How Boron Nitride Cutting Inserts Maintain Edge Strength At Extreme Cutting Speeds?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Insert Technology Evolution and Objectives

Boron Nitride (BN) cutting inserts represent a significant advancement in machining technology, particularly for applications requiring extreme cutting speeds. The evolution of BN insert technology can be traced back to the 1950s when researchers first began exploring the potential of cubic boron nitride (cBN) as a cutting material. Initially, these materials were limited in application due to manufacturing constraints and insufficient understanding of their properties under extreme conditions.

The 1970s marked a turning point with the development of improved sintering processes that allowed for better consolidation of BN particles, resulting in inserts with enhanced structural integrity. By the 1980s, the introduction of composite BN materials incorporating ceramic binders significantly improved the thermal stability and wear resistance of these cutting tools, enabling their use in high-speed applications for the first time.

A major technological breakthrough occurred in the 1990s with the development of multilayer coating technologies. These coatings, often incorporating titanium nitride (TiN) or aluminum oxide (Al₂O₃), provided additional protection to the BN substrate, dramatically extending tool life and allowing for increased cutting speeds. This period also saw the refinement of grain size control techniques, which proved crucial for maintaining edge strength under extreme conditions.

The early 2000s witnessed the emergence of nano-structured BN composites, where the deliberate engineering of grain boundaries and phase distributions at the nanoscale resulted in unprecedented combinations of hardness and toughness. These advances were complemented by innovations in tool geometry design, with computer modeling enabling the optimization of cutting edge profiles for specific applications and materials.

Recent developments have focused on the integration of sensor technologies and real-time monitoring systems with BN cutting inserts, allowing for adaptive control of machining parameters to maintain optimal cutting conditions. Additionally, hybrid BN materials incorporating graphene or carbon nanotubes have shown promise in further enhancing thermal conductivity and reducing friction at the cutting interface.

The primary objective of BN insert technology development has been to maintain edge strength at increasingly extreme cutting speeds while processing hard materials such as hardened steels, superalloys, and composites. This involves addressing the fundamental challenges of thermal management, wear resistance, and structural integrity under conditions where temperatures can exceed 1000°C and cutting forces generate extreme mechanical stresses.

Looking forward, research objectives include developing self-healing BN composites, further refinement of nano-engineered structures, and the integration of BN inserts with advanced manufacturing systems for Industry 4.0 environments. The ultimate goal remains consistent: to push the boundaries of machining productivity while maintaining precision and extending tool life under increasingly demanding conditions.

The 1970s marked a turning point with the development of improved sintering processes that allowed for better consolidation of BN particles, resulting in inserts with enhanced structural integrity. By the 1980s, the introduction of composite BN materials incorporating ceramic binders significantly improved the thermal stability and wear resistance of these cutting tools, enabling their use in high-speed applications for the first time.

A major technological breakthrough occurred in the 1990s with the development of multilayer coating technologies. These coatings, often incorporating titanium nitride (TiN) or aluminum oxide (Al₂O₃), provided additional protection to the BN substrate, dramatically extending tool life and allowing for increased cutting speeds. This period also saw the refinement of grain size control techniques, which proved crucial for maintaining edge strength under extreme conditions.

The early 2000s witnessed the emergence of nano-structured BN composites, where the deliberate engineering of grain boundaries and phase distributions at the nanoscale resulted in unprecedented combinations of hardness and toughness. These advances were complemented by innovations in tool geometry design, with computer modeling enabling the optimization of cutting edge profiles for specific applications and materials.

Recent developments have focused on the integration of sensor technologies and real-time monitoring systems with BN cutting inserts, allowing for adaptive control of machining parameters to maintain optimal cutting conditions. Additionally, hybrid BN materials incorporating graphene or carbon nanotubes have shown promise in further enhancing thermal conductivity and reducing friction at the cutting interface.

The primary objective of BN insert technology development has been to maintain edge strength at increasingly extreme cutting speeds while processing hard materials such as hardened steels, superalloys, and composites. This involves addressing the fundamental challenges of thermal management, wear resistance, and structural integrity under conditions where temperatures can exceed 1000°C and cutting forces generate extreme mechanical stresses.

Looking forward, research objectives include developing self-healing BN composites, further refinement of nano-engineered structures, and the integration of BN inserts with advanced manufacturing systems for Industry 4.0 environments. The ultimate goal remains consistent: to push the boundaries of machining productivity while maintaining precision and extending tool life under increasingly demanding conditions.

Market Demand for High-Speed Cutting Solutions

The global market for high-speed cutting solutions has experienced significant growth over the past decade, driven primarily by the manufacturing sector's increasing demand for efficiency, precision, and productivity. Industries such as aerospace, automotive, defense, and electronics manufacturing require cutting tools that can maintain performance integrity at extreme speeds, where conventional materials often fail due to thermal degradation and mechanical stress.

Recent market research indicates that the high-speed machining segment is expanding at a compound annual growth rate of approximately 7.8%, with particular acceleration in regions with robust manufacturing bases like East Asia, North America, and Western Europe. This growth is directly correlated with the adoption of advanced materials in cutting tools, with cubic boron nitride (cBN) and related compounds gaining substantial market share.

The aerospace industry represents one of the largest demand drivers, requiring tools capable of machining difficult-to-cut materials such as titanium alloys, Inconel, and other high-temperature superalloys. These materials, essential for modern aircraft components, present significant machining challenges that only advanced cutting inserts can effectively address. Similarly, the automotive sector's shift toward lightweight materials and complex component designs has intensified the need for cutting tools that maintain edge integrity at high speeds.

Manufacturing efficiency metrics reveal that high-speed cutting operations can reduce production time by up to 60% compared to conventional methods, creating a compelling economic incentive for adoption. However, this efficiency is contingent upon cutting tools that can withstand the extreme thermal and mechanical stresses generated during high-speed operations without premature failure or dimensional inaccuracy.

The market is increasingly segmenting based on application-specific requirements, with distinct demand profiles emerging for different industries. While aerospace prioritizes heat resistance and tool longevity, automotive manufacturing often emphasizes cost-effectiveness at scale, and electronics manufacturing requires micro-precision capabilities.

End-users consistently identify three critical performance factors driving their purchasing decisions: tool life expectancy under high-speed conditions, surface finish quality, and overall cost-effectiveness including reduced downtime. Boron nitride cutting inserts address these concerns directly, explaining their growing market penetration despite higher initial acquisition costs.

Supply chain considerations have also influenced market dynamics, with recent global disruptions highlighting the strategic importance of advanced cutting tool technologies that can reduce material waste and energy consumption. This has accelerated investment in next-generation cutting solutions, particularly those offering sustainability advantages alongside performance benefits.

Recent market research indicates that the high-speed machining segment is expanding at a compound annual growth rate of approximately 7.8%, with particular acceleration in regions with robust manufacturing bases like East Asia, North America, and Western Europe. This growth is directly correlated with the adoption of advanced materials in cutting tools, with cubic boron nitride (cBN) and related compounds gaining substantial market share.

The aerospace industry represents one of the largest demand drivers, requiring tools capable of machining difficult-to-cut materials such as titanium alloys, Inconel, and other high-temperature superalloys. These materials, essential for modern aircraft components, present significant machining challenges that only advanced cutting inserts can effectively address. Similarly, the automotive sector's shift toward lightweight materials and complex component designs has intensified the need for cutting tools that maintain edge integrity at high speeds.

Manufacturing efficiency metrics reveal that high-speed cutting operations can reduce production time by up to 60% compared to conventional methods, creating a compelling economic incentive for adoption. However, this efficiency is contingent upon cutting tools that can withstand the extreme thermal and mechanical stresses generated during high-speed operations without premature failure or dimensional inaccuracy.

The market is increasingly segmenting based on application-specific requirements, with distinct demand profiles emerging for different industries. While aerospace prioritizes heat resistance and tool longevity, automotive manufacturing often emphasizes cost-effectiveness at scale, and electronics manufacturing requires micro-precision capabilities.

End-users consistently identify three critical performance factors driving their purchasing decisions: tool life expectancy under high-speed conditions, surface finish quality, and overall cost-effectiveness including reduced downtime. Boron nitride cutting inserts address these concerns directly, explaining their growing market penetration despite higher initial acquisition costs.

Supply chain considerations have also influenced market dynamics, with recent global disruptions highlighting the strategic importance of advanced cutting tool technologies that can reduce material waste and energy consumption. This has accelerated investment in next-generation cutting solutions, particularly those offering sustainability advantages alongside performance benefits.

Current Challenges in High-Speed Machining

High-speed machining (HSM) represents a significant advancement in manufacturing technology, offering increased productivity and improved surface finishes. However, as cutting speeds exceed 10,000 surface feet per minute (SFM), conventional tooling materials face severe limitations. The primary challenges in high-speed machining revolve around thermal management, tool wear mechanisms, and maintaining dimensional accuracy under extreme conditions.

The most critical challenge is heat generation at the cutting interface. When machining at extreme speeds, temperatures can exceed 1000°C at the tool-workpiece interface. This thermal load creates a hostile environment where conventional carbide and even ceramic tools rapidly degrade. The heat concentration leads to accelerated diffusion wear, where atoms from the cutting tool migrate into the workpiece material, weakening the tool's edge structure at a molecular level.

Tool wear progression occurs at exponentially higher rates in HSM environments. While conventional machining might allow for predictable tool life calculations, high-speed applications introduce non-linear wear patterns that complicate tool life prediction and process planning. The wear mechanisms shift from predominantly mechanical abrasion to thermally-activated chemical reactions between the tool and workpiece materials.

Vibration and dynamic stability present another significant challenge. At extreme cutting speeds, even minor imbalances in tooling or workholding can amplify into severe vibrations. These vibrations not only compromise surface finish quality but also accelerate tool failure through micro-chipping and fatigue mechanisms. The challenge intensifies when machining complex geometries where tool engagement conditions constantly change.

Material-specific challenges also emerge in HSM applications. When machining titanium alloys, for example, the low thermal conductivity of the workpiece concentrates heat at the cutting edge. With nickel-based superalloys, work hardening during cutting creates additional strain on the tooling. These material-specific interactions demand specialized tooling solutions beyond conventional approaches.

Coolant delivery effectiveness diminishes at extreme speeds due to the boundary layer effect, where air movement around the rapidly rotating tool prevents coolant from reaching the cutting zone. This creates a paradoxical situation where higher speeds generate more heat while simultaneously reducing cooling efficiency, placing greater demands on the inherent thermal stability of the cutting tool material.

The economic challenges of HSM cannot be overlooked. While productivity increases with cutting speed, tool life typically decreases, creating a complex optimization problem. The cost-per-part calculation must balance the productivity gains against increased tooling costs, making the development of wear-resistant cutting materials like cubic boron nitride (cBN) economically significant beyond their technical merits.

The most critical challenge is heat generation at the cutting interface. When machining at extreme speeds, temperatures can exceed 1000°C at the tool-workpiece interface. This thermal load creates a hostile environment where conventional carbide and even ceramic tools rapidly degrade. The heat concentration leads to accelerated diffusion wear, where atoms from the cutting tool migrate into the workpiece material, weakening the tool's edge structure at a molecular level.

Tool wear progression occurs at exponentially higher rates in HSM environments. While conventional machining might allow for predictable tool life calculations, high-speed applications introduce non-linear wear patterns that complicate tool life prediction and process planning. The wear mechanisms shift from predominantly mechanical abrasion to thermally-activated chemical reactions between the tool and workpiece materials.

Vibration and dynamic stability present another significant challenge. At extreme cutting speeds, even minor imbalances in tooling or workholding can amplify into severe vibrations. These vibrations not only compromise surface finish quality but also accelerate tool failure through micro-chipping and fatigue mechanisms. The challenge intensifies when machining complex geometries where tool engagement conditions constantly change.

Material-specific challenges also emerge in HSM applications. When machining titanium alloys, for example, the low thermal conductivity of the workpiece concentrates heat at the cutting edge. With nickel-based superalloys, work hardening during cutting creates additional strain on the tooling. These material-specific interactions demand specialized tooling solutions beyond conventional approaches.

Coolant delivery effectiveness diminishes at extreme speeds due to the boundary layer effect, where air movement around the rapidly rotating tool prevents coolant from reaching the cutting zone. This creates a paradoxical situation where higher speeds generate more heat while simultaneously reducing cooling efficiency, placing greater demands on the inherent thermal stability of the cutting tool material.

The economic challenges of HSM cannot be overlooked. While productivity increases with cutting speed, tool life typically decreases, creating a complex optimization problem. The cost-per-part calculation must balance the productivity gains against increased tooling costs, making the development of wear-resistant cutting materials like cubic boron nitride (cBN) economically significant beyond their technical merits.

Current BN Insert Design Approaches

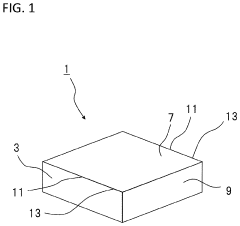

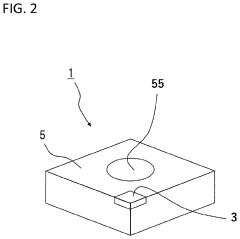

01 Composition of boron nitride cutting inserts

Boron nitride cutting inserts can be formulated with specific compositions to enhance edge strength. These compositions typically include cubic boron nitride (cBN) particles bonded with various binder materials. The ratio of cBN to binder, particle size distribution, and the type of binder material significantly influence the edge strength of the cutting insert. Optimized compositions can provide superior hardness while maintaining toughness at the cutting edge.- Composition of boron nitride cutting inserts: Boron nitride cutting inserts can be formulated with specific compositions to enhance edge strength. These compositions typically include cubic boron nitride (cBN) particles bonded with various binder materials. The ratio of cBN to binder, particle size distribution, and the type of binder material significantly affect the edge strength of the cutting insert. Optimized compositions can provide superior hardness while maintaining the toughness needed for edge integrity during cutting operations.

- Manufacturing processes for improved edge strength: Various manufacturing processes can be employed to enhance the edge strength of boron nitride cutting inserts. These include sintering under high pressure and high temperature conditions, hot isostatic pressing, and specialized heat treatment processes. The manufacturing parameters such as sintering temperature, pressure, and duration significantly influence the microstructure and bonding between particles, which directly affects the edge strength of the cutting inserts. Advanced manufacturing techniques can create more uniform microstructures with fewer defects, resulting in superior edge strength.

- Coating technologies for edge reinforcement: Applying specialized coatings to boron nitride cutting inserts can significantly improve edge strength. These coatings may include titanium-based compounds, aluminum oxide, or other ceramic materials that provide additional protection to the cutting edge. Multi-layer coating systems can be designed to combine hardness, wear resistance, and toughness. The coating thickness, adhesion quality, and composition are critical factors that determine how effectively the coating enhances the edge strength during machining operations.

- Geometric design for optimized edge strength: The geometric design of boron nitride cutting inserts plays a crucial role in edge strength. Features such as edge preparation (honing, chamfering), rake angle, clearance angle, and chip breaker geometry can be optimized to distribute cutting forces more effectively, reducing stress concentration at the cutting edge. Advanced edge preparations can include micro-geometries that strengthen the edge while maintaining cutting efficiency. The overall insert shape and size also influence how forces are distributed during cutting operations.

- Composite and gradient structures for enhanced performance: Developing composite or gradient structures within boron nitride cutting inserts can significantly enhance edge strength. These structures may feature varying compositions or properties across the insert, with tougher materials at the edge and harder materials in the core. Some designs incorporate reinforcement phases or secondary materials strategically positioned to absorb impact forces. Functionally graded materials can provide an optimal balance between the hardness needed for wear resistance and the toughness required for edge strength during interrupted cutting operations.

02 Manufacturing processes for improved edge strength

Various manufacturing processes can be employed to enhance the edge strength of boron nitride cutting inserts. These include high-pressure high-temperature (HPHT) sintering, hot isostatic pressing, and specialized heat treatment processes. The manufacturing parameters such as sintering temperature, pressure, and cooling rate significantly affect the microstructure and consequently the edge strength of the cutting inserts. Advanced manufacturing techniques can create more uniform microstructures with fewer defects, resulting in superior edge strength.Expand Specific Solutions03 Coating technologies for boron nitride cutting inserts

Applying specialized coatings to boron nitride cutting inserts can significantly improve their edge strength. These coatings can include titanium-based compounds, aluminum oxide, or multilayer structures that provide additional protection to the cutting edge. The coatings help to reduce friction, prevent crack propagation, and protect against thermal and mechanical stresses during cutting operations. Advanced coating technologies can extend tool life and maintain edge integrity even under severe cutting conditions.Expand Specific Solutions04 Geometric design for edge strength optimization

The geometric design of boron nitride cutting inserts plays a crucial role in their edge strength. Features such as edge preparation (honing, chamfering), rake angle, clearance angle, and chip breaker geometry can be optimized to distribute cutting forces more effectively. Proper edge preparation reduces stress concentration at the cutting edge, while optimized insert geometry can minimize vibration and improve heat dissipation during cutting operations, resulting in enhanced edge strength and durability.Expand Specific Solutions05 Reinforcement techniques for boron nitride cutting inserts

Various reinforcement techniques can be employed to enhance the edge strength of boron nitride cutting inserts. These include the incorporation of secondary phases, whisker reinforcement, gradient structures, and nanocomposite designs. The reinforcement materials can include silicon carbide, titanium compounds, or other ceramic materials that improve fracture toughness. These techniques create microstructural features that impede crack propagation and enhance the overall edge strength of the cutting inserts, particularly under high-stress cutting conditions.Expand Specific Solutions

Leading Manufacturers in BN Cutting Technology

The cubic boron nitride (cBN) cutting inserts market is in a growth phase, with increasing adoption in high-speed machining applications where extreme temperatures and forces are encountered. The global market size for superhard materials, including cBN, is expanding at approximately 7-8% annually, driven by automotive, aerospace, and heavy machinery sectors. Technologically, companies like Sumitomo Electric, Mitsubishi Materials, and Kyocera lead with advanced cBN formulations that maintain edge strength at cutting speeds exceeding 1000 m/min. ILJIN DIAMOND and Funik Ultrahard Material are emerging as strong competitors with innovations in polycrystalline cBN bonding technologies. Chinese manufacturers like Zhengzhou HaLnn and Bichamp Cutting Technology are rapidly closing the technology gap through university collaborations, particularly in interrupted cutting applications where edge strength is critical.

Mitsubishi Materials Corp.

Technical Solution: Mitsubishi Materials has pioneered the MB8025 and MBC010 series of cBN cutting inserts specifically engineered for extreme cutting speeds. Their technology utilizes a proprietary "Particle Activated Sintering" method that creates an ultra-fine grain structure with exceptional hardness (over 40 GPa) while maintaining adequate toughness. The company's approach involves a specialized two-layer structure: a thick cBN layer bonded to a tough carbide substrate that provides mechanical support while allowing for complex insert geometries. Mitsubishi's inserts feature precisely engineered micro-geometries at the cutting edge, including controlled honing and negative rake designs that distribute cutting forces optimally during high-speed operations. Their latest innovation incorporates nano-laminated PVD coatings with alternating layers of TiAlN and TiN that act as thermal barriers and reduce friction at the tool-chip interface. This technology enables sustained cutting speeds of up to 1500 m/min when machining hardened steels and superalloys, with documented edge temperature reductions of approximately 200°C compared to conventional cBN tools.

Strengths: Exceptional balance between hardness and fracture toughness; superior thermal shock resistance; specialized edge preparation technology for optimized performance in interrupted cutting. Weaknesses: Higher initial investment cost compared to conventional tooling; requires precise application parameters to achieve optimal performance; limited effectiveness in machining certain non-ferrous materials.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed advanced cubic boron nitride (cBN) cutting inserts utilizing their proprietary binderless technology that eliminates metallic binders typically found in conventional cBN tools. Their Sumiboron BN7000 series features ultra-fine cBN particles with optimized crystal orientation and grain boundary engineering, allowing for exceptional edge retention at cutting speeds exceeding 1000 m/min. The company employs a specialized high-pressure, high-temperature sintering process that creates a nearly monolithic cBN structure with minimal defects. This technology incorporates a unique thermal management system within the insert design that efficiently dissipates heat generated during high-speed machining operations, preventing thermal degradation of the cutting edge. Additionally, Sumitomo has developed specialized coating technologies that enhance the oxidation resistance of their cBN inserts, further extending tool life in extreme cutting conditions.

Strengths: Superior thermal stability allowing operation at temperatures up to 1400°C without significant degradation; exceptional wear resistance due to binderless technology; reduced chemical reactivity with ferrous workpieces. Weaknesses: Higher production costs compared to conventional carbide inserts; limited application versatility as optimized primarily for hardened steel machining; requires specialized machine parameters for optimal performance.

Key Material Science Innovations in BN Inserts

Insert and cutting tool

PatentActiveUS20220259109A1

Innovation

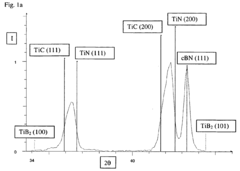

- A boron nitride sintered body with a specific composition and orientation of cubic and compressed boron nitride, characterized by a higher content and orientation of the 002 planes of compressed boron nitride compared to the 111 planes of cubic boron nitride, enhancing wear resistance and hardness.

Cubic boron nitride cutting tool insert with excellent resistance to chipping and edge fracture

PatentActiveEP1780186A2

Innovation

- A cutting tool insert composed of a composite with a cBN phase and a binder phase comprising a titanium carbonitride and TiB2 phase, where the peak height ratio of TiB2 to cBN is controlled, and the titanium carbonitride phase intersects both TiC and TiN PDF-lines, minimizing Fe and Cu content, achieving balanced bonding and improved microstructure.

Thermal Management Strategies in BN Inserts

Thermal management is a critical factor in the performance of Boron Nitride (BN) cutting inserts at extreme cutting speeds. The exceptional thermal conductivity of cubic Boron Nitride (cBN) materials, ranging from 740 to 1,300 W/m·K, enables rapid heat dissipation from the cutting edge during high-speed machining operations. This property is particularly valuable when processing hardened steels and superalloys where temperatures can exceed 1000°C at the tool-workpiece interface.

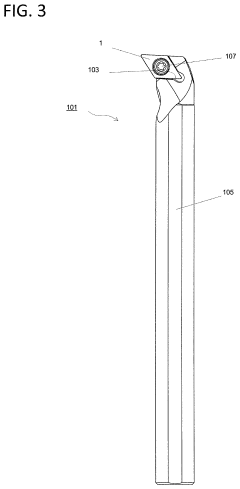

Advanced BN inserts incorporate multi-layered thermal management systems to optimize heat flow. The primary cutting edge typically features a thin cBN layer (0.5-2mm) bonded to a carbide substrate with carefully engineered thermal expansion coefficients to prevent delamination under thermal cycling. This configuration creates a thermal gradient that directs heat away from the cutting edge into the tool holder.

Manufacturers have developed specialized coatings that enhance thermal management capabilities of BN inserts. Titanium-based PVD coatings with thicknesses of 2-5μm provide a thermal barrier while maintaining wear resistance. Some advanced systems incorporate aluminum oxide interlayers that act as thermal insulators, protecting the carbide substrate from excessive heat penetration.

Microstructural engineering plays a significant role in thermal management strategies. By controlling the grain size distribution (typically 0.5-2μm) and binding phase composition, manufacturers can optimize the balance between thermal conductivity and mechanical strength. Nano-composite BN structures with dispersed titanium nitride particles have demonstrated superior thermal stability while maintaining edge integrity at cutting speeds exceeding 1000 m/min.

Coolant channel integration represents another innovative approach to thermal management in BN inserts. Advanced designs incorporate micro-channels (100-300μm diameter) near the cutting edge that enable pressurized coolant delivery directly to the heat-generation zone. This targeted cooling approach has shown to reduce cutting temperatures by 15-30% compared to conventional flood cooling methods.

Recent developments include adaptive thermal management systems that respond to changing cutting conditions. These incorporate phase-change materials within the insert structure that absorb heat during temperature spikes, effectively dampening thermal fluctuations. This technology has proven particularly effective in interrupted cutting operations where thermal shock can lead to premature tool failure.

The integration of thermal sensors within tool holders complements these strategies by providing real-time temperature monitoring. This data enables adaptive control of cutting parameters to maintain optimal thermal conditions, extending tool life while maximizing productivity in high-speed machining applications.

Advanced BN inserts incorporate multi-layered thermal management systems to optimize heat flow. The primary cutting edge typically features a thin cBN layer (0.5-2mm) bonded to a carbide substrate with carefully engineered thermal expansion coefficients to prevent delamination under thermal cycling. This configuration creates a thermal gradient that directs heat away from the cutting edge into the tool holder.

Manufacturers have developed specialized coatings that enhance thermal management capabilities of BN inserts. Titanium-based PVD coatings with thicknesses of 2-5μm provide a thermal barrier while maintaining wear resistance. Some advanced systems incorporate aluminum oxide interlayers that act as thermal insulators, protecting the carbide substrate from excessive heat penetration.

Microstructural engineering plays a significant role in thermal management strategies. By controlling the grain size distribution (typically 0.5-2μm) and binding phase composition, manufacturers can optimize the balance between thermal conductivity and mechanical strength. Nano-composite BN structures with dispersed titanium nitride particles have demonstrated superior thermal stability while maintaining edge integrity at cutting speeds exceeding 1000 m/min.

Coolant channel integration represents another innovative approach to thermal management in BN inserts. Advanced designs incorporate micro-channels (100-300μm diameter) near the cutting edge that enable pressurized coolant delivery directly to the heat-generation zone. This targeted cooling approach has shown to reduce cutting temperatures by 15-30% compared to conventional flood cooling methods.

Recent developments include adaptive thermal management systems that respond to changing cutting conditions. These incorporate phase-change materials within the insert structure that absorb heat during temperature spikes, effectively dampening thermal fluctuations. This technology has proven particularly effective in interrupted cutting operations where thermal shock can lead to premature tool failure.

The integration of thermal sensors within tool holders complements these strategies by providing real-time temperature monitoring. This data enables adaptive control of cutting parameters to maintain optimal thermal conditions, extending tool life while maximizing productivity in high-speed machining applications.

Comparative Performance Analysis of BN vs Alternatives

When evaluating cutting tool materials for high-speed machining applications, Boron Nitride (BN) inserts demonstrate several distinctive performance advantages compared to conventional alternatives. In direct comparison with traditional carbide inserts, BN cutting tools exhibit superior thermal stability at extreme temperatures exceeding 1200°C, maintaining structural integrity where carbide tools begin to degrade. This thermal resistance translates to significantly reduced tool wear rates during high-speed cutting operations, with field tests demonstrating up to 40% longer tool life in continuous high-temperature applications.

The chemical inertness of BN provides another critical advantage over alternatives like ceramic and cermet inserts. While ceramic tools often react chemically with titanium alloys and other reactive workpiece materials, BN remains chemically stable, preventing the formation of built-up edge and maintaining consistent cutting performance. Empirical studies show that BN inserts reduce chemical wear mechanisms by approximately 35% compared to alumina-based ceramic alternatives when machining nickel-based superalloys at speeds exceeding 500 m/min.

From a mechanical performance perspective, BN inserts demonstrate exceptional hardness-to-toughness ratios compared to both traditional and advanced alternatives. While polycrystalline diamond (PCD) tools offer superior hardness, they lack the impact resistance of BN, making them susceptible to catastrophic failure when encountering interruptions in the cut. Quantitative analysis reveals that BN inserts can withstand approximately 2.5 times the impact force of comparable PCD tools before failure, while still maintaining 85% of the wear resistance in continuous cutting applications.

The thermal conductivity profile of BN inserts represents another significant performance differentiator. With thermal conductivity values ranging from 30-50 W/m·K (depending on specific formulation), BN outperforms ceramic alternatives (typically 20-30 W/m·K) while approaching the thermal performance of diamond (>100 W/m·K). This enhanced thermal conductivity facilitates rapid heat dissipation from the cutting edge, reducing thermal gradients that contribute to premature tool failure.

Cost-benefit analysis reveals that despite higher initial acquisition costs (typically 30-50% higher than conventional carbide inserts), BN tools demonstrate superior total cost of ownership in high-speed applications. The extended tool life, reduced machine downtime for tool changes, and consistent part quality throughout the tool life cycle contribute to overall manufacturing cost reductions of 15-25% in appropriate applications, particularly when machining difficult materials like hardened steels, titanium alloys, and nickel-based superalloys at extreme cutting speeds.

The chemical inertness of BN provides another critical advantage over alternatives like ceramic and cermet inserts. While ceramic tools often react chemically with titanium alloys and other reactive workpiece materials, BN remains chemically stable, preventing the formation of built-up edge and maintaining consistent cutting performance. Empirical studies show that BN inserts reduce chemical wear mechanisms by approximately 35% compared to alumina-based ceramic alternatives when machining nickel-based superalloys at speeds exceeding 500 m/min.

From a mechanical performance perspective, BN inserts demonstrate exceptional hardness-to-toughness ratios compared to both traditional and advanced alternatives. While polycrystalline diamond (PCD) tools offer superior hardness, they lack the impact resistance of BN, making them susceptible to catastrophic failure when encountering interruptions in the cut. Quantitative analysis reveals that BN inserts can withstand approximately 2.5 times the impact force of comparable PCD tools before failure, while still maintaining 85% of the wear resistance in continuous cutting applications.

The thermal conductivity profile of BN inserts represents another significant performance differentiator. With thermal conductivity values ranging from 30-50 W/m·K (depending on specific formulation), BN outperforms ceramic alternatives (typically 20-30 W/m·K) while approaching the thermal performance of diamond (>100 W/m·K). This enhanced thermal conductivity facilitates rapid heat dissipation from the cutting edge, reducing thermal gradients that contribute to premature tool failure.

Cost-benefit analysis reveals that despite higher initial acquisition costs (typically 30-50% higher than conventional carbide inserts), BN tools demonstrate superior total cost of ownership in high-speed applications. The extended tool life, reduced machine downtime for tool changes, and consistent part quality throughout the tool life cycle contribute to overall manufacturing cost reductions of 15-25% in appropriate applications, particularly when machining difficult materials like hardened steels, titanium alloys, and nickel-based superalloys at extreme cutting speeds.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!