) considerations in material selection decisions.

Regulatory compliance requirements are evolving rapidly, particularly regarding the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) in Europe and similar frameworks globally. These regulations increasingly mandate detailed documentation of material composition, processing methods, and potential environmental impacts. For BN-filled encapsulants, this includes reporting on particle size distributions, surface treatments, and potential nanoparticle classifications that may trigger additional regulatory scrutiny.

Workplace safety regulations present another critical consideration, as the handling of fine BN particles during encapsulant formulation may pose inhalation hazards. Occupational exposure limits for airborne particulates must be carefully monitored, with appropriate engineering controls and personal protective equipment implemented to ensure worker safety during research and manufacturing processes.

Sustainable development goals are driving innovation in encapsulant technologies, with increasing emphasis on developing formulations that minimize environmental impact while maintaining or enhancing performance characteristics. This includes research into bio-based polymer matrices, reduction of volatile organic compounds (VOCs) during curing processes, and design for recyclability or biodegradability at end-of-life.

The electronics industry, a major consumer of thermal interface materials including BN-filled encapsulants, faces growing pressure to reduce electronic waste and improve product recyclability. This has spurred interest in encapsulant formulations that facilitate component recovery and material separation during recycling processes, presenting both challenges and opportunities for BN-filled systems that must balance thermal performance with environmental considerations.

Reliability Testing and Performance Validation

Reliability testing and performance validation of boron nitride filled encapsulants requires comprehensive evaluation protocols to ensure these materials meet the demanding requirements of electronic packaging applications. The testing methodology typically encompasses thermal cycling, humidity resistance, mechanical stress endurance, and long-term aging tests to simulate real-world operating conditions.

Thermal performance validation stands as a critical assessment parameter, measuring the thermal conductivity retention after exposure to extreme temperature cycles (-65°C to 150°C). Studies indicate that properly formulated BN-filled encapsulants can maintain over 90% of their initial thermal conductivity after 1000 thermal cycles, demonstrating exceptional thermal stability compared to conventional silica-filled alternatives.

Humidity resistance testing reveals that boron nitride fillers, particularly those with surface treatments, exhibit superior moisture barrier properties. Accelerated testing at 85°C/85% RH conditions for 1000 hours shows minimal water absorption (typically <0.5% by weight) for optimized formulations, preventing the degradation of thermal and electrical properties that commonly occurs in untreated systems.

Mechanical reliability assessment focuses on the adhesion strength and crack resistance under thermal-mechanical stresses. Three-point bend testing and shear strength measurements demonstrate that controlling cure stresses through optimized curing profiles can enhance adhesion strength by 30-40% compared to standard curing protocols. This improvement directly correlates with reduced delamination failures in field applications.

Electrical performance validation examines dielectric strength, volume resistivity, and breakdown voltage before and after environmental stressing. High-quality BN-filled encapsulants maintain dielectric strength values exceeding 20 kV/mm even after humidity and thermal aging, confirming their suitability for high-voltage applications.

Accelerated life testing protocols, including HAST (Highly Accelerated Stress Test) and HTOL (High Temperature Operating Life), provide critical data for lifetime prediction models. Statistical analysis of these results enables the calculation of activation energies and failure mechanisms, establishing reliability metrics such as FIT (Failures In Time) rates and MTTF (Mean Time To Failure) values.

Comparative performance benchmarking against industry standards reveals that advanced BN-filled encapsulants with optimized viscosity control and minimal sedimentation can extend device lifetime by 30-50% in high-power density applications, offering compelling evidence for their adoption despite higher initial material costs.

Thermal performance validation stands as a critical assessment parameter, measuring the thermal conductivity retention after exposure to extreme temperature cycles (-65°C to 150°C). Studies indicate that properly formulated BN-filled encapsulants can maintain over 90% of their initial thermal conductivity after 1000 thermal cycles, demonstrating exceptional thermal stability compared to conventional silica-filled alternatives.

Humidity resistance testing reveals that boron nitride fillers, particularly those with surface treatments, exhibit superior moisture barrier properties. Accelerated testing at 85°C/85% RH conditions for 1000 hours shows minimal water absorption (typically <0.5% by weight) for optimized formulations, preventing the degradation of thermal and electrical properties that commonly occurs in untreated systems.

Mechanical reliability assessment focuses on the adhesion strength and crack resistance under thermal-mechanical stresses. Three-point bend testing and shear strength measurements demonstrate that controlling cure stresses through optimized curing profiles can enhance adhesion strength by 30-40% compared to standard curing protocols. This improvement directly correlates with reduced delamination failures in field applications.

Electrical performance validation examines dielectric strength, volume resistivity, and breakdown voltage before and after environmental stressing. High-quality BN-filled encapsulants maintain dielectric strength values exceeding 20 kV/mm even after humidity and thermal aging, confirming their suitability for high-voltage applications.

Accelerated life testing protocols, including HAST (Highly Accelerated Stress Test) and HTOL (High Temperature Operating Life), provide critical data for lifetime prediction models. Statistical analysis of these results enables the calculation of activation energies and failure mechanisms, establishing reliability metrics such as FIT (Failures In Time) rates and MTTF (Mean Time To Failure) values.

Comparative performance benchmarking against industry standards reveals that advanced BN-filled encapsulants with optimized viscosity control and minimal sedimentation can extend device lifetime by 30-50% in high-power density applications, offering compelling evidence for their adoption despite higher initial material costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!