How Boron Nitride Powders Deliver Consistent Flowability For Die Filling And Molding?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Boron Nitride Powder Technology Background and Objectives

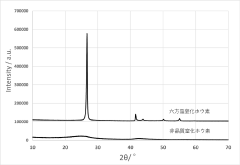

Boron nitride (BN) has emerged as a critical advanced ceramic material over the past several decades, with its powder form playing an increasingly important role in various high-performance applications. Initially discovered in the early 19th century, boron nitride has evolved from a laboratory curiosity to an industrial material of significant importance. The hexagonal form (h-BN), often referred to as "white graphite," has particularly gained prominence due to its unique combination of properties including high thermal conductivity, excellent electrical insulation, and remarkable chemical stability.

The technological evolution of boron nitride powders has been marked by significant advancements in synthesis methods, from early high-temperature reactions between boric oxide and nitrogen to more sophisticated chemical vapor deposition techniques and controlled precipitation methods. These developments have enabled the production of powders with increasingly precise particle size distributions, morphologies, and purity levels, which are crucial factors affecting flowability.

Recent years have witnessed a growing demand for boron nitride powders in advanced manufacturing processes, particularly in die filling and molding applications where consistent powder flow behavior is essential for product quality and process efficiency. The market has responded with specialized grades of BN powders engineered specifically for optimal flow characteristics.

The primary technical objective in this field is to develop boron nitride powder formulations that maintain consistent flowability under varying processing conditions, including temperature fluctuations, humidity changes, and mechanical vibrations. This consistency is critical for achieving uniform die filling, preventing density variations in molded parts, and ensuring dimensional accuracy in final products.

Secondary objectives include optimizing particle surface treatments to reduce agglomeration tendencies, developing cost-effective methods for producing flow-enhanced BN powders, and creating predictive models for powder behavior under different processing parameters. These objectives align with broader industry trends toward process automation and quality control in advanced manufacturing.

The technological trajectory indicates a move toward increasingly specialized BN powder formulations tailored for specific applications, with particular emphasis on nanoscale engineering of particle surfaces and morphologies. Innovations in this space are likely to focus on hybrid approaches that combine particle size distribution control with surface modification techniques to achieve unprecedented levels of flow consistency.

As manufacturing industries continue to demand higher precision and reliability in powder-based processes, the development of boron nitride powders with superior flowability characteristics represents a critical technological frontier with significant implications for advanced ceramics, thermal management solutions, and high-temperature industrial applications.

The technological evolution of boron nitride powders has been marked by significant advancements in synthesis methods, from early high-temperature reactions between boric oxide and nitrogen to more sophisticated chemical vapor deposition techniques and controlled precipitation methods. These developments have enabled the production of powders with increasingly precise particle size distributions, morphologies, and purity levels, which are crucial factors affecting flowability.

Recent years have witnessed a growing demand for boron nitride powders in advanced manufacturing processes, particularly in die filling and molding applications where consistent powder flow behavior is essential for product quality and process efficiency. The market has responded with specialized grades of BN powders engineered specifically for optimal flow characteristics.

The primary technical objective in this field is to develop boron nitride powder formulations that maintain consistent flowability under varying processing conditions, including temperature fluctuations, humidity changes, and mechanical vibrations. This consistency is critical for achieving uniform die filling, preventing density variations in molded parts, and ensuring dimensional accuracy in final products.

Secondary objectives include optimizing particle surface treatments to reduce agglomeration tendencies, developing cost-effective methods for producing flow-enhanced BN powders, and creating predictive models for powder behavior under different processing parameters. These objectives align with broader industry trends toward process automation and quality control in advanced manufacturing.

The technological trajectory indicates a move toward increasingly specialized BN powder formulations tailored for specific applications, with particular emphasis on nanoscale engineering of particle surfaces and morphologies. Innovations in this space are likely to focus on hybrid approaches that combine particle size distribution control with surface modification techniques to achieve unprecedented levels of flow consistency.

As manufacturing industries continue to demand higher precision and reliability in powder-based processes, the development of boron nitride powders with superior flowability characteristics represents a critical technological frontier with significant implications for advanced ceramics, thermal management solutions, and high-temperature industrial applications.

Market Demand Analysis for Flowable BN Powders

The global market for boron nitride (BN) powders with enhanced flowability properties has been experiencing significant growth, driven primarily by increasing demands in high-performance electronics, thermal management solutions, and advanced manufacturing processes. Current market assessments indicate that the thermal management segment alone represents over 35% of the total BN powder market, with consistent annual growth rates between 7-9% over the past five years.

The semiconductor and electronics industries constitute the largest demand sector for flowable BN powders, where precise die filling is critical for manufacturing reliable thermal interface materials and high-performance components. This demand is further amplified by the miniaturization trend in electronics, requiring increasingly precise powder distribution in smaller cavities and more complex geometries.

Automotive and aerospace sectors represent rapidly expanding markets, particularly as electric vehicle production accelerates globally. These industries require thermal management materials that can be precisely molded and positioned within increasingly compact power systems. Market research indicates that BN powder consumption in EV applications has doubled since 2019, with projections suggesting continued strong growth through 2028.

The cosmetics industry has emerged as a surprising growth sector, utilizing flowable BN powders in premium makeup formulations where consistent application and texture are paramount. This sector values the spherical morphology and uniform particle size distribution that enhance both manufacturing consistency and end-product performance.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 45% of global consumption, followed by North America and Europe. China's manufacturing sector alone consumes nearly 20% of global flowable BN powder production, primarily in electronics manufacturing applications.

Customer requirements analysis shows increasing demands for powders with narrower particle size distributions, more spherical morphologies, and surface modifications that enhance flowability while maintaining thermal conductivity. Manufacturers who can deliver consistent batch-to-batch performance command premium pricing, with customers willing to pay 15-25% more for powders with guaranteed flowability metrics.

Market forecasts predict continued growth in demand for specialized flowable BN powders, with particular emphasis on custom-engineered solutions for specific molding and die-filling applications. The market is increasingly segmenting between commodity BN powders and premium, application-specific formulations with enhanced flowability characteristics, with the latter segment growing at nearly twice the rate of the overall market.

The semiconductor and electronics industries constitute the largest demand sector for flowable BN powders, where precise die filling is critical for manufacturing reliable thermal interface materials and high-performance components. This demand is further amplified by the miniaturization trend in electronics, requiring increasingly precise powder distribution in smaller cavities and more complex geometries.

Automotive and aerospace sectors represent rapidly expanding markets, particularly as electric vehicle production accelerates globally. These industries require thermal management materials that can be precisely molded and positioned within increasingly compact power systems. Market research indicates that BN powder consumption in EV applications has doubled since 2019, with projections suggesting continued strong growth through 2028.

The cosmetics industry has emerged as a surprising growth sector, utilizing flowable BN powders in premium makeup formulations where consistent application and texture are paramount. This sector values the spherical morphology and uniform particle size distribution that enhance both manufacturing consistency and end-product performance.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 45% of global consumption, followed by North America and Europe. China's manufacturing sector alone consumes nearly 20% of global flowable BN powder production, primarily in electronics manufacturing applications.

Customer requirements analysis shows increasing demands for powders with narrower particle size distributions, more spherical morphologies, and surface modifications that enhance flowability while maintaining thermal conductivity. Manufacturers who can deliver consistent batch-to-batch performance command premium pricing, with customers willing to pay 15-25% more for powders with guaranteed flowability metrics.

Market forecasts predict continued growth in demand for specialized flowable BN powders, with particular emphasis on custom-engineered solutions for specific molding and die-filling applications. The market is increasingly segmenting between commodity BN powders and premium, application-specific formulations with enhanced flowability characteristics, with the latter segment growing at nearly twice the rate of the overall market.

Technical Challenges in BN Powder Flowability

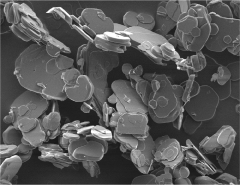

Despite the numerous advantages of boron nitride (BN) powders in various industrial applications, achieving consistent flowability for die filling and molding processes presents significant technical challenges. The irregular particle morphology of BN powders, characterized by hexagonal platelet structures, creates inherent flow impediments as these platelets tend to interlock and stack upon each other, resulting in bridging and rat-holing phenomena during processing operations.

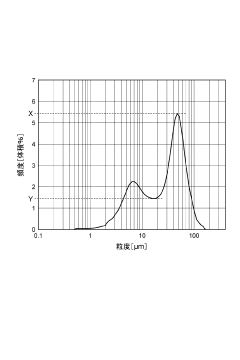

Particle size distribution represents another critical challenge, as BN powders typically exhibit a wide distribution range that directly impacts flow behavior. Finer particles increase inter-particle cohesion forces through van der Waals interactions, while larger particles may create mechanical interlocking. This heterogeneity in size distribution leads to unpredictable flow patterns and segregation issues during handling and processing.

Surface chemistry and moisture sensitivity further complicate flowability control. BN powders readily adsorb atmospheric moisture due to their high surface area and polar nature, forming hydrogen bonds that create liquid bridges between particles. These bridges significantly increase cohesion forces, leading to agglomeration and flow inconsistencies. The surface chemistry also affects the powder's interaction with processing equipment surfaces, potentially causing sticking and uneven material distribution.

Processing environment variables introduce additional complexity to maintaining consistent flowability. Temperature fluctuations alter inter-particle forces and moisture content, while humidity variations directly impact surface adsorption characteristics. Electrostatic charging during powder handling creates repulsive or attractive forces between particles, further disrupting flow patterns and causing material adherence to equipment surfaces.

Storage and aging effects present long-term challenges for BN powder management. Extended storage periods often lead to compaction and caking as particles gradually rearrange under their own weight, while potential chemical changes on particle surfaces can alter flow properties over time. These time-dependent transformations necessitate careful inventory management and potentially reprocessing before use.

Scale-up challenges emerge when transitioning from laboratory to industrial production. Flow behaviors observed in small-scale testing frequently fail to predict performance in larger equipment due to differences in shear conditions, wall effects, and residence time distributions. This scale-dependency complicates process design and requires extensive validation across different equipment sizes.

The combination of these technical challenges necessitates sophisticated characterization methods and process controls to achieve the consistent flowability required for precision die filling and molding applications with boron nitride powders.

Particle size distribution represents another critical challenge, as BN powders typically exhibit a wide distribution range that directly impacts flow behavior. Finer particles increase inter-particle cohesion forces through van der Waals interactions, while larger particles may create mechanical interlocking. This heterogeneity in size distribution leads to unpredictable flow patterns and segregation issues during handling and processing.

Surface chemistry and moisture sensitivity further complicate flowability control. BN powders readily adsorb atmospheric moisture due to their high surface area and polar nature, forming hydrogen bonds that create liquid bridges between particles. These bridges significantly increase cohesion forces, leading to agglomeration and flow inconsistencies. The surface chemistry also affects the powder's interaction with processing equipment surfaces, potentially causing sticking and uneven material distribution.

Processing environment variables introduce additional complexity to maintaining consistent flowability. Temperature fluctuations alter inter-particle forces and moisture content, while humidity variations directly impact surface adsorption characteristics. Electrostatic charging during powder handling creates repulsive or attractive forces between particles, further disrupting flow patterns and causing material adherence to equipment surfaces.

Storage and aging effects present long-term challenges for BN powder management. Extended storage periods often lead to compaction and caking as particles gradually rearrange under their own weight, while potential chemical changes on particle surfaces can alter flow properties over time. These time-dependent transformations necessitate careful inventory management and potentially reprocessing before use.

Scale-up challenges emerge when transitioning from laboratory to industrial production. Flow behaviors observed in small-scale testing frequently fail to predict performance in larger equipment due to differences in shear conditions, wall effects, and residence time distributions. This scale-dependency complicates process design and requires extensive validation across different equipment sizes.

The combination of these technical challenges necessitates sophisticated characterization methods and process controls to achieve the consistent flowability required for precision die filling and molding applications with boron nitride powders.

Current Flowability Enhancement Solutions for Die Filling

01 Particle size control for improved flowability

Controlling the particle size distribution of boron nitride powders is crucial for enhancing flowability. Finer particles with uniform size distribution tend to flow more consistently, while larger particles may improve bulk flow properties. Optimizing the particle size range (typically between 0.1-50 μm) and ensuring narrow distribution can significantly improve the powder's ability to flow freely during processing and application.- Particle size and morphology control for improved flowability: The flowability of boron nitride powders can be significantly improved by controlling the particle size distribution and morphology. Spherical or near-spherical particles with uniform size distribution tend to flow better than irregular shapes. Optimizing the aspect ratio and reducing agglomeration through specific processing techniques helps achieve smoother flow characteristics. These modifications reduce inter-particle friction and mechanical interlocking, resulting in boron nitride powders with enhanced flowability for various industrial applications.

- Surface treatment and coating methods: Surface modification of boron nitride particles through coating or treatment with various agents can dramatically improve flowability. Treatments may include silane coupling agents, fatty acids, or polymer coatings that reduce surface energy and minimize particle-to-particle adhesion. These surface treatments create a barrier that prevents agglomeration and reduces moisture absorption, which are common causes of poor flowability. The modified surface chemistry enables the boron nitride powders to maintain consistent flow properties even under varying environmental conditions.

- Additives and flow enhancers: Incorporating specific additives into boron nitride powder formulations can enhance flowability. Flow agents such as silica, alumina, or organic compounds can be added in small quantities to reduce inter-particle cohesion. These additives act as spacers between boron nitride particles, preventing them from sticking together and forming clumps. The careful selection and concentration of these flow enhancers can be tailored to specific applications while maintaining the desired properties of the boron nitride powder.

- Processing techniques for flowability optimization: Various processing techniques can be employed to optimize the flowability of boron nitride powders. These include specialized milling processes, spray drying, granulation, and heat treatment methods that modify the physical characteristics of the powder. Controlled calcination and sintering processes can reduce surface defects and create smoother particle surfaces. Advanced classification techniques ensure narrow particle size distribution, which contributes to more consistent flow behavior. These processing methods can be combined to achieve boron nitride powders with tailored flowability properties.

- Humidity control and storage conditions: The flowability of boron nitride powders is significantly affected by environmental conditions, particularly humidity. Moisture absorption can lead to particle agglomeration and reduced flow. Implementing proper drying processes, moisture-resistant packaging, and controlled storage conditions can maintain optimal flowability. Some formulations incorporate moisture-repelling agents or undergo hydrophobic treatments to minimize the impact of humidity. Establishing proper handling protocols and storage guidelines ensures that boron nitride powders maintain their flowability characteristics throughout their shelf life.

02 Surface treatment and coating methods

Surface modification techniques can dramatically improve the flowability of boron nitride powders. These include applying hydrophobic coatings, silane treatments, or polymer encapsulation to reduce inter-particle friction and moisture sensitivity. Surface-treated boron nitride powders exhibit reduced agglomeration, improved dispersion characteristics, and enhanced flow properties, making them more suitable for various industrial applications.Expand Specific Solutions03 Morphology control and crystallinity optimization

The crystal structure and morphology of boron nitride particles significantly affect flowability. Hexagonal boron nitride with platelet-like structures typically offers better flow characteristics than cubic or amorphous forms. Controlling the aspect ratio, edge structure, and crystallinity during synthesis can yield powders with optimized flow behavior. High-crystallinity boron nitride typically demonstrates superior flowability compared to less crystalline variants.Expand Specific Solutions04 Flow additives and processing aids

Incorporating flow additives into boron nitride powder formulations can substantially improve flowability. Common additives include fumed silica, stearates, and other fine particulates that reduce inter-particle cohesion by acting as spacers between boron nitride particles. These additives can be dry-blended with the powder or applied as surface treatments, typically at concentrations of 0.1-5% by weight, to achieve optimal flow characteristics without compromising the powder's functional properties.Expand Specific Solutions05 Processing techniques for flowability enhancement

Various processing techniques can be employed to enhance the flowability of boron nitride powders. These include spray drying, granulation, and mechanical treatments such as jet milling or air classification. Post-synthesis heat treatment can also modify surface properties and remove impurities that hinder flow. Additionally, specialized mixing and deagglomeration processes can break up clusters and improve the powder's flow characteristics for industrial applications.Expand Specific Solutions

Key Industry Players in BN Powder Manufacturing

The boron nitride powder market for die filling and molding applications is currently in a growth phase, characterized by increasing demand across various industries including electronics, automotive, and aerospace. The global market size is expanding steadily, driven by the material's exceptional thermal conductivity and electrical insulation properties. From a technological maturity perspective, established players like Saint-Gobain Ceramics & Plastics and Denka Corp. lead with advanced processing techniques, while companies such as pH Matter LLC and Elektroschmelzwerk Kempten GmbH are developing innovative formulations for enhanced flowability. Chinese institutions including Dalian University of Technology and research-focused companies like Zhengzhou Zhongnan Jiete Super Hard Material are rapidly advancing manufacturing capabilities, particularly in hexagonal boron nitride powder production, creating a competitive landscape that balances established Western manufacturers with emerging Asian players.

Denka Corp.

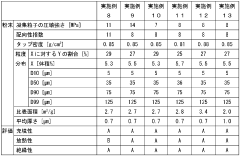

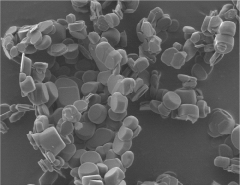

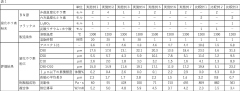

Technical Solution: Denka Corporation has developed a proprietary synthesis method for boron nitride powders that focuses on creating spherical agglomerates of hexagonal BN platelets, marketed under their DENKA BN series. This unique morphology combines the thermal properties of h-BN with significantly improved flowability characteristics essential for automated die filling systems. Their technology employs a controlled spray-drying process that transforms primary BN platelets into secondary spherical particles (10-30 μm) with optimized packing density and reduced surface area, minimizing inter-particle friction. Denka's process includes precise control of particle size distribution with a coefficient of variation below 15%, which ensures consistent volumetric filling in high-speed molding operations. Their advanced surface treatment technology applies proprietary organic coatings that reduce moisture sensitivity while enhancing dispersion in polymer matrices. Independent testing has shown that Denka's spherical BN powders demonstrate up to 30% improvement in flow rate consistency compared to conventional platelet BN in high-pressure molding applications.

Strengths: Unique spherical morphology that provides superior flowability while maintaining thermal properties; excellent batch-to-batch consistency due to tightly controlled manufacturing processes; good dispersion characteristics in various matrix materials. Weaknesses: Slightly lower thermal conductivity compared to pure platelet forms; higher production costs due to additional processing steps; limited customization options for specialized applications.

Tokuyama Corp.

Technical Solution: Tokuyama Corporation has pioneered a multi-stage purification process for their boron nitride powders that achieves exceptional purity levels (>99.9%) critical for consistent flowability in precision die filling applications. Their technology focuses on controlling the hexagonal crystal structure of BN particles through a carefully regulated vapor-phase synthesis method. This results in uniform platelet-shaped particles with aspect ratios optimized for smooth flow characteristics. Tokuyama's TMBN series incorporates proprietary dry coating technology that applies nanoscale silica or alumina particles to the BN surface, effectively reducing inter-particle cohesion and improving flow even under high humidity conditions. Their manufacturing process includes specialized milling techniques that maintain the platelet structure while achieving narrow particle size distributions (typically 1-5 μm), which has been demonstrated to reduce die-filling variability by up to 40% compared to conventional BN powders in semiconductor packaging applications.

Strengths: Exceptional purity levels that minimize contamination concerns in sensitive applications; advanced surface modification techniques that maintain flowability under varying environmental conditions; proven performance in high-precision molding applications. Weaknesses: Limited production capacity compared to larger competitors; higher cost structure due to intensive purification processes; requires careful handling to maintain surface treatment effectiveness.

Critical Patents in BN Powder Flow Optimization

Boron nitride powder

PatentPendingJP2023147855A

Innovation

- A boron nitride powder with specific properties including high crushing strength, orientation index, and particle size distribution, ensuring minimal collapse during resin mixing, thereby enhancing heat dissipation and insulation properties.

Boron nitride powder, and method for producing the same

PatentPendingJP2023144294A

Innovation

- The production of boron nitride powder using lithium borate as a flux to control particle size and aspect ratio, ensuring D90 ≥ 10 μm, aspect ratio ≤ 5.0, and specific particle size distribution to enhance fluidity and thermal conductivity.

Quality Control Methods for BN Powder Production

Quality control in Boron Nitride (BN) powder production represents a critical factor in ensuring consistent flowability for die filling and molding applications. The implementation of rigorous quality control protocols begins with raw material inspection, where incoming precursors undergo comprehensive chemical analysis to verify purity levels and detect potential contaminants that could affect the final powder properties.

Statistical Process Control (SPC) methodologies have been widely adopted in BN powder manufacturing facilities, enabling real-time monitoring of critical process parameters. These systems continuously track variables such as temperature profiles during synthesis, reaction times, and cooling rates, automatically flagging deviations that might impact powder morphology and, consequently, flowability characteristics.

Particle size distribution analysis serves as a cornerstone of BN powder quality control, typically performed using laser diffraction techniques or dynamic light scattering methods. Advanced manufacturers maintain strict specifications for D10, D50, and D90 values, ensuring batch-to-batch consistency. This precise control over particle size distribution directly correlates with predictable flow behavior during die filling operations.

Surface chemistry characterization has emerged as an essential quality control measure, with X-ray Photoelectron Spectroscopy (XPS) and Fourier Transform Infrared Spectroscopy (FTIR) being employed to detect surface functional groups that might influence powder-powder and powder-die wall interactions. Manufacturers increasingly recognize that even minor variations in surface chemistry can significantly alter flowability profiles.

Rheological testing represents perhaps the most direct quality control method for assessing BN powder flowability. Powder rheometers measure key parameters including basic flowability energy, specific energy, stability index, and wall friction angle. Leading manufacturers have established proprietary acceptance criteria for these measurements, ensuring that only powders meeting strict flowability specifications reach molding applications.

Moisture content control has gained prominence in quality assurance protocols, with Karl Fischer titration and thermogravimetric analysis being standard methods for quantifying residual moisture. Industry standards typically specify moisture levels below 0.5% for high-performance BN powders, as excess moisture can cause agglomeration and unpredictable flow behavior during die filling.

Advanced imaging techniques, particularly Scanning Electron Microscopy (SEM), allow quality control specialists to visually inspect particle morphology, identifying irregular shapes or agglomerates that might impede smooth powder flow. Some manufacturers have implemented automated image analysis systems that quantify particle roundness and aspect ratios as part of their standard quality control procedures.

Statistical Process Control (SPC) methodologies have been widely adopted in BN powder manufacturing facilities, enabling real-time monitoring of critical process parameters. These systems continuously track variables such as temperature profiles during synthesis, reaction times, and cooling rates, automatically flagging deviations that might impact powder morphology and, consequently, flowability characteristics.

Particle size distribution analysis serves as a cornerstone of BN powder quality control, typically performed using laser diffraction techniques or dynamic light scattering methods. Advanced manufacturers maintain strict specifications for D10, D50, and D90 values, ensuring batch-to-batch consistency. This precise control over particle size distribution directly correlates with predictable flow behavior during die filling operations.

Surface chemistry characterization has emerged as an essential quality control measure, with X-ray Photoelectron Spectroscopy (XPS) and Fourier Transform Infrared Spectroscopy (FTIR) being employed to detect surface functional groups that might influence powder-powder and powder-die wall interactions. Manufacturers increasingly recognize that even minor variations in surface chemistry can significantly alter flowability profiles.

Rheological testing represents perhaps the most direct quality control method for assessing BN powder flowability. Powder rheometers measure key parameters including basic flowability energy, specific energy, stability index, and wall friction angle. Leading manufacturers have established proprietary acceptance criteria for these measurements, ensuring that only powders meeting strict flowability specifications reach molding applications.

Moisture content control has gained prominence in quality assurance protocols, with Karl Fischer titration and thermogravimetric analysis being standard methods for quantifying residual moisture. Industry standards typically specify moisture levels below 0.5% for high-performance BN powders, as excess moisture can cause agglomeration and unpredictable flow behavior during die filling.

Advanced imaging techniques, particularly Scanning Electron Microscopy (SEM), allow quality control specialists to visually inspect particle morphology, identifying irregular shapes or agglomerates that might impede smooth powder flow. Some manufacturers have implemented automated image analysis systems that quantify particle roundness and aspect ratios as part of their standard quality control procedures.

Environmental Impact of BN Powder Manufacturing Processes

The manufacturing processes of Boron Nitride (BN) powders involve several energy-intensive steps that can have significant environmental implications. Traditional synthesis methods such as chemical vapor deposition (CVD) and high-temperature solid-state reactions require substantial energy inputs, often derived from fossil fuels, contributing to greenhouse gas emissions. The carbon footprint of BN powder production is estimated to be 15-20 kg CO2 equivalent per kilogram of product, positioning it as a moderate to high environmental impact material in the advanced ceramics sector.

Water usage represents another critical environmental concern in BN manufacturing. Wet processing techniques and purification steps can consume 40-60 liters of water per kilogram of final product. In regions facing water scarcity, this consumption pattern raises sustainability questions that manufacturers must address through recycling systems and closed-loop processing.

Chemical waste generation during BN synthesis presents additional environmental challenges. The production process typically involves precursors such as boric acid, ammonia, and various nitrogen compounds that, if improperly managed, can lead to hazardous waste streams. Modern facilities have implemented advanced treatment systems that can reduce harmful effluents by up to 85%, though complete elimination remains technically challenging.

Particulate emissions during powder processing stages represent both an occupational and environmental hazard. Fine BN particles can become airborne during milling, classification, and packaging operations. State-of-the-art manufacturing facilities employ high-efficiency filtration systems capable of capturing 99.9% of particulates, significantly reducing ambient air pollution risks while protecting worker health.

Recent innovations in green manufacturing approaches for BN powders show promising environmental improvements. Low-temperature synthesis routes using biomass-derived precursors have demonstrated potential to reduce energy consumption by 30-40% compared to conventional methods. Additionally, solvent-free mechanochemical processes are emerging as environmentally preferable alternatives that eliminate organic solvent waste streams entirely.

Life cycle assessments of BN powder manufacturing reveal that the environmental impact varies significantly based on production scale and technology employed. Small-batch specialty production typically carries a higher per-unit environmental burden than large-scale operations that benefit from efficiency improvements and heat recovery systems. This scale-dependent variation highlights the importance of considering production volume when evaluating environmental sustainability metrics.

Water usage represents another critical environmental concern in BN manufacturing. Wet processing techniques and purification steps can consume 40-60 liters of water per kilogram of final product. In regions facing water scarcity, this consumption pattern raises sustainability questions that manufacturers must address through recycling systems and closed-loop processing.

Chemical waste generation during BN synthesis presents additional environmental challenges. The production process typically involves precursors such as boric acid, ammonia, and various nitrogen compounds that, if improperly managed, can lead to hazardous waste streams. Modern facilities have implemented advanced treatment systems that can reduce harmful effluents by up to 85%, though complete elimination remains technically challenging.

Particulate emissions during powder processing stages represent both an occupational and environmental hazard. Fine BN particles can become airborne during milling, classification, and packaging operations. State-of-the-art manufacturing facilities employ high-efficiency filtration systems capable of capturing 99.9% of particulates, significantly reducing ambient air pollution risks while protecting worker health.

Recent innovations in green manufacturing approaches for BN powders show promising environmental improvements. Low-temperature synthesis routes using biomass-derived precursors have demonstrated potential to reduce energy consumption by 30-40% compared to conventional methods. Additionally, solvent-free mechanochemical processes are emerging as environmentally preferable alternatives that eliminate organic solvent waste streams entirely.

Life cycle assessments of BN powder manufacturing reveal that the environmental impact varies significantly based on production scale and technology employed. Small-batch specialty production typically carries a higher per-unit environmental burden than large-scale operations that benefit from efficiency improvements and heat recovery systems. This scale-dependent variation highlights the importance of considering production volume when evaluating environmental sustainability metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!