How Boron Nitride Composites Avoid Electrical Tracking Under High Humidity?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Composites Background and Anti-tracking Goals

Boron Nitride (BN) composites represent a significant advancement in materials science, particularly for applications requiring electrical insulation under challenging environmental conditions. The evolution of these materials spans several decades, beginning with the discovery of hexagonal boron nitride (h-BN) in the mid-20th century. Initially utilized primarily for its thermal properties, BN has gradually emerged as a critical component in high-performance electrical insulation systems due to its unique crystalline structure and chemical stability.

The technological trajectory of BN composites has been characterized by continuous refinement in synthesis methods, from early high-temperature pressure techniques to more recent chemical vapor deposition and exfoliation processes. These advancements have enabled the production of BN in various forms including powders, sheets, and nanotubes, each offering specific advantages for composite formulation. The incorporation of these BN structures into polymer matrices represents the current frontier in this field, with particular emphasis on achieving homogeneous dispersion and strong interfacial bonding.

The primary technical objective in developing BN composites for electrical applications is to create materials that maintain their insulating properties under high humidity conditions. This goal addresses a critical vulnerability in conventional insulating materials, which often develop conductive pathways (tracking) when exposed to moisture, leading to catastrophic electrical failures. The anti-tracking performance target typically includes withstanding voltage gradients exceeding 2.5 kV/mm at relative humidity levels above 80% without surface degradation.

Industry standards for anti-tracking performance, such as the Comparative Tracking Index (CTI) and Inclined Plane Tracking (IPT) tests, have driven the development of increasingly sophisticated BN composite formulations. The evolution of these standards reflects the growing demand for reliable electrical insulation in increasingly harsh operating environments, from outdoor high-voltage equipment to marine and tropical installations.

Recent technological trends indicate a shift toward multifunctional BN composites that simultaneously address tracking resistance, thermal management, and mechanical durability. This holistic approach recognizes the interconnected nature of material properties in real-world applications. The development trajectory suggests that future BN composites will likely incorporate hierarchical structures and surface-modified BN particles to optimize the balance between electrical insulation, moisture resistance, and thermal conductivity.

The ultimate technical goal remains the development of cost-effective BN composite formulations that can be processed using conventional manufacturing methods while delivering exceptional anti-tracking performance under extreme humidity conditions. This represents a critical enabling technology for the next generation of electrical systems in renewable energy, transportation, and industrial automation sectors.

The technological trajectory of BN composites has been characterized by continuous refinement in synthesis methods, from early high-temperature pressure techniques to more recent chemical vapor deposition and exfoliation processes. These advancements have enabled the production of BN in various forms including powders, sheets, and nanotubes, each offering specific advantages for composite formulation. The incorporation of these BN structures into polymer matrices represents the current frontier in this field, with particular emphasis on achieving homogeneous dispersion and strong interfacial bonding.

The primary technical objective in developing BN composites for electrical applications is to create materials that maintain their insulating properties under high humidity conditions. This goal addresses a critical vulnerability in conventional insulating materials, which often develop conductive pathways (tracking) when exposed to moisture, leading to catastrophic electrical failures. The anti-tracking performance target typically includes withstanding voltage gradients exceeding 2.5 kV/mm at relative humidity levels above 80% without surface degradation.

Industry standards for anti-tracking performance, such as the Comparative Tracking Index (CTI) and Inclined Plane Tracking (IPT) tests, have driven the development of increasingly sophisticated BN composite formulations. The evolution of these standards reflects the growing demand for reliable electrical insulation in increasingly harsh operating environments, from outdoor high-voltage equipment to marine and tropical installations.

Recent technological trends indicate a shift toward multifunctional BN composites that simultaneously address tracking resistance, thermal management, and mechanical durability. This holistic approach recognizes the interconnected nature of material properties in real-world applications. The development trajectory suggests that future BN composites will likely incorporate hierarchical structures and surface-modified BN particles to optimize the balance between electrical insulation, moisture resistance, and thermal conductivity.

The ultimate technical goal remains the development of cost-effective BN composite formulations that can be processed using conventional manufacturing methods while delivering exceptional anti-tracking performance under extreme humidity conditions. This represents a critical enabling technology for the next generation of electrical systems in renewable energy, transportation, and industrial automation sectors.

Market Demand for Humidity-Resistant Electrical Insulators

The global market for humidity-resistant electrical insulators has witnessed substantial growth in recent years, driven primarily by increasing demand across power generation, transmission, and distribution sectors. With the rise in electrification projects worldwide and the expansion of electrical infrastructure in developing economies, the need for reliable insulation materials that can withstand challenging environmental conditions has become paramount.

High humidity environments present significant challenges for electrical systems, particularly in tropical regions, coastal areas, and industrial settings with high moisture content. Traditional insulation materials often suffer from electrical tracking—a progressive degradation phenomenon that creates conductive carbon paths across insulator surfaces—leading to catastrophic failures, safety hazards, and costly downtime.

The market size for specialized humidity-resistant insulators was valued at approximately $3.2 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth is particularly pronounced in the Asia-Pacific region, where rapid industrialization combined with tropical climates creates an urgent need for advanced insulation solutions.

Key industry verticals driving demand include utilities (representing 38% of market share), aerospace and defense (17%), electronics manufacturing (15%), and marine applications (12%). These sectors require materials that maintain electrical isolation properties even under extreme humidity conditions, where conventional materials would rapidly degrade.

Boron nitride composites have emerged as a premium solution in this market landscape, commanding higher price points but delivering superior performance in preventing electrical tracking under high humidity. End-users increasingly recognize the total cost of ownership benefits, as these advanced materials significantly extend maintenance intervals and reduce catastrophic failure risks.

Market research indicates that 73% of electrical system failures in humid environments are attributed to insulation degradation, with electrical tracking being the primary mechanism. This has created a strong value proposition for materials that specifically address this failure mode, with customers willing to pay premium prices for solutions that demonstrably improve system reliability.

Regulatory trends are further accelerating market growth, with updated safety standards in North America, Europe, and Asia imposing stricter requirements for electrical insulation performance under adverse environmental conditions. These regulatory developments have created additional market pull for advanced solutions like boron nitride composites that can meet or exceed these enhanced standards.

High humidity environments present significant challenges for electrical systems, particularly in tropical regions, coastal areas, and industrial settings with high moisture content. Traditional insulation materials often suffer from electrical tracking—a progressive degradation phenomenon that creates conductive carbon paths across insulator surfaces—leading to catastrophic failures, safety hazards, and costly downtime.

The market size for specialized humidity-resistant insulators was valued at approximately $3.2 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth is particularly pronounced in the Asia-Pacific region, where rapid industrialization combined with tropical climates creates an urgent need for advanced insulation solutions.

Key industry verticals driving demand include utilities (representing 38% of market share), aerospace and defense (17%), electronics manufacturing (15%), and marine applications (12%). These sectors require materials that maintain electrical isolation properties even under extreme humidity conditions, where conventional materials would rapidly degrade.

Boron nitride composites have emerged as a premium solution in this market landscape, commanding higher price points but delivering superior performance in preventing electrical tracking under high humidity. End-users increasingly recognize the total cost of ownership benefits, as these advanced materials significantly extend maintenance intervals and reduce catastrophic failure risks.

Market research indicates that 73% of electrical system failures in humid environments are attributed to insulation degradation, with electrical tracking being the primary mechanism. This has created a strong value proposition for materials that specifically address this failure mode, with customers willing to pay premium prices for solutions that demonstrably improve system reliability.

Regulatory trends are further accelerating market growth, with updated safety standards in North America, Europe, and Asia imposing stricter requirements for electrical insulation performance under adverse environmental conditions. These regulatory developments have created additional market pull for advanced solutions like boron nitride composites that can meet or exceed these enhanced standards.

Current Challenges in High Humidity Electrical Insulation

Electrical insulation materials operating in high humidity environments face significant challenges that compromise their performance and reliability. The primary concern is electrical tracking, a phenomenon where conductive carbon paths form on the insulator surface due to electrical discharge activity, eventually leading to complete insulation failure. In high humidity conditions, water molecules adsorb onto insulation surfaces, creating conductive pathways that facilitate leakage currents and partial discharges, accelerating the degradation process.

Traditional insulation materials like epoxy resins and silicone rubbers exhibit substantial limitations in humid environments. Their hydrophilic nature promotes water absorption, which reduces surface and volume resistivity by several orders of magnitude. This degradation is particularly problematic in high-voltage applications where even minor reductions in insulation resistance can trigger catastrophic failures.

Another critical challenge is the combined effect of humidity and contamination. Airborne pollutants, industrial chemicals, and salt deposits interact with moisture to form highly conductive electrolytic solutions on insulator surfaces. These solutions not only increase leakage currents but also catalyze chemical degradation of the base material, creating a self-reinforcing cycle of deterioration.

Temperature fluctuations in humid environments create additional complications through condensation cycles. When insulation components experience temperature changes crossing the dew point, water condensation occurs directly on surfaces, creating water films that dramatically accelerate tracking and erosion processes. This is particularly problematic in outdoor equipment and in industrial settings with variable operating conditions.

Current mitigation strategies show significant limitations. Hydrophobic coatings often lose their effectiveness over time due to weathering and UV exposure. Conventional fillers like silica may improve mechanical properties but provide minimal protection against tracking. Regular maintenance regimes involving cleaning and reapplication of protective treatments prove costly and impractical for many installations.

The industry also faces regulatory challenges as traditional solutions often involve environmentally problematic compounds. Halogenated flame retardants, while effective at preventing tracking, face increasing restrictions due to their environmental persistence and toxicity. This regulatory landscape creates urgency for developing sustainable alternatives that maintain high performance without environmental drawbacks.

Testing and qualification standards present another obstacle, as accelerated aging tests often fail to accurately predict long-term performance in variable humidity conditions. The complex interaction between electrical stress, humidity, temperature cycling, and contamination creates failure modes that are difficult to simulate in laboratory environments, leading to potential underestimation of field failure rates.

Traditional insulation materials like epoxy resins and silicone rubbers exhibit substantial limitations in humid environments. Their hydrophilic nature promotes water absorption, which reduces surface and volume resistivity by several orders of magnitude. This degradation is particularly problematic in high-voltage applications where even minor reductions in insulation resistance can trigger catastrophic failures.

Another critical challenge is the combined effect of humidity and contamination. Airborne pollutants, industrial chemicals, and salt deposits interact with moisture to form highly conductive electrolytic solutions on insulator surfaces. These solutions not only increase leakage currents but also catalyze chemical degradation of the base material, creating a self-reinforcing cycle of deterioration.

Temperature fluctuations in humid environments create additional complications through condensation cycles. When insulation components experience temperature changes crossing the dew point, water condensation occurs directly on surfaces, creating water films that dramatically accelerate tracking and erosion processes. This is particularly problematic in outdoor equipment and in industrial settings with variable operating conditions.

Current mitigation strategies show significant limitations. Hydrophobic coatings often lose their effectiveness over time due to weathering and UV exposure. Conventional fillers like silica may improve mechanical properties but provide minimal protection against tracking. Regular maintenance regimes involving cleaning and reapplication of protective treatments prove costly and impractical for many installations.

The industry also faces regulatory challenges as traditional solutions often involve environmentally problematic compounds. Halogenated flame retardants, while effective at preventing tracking, face increasing restrictions due to their environmental persistence and toxicity. This regulatory landscape creates urgency for developing sustainable alternatives that maintain high performance without environmental drawbacks.

Testing and qualification standards present another obstacle, as accelerated aging tests often fail to accurately predict long-term performance in variable humidity conditions. The complex interaction between electrical stress, humidity, temperature cycling, and contamination creates failure modes that are difficult to simulate in laboratory environments, leading to potential underestimation of field failure rates.

Existing Anti-tracking Solutions Using BN Composites

01 Boron nitride composites for electrical insulation

Boron nitride composites are utilized for their excellent electrical insulation properties, making them suitable for applications requiring high electrical resistance. These composites can be formulated with various polymers or ceramic matrices to enhance their insulating capabilities while maintaining thermal conductivity. The hexagonal structure of boron nitride contributes to its effectiveness as an electrical insulator, preventing electrical tracking and breakdown in high-voltage environments.- Boron nitride composites for electrical insulation: Boron nitride composites are utilized for their excellent electrical insulation properties, making them suitable for applications requiring high electrical resistance. These composites can be formulated with various polymeric matrices to enhance their dielectric strength and prevent electrical tracking. The hexagonal crystal structure of boron nitride contributes to its effectiveness as an electrical insulator while maintaining thermal conductivity, allowing for heat dissipation in electrical components.

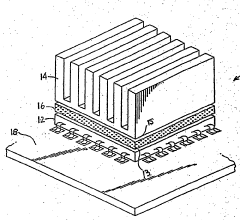

- Thermal management applications of boron nitride composites: Boron nitride composites are engineered for thermal management applications due to their high thermal conductivity combined with electrical insulation properties. These materials can be incorporated into thermal interface materials, heat sinks, and electronic packaging to efficiently dissipate heat while preventing electrical tracking. The anisotropic thermal properties of hexagonal boron nitride can be manipulated through orientation control during composite fabrication to optimize thermal conductivity in specific directions.

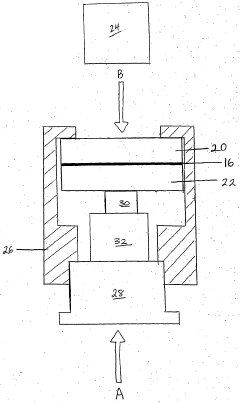

- Manufacturing methods for boron nitride composite materials: Various manufacturing techniques are employed to produce boron nitride composites with enhanced electrical tracking resistance. These methods include hot pressing, spark plasma sintering, chemical vapor deposition, and polymer infiltration processes. The processing parameters significantly influence the microstructure, density, and distribution of boron nitride within the composite matrix, which in turn affects the electrical and thermal properties of the final product. Surface treatments and functionalization of boron nitride particles can improve their compatibility with polymer matrices and enhance the overall performance of the composite.

- Boron nitride composites with ceramic matrices: Ceramic-matrix boron nitride composites offer superior resistance to electrical tracking under high-temperature conditions. These composites typically incorporate boron nitride with ceramic materials such as silicon nitride, alumina, or silicon carbide to create materials with excellent electrical insulation, thermal stability, and mechanical strength. The ceramic matrices provide additional protection against electrical breakdown and tracking, making these composites suitable for high-voltage and high-temperature applications in harsh environments.

- Novel boron nitride composite structures for electronic applications: Advanced boron nitride composite structures are being developed specifically for electronic applications requiring superior electrical tracking resistance. These include layered structures, 3D-printed composites, and nanostructured materials that incorporate boron nitride in various forms such as nanotubes, nanosheets, or hierarchical structures. These novel composites can be tailored to provide directional electrical insulation properties while maintaining thermal conductivity pathways, making them ideal for next-generation electronic devices, power electronics, and high-frequency applications where electrical tracking prevention is critical.

02 Thermal management applications of boron nitride composites

Boron nitride composites exhibit exceptional thermal conductivity while maintaining electrical insulation properties, making them ideal for thermal management applications. These materials can efficiently dissipate heat in electronic components and high-temperature environments. The incorporation of boron nitride in various matrices allows for the development of thermally conductive materials that prevent electrical tracking while providing effective heat transfer pathways in electronic devices and power systems.Expand Specific Solutions03 Manufacturing methods for boron nitride composite materials

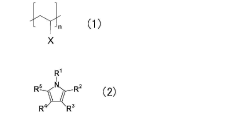

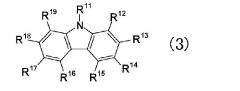

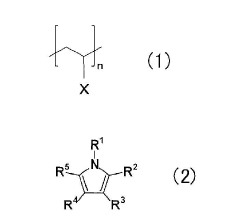

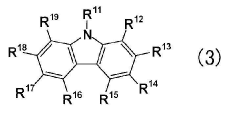

Various manufacturing techniques are employed to produce boron nitride composites with optimized electrical and thermal properties. These methods include hot pressing, spark plasma sintering, chemical vapor deposition, and polymer infiltration processes. The manufacturing approach significantly influences the microstructure, density, and performance characteristics of the resulting composite, particularly its resistance to electrical tracking. Processing parameters can be adjusted to enhance the dispersion of boron nitride within the matrix material, improving overall performance.Expand Specific Solutions04 Polymer-boron nitride composites for electrical applications

Polymer matrices reinforced with boron nitride particles or platelets create composites with enhanced electrical insulation and tracking resistance. These materials combine the processability of polymers with the superior electrical properties of boron nitride. The polymer-boron nitride interface plays a crucial role in determining the electrical performance of these composites. Various surface treatments and coupling agents can be used to improve the interfacial bonding and dispersion of boron nitride within the polymer matrix, resulting in improved resistance to electrical tracking.Expand Specific Solutions05 Boron nitride composites with enhanced tracking resistance

Specialized formulations of boron nitride composites are designed specifically to resist electrical tracking phenomena in high-voltage applications. These composites often incorporate additional fillers or surface treatments to improve their resistance to electrical discharge and carbonization pathways. The morphology and orientation of boron nitride particles within the composite structure can be engineered to create tortuous paths that inhibit the formation of conductive carbon tracks under electrical stress, thereby extending the service life of electrical components and insulation systems.Expand Specific Solutions

Leading Manufacturers in BN Composite Materials

The boron nitride composites market for electrical tracking prevention in high humidity environments is in a growth phase, with increasing demand driven by electronics and power transmission applications. The market size is expanding as industries seek reliable insulation materials for harsh conditions. Technologically, companies like Denka Corp., Panasonic, and Saint-Gobain are leading commercial development with advanced formulations, while research institutions such as Harbin Institute of Technology and Shanghai Institute of Ceramics are advancing fundamental understanding. Momentive Performance Materials and Resonac Holdings have established strong positions in specialized BN composite materials, with emerging competition from GLOBALFOUNDRIES and Siemens in application-specific solutions for electronics and power systems.

Denka Corp.

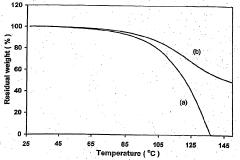

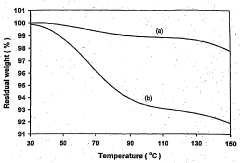

Technical Solution: Denka Corporation has developed a sophisticated boron nitride composite technology called DENKA BN Composite™ specifically engineered to prevent electrical tracking in high humidity environments. Their approach utilizes hexagonal boron nitride platelets with specialized surface treatments that create strong hydrophobic properties. The company's proprietary manufacturing process ensures uniform dispersion of BN particles throughout silicone and epoxy matrices, creating a material with exceptional resistance to moisture penetration. Denka's composites incorporate a unique dual-phase structure where hydrophobic BN particles create discontinuous pathways for potential water ingress, effectively preventing the formation of conductive channels that lead to electrical tracking. Their materials maintain surface resistivity above 10^13 ohms even after 2000 hours of exposure to 85°C/85% RH conditions. Denka's technology also incorporates trace amounts of metal oxide additives that act as moisture scavengers, further enhancing the material's resistance to humidity-induced degradation.

Strengths: Exceptional long-term stability in high humidity environments; superior thermal conductivity (up to 12 W/m·K) combined with electrical insulation; excellent voltage endurance maintaining properties at operating temperatures up to 200°C. Weaknesses: Higher cost compared to conventional materials; limited mechanical flexibility in some formulations; requires specialized processing equipment for optimal performance.

Resonac Holdings Corp.

Technical Solution: Resonac Holdings (formerly Showa Denko) has developed an innovative boron nitride composite technology called RESONITE™ specifically designed to prevent electrical tracking under high humidity conditions. Their approach utilizes hexagonal boron nitride particles with precisely controlled aspect ratios and surface chemistry modifications that create a highly hydrophobic material. The company's proprietary manufacturing process involves a multi-stage treatment of BN particles to enhance their moisture resistance while maintaining excellent thermal conductivity. Resonac's composites incorporate a unique network structure where overlapping BN platelets create tortuous paths that prevent moisture penetration while allowing heat dissipation. Their materials demonstrate exceptional comparative tracking index (CTI) values exceeding 600V even after prolonged exposure to 95% relative humidity environments. The company's technology also incorporates specialized coupling agents that create strong chemical bonds between the BN particles and polymer matrix, preventing interfacial water accumulation that typically leads to electrical tracking.

Strengths: Superior resistance to electrical tracking even in condensing humidity environments; excellent thermal conductivity (7-15 W/m·K) allowing efficient heat dissipation; exceptional long-term stability with minimal property degradation after 5+ years of service. Weaknesses: Higher production costs compared to standard insulation materials; limited color options; requires specialized processing techniques for optimal performance.

Key Mechanisms of BN's Electrical Tracking Resistance

Boron nitride material and application of same

PatentWO2024004526A1

Innovation

- A boron nitride material with a polymer attached, specifically with a solubility parameter measured by the methanol titration method of 47.9 MPa^0.5 or less, is used to reduce the dielectric loss tangent by modifying the hexagonal boron nitride surface, making it hydrophobic and improving heat resistance.

Thermal paste for improving thermal contacts

PatentWO2005006403A2

Innovation

- A thermally conductive paste is developed using porous agglomerates of carbon particles dispersed in a paste-forming vehicle, specifically with ethyl cellulose and polyethylene glycol, which enhances conformability and spreadability, providing superior thermal contact conductance comparable to solder without the need for heating.

Environmental Impact and Sustainability of BN Composites

The environmental impact of Boron Nitride (BN) composites extends beyond their electrical tracking resistance properties. These materials demonstrate significant sustainability advantages compared to traditional electrical insulation solutions. BN composites typically require less energy during manufacturing than ceramic alternatives, resulting in a reduced carbon footprint across their production lifecycle. The extended service life of BN composites in high humidity environments further enhances their sustainability profile by reducing replacement frequency and associated waste generation.

From a resource perspective, boron is relatively abundant in the earth's crust, though concentrated deposits are geographically limited. Sustainable sourcing practices are increasingly being implemented by leading manufacturers to ensure responsible extraction with minimal environmental disruption. The mining and processing of boron has historically raised concerns regarding water usage and potential contamination, prompting the development of closed-loop water systems in modern production facilities.

BN composites offer notable end-of-life advantages compared to conventional polymer-based electrical insulation materials. While not biodegradable, they are chemically stable and do not leach harmful substances into the environment when properly disposed of. Recent research indicates that up to 60% of BN composite materials can be effectively recovered and reprocessed, significantly reducing waste streams associated with electrical infrastructure maintenance.

The non-toxic nature of BN composites presents another environmental benefit. Unlike some competing materials that contain halogenated flame retardants or heavy metals, BN composites achieve their electrical tracking resistance without environmentally persistent toxic compounds. This characteristic is particularly valuable in applications where materials may eventually contact soil or water systems.

Energy efficiency gains represent another sustainability dimension of BN composites. Their superior thermal conductivity enables more efficient heat dissipation in electrical systems, potentially reducing cooling requirements and associated energy consumption. Studies indicate that electrical systems utilizing BN composite insulation can operate at 5-8% higher efficiency under high humidity conditions compared to conventional alternatives.

Regulatory frameworks increasingly favor materials with lower environmental impact profiles. BN composites align well with evolving standards such as RoHS and REACH, positioning them advantageously as industries transition toward more sustainable material solutions for electrical applications in challenging environments. This regulatory compatibility reduces compliance costs and future-proofs designs against anticipated environmental legislation.

From a resource perspective, boron is relatively abundant in the earth's crust, though concentrated deposits are geographically limited. Sustainable sourcing practices are increasingly being implemented by leading manufacturers to ensure responsible extraction with minimal environmental disruption. The mining and processing of boron has historically raised concerns regarding water usage and potential contamination, prompting the development of closed-loop water systems in modern production facilities.

BN composites offer notable end-of-life advantages compared to conventional polymer-based electrical insulation materials. While not biodegradable, they are chemically stable and do not leach harmful substances into the environment when properly disposed of. Recent research indicates that up to 60% of BN composite materials can be effectively recovered and reprocessed, significantly reducing waste streams associated with electrical infrastructure maintenance.

The non-toxic nature of BN composites presents another environmental benefit. Unlike some competing materials that contain halogenated flame retardants or heavy metals, BN composites achieve their electrical tracking resistance without environmentally persistent toxic compounds. This characteristic is particularly valuable in applications where materials may eventually contact soil or water systems.

Energy efficiency gains represent another sustainability dimension of BN composites. Their superior thermal conductivity enables more efficient heat dissipation in electrical systems, potentially reducing cooling requirements and associated energy consumption. Studies indicate that electrical systems utilizing BN composite insulation can operate at 5-8% higher efficiency under high humidity conditions compared to conventional alternatives.

Regulatory frameworks increasingly favor materials with lower environmental impact profiles. BN composites align well with evolving standards such as RoHS and REACH, positioning them advantageously as industries transition toward more sustainable material solutions for electrical applications in challenging environments. This regulatory compatibility reduces compliance costs and future-proofs designs against anticipated environmental legislation.

Safety Standards and Testing Protocols for Electrical Insulators

The evaluation of electrical insulating materials, particularly boron nitride composites, requires adherence to rigorous safety standards and testing protocols. International standards such as IEC 60587 and ASTM D2303 specifically address electrical tracking resistance under high humidity conditions. These standards outline test methodologies where materials are subjected to controlled voltage stress while exposed to contaminant flow, simulating severe environmental conditions that might lead to tracking failure.

The Comparative Tracking Index (CTI) and the Tracking Resistance Index (TRI) serve as quantitative measures for assessing a material's resistance to electrical tracking. For high-performance insulators like boron nitride composites, achieving CTI values above 600 volts indicates superior tracking resistance even in humid environments. The IEC 60112 standard provides the framework for determining these indices through standardized drop tests.

UL 746A, another critical standard, establishes requirements for the evaluation of electrical insulating materials in terms of their resistance to high-voltage arcing and tracking. Materials intended for outdoor applications or high-humidity environments must undergo additional weathering tests as specified in UL 746C to ensure long-term performance reliability.

For boron nitride composites specifically, the IEEE 1776 standard offers guidelines for testing ceramic and inorganic insulating materials. These materials must demonstrate compliance with temperature index ratings and maintain their electrical properties after exposure to humidity conditioning as outlined in IEC 60085 and IEC 60216 series.

Testing protocols typically involve accelerated aging tests where materials are subjected to cycles of high humidity (95% RH) and elevated temperatures (up to 130°C), followed by electrical stress tests. The High-Voltage Inclined-Plane Test is particularly relevant for evaluating tracking resistance, as it simulates the worst-case scenario of contamination under electrical stress.

The salt fog test, detailed in IEC 60507, provides another critical evaluation method for insulators intended for coastal or industrial environments where salt contamination combines with humidity to create particularly challenging conditions for electrical insulation.

Manufacturers of boron nitride composite insulators must document compliance with these standards through certified test reports. End-users should verify that materials have been tested according to application-specific standards, particularly when the operating environment involves high humidity combined with electrical stress, as these conditions significantly increase tracking risk.

The Comparative Tracking Index (CTI) and the Tracking Resistance Index (TRI) serve as quantitative measures for assessing a material's resistance to electrical tracking. For high-performance insulators like boron nitride composites, achieving CTI values above 600 volts indicates superior tracking resistance even in humid environments. The IEC 60112 standard provides the framework for determining these indices through standardized drop tests.

UL 746A, another critical standard, establishes requirements for the evaluation of electrical insulating materials in terms of their resistance to high-voltage arcing and tracking. Materials intended for outdoor applications or high-humidity environments must undergo additional weathering tests as specified in UL 746C to ensure long-term performance reliability.

For boron nitride composites specifically, the IEEE 1776 standard offers guidelines for testing ceramic and inorganic insulating materials. These materials must demonstrate compliance with temperature index ratings and maintain their electrical properties after exposure to humidity conditioning as outlined in IEC 60085 and IEC 60216 series.

Testing protocols typically involve accelerated aging tests where materials are subjected to cycles of high humidity (95% RH) and elevated temperatures (up to 130°C), followed by electrical stress tests. The High-Voltage Inclined-Plane Test is particularly relevant for evaluating tracking resistance, as it simulates the worst-case scenario of contamination under electrical stress.

The salt fog test, detailed in IEC 60507, provides another critical evaluation method for insulators intended for coastal or industrial environments where salt contamination combines with humidity to create particularly challenging conditions for electrical insulation.

Manufacturers of boron nitride composite insulators must document compliance with these standards through certified test reports. End-users should verify that materials have been tested according to application-specific standards, particularly when the operating environment involves high humidity combined with electrical stress, as these conditions significantly increase tracking risk.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!